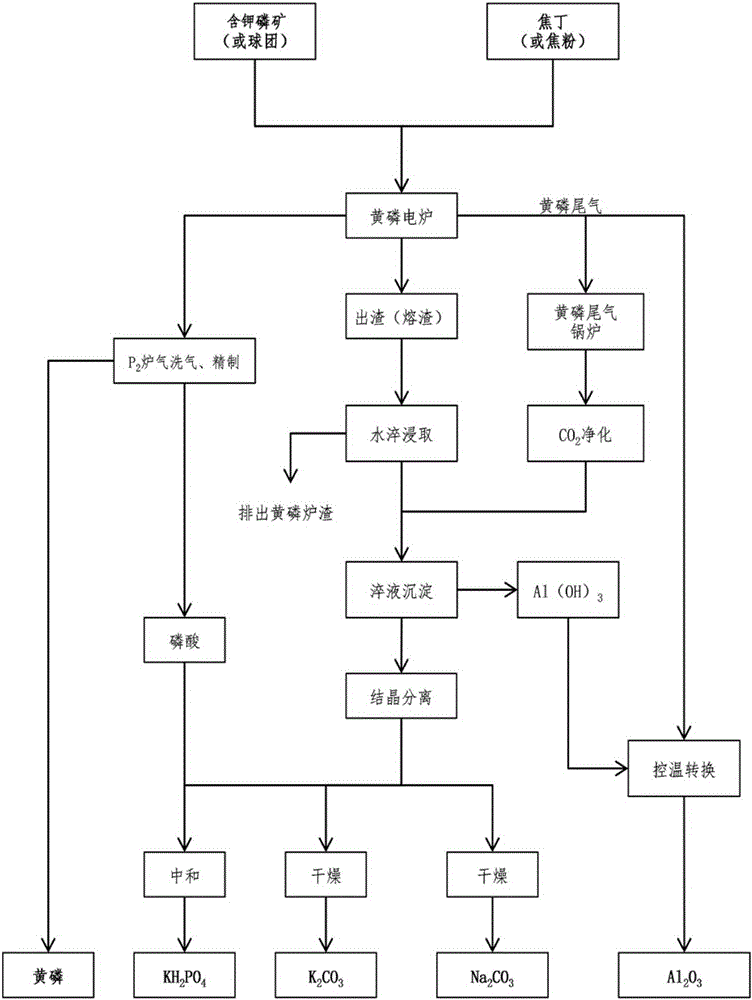

Energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite

A sodium carbonate and alumina technology, applied in the chemical industry, can solve the problems of not being able to produce high-quality yellow phosphorus, not making full use of heat, and not conforming to yellow phosphorus enterprises, so as to achieve comprehensive production cost reduction, prominent energy saving effect, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] with P 2 o 5 Content is 23.19%, SiO 2 content of 21.82%, CaO content of 32.58%, K 2 O content is 2.51%, Na 2 Trace O content, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 3.96% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:146.

[0059] According to the method of the present invention, 15kt / a yellow phosphorus production plant can produce yellow phosphorus 15kt annually, K 2 CO 3 4.7kt, Al 2 o 3 3.5kt. produced K 2 CO 3 Can be further processed to generate 9.25kt of KH 2 PO 4 .

Embodiment 2

[0061] with P 2 o 5 content of 20.5%, SiO 2 content of 22.2%, CaO content of 33.0%, K 2 O content is 1.89%, Na 2 O content is 0.44%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:131.5.

[0062] According to the method of the present invention, 10kt / a yellow phosphorus production plant can produce yellow phosphorus 10kt annually, K 2 CO 3 2.9kt, Al 2 o 3 2.6 kt, Na 2 CO 3 520t. produced K 2 CO 3 Can be further processed to generate 5.7kt KH 2 PO 4 .

Embodiment 3

[0064] with P 2 o 5 content of 19.5%, SiO 2 content of 21.9%, CaO content of 32.7%, K 2 O content is 2.29%, Na 2 O content is 0.15%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:126.

[0065] According to the method of the present invention, 20kt / a yellow phosphorus production plant can produce yellow phosphorus 20kt annually, K 2 CO 3 7.0kt, Al 2 o 3 5.5kt, Na 2 CO 3 360t. produced K 2 CO 3 It can be further processed to generate 13.8kt KH 2 PO 4 .

[0066] Compared with the existing potassium feldspar-lime sintering method, the aforementioned embodiments of the present invention can save energy and reduce consumption and CO 2 The emission reduction indicators are shown in Table 1:

[0067] Table 1

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com