Method for efficiently preparing micromolecular chondroitin sulfate and micromolecular hyaluronic acid by one step

A technology of chondroitin sulfate and hyaluronic acid, applied in the biological field, can solve the problems of affecting enzyme-related properties, low enzyme activity of ChSaseABC, and less research on recombinant expression of ChSaseABC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

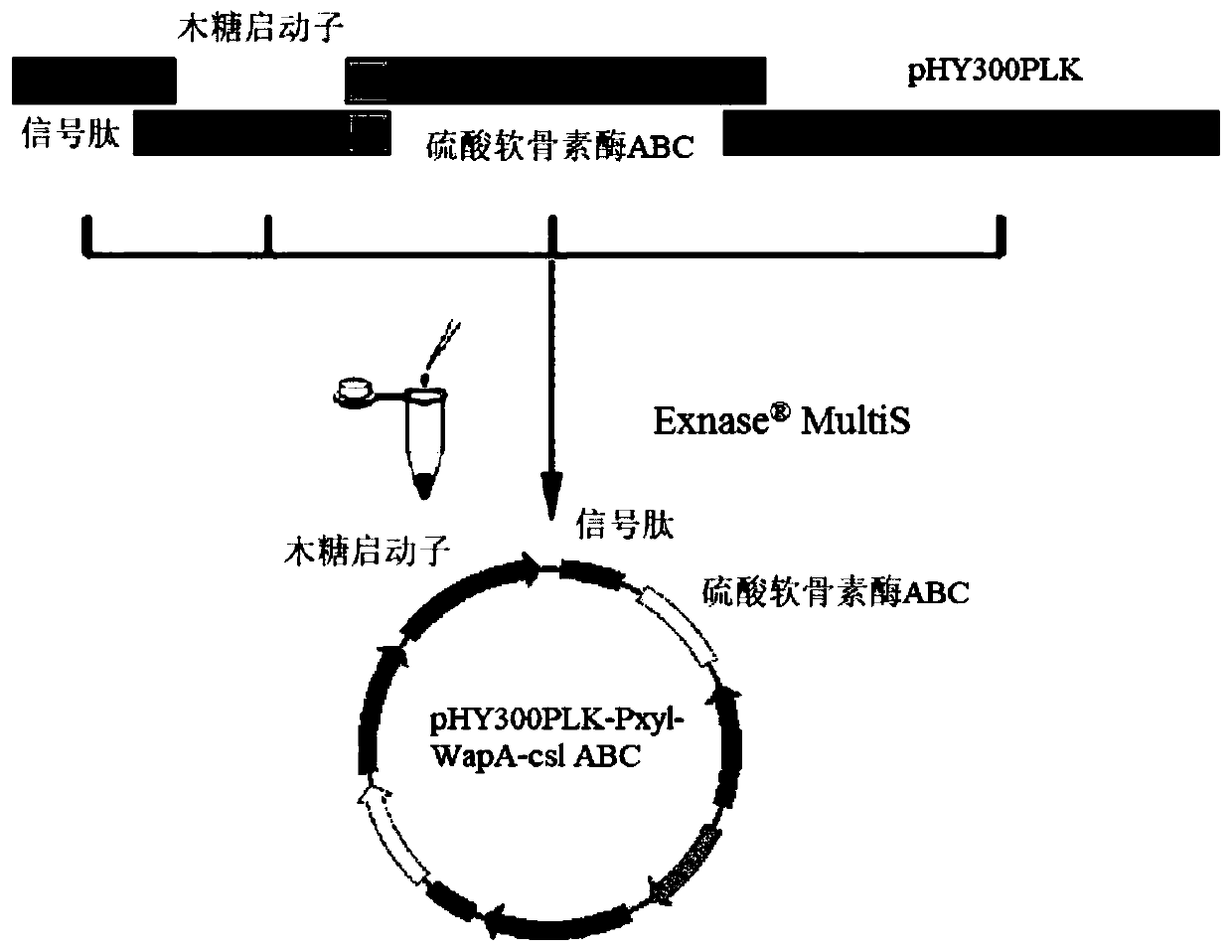

[0082] Embodiment 1: Construction of recombinant Bacillus subtilis

[0083] Amplification of the chondroitin sulfate ABC lyase gene: the genome of Proteus vulgaris ATCC33420 was used as a template to amplify the chondroitin sulfate ABC lyase gene fragment. The PCR amplification system was 1 μL of genomic DNA, 4 μL of each primer 1 and primer 2, 50 μL of KOD polymerase, ddH 2 O 41 μL, PCR reaction program: pre-denaturation at 94°C for 4 min, denaturation at 94°C for 2 min; then annealing at 60°C for 30 s, extension at 72°C for 1.2 min, cycle 35 times; extension at 72°C for 1 min.

[0084] Amplification of the linearized pHY300PLK gene: using pHY300PLK as a template, amplify the linearized fragment of pHY300PLK that changes the restriction site. The PCR amplification system was pHY300PLK 1 μL, primer 3 and primer 4 each 4 μL, KOD polymerase 50 μL, ddH 2 O 41 μL, PCR reaction program: 94°C pre-denaturation for 4 min, 94°C denaturation for 2 min; then annealing at 62°C for 30 s,...

Embodiment 2

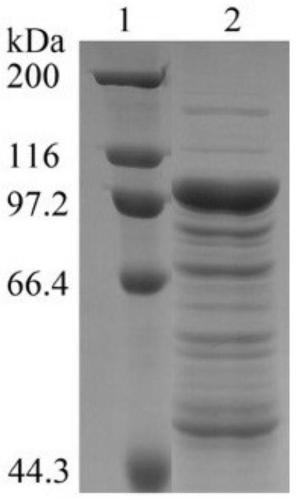

[0091] Example 2: Induced expression of chondroitin sulfate ABC lyase

[0092] Inoculate the constructed recombinant Bacillus subtilis str.l68-△spoOA-pHY300PLK-Pxyl-wapA-csl ABC in LB liquid medium containing tetracycline resistance, and culture overnight at 37°C; Received into 1L of tetracycline-containing fermentation medium, fermented for 2-4 hours to OD 660 When reaching 0.6, add 8g / L xylose to induce expression for 24h, and because the host in the present invention knocks out the key gene Bacillus subtilis required for spore growth, it is conducive to the secretion and expression of chondroitin sulfate ABC lyase, and the final fermentation The activity of chondroitin sulfate ABC lyase in the liquid supernatant can reach 24U / mL, which is the highest level at present.

Embodiment 3

[0093] Embodiment 3: the chondroitin sulfate ABC lyase enzyme activity assay of fermented liquid

[0094] Take 1mL of fermentation broth and centrifuge, take 0.1mL supernatant and 7.9mL 1g / L chondroitin sulfate (prepared with 0.02mol / LTris-HCL, pH7.5) respectively, add them to a 15mL colorimetric tube, and place at 37°C React in a water bath for 20 minutes, immediately place it in a boiling water bath and boil for 5 minutes, add inactivated fermentation broth supernatant to the control tube under the same conditions, and measure the light absorption value at 232nm. The enzyme activity unit U is defined as the amount of enzyme required to catalyze the formation of 1 μmol of unsaturated disaccharide per minute at 37°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com