Preparation method of human milk fat substitute, human milk fat substitute prepared by method, and use of milk fat substitute

A human milk fat substitute and oil technology, which is applied in milk substitutes, dairy products, applications, etc., can solve the problems of increasing process costs, achieve low cost, realize large-scale industrial production, and achieve high yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

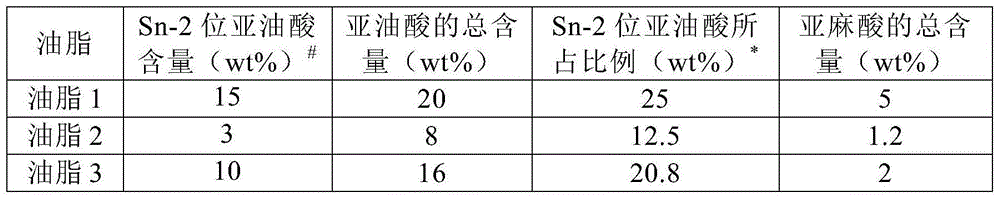

Image

Examples

preparation example Construction

[0090] (2) The preparation method of the present invention adopts edible oils and fats of natural origin as raw materials, and because the source of raw materials is widely and easily available, the production cost is lower, and when the human milk fat substitute is prepared according to the method of the present invention, the product can be significantly improved. The profit margins bring good economic benefits to the production enterprises.

[0091] (3) In the preparation method of the present invention, by combining random transesterification, directional transesterification and physical mixing, the desired human milk fat substitute is prepared in a simple and controllable process, which is ultimately beneficial to The desired human milk fat substitute is produced on an industrial scale.

[0092] (4) The preparation method of the present invention realizes the efficient production of the desired human milk fat substitute of the present invention in a simple process by mixi...

Embodiment 1

[0099] The palm oil fraction with IV=25 was placed in the reactor, and vacuum-dried at 105° C. for 30 minutes to remove the moisture in the palm oil fraction. Then, the temperature of the reactor was lowered to 100° C. and kept at this temperature, 0.3 wt % of sodium methoxide was added to the reactor, and the vacuum condition was maintained to carry out random transesterification. After the random transesterification reaction was carried out for 0.1 hour, 25% citric acid aqueous solution (concentration: 8wt%) was added to the reactor to terminate the random transesterification reaction and obtain a reaction product. The reaction product was vibrated and mixed, then centrifuged, washed with water and vacuum dried, and finally refined through decolorization and deodorization operations (at a temperature of 110° C., under a vacuum of 8 mmHg, adding 1.0 wt. % clay, decolorized for 20 minutes; at a temperature of 245°C, under a vacuum of 4mmHg, feed water vapor accounting for 5wt%...

Embodiment 2

[0103]The palm oil fraction of IV=8 is placed in the reactor, adds the lipase LipozymeTLIM (Novozyme (China) Biotechnology Co., Ltd.) that accounts for 8wt% of described palm oil fraction weight in the reactor, Random transesterification was carried out at 65°C for 8h. The lipase is removed by filtration, thereby terminating the random transesterification reaction to obtain a random transesterification product. The random transesterification reaction product was processed through the refining operation described in Example 1 to obtain random transesterification oil.

[0104] Take 20 parts by mass of the random transesterified oil, 40 parts by mass of olive oil, 29 parts by mass of soybean oil, 10 parts by mass of palm kernel oil and 1 part by mass of perilla oil and mix them uniformly at 80°C to obtain the formulated grease.

[0105] Add 0.5wt% lipase LipozymeRMIM (Novozymes (China) Biotechnology Co., Ltd.) to the prepared oil, and carry out directional transesterification a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com