Calcium treatment-free production process of low-carbon silicon-containing killed clean steel

A production process, clean steel technology, applied in the field of calcium-free treatment of low-carbon silicon-containing killed clean steel production process, can solve the problems of limiting the production efficiency of thin slab continuous casting, affecting the forming performance of steel plates, CaS inclusions, etc., to meet the cleanliness requirements and pourability requirements, saving calcium treatment costs, and obvious adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

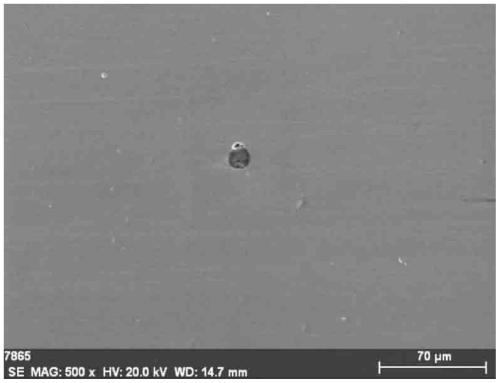

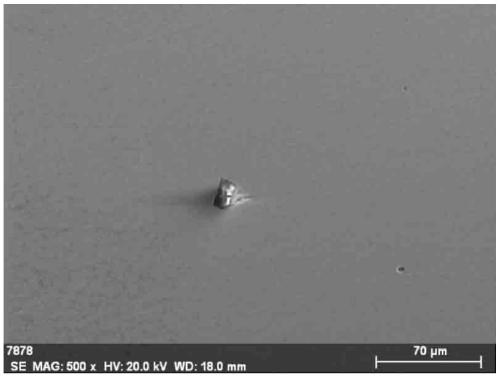

Image

Examples

Embodiment 1

[0043] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0044] (2) Oxygen top-bottom double-blown converter: adopt sub-lance technology and bottom-blown argon technology to control the molten steel [O] at the end of the converter to 2 o 3 The total amount of deoxygenated inclusions.

[0045] (3) LF Refining: Adjust refining incoming molten steel [Al] 0.030-0.060%, molten steel temperature ≥ 1550°C; add lime at 8-12Kg / ton, control slag composition to be CaO 55-60%, Al 2 o 3 35-40%; SiO 2 3~4%; MgO 5~7%, alkalinity CaO / SiO 2The value is 20-26; white slag is produced by refining; the aluminum composition of molten steel is adjusted, and the number of times of aluminum mixing is less than 3 times, specifically twice in this embodiment; 500 meters of limestone cored wire is fed; the silicon content of molten steel is 0.025-0.035%; refining out of the station The mass percentage of molten steel comp...

Embodiment 2

[0062] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0063] (2) Oxygen top-bottom double-blown converter: adopt sub-lance technology and bottom-blown argon technology to control the molten steel at the end point of the converter [O] 2 o 3 The total amount of deoxygenated inclusions.

[0064] (3) LF Refining: Adjust refining incoming molten steel [Al] 0.04-0.06%, molten steel temperature ≥ 1550°C; add lime at 9Kg / ton, control slag composition to be CaO 57-60%, Al 2 o 3 35-40%; SiO 2 2~3.5%; MgO 5~7%, alkalinity CaO / SiO 2 The value is 22~25; white slag is produced by refining; the aluminum composition of molten steel is adjusted, and the number of times of aluminum blending is 2 times; the silicon content of molten steel is 0.025~0.035%; 0.025-0.035%, Mn: 0.08-0.20%, P≤0.015%, S≤0.003%, Alt: 0.015-0.040%, and the balance is iron and trace unavoidable impurities. Adjust the content of acid-solu...

Embodiment 3

[0078] (1) Molten iron: reduce the sulfur content of the molten iron to less than 0.02% by means of pretreatment of the molten iron;

[0079] (2) Oxygen top-bottom double-blown converter: adopt sub-lance technology and bottom-blown argon technology to control the molten steel [O] at the end of the converter 2 o 3 The total amount of deoxygenated inclusions. The end point of the converter and the tapping operation are important links in nitrogen control in the present invention.

[0080] (3) LF refining: Refining incoming molten steel [Al] 0.020-0.030%, molten steel temperature ≥ 1550°C; adding lime at 6-7Kg / ton, controlling slag composition to be CaO 55-60%; Al 2 o 3 25-30%; SiO 2 7~8%; MgO 5~7%, alkalinity CaO / SiO 2 The value is 7-8; white slag is produced by refining; the aluminum composition of molten steel is adjusted, and the number of times of aluminum distribution is strictly controlled to be less than 3 times, specifically twice in this embodiment; the mass perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com