Industrial gear oil

A technology of industrial gear oil and mixture, which is applied in the field of lubricating oil, can solve the problems of reducing production and processing efficiency and cost, insufficient rust and corrosion resistance, and reduced surface quality of workpieces, so as to save enterprise costs, eliminate health effects, stickiness, etc. The effect of low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

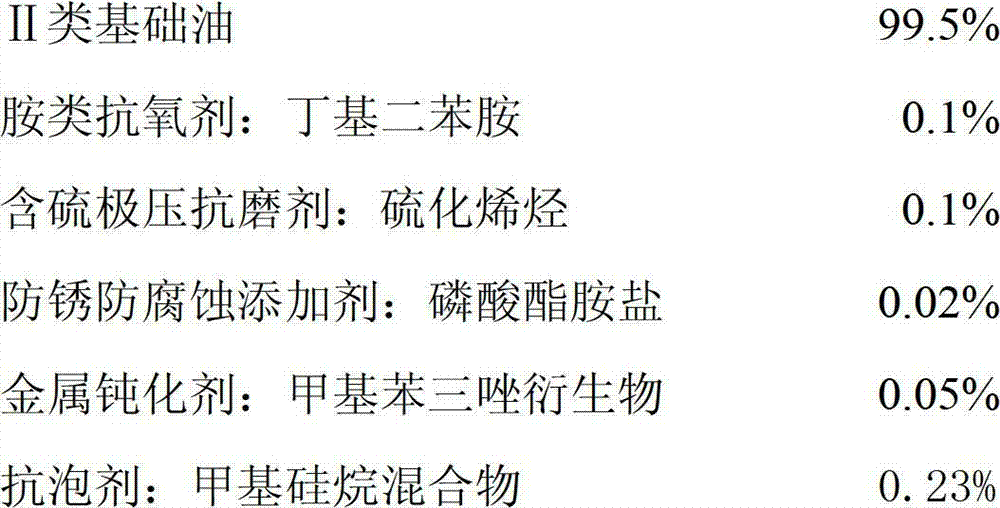

[0020] 1# industrial gear oil consists of the following components by weight:

[0021]

[0022] The preparation method and steps are as follows:

[0023] Heat the base oil to 50°C, add amine antioxidant, sulfur-containing extreme pressure antiwear agent, antirust and anticorrosion additive, metal passivator, defoamer in sequence, stir and mix for 5 hours, cool and fine filter to obtain sample.

Embodiment 2

[0025] 2# Industrial gear oil consists of the following components by weight:

[0026]

[0027] The preparation method and steps are as follows:

[0028] Heat the base oil to 80°C, add amine antioxidant, sulfur-containing extreme pressure antiwear agent, antirust and anticorrosion additive, metal passivator, defoamer in sequence, stir and mix for 1 hour, cool and fine filter to obtain sample.

Embodiment 3

[0030] 3# Industrial gear oil consists of the following components by weight:

[0031]

[0032] The preparation method and steps are as follows:

[0033] Heat the base oil to 60°C, add amine antioxidants, sulfur-containing extreme pressure antiwear agents, antirust and anticorrosion additives, metal passivators, and defoamers in sequence, stir and mix for 3 hours, cool and fine filter to obtain sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com