A process for continuously producing m-toluic acid

A technology for the production process of toluic acid, which is applied in the field of continuous production of m-toluic acid, can solve the problems of long heating time of the mixture to be separated, high energy consumption of process operation, and low single-pass yield of m-toluic acid. , to achieve the effect of inhibiting the generation of deep by-products, improving product production capacity, and improving corporate profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

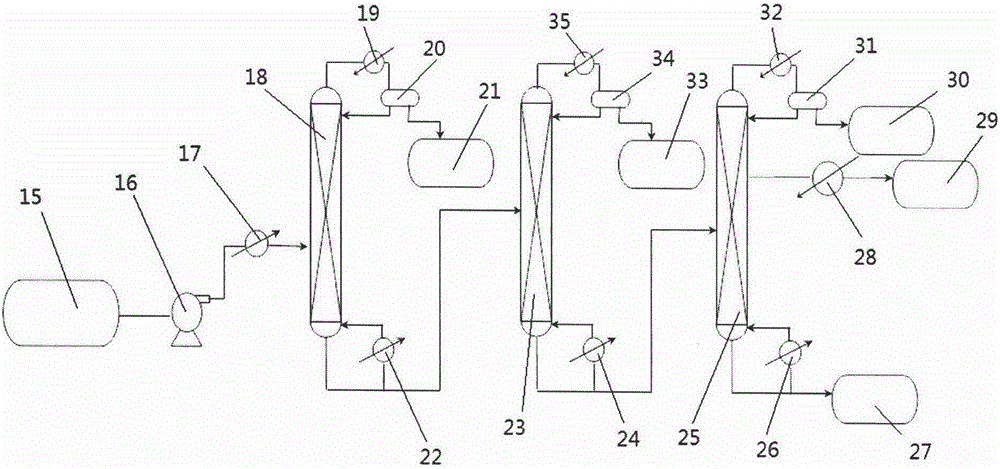

[0035] Such as figure 1 , figure 2 As shown, the continuous production process of m-toluic acid includes the synthesis production process corresponding to the synthesis section and the rectification production process corresponding to the rectification section.

[0036] The synthesis section includes a meta-xylene intermediate tank 1 for storing meta-xylene, and the meta-xylene intermediate tank 1 is connected with a meta-xylene feed pump 2 through a pipeline, and the meta-xylene feed pump 2 is connected with a meta-xylene exchange through a pipeline. Heater 3 and m-xylene heat exchanger 3 are connected to multi-stage external circulation reaction tower groups through pipelines.

[0037] The multi-stage external circulation reaction tower group includes two multi-stage external circulation reaction tower groups connected to each other, and is divided into a first multi-stage external circulation reaction tower 4 and a second multi-stage external circulation reaction tower 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com