Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Wide range of market applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

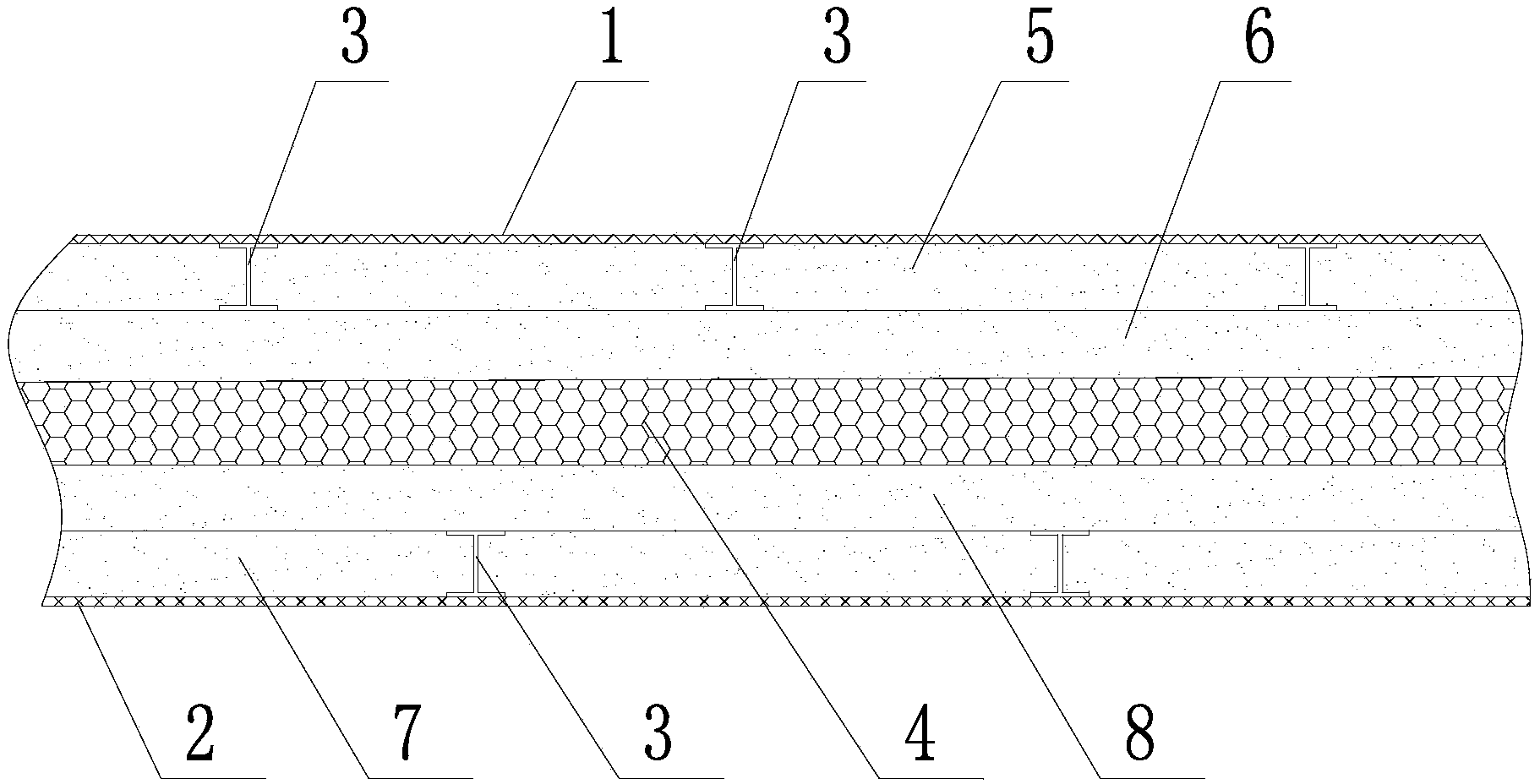

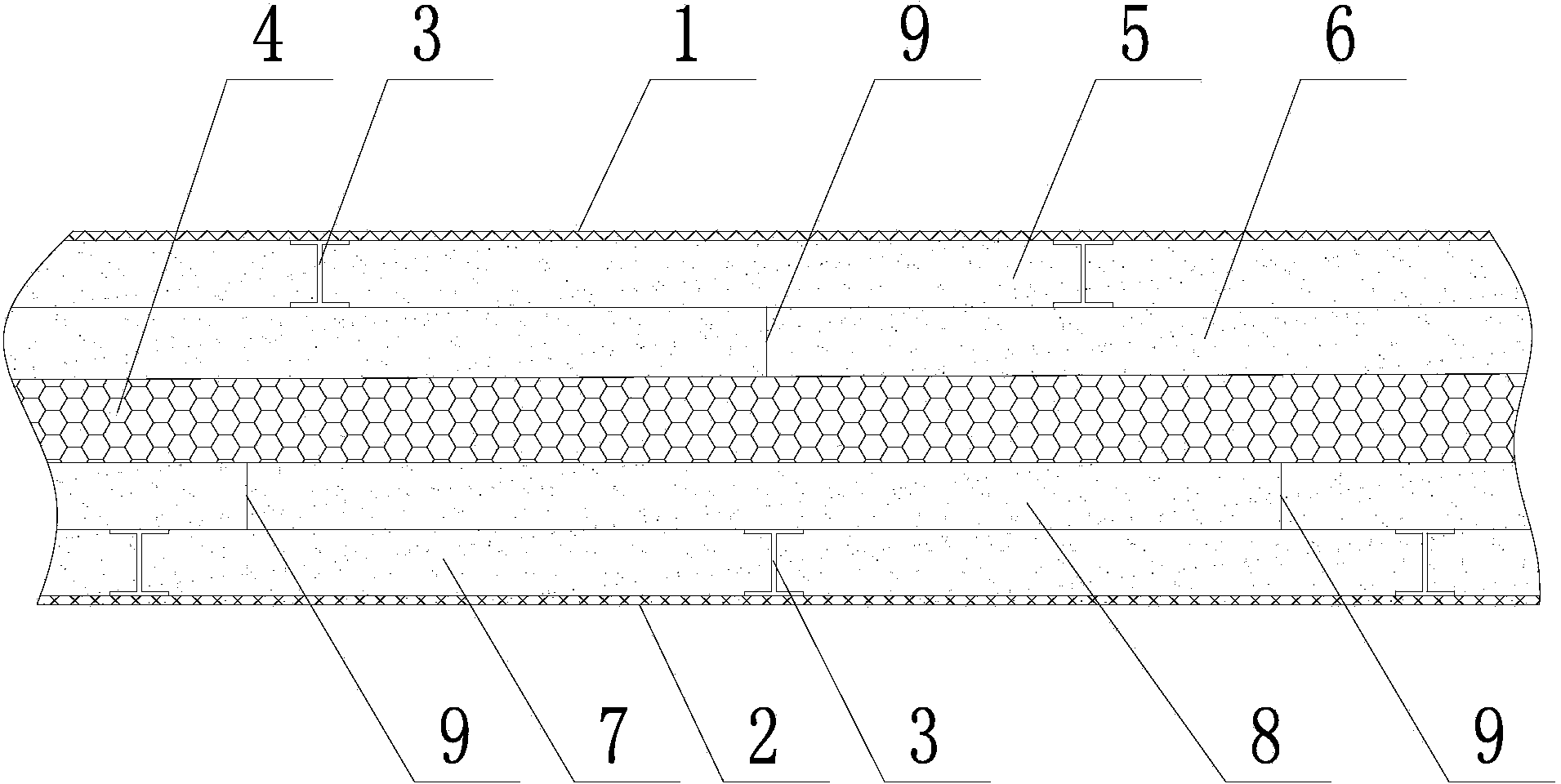

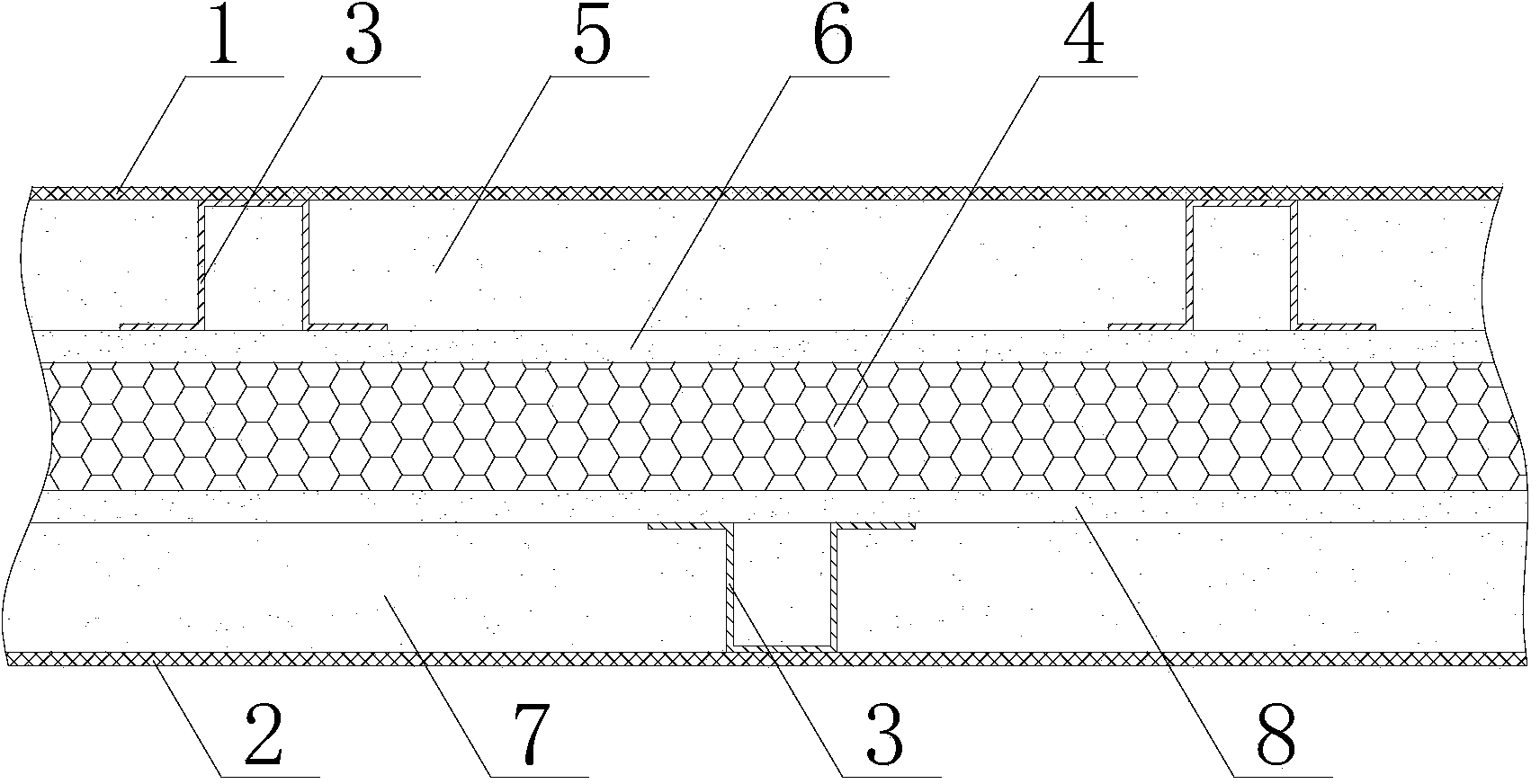

Refrigerated transport car, composite insulation board and manufacturing method of composite insulation board

ActiveCN103660446AHigh strengthAvoid punctureRefrigerated goods vehicleSynthetic resin layered productsThermal insulationArchitectural engineering

The invention discloses a composite insulation board, comprising an inner wall plate, an outer wall plate and a heat-insulated combination layer, wherein the heat-insulated combination layer is fixedly arranged between the inner wall plate and the outer wall plate and comprises reinforcing ribs, a vacuum heat-insulating board, an inner protection layer and an outer protection layer; the inner protection layer and the outer protection layer are fixed at two sides of the vacuum heat-insulating board; the reinforcing ribs are respectively embedded into the inner protection layer and the outer protection layer; and the inner protection layer and the outer protection layer are respectively connected with the inner wall plate and the outer wall plate. The invention also discloses a refrigerated transport car using the composite insulation board disclosed by the invention and a manufacturing method of the composite insulation board. The vacuum heat-insulating board and a rigid polyurethane board are used together; comprehensive cold broken bridge treatment is carried out on inner and outer parts of the composite insulation board, so that the heat insulation and preservation performances are improved and the weight is light. The strength of the composite insulation board is improved by arrangement of a reinforcing layer, and the inner protection layer and the outer protection layer can effectively prevent the vacuum heat-insulating board from being punctured; therefore, the composite insulation board has a long service life, a broad market application and popularization prospects.

Owner:SOUTH CHINA AGRI UNIV

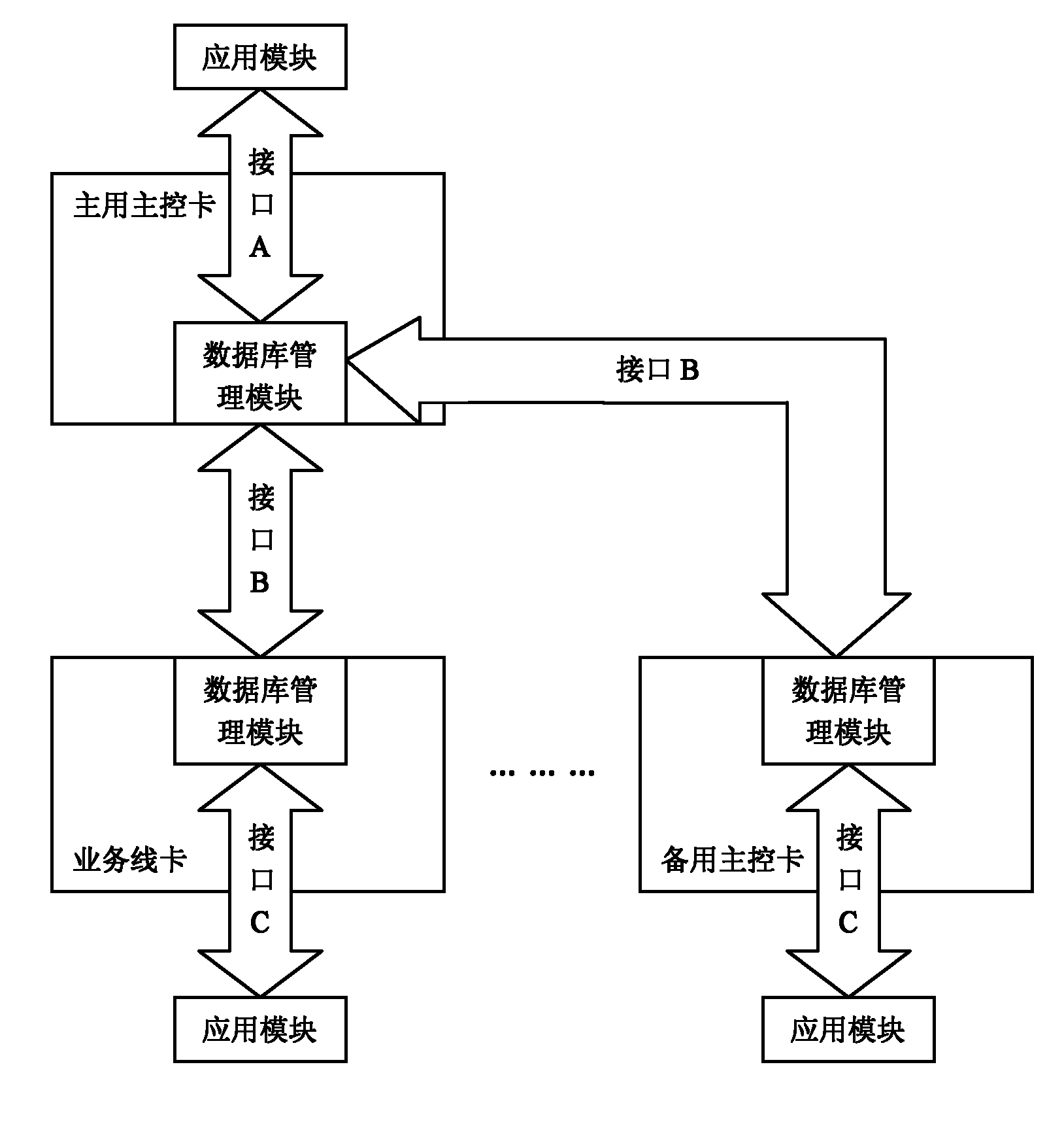

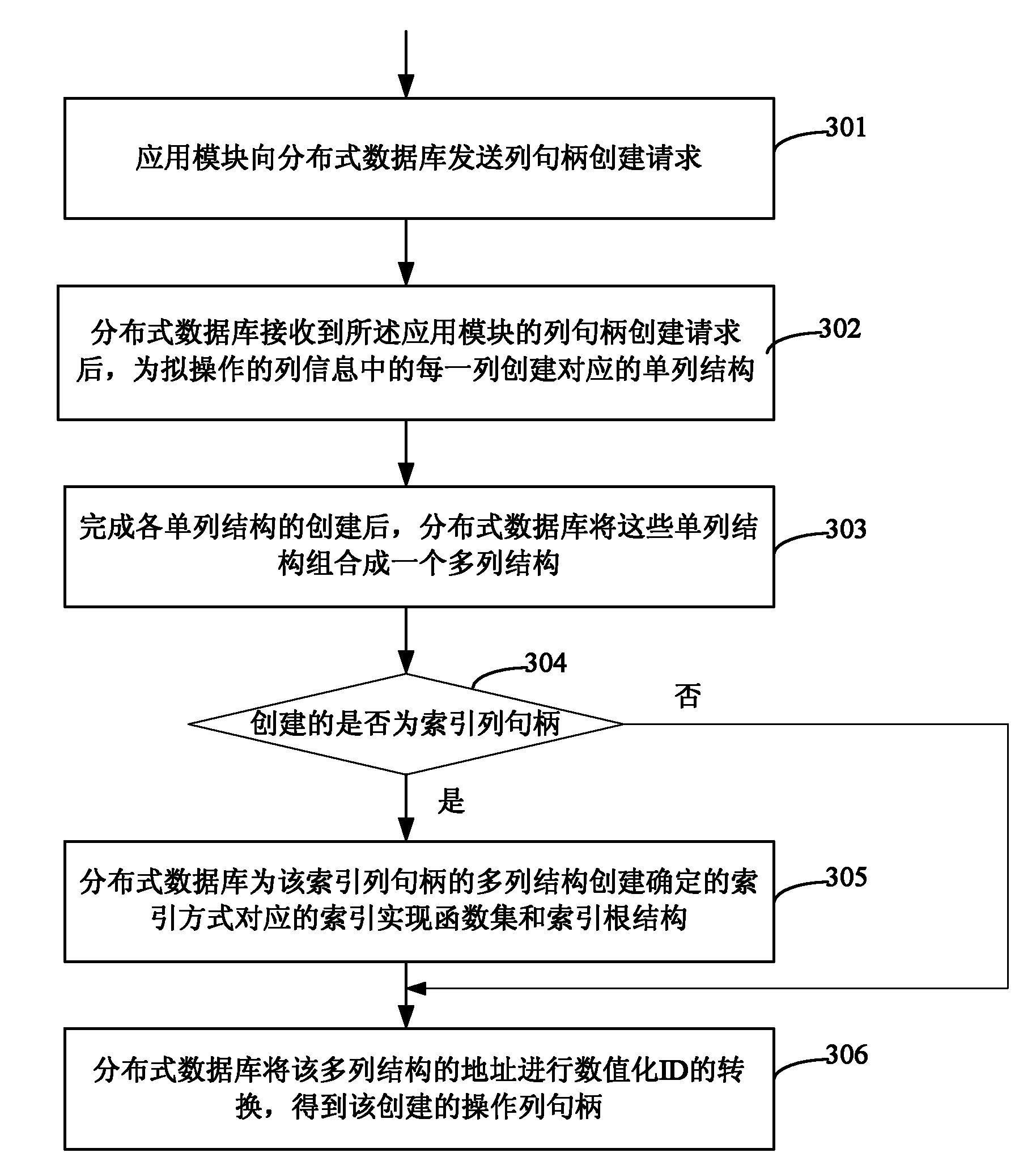

Data operation method for distributed database in embedded system and board card

ActiveCN102654878AWide range of market applicationsSpecial data processing applicationsOpen source dataData operations

The invention relates to a database technology, solves the problem of low efficiency of the conventional open source database system, and provides a data operation method for a distributed database in an embedded system and a board card. According to the technical scheme, the distributed database is operated by an application module according to multiple operation column handle modes adopted in the data operation method, and data can be stored. The board card consists of at least one application module and the distributed database, wherein each application module comprises a database table establishment request unit, a column handle establishment request unit and a database table operation request unit; and the distributed database comprises an interface unit, a column handle establishment unit and a database table index operation unit. The data operation method and the board card have the advantage of improving the system efficiency and being suitable for the distributed database.

Owner:MAIPU COMM TECH CO LTD

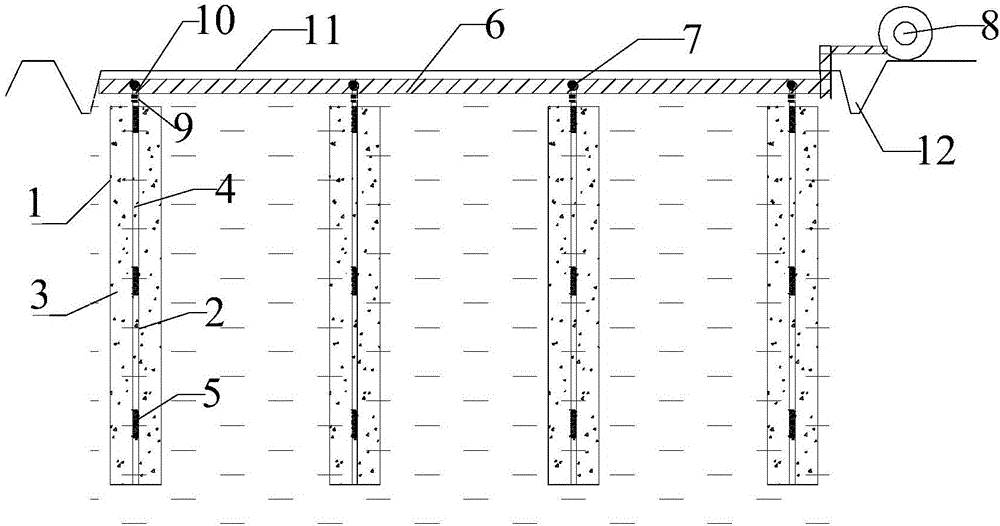

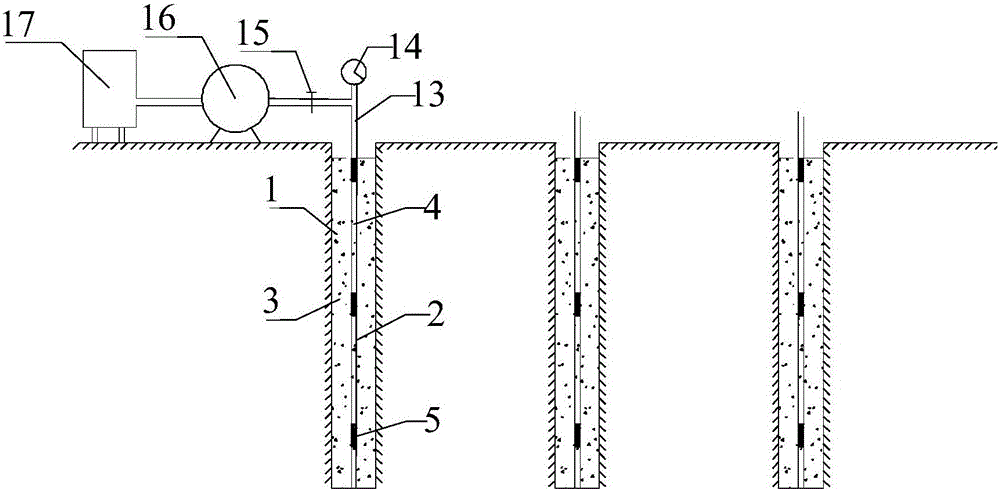

Equipment for strengthening deep soft soil foundation by vacuum preloading of filter well and method

InactiveCN105804045AImprove reinforcement effectImprove bearing capacitySoil preservationSlurryCement mortar

The invention belongs to the technical field of foundation treatment of geotechnical engineering and provides equipment for strengthening a deep soft soil foundation by vacuum preloading of a filter well and a method. The equipment comprises the filter well, a vacuum device, a sealing structure, a grouting device and a connecting pipeline, wherein the vacuum device is connected to the upper end of the filter well through the connecting pipeline; the sealing structure is used for ensuring sealing of the whole equipment during vacuum preloading operation; the filter well is formed by combining a sand well and a vacuum pipe; the vacuum pipe is formed in the middle part of the sand well and is composed of a plurality of sections of PVC pipes and a plurality of sections of filter pipes; and the grouting device is used for filling cement-clay grout into a pore of the filter well by the vacuum pipe of the filter well to form a cement mortar pile after vacuum preloading is finished. The equipment can reduce the route loss of the vacuum degree of the filter well to make the vacuum degree of the whole section of the filter well keep a high value, so that the whole strengthening effect of the deep soft soil foundation is ensured; and meanwhile, cement mortar is poured into the sand well by utilizing the vacuum pipe to form a cement pile, and thus the bearing capacity of the foundation is dramatically improved.

Owner:JIANGSU HONGJI GEOTECHNICAL ENG CO LTD +1

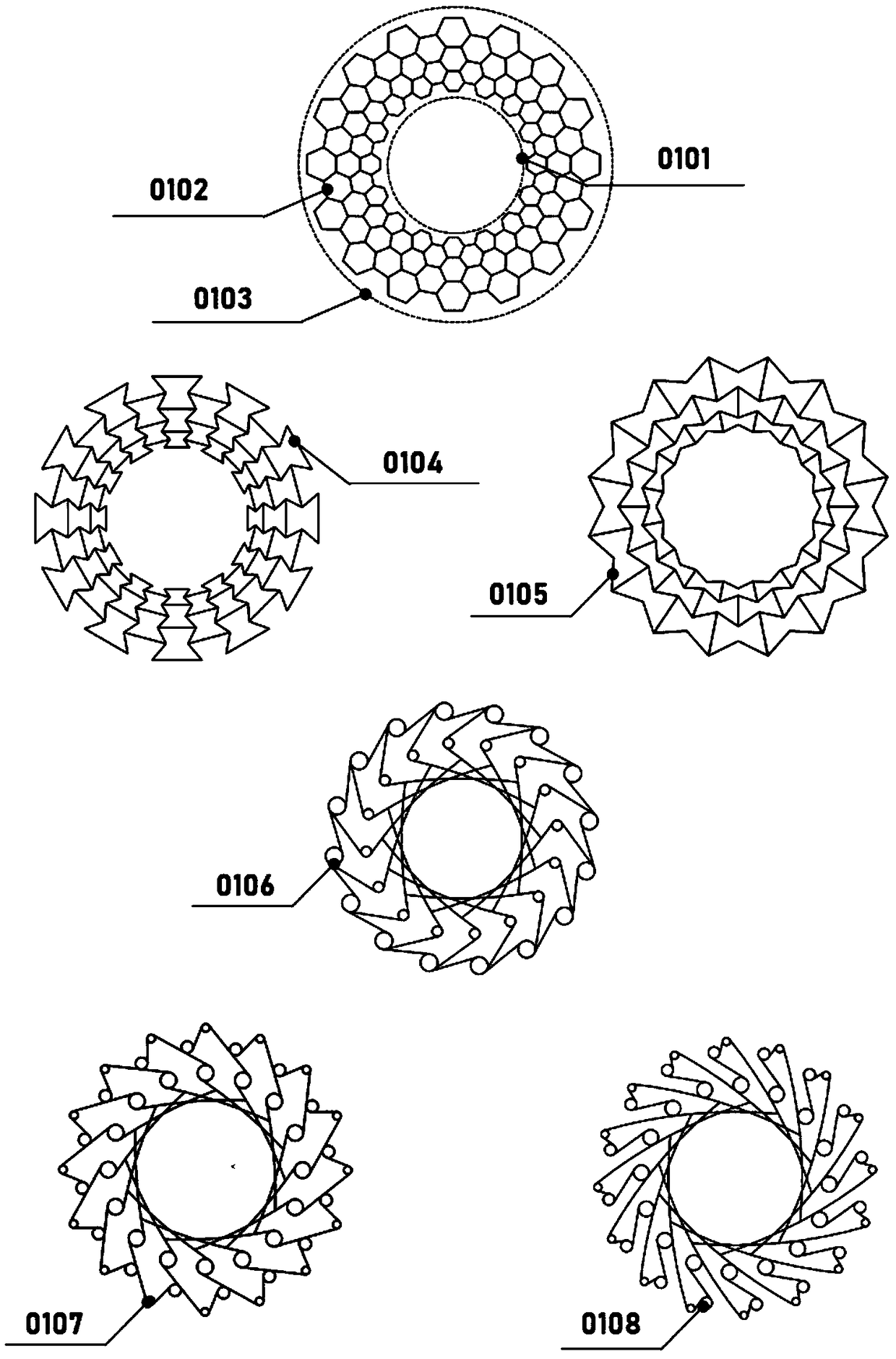

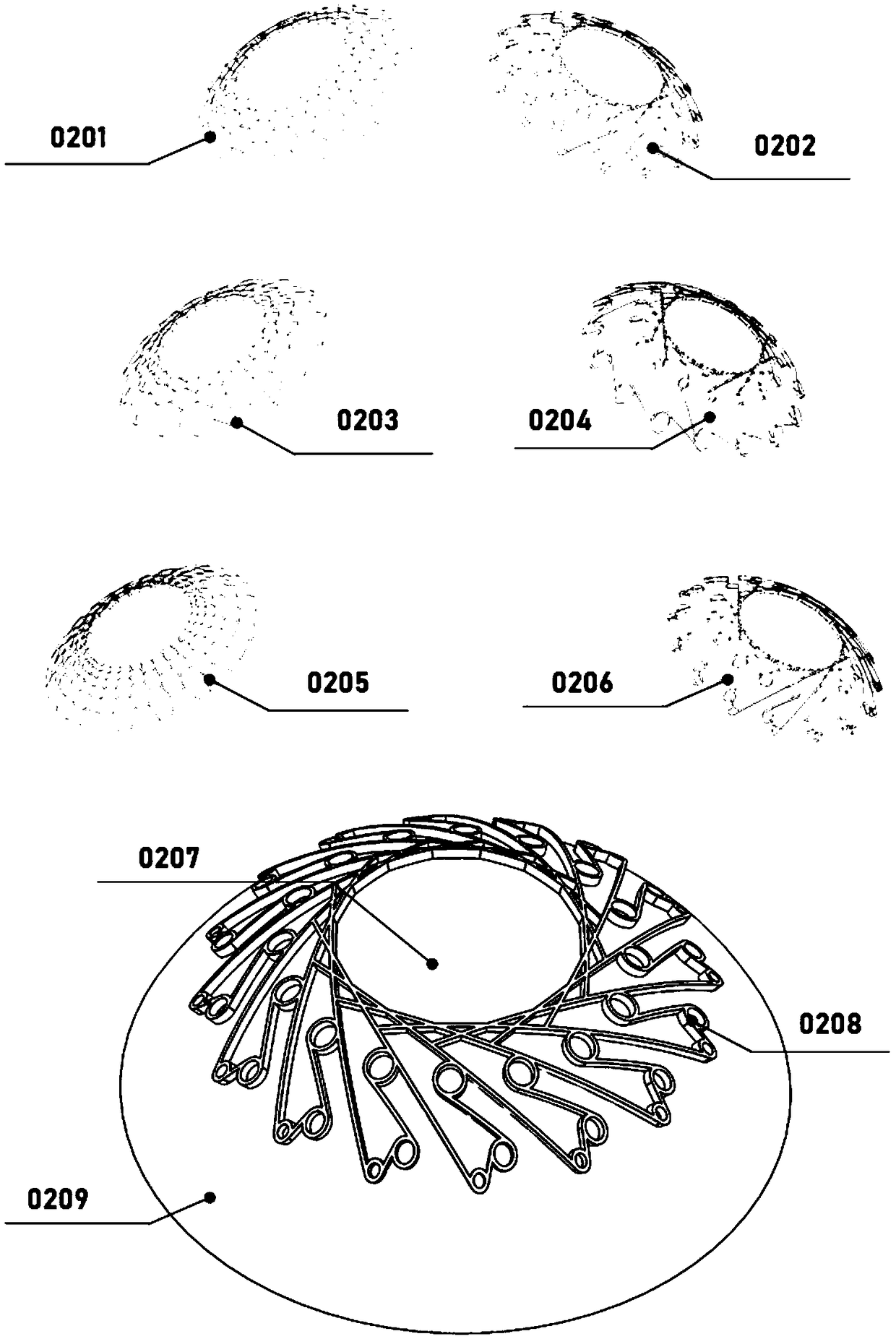

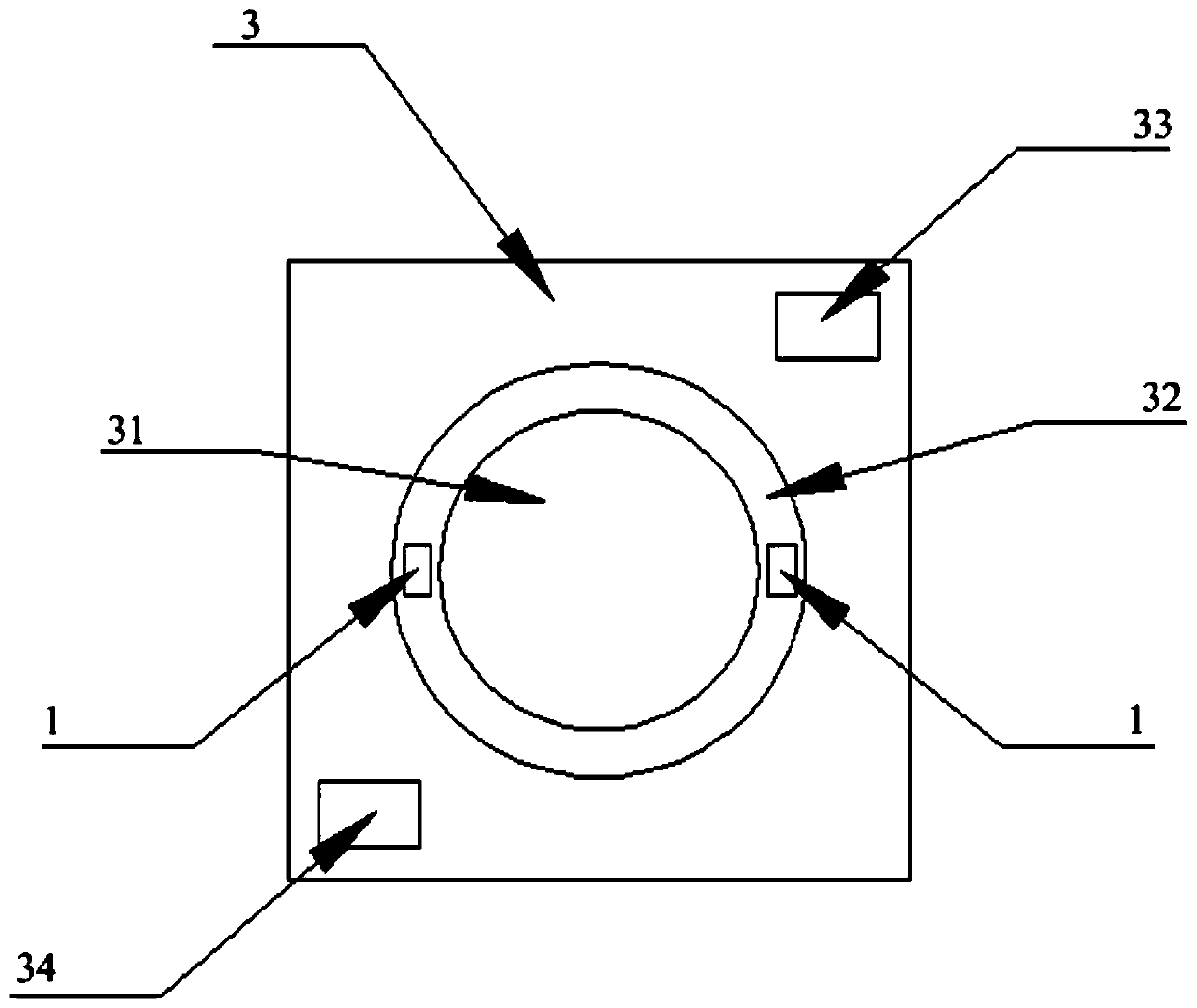

Micro-structure corneal contact lens and preparation method thereof

ActiveCN109116578AImprove eyesightFunctional expansion of eyesightOptical partsMicro structureEngineering

The invention relates to a micro-structure corneal contact lens and a preparation method thereof. The corneal contact lens adopts a mechanical flexible material and comprises a porous grid structure of a hollow annular layout formed by one or more deformable elastic mechanical units according to one or more distribution rules, wherein the annular layout is formed by periodically annularly and radially combining and distributing or orthogonally combining and distributing the deformable elastic mechanical units. The micro-structure corneal contact lens and the preparation method thereof with certain biological tearful eyes detection capacity are low in cost, expandable, capable of being customized and capable of realizing the mass production and wide in application range of people.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

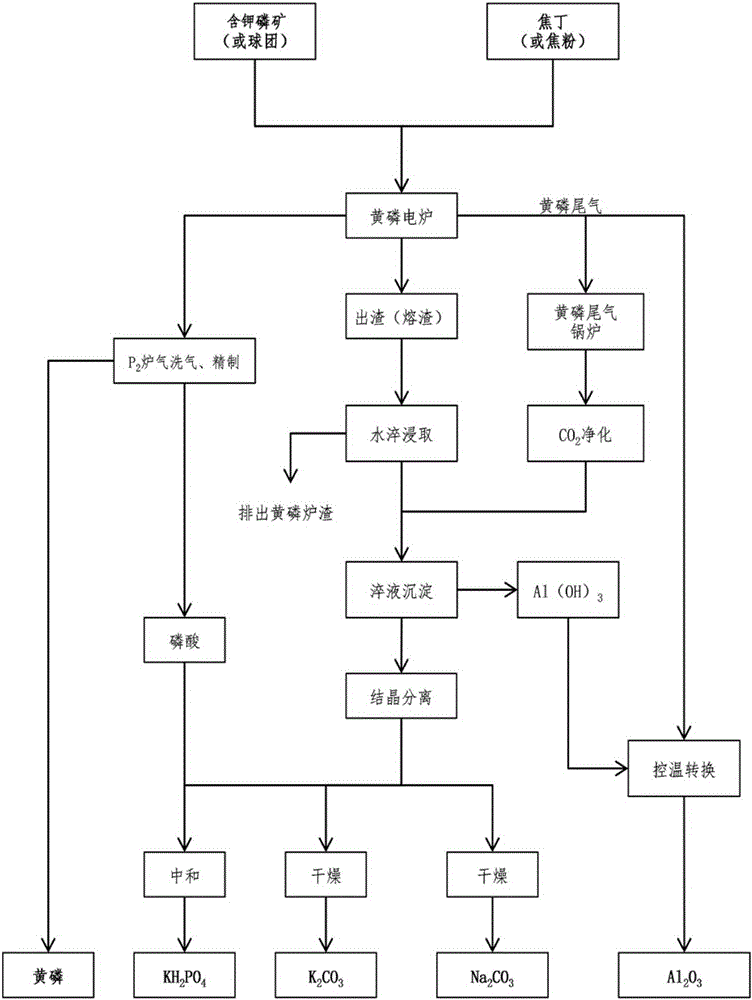

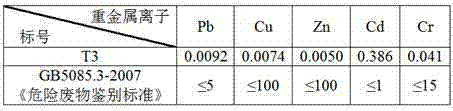

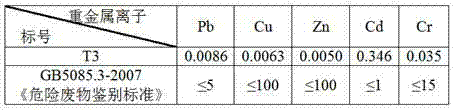

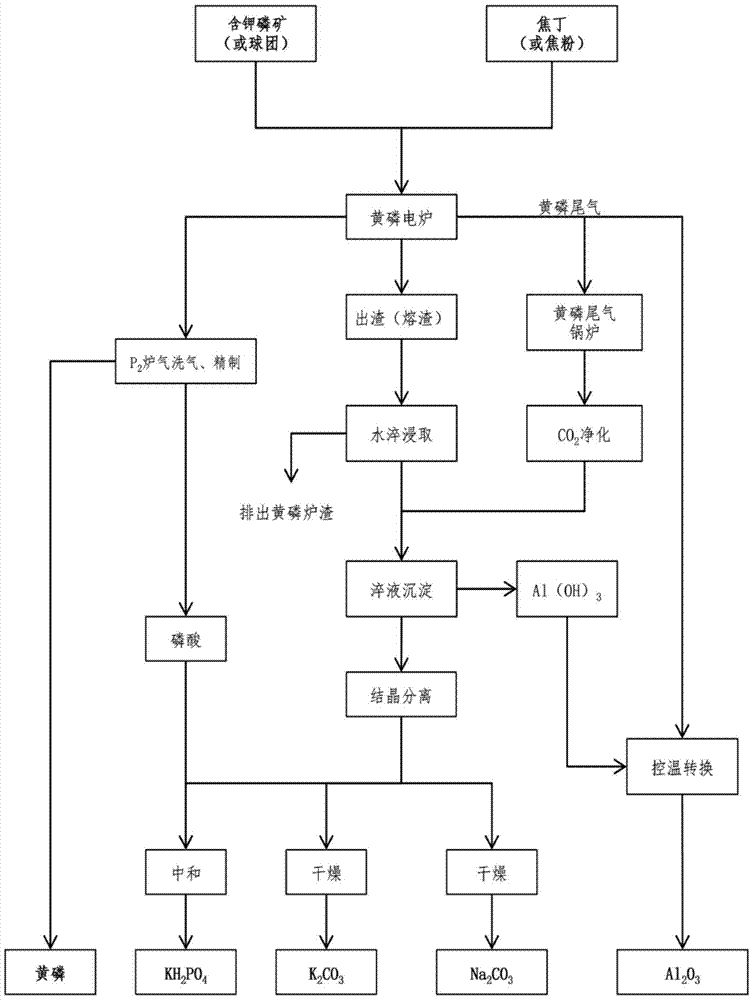

Energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite

ActiveCN105197901AReduce manufacturing costTake advantage ofChemical industryAlkali metal carbonatesFiltrationQuenching

The invention relates to an energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite. The method comprises the steps that the potassium-bearing phosphorite and coke nuts are added into a yellow phosphorus electric furnace to be reacted to obtain furnace gas containing P2; washing is conducted on the furnace gas, crude phosphorous is collected, refining is conducted, and high quality yellow phosphorus is obtained; water quenching is conducted on yellow phosphorus slags, the slags are removed, KAlO2 is dissolved out, filtration is conducted, Al(OH)3 is settled after CO2 is added, and water quench filtrate is obtained. The Al(OH)3 is converted through temperature control to obtain Al2O3, crystal separation and drying are conducted on the water quench filtrate, and K2CO3 and Na2CO3 are obtained. According to the energy-saving method for preparing the yellow phosphorus, the sylvite, the sodium carbonate and the aluminum oxide through the potassium-bearing phosphorite, series of problems that for a traditional electrothermal method that the potassium-bearing phosphorite is used for producing the yellow phosphorus through the yellow phosphorus electric furnace, the reaction is complex, the efficiency is low, furnace ore is unstable, and the benefit is poor are solved; compared with preparing K2CO3 through a traditional orthoclase sintering method, a high-temperature melting method, a hydrothermal method, a blast furnace smelting method and a low-temperature decomposition method, the energy consumption, material consumption and production cost can be greatly reduced, product profit margins are improved, and meanwhile environmental pollution is reduced.

Owner:黄钰雪

Preparation of ductility cement product by utilizing lead zinc tail mineral powder

ActiveCN104761232AReduce pollutionSimple operation processSolid waste managementClinker (cement)Materials science

The invention provides a method for preparing a ductility cement product by utilizing lead zinc tail mineral powder. The method comprises the following steps: by using lead zinc tail mineral powder, cement clinker and gypsum as raw materials; adding the three raw materials into a ball milling tank, and performing ball milling and uniformly mixing; uniformly mixing and stirring a mixture and water; compacting the obtained plasticity mixture into sections; and conserving at a certain temperature to obtain the ductility cement product. The ductility cement product prepared by using the method has the advantages that the fragility is greatly improved, the toughness is improved, the strong plasticity is achieved, and the application range is relatively wide. The preparation method is simple and feasible, and has a good economic benefit and good application prospect; moreover, the pollution to ecological environment by the tailings can be alleviated.

Owner:FUZHOU UNIV

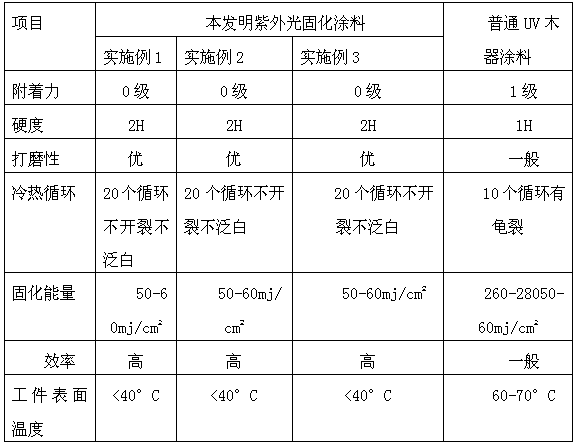

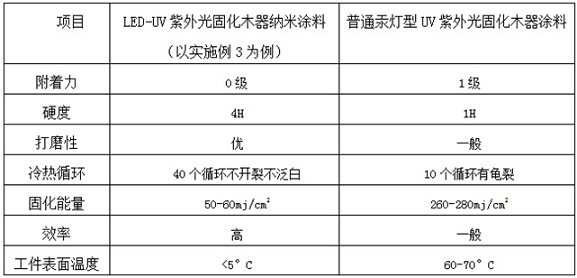

LED-UV (Light Emitting Diode-Ultraviolet) curing nano-coating for woodenware and preparation method thereof

ActiveCN107513344AHigh solid contentLow viscosityPolyurea/polyurethane coatingsPolyester coatingsPolyesterDipropylene glycol diacrylate

The invention discloses LED-UV (Light Emitting Diode-Ultraviolet) curing nano-coating for woodenware and a preparation method thereof. The LED-UV curing nano-coating for the woodenware is prepared from the following raw materials in percentage by weight: 25 percent to 30 percent of polyurethane acrylate formed by crossly linking pentaerythritol triacrylate and polyisocynate, 10 percent to 15 percent of fatty acid modified polyester acrylate resin, 20 percent to 25 percent of ethoxylated modified trimethylolpropane triacrylate, 10 percent to 20 percent of dipropylene glycol diacrylate, 0.2 percent to 1.0 percent of a wetting dispersant, 10 percent to 15 percent of nano barium sulfate powder, 2 percent to 5 percent of a UV curing monomer dispersion solution of nano wear-resisting particles, 2 percent to 4 percent of a hydrogen abstraction type photoinitiator, 1 percent to 3 percent of active amine, 2 percent to 4 percent of a cracking type photoinitiator, 0.2 percent to 0.5 percent of a leveling agent, 0.2 percent to 0.5 percent of a de-foaming agent and 0.1 percent to 0.3 percent of a polymerization inhibitor. The ultraviolet curing coating disclosed by the invention can reach a needed curing degree only through 50mj / cm<2> to 60mj / cm<2> of LED-UV energy, so that the energy needed by coating curing is greatly reduced, the construction efficiency is improved and the possibility of causing quality defects in woodenware surface coating construction is reduced.

Owner:SHANDONG UNIV +1

Microfluidic sensor chip system and preparation method thereof

ActiveCN107670735AHighly integratedNo pollutionLaboratory glasswaresMicro fluidicElectrical and Electronics engineering

The invention discloses a microfluidic sensor chip system, and a preparation method thereof. The microfluidic sensor chip system comprises a substrate layer, one or a plurality of micro fluidic chip layers, one or a plurality of sensor chip layers, and a sensor bearing layer which are laminated via bonding successively; sensor layers are composed via combination of the sensor chip layers and the sensor bearing layer; each sensor layer is designed to be corresponding to different micro fluidic channels of a micro fluidic chip layer or different layers of the plurality of micro fluidic chip layers, so that each micro fluidic chip layer or each micro fluidic channel is provided with a corresponding sensor layer for detection. The microfluidic sensor chip system and the preparation method possess following advantages: the integration degree is high; operation is convenient; cost is low; the sensitivity is high; the micro fluidic channels and the sensors can be separated effectively; flexibility is achieved; and batch production can be realized.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

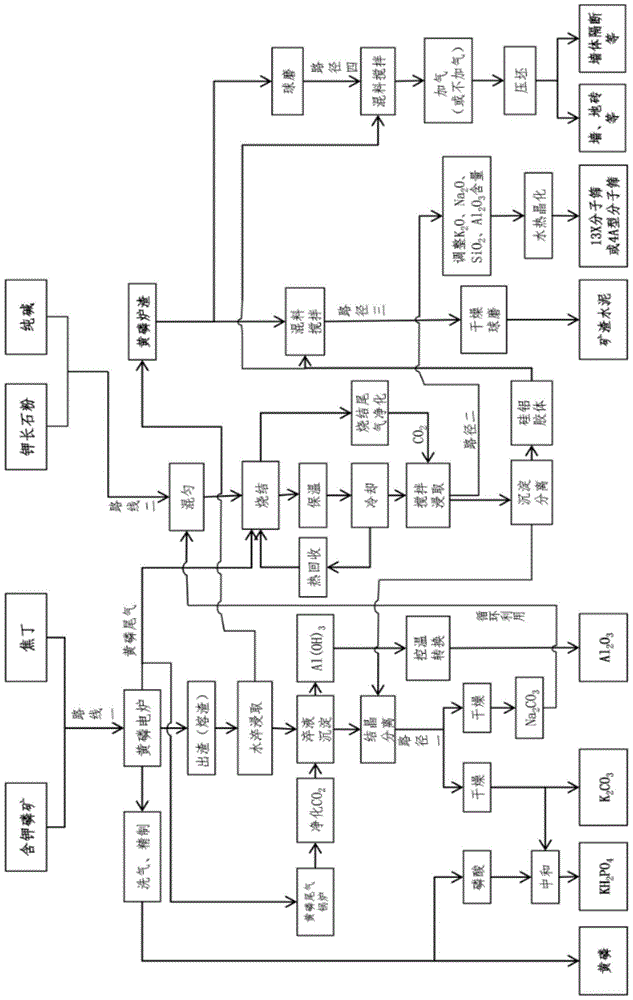

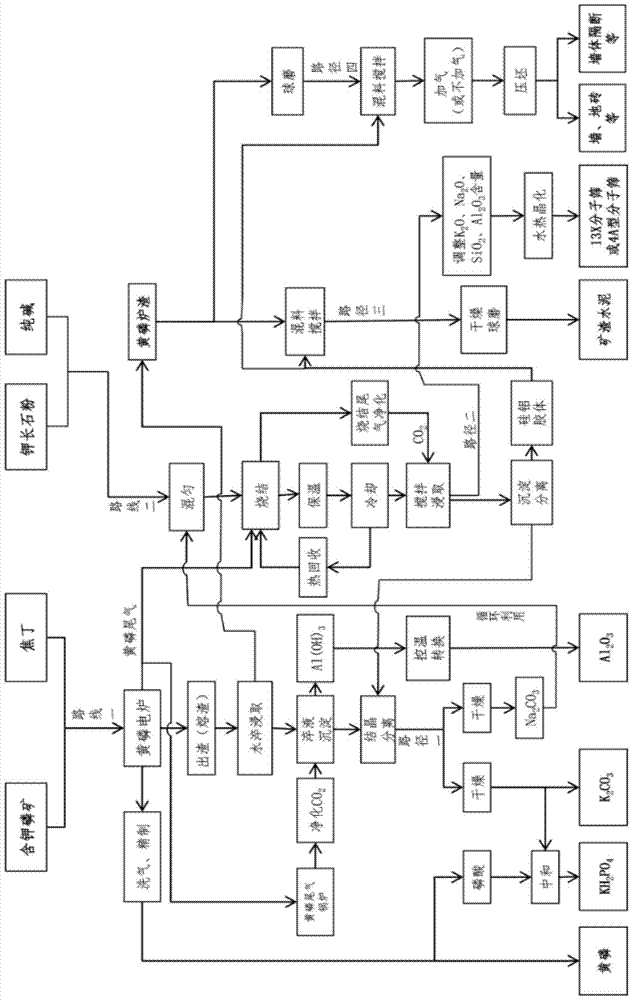

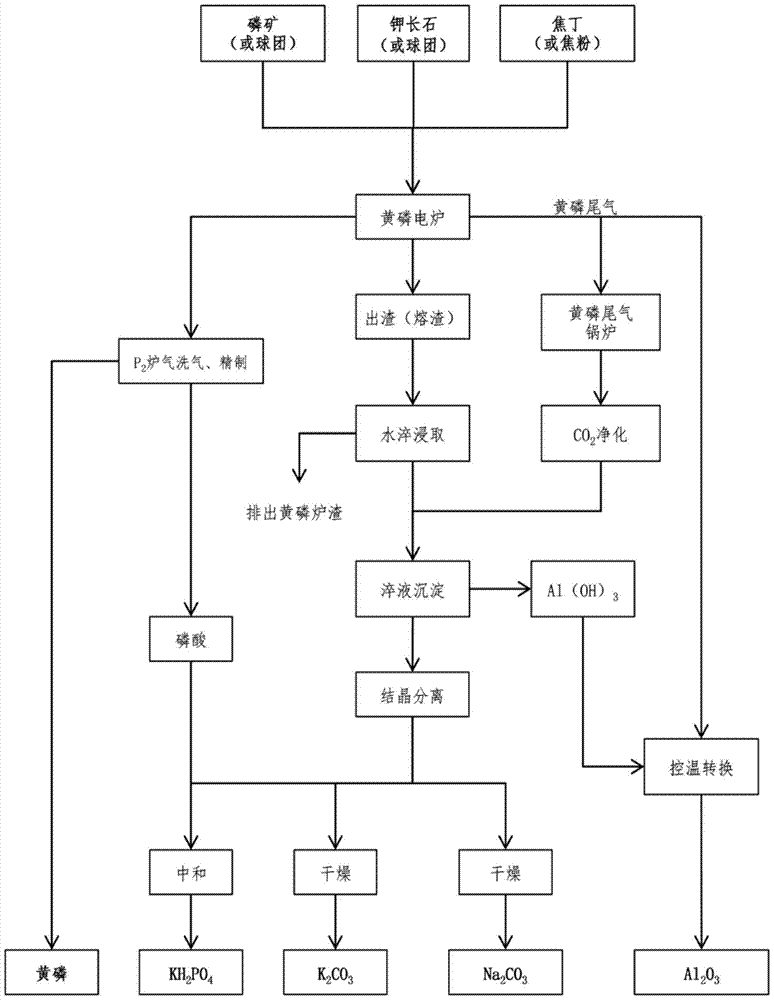

Recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite

ActiveCN105197902AReduce manufacturing costTake advantage ofSolid waste managementChemical industryFiltrationSlag

The invention relates to a recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite. The method utilizes two routes, for the first route, high quality yellow phosphorus is produced by the potassium-bearing phosphorite and coke nuts through an electrothermal method, water quenching is conducted on yellow phosphorus slags, KAlO2 is dissolved out, filtration is conducted, CO2 is introduced, Al(OH)3 is settled, first filtrate is obtained, and the Al(OH)3 is converted through temperature control to obtain Al2O3. For the second route, orthoclase power and Na2CO3 are evenly mixed, roasting is conducted through yellow phosphorus tail gas, water leaching is conducted through water, the CO2 is introduced to settle out silicon-aluminum colloid, and second filtrate is obtained. Crystallization and drying are conducted on the first filtrate and the second filtrate, and K2CO3 and Na2CO3 are obtained. The Na2CO3 returns to the second route to be recycled. The content of K2O, Na2O, SiO2 and Al2O3 is adjusted for partial silicon-aluminum colloid which is not subjected to sedimentation and the filtrate, hydrothermal crystallization reaction is conducted, and the molecular sieves are obtained; settled silicon-aluminum colloid is mixed with the yellow phosphorus slags to prepare the slag cement and / or the architectural profiles.

Owner:黄钰雪

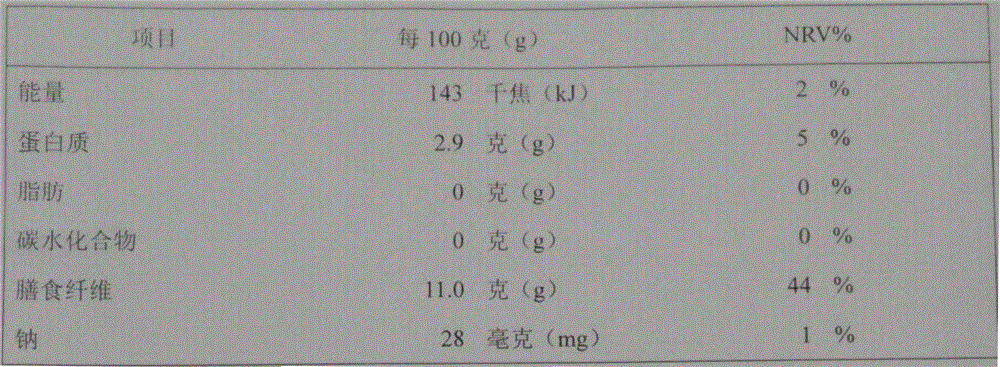

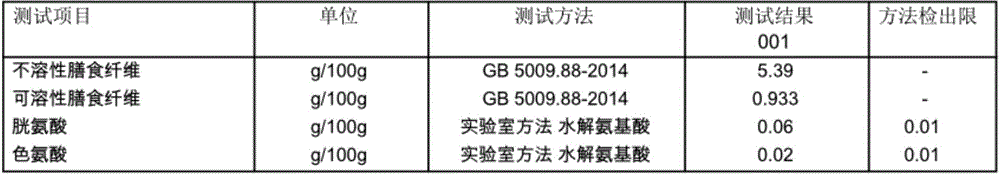

Bamboo shoot powder and processing and preparing method thereof

The invention belongs to the field of food, and relates to a food raw material and a processing and preparing method thereof, in particular to bamboo shoot powder and a processing and preparing method thereof. The concrete preparing method of bamboo shoot powder comprises the following steps: 1, cleaning raw materials, namely bamboo shoots, dicing the bamboo shoots and draining the diced bamboo shoots for later use, wherein the diced bamboo shoots are cubes with the size of 1-20mm; 2, performing dehydration treatment on the prepared bamboo shoot cubes for removing 30-70% water from the prepared bamboo shoot cubes, and then naturally drying the dehydrated bamboo shoot cubes until no obvious moisture exists on the surface; 3, quick-freezing the bamboo shoot cubes subjected to dehydration treatment to crystallization by spraying liquid nitrogen, and then grinding the crystallized bamboo shoot cubes into powder, wherein the mesh number is greater than 120 meshes; and 4, immediately packaging the prepared bamboo shoot powder and sealing for storage. The large-scale preparation of bamboo shoot powder is realized, the cost is effectively reduced, and the productivity is increased.

Owner:伊奎鑫

Hole-sealing agent and preparation method thereof

InactiveCN104451822AReduce pollutionExtended temperature rangeSurface reaction electrolytic coatingActive agentPhosphoric acid

The invention discloses a hole-sealing agent. The hole-sealing agent comprises an accelerator, a surfactant and a stabilizer, wherein the accelerator comprises citric acid and trisodium phosphate, the surfactant comprises sodium p-toluenesulfonate and ammonium lignosulfonate and the stabilizer comprises sodium heptonate, sodium carbonate and boric acid. The hole-sealing agent disclosed by the invention has the beneficial effects that the operable temperature range of the product is 50-100 DEG C, the temperature applicable range of a device is effectively increased, the energy consumption is saved, the device is convenient to operate, the service life is long, the level of the environmental pollution is decreased, the market scope of application is broad and the hole-sealing agent is conducive to the promotion and application of the market.

Owner:DONGGUAN RIYE CHEM TECH

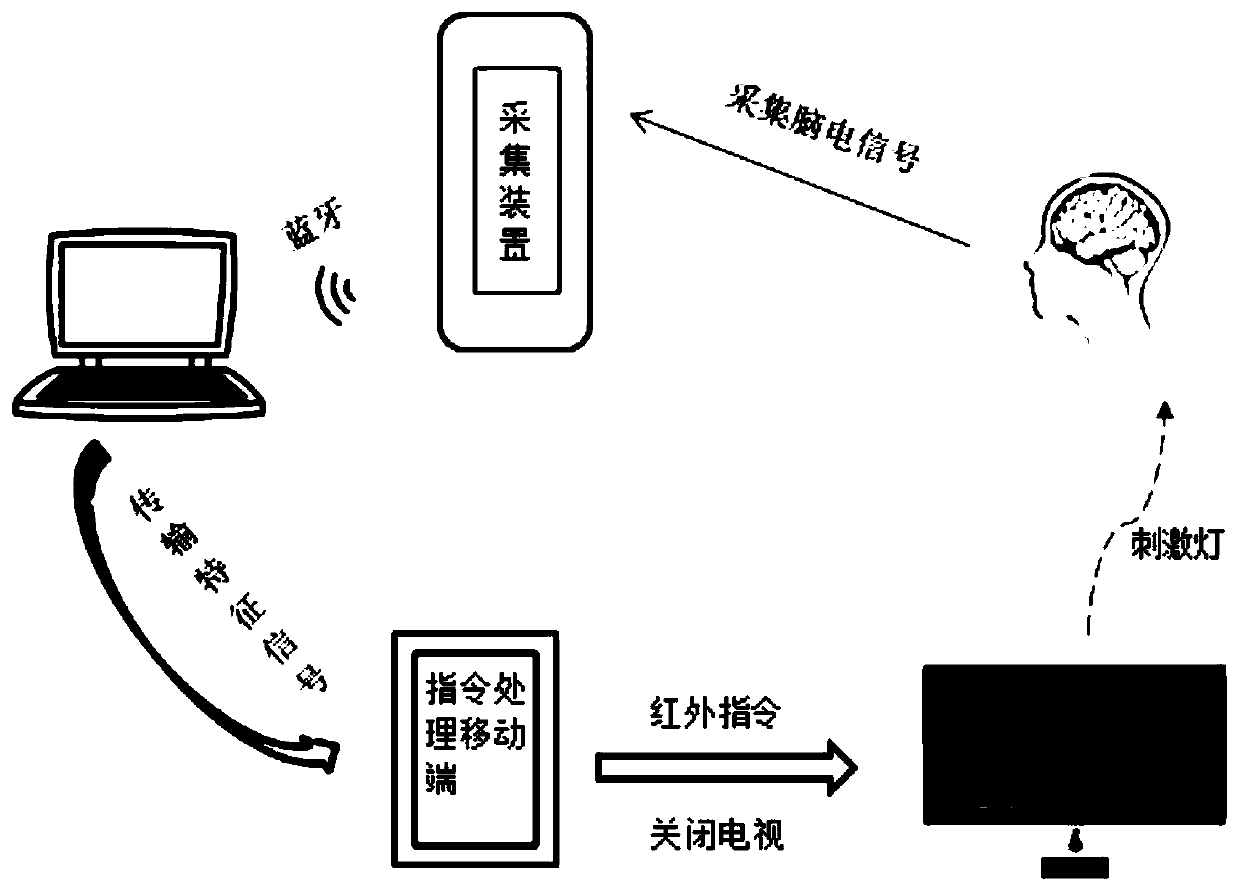

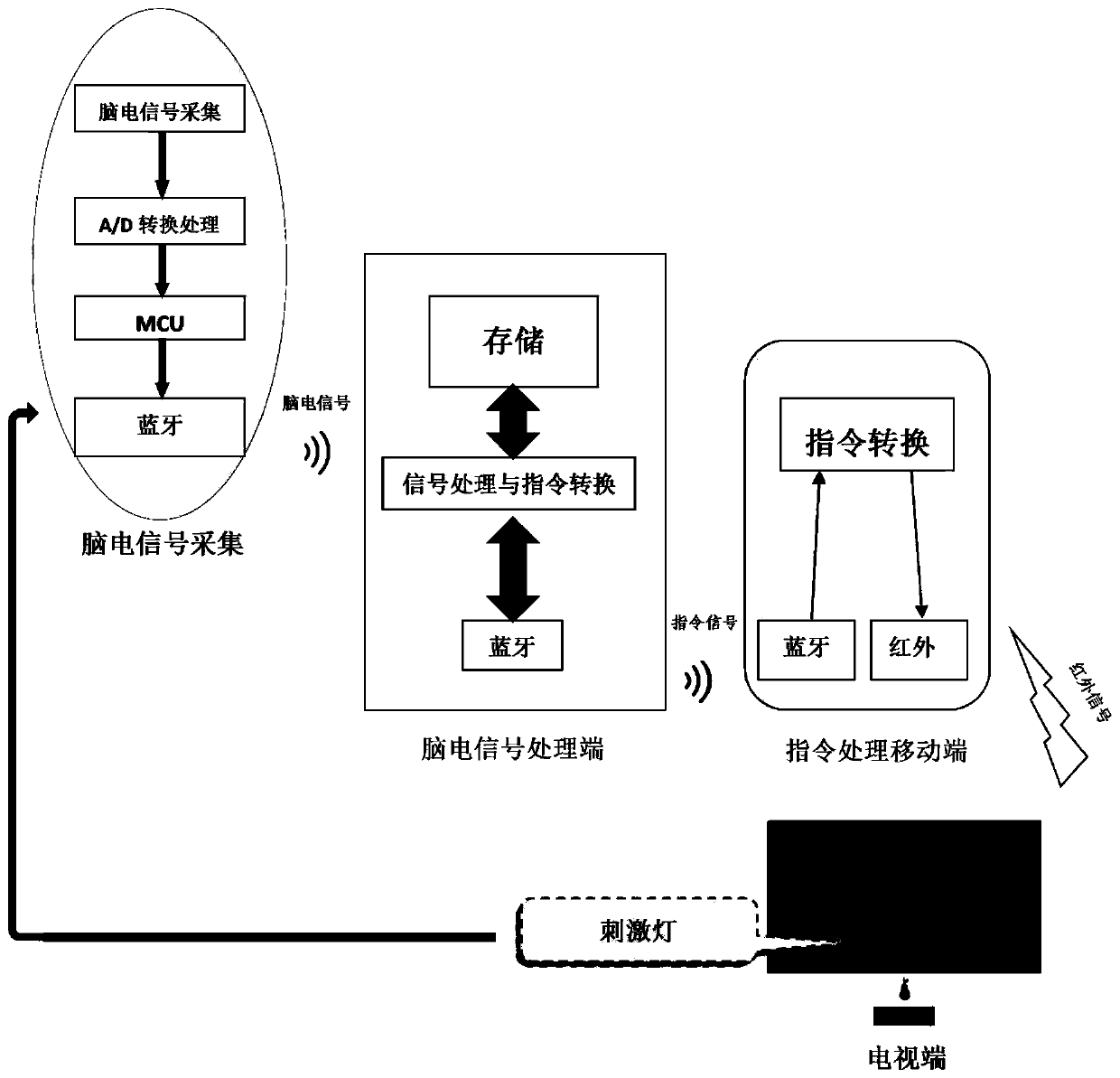

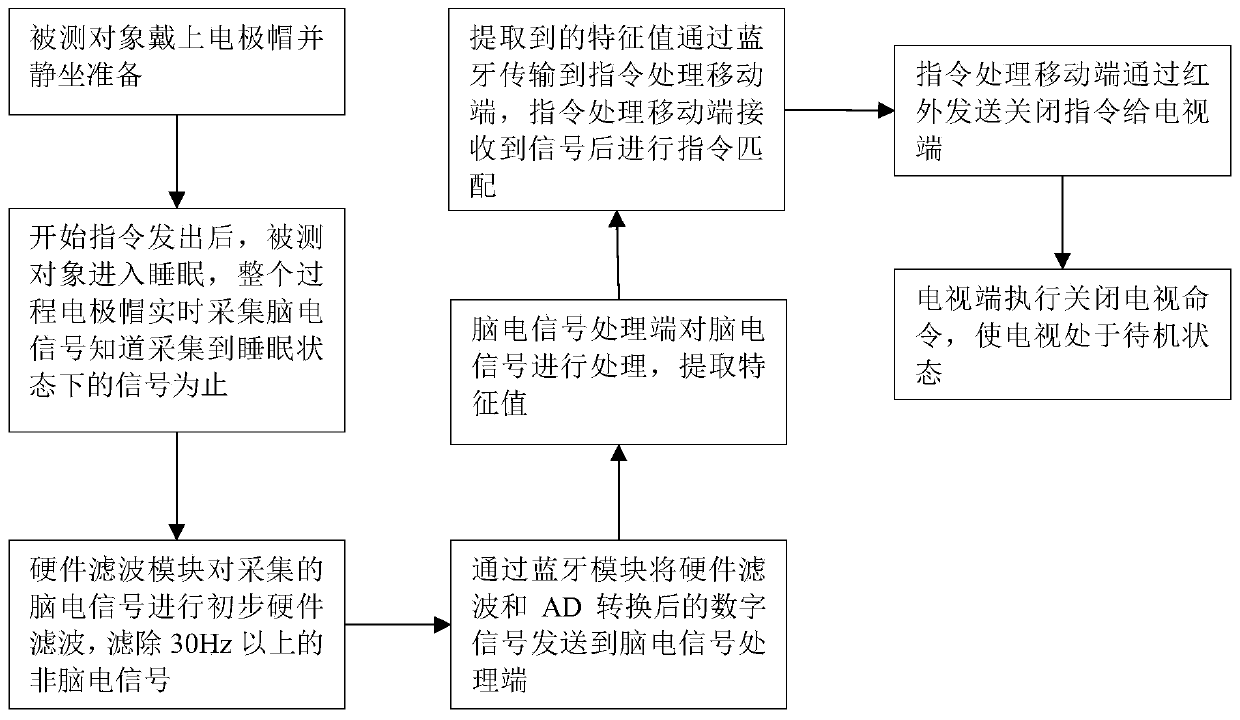

Television intelligent remote control system based on brain-computer interface

InactiveCN110198465ACause wasteImprove comfortSelective content distributionBrain computer interfacingSleep state

The invention relates to a television intelligent remote control system based on brain-computer interface, and belongs to the technical field of electroencephalogram application. The system comprisesan electroencephalogram signal acquisition device, an electroencephalogram signal processing end and an instruction processing mobile end. The electroencephalogram signal collecting device is used forcollecting and sending weak electroencephalogram signals. The electroencephalogram signal processing end is used for analyzing and processing EEG signals and has a first-level instruction sending function, and the instruction processing mobile end is used for converting first-level instructions sent by the electroencephalogram signal processing end into corresponding second-level control instructions and sending the second-level control instructions to the television end. By detecting brain waves of a person in a sleep state, a corresponding instruction is formed to control the television tobe turned off, and a user does not need to cause energy waste due to accidental sleeping in the process of watching the television.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

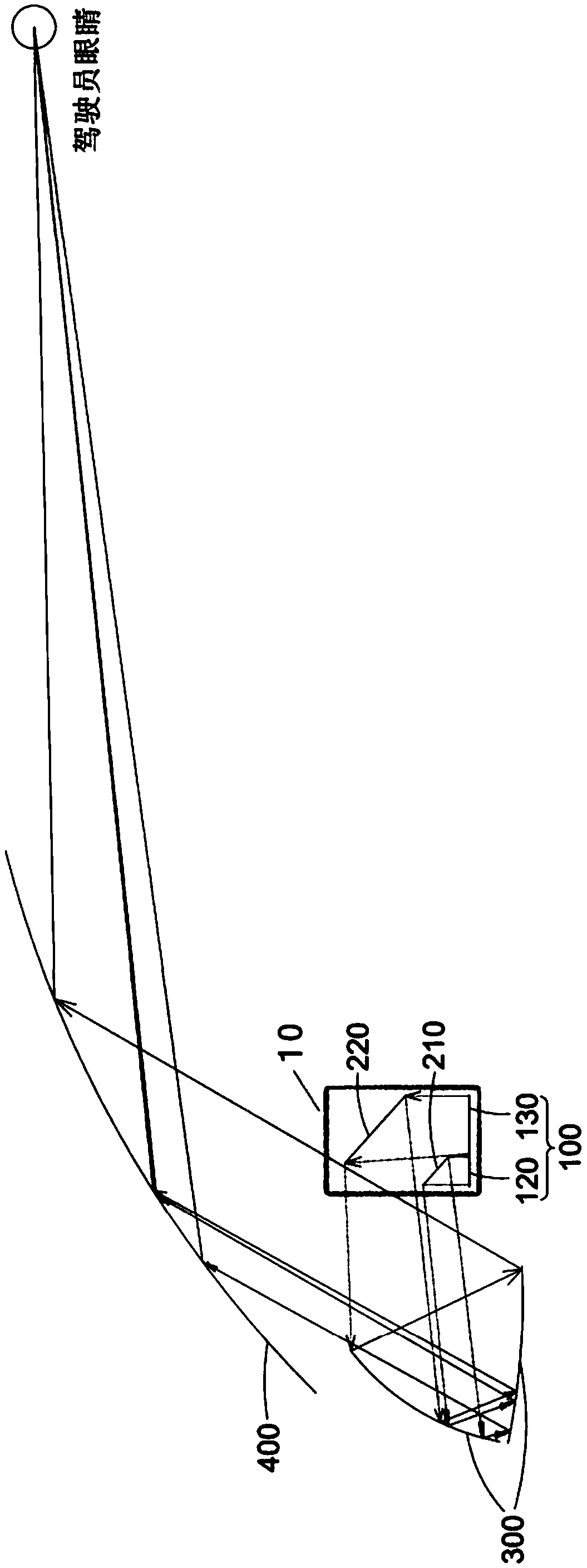

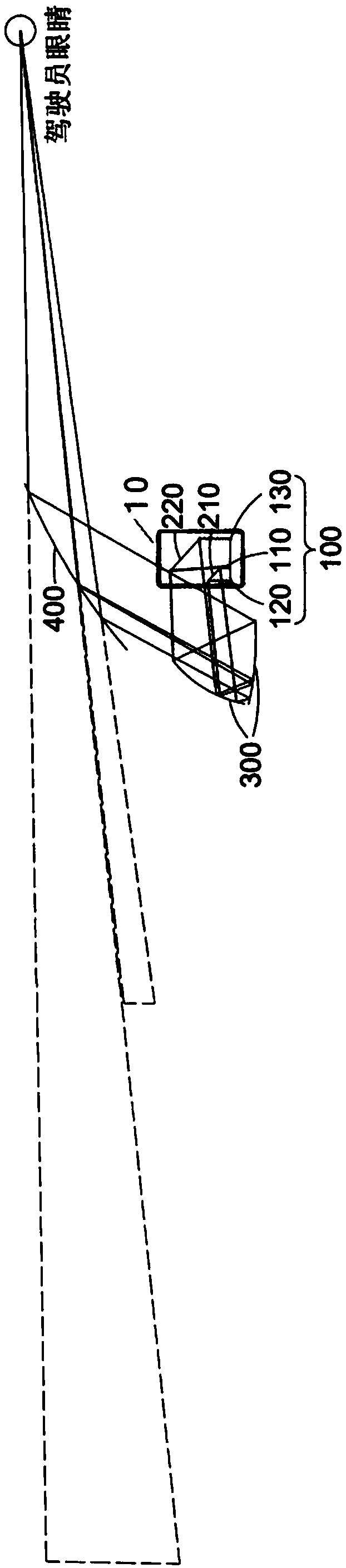

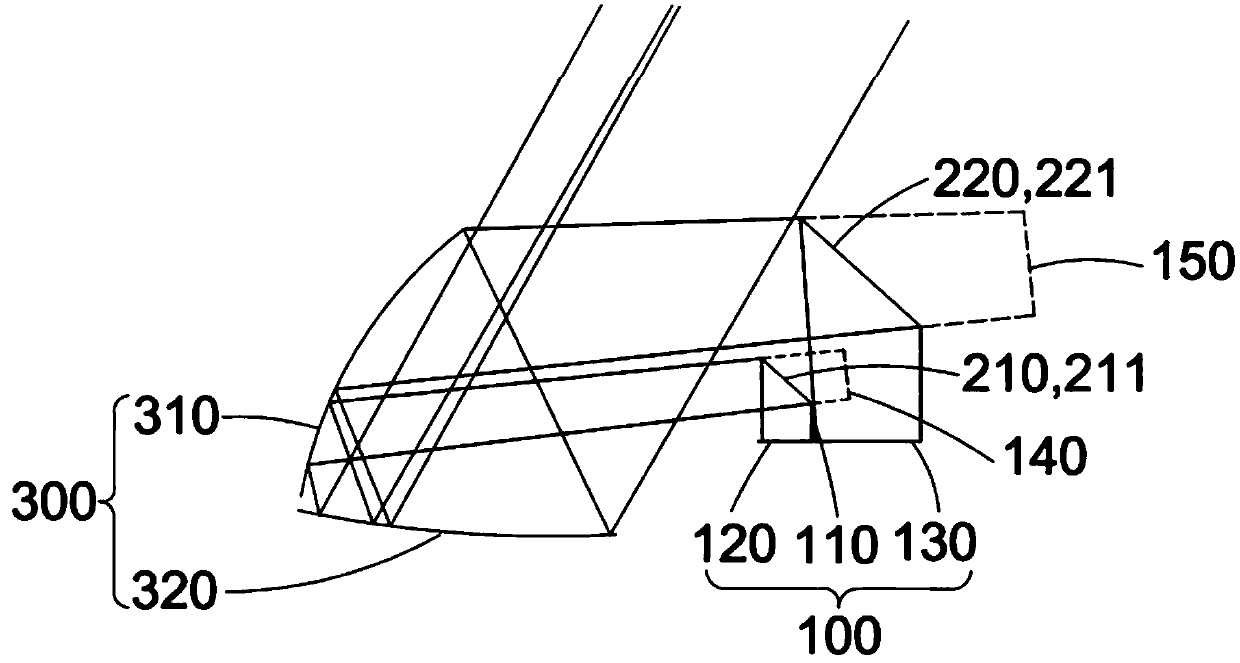

Implementation method of optical engine, optical engine and double-display head-up display system for automobile

PendingCN110824701APhysical adaptabilityWide range of market applicationsOptical viewingOptical elementsLight beamEngineering

The invention discloses an implementation method of an optical engine. The implementation method comprises the following steps that: an image segmentation device is arranged on an imaging unit, and the imaging unit is segmented into a close-range image area and a long-range image area; a close-range image source reflector group and a long-range image source reflector group are respectively arranged above or in front of the close-range image area and the long-range image area, a distance between the close-range image area and the close-range image source reflector group is smaller than a distance between the long-range image area and the long-range image source reflector group, so that a close-range imaging light beams and a long-range imaging light beam which are emitted by the close-rangeimage area and the long-range image area are respectively reflected to form a close-range image source and a long-range image source which are in the same direction and have different distances. According to the method of the invention, the imaging unit is divided into the close-range image area and the long-range image area; an image position heterogeneity effect can be obtained without multipleimaging units and light path structures required; the size and cost of the optical engine are decreased; and a head-up display method has higher practical value.

Owner:深圳前海智云谷科技有限公司

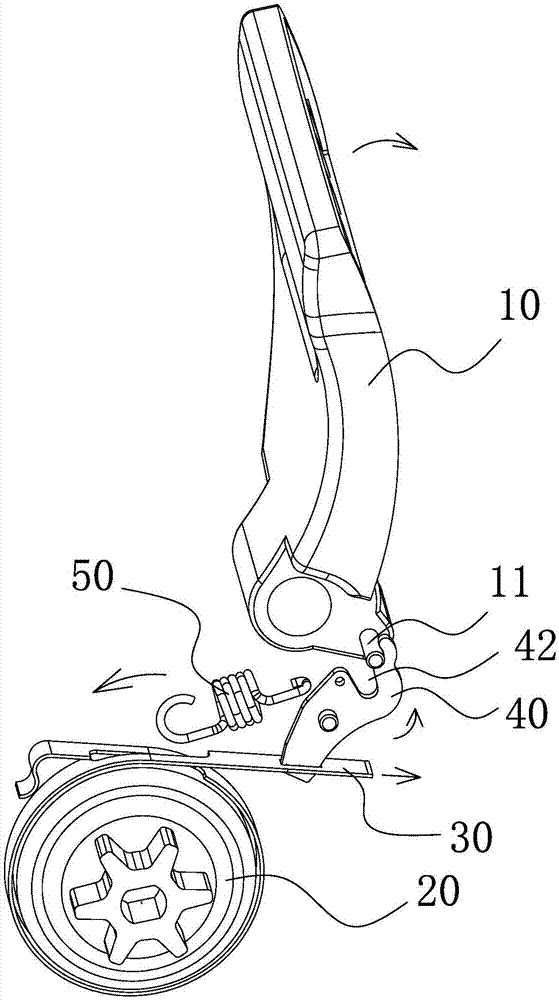

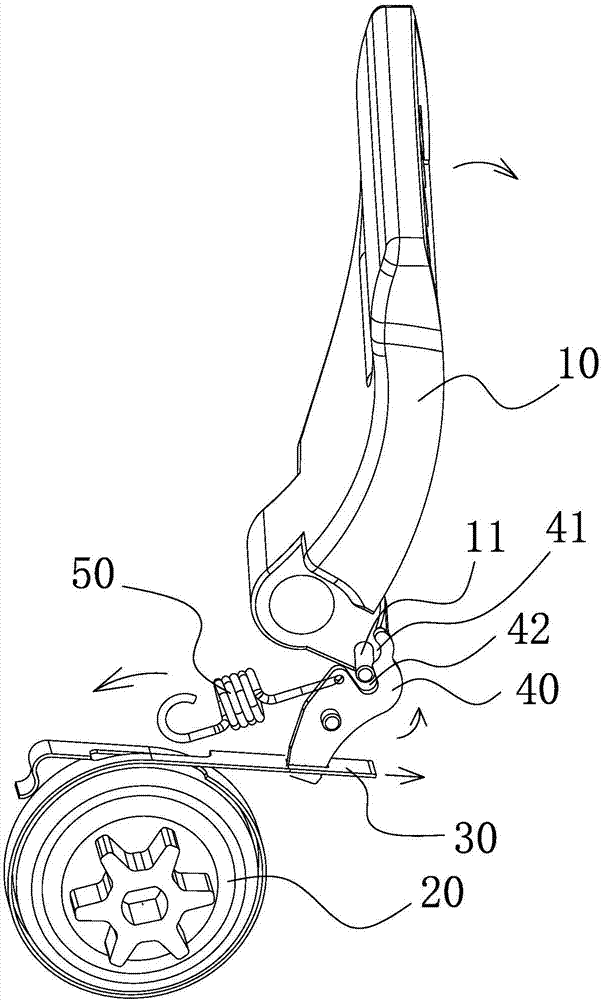

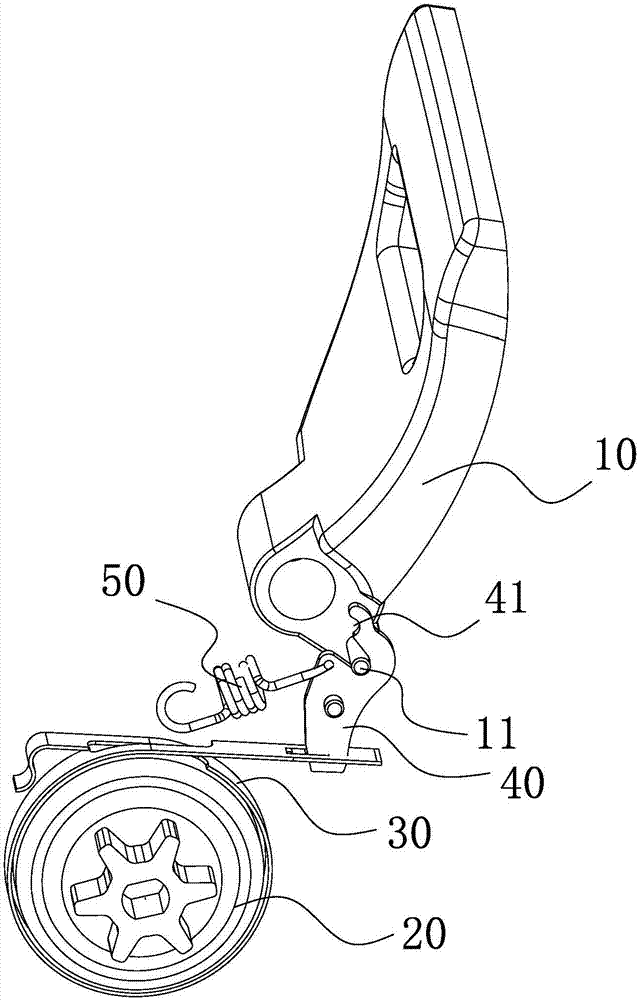

Brake structure of chain saw and chain saw

PendingCN107470962ASimple structural designIngenious structural designMetal sawing devicesChain sawsBrakeControl theory

The invention provides a brake structure of a chain saw. The brake structure of the chain saw comprises a chain saw rack, a brake disc, a protective plate, a brake part and a brake tension spring; a brake steel belt is closely arranged at the periphery of the brake disc in a surrounding manner; the protective plate is hinged to the chain saw rack, and the lower end of the protective plate is provided with a limiting column; the middle of the brake part is hinged to the chain saw rack, the lower end of the brake part is connected with the brake steel belt, and the upper end of the brake part is provided with a limiting groove matched with the limiting column and a brake gap located on the side, close to the brake steel belt, of the limiting groove; the brake tension spring is connected between the brake part and the chain saw rack, and when the chain saw is in a normal working state, the brake tension spring is in a tensional state, and the limiting column is arranged in the limiting groove. The brake structure of the chain saw has the advantages of being more simple in structure and reliable in work.

Owner:ZHEJIANG LERA NEW ENERGY POWER TECH CO LTD

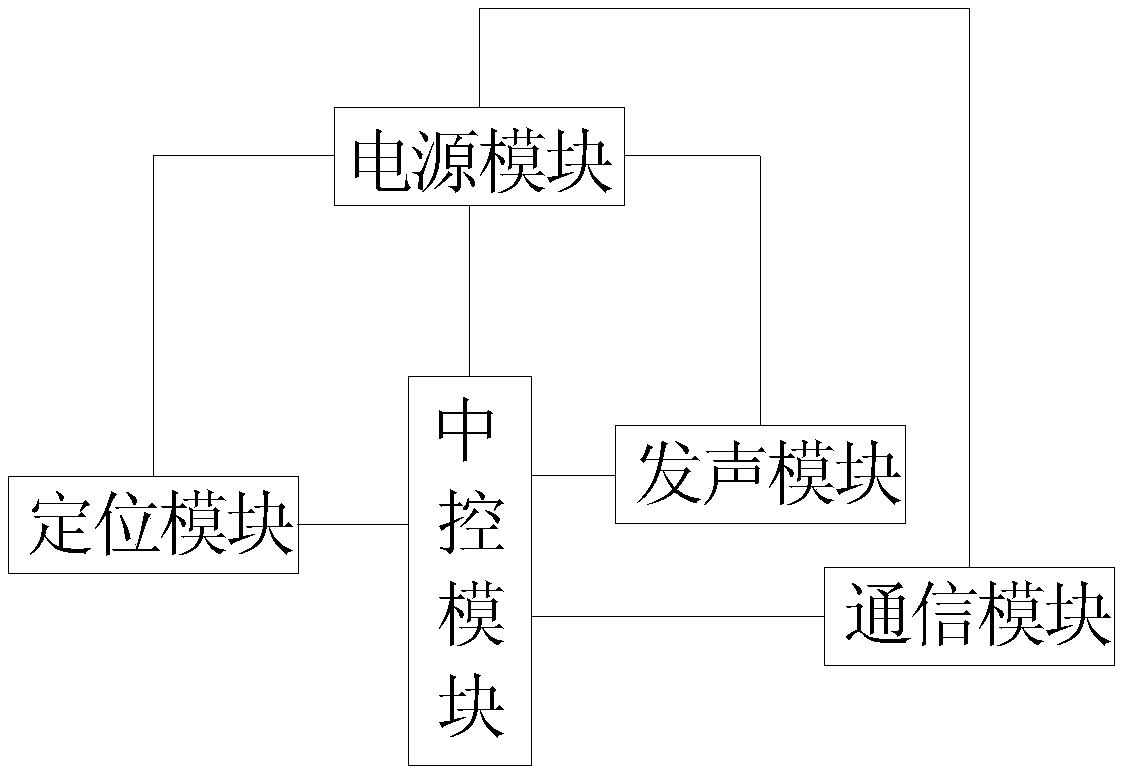

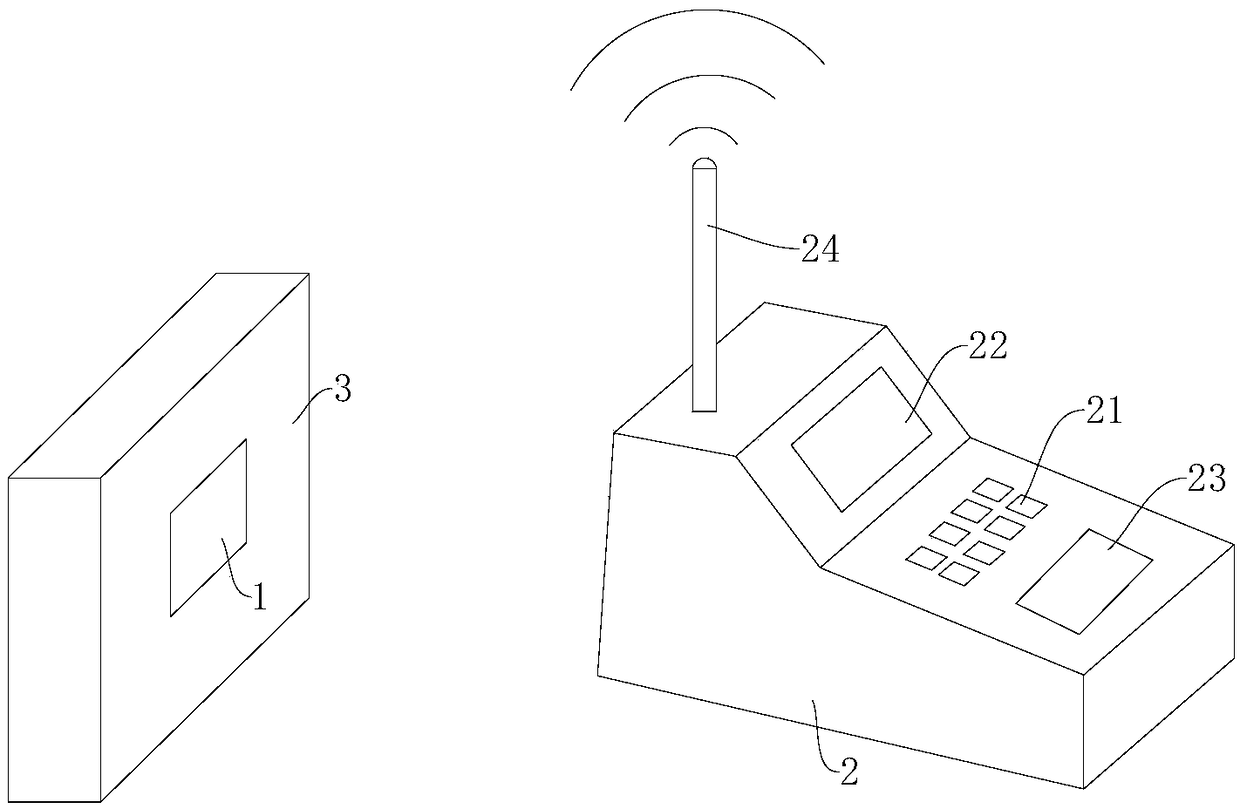

Logistics management system and control method therefor

PendingCN108665209ARealize batch transfer registrationImprove management efficiencyAutomatic card filesLogisticsLogistics managementComputer module

The invention discloses a logistics management system. The system comprises an electronic tag and a reader-writer, wherein the electronic tag includes a power module, a central control module, a communication module, a sounding module and a positioning module. The power module is connected to other modules to provide electrical energy; the communication module is connected to the central control module, wherein the communication module includes a signal projector and a signal receiver; the electronic tag exchanges data with the reader-writer through the communication module; the sounding module is connected to the central control module, wherein the sounding module includes a public address set which is provided with a control chip; the positioning module includes a GPS (Global Position System) positioning apparatus, and the positioning module is connected to the central control module. According to the logistics management system, technical problems of low efficiency in circulation registration, management, positioning and searching of logistics management objects can be solved.

Owner:BAISE UNIV

Waterproof antibacterial coating for exterior walls of buildings applied in mycotic environment and manufacturing method thereof

InactiveCN109135382AGood water solubilityImprove brittlenessAntifouling/underwater paintsPaints with biocidesFiberPollution

The invention discloses a waterproof antibacterial coating for exterior walls of buildings applied in a mycotic environment and a manufacturing method thereof. The waterproof antibacterial coating comprises three parts of a component A, a component B and a component C, wherein the component A is a viscous solution involving the steps that under the combined action of ligninase and diluted hydrochloric acid, an aqueous solution composed of acid-modified polysaccharides and trace useless water-soluble organic matters and water is acquired from schizonepeta stem and houttuynia cordata root, and after heating concentration is carried out, the viscous solution is obtained; the component B is a mixed liquid involving the steps that activated carbon micro powder, chitosan antibacterial gel and Bossini nano-latex paint are mixed in absolute ethyl alcohol and then react with sodium hydroxide, after heating steaming from ethyl alcohol is carried out at 60-70 DEG C, the mixed liquid of a hydroxylated organic matter and activated carbon powder is obtained; the component C is a mixed dry fiber involving the steps that the schizonepeta stem and the houttuynia cordata root are subjected to complete dehydration and then physical mixing, and the mixed dry fiber is obtained. The waterproof antibacterial coating for the exterior walls of the buildings applied in the mycotic environment and the manufacturing method thereof have the advantages that the manufacturing process is detailed and easy to implement, the antibacterial effect is good, the effect is lasting, and the waterproof antibacterial coating is green, environmentally friendly and pollution-free, has no pungent smell, is resistant to water, and has a self-cleaning function.

Owner:山东天汇防水股份有限公司

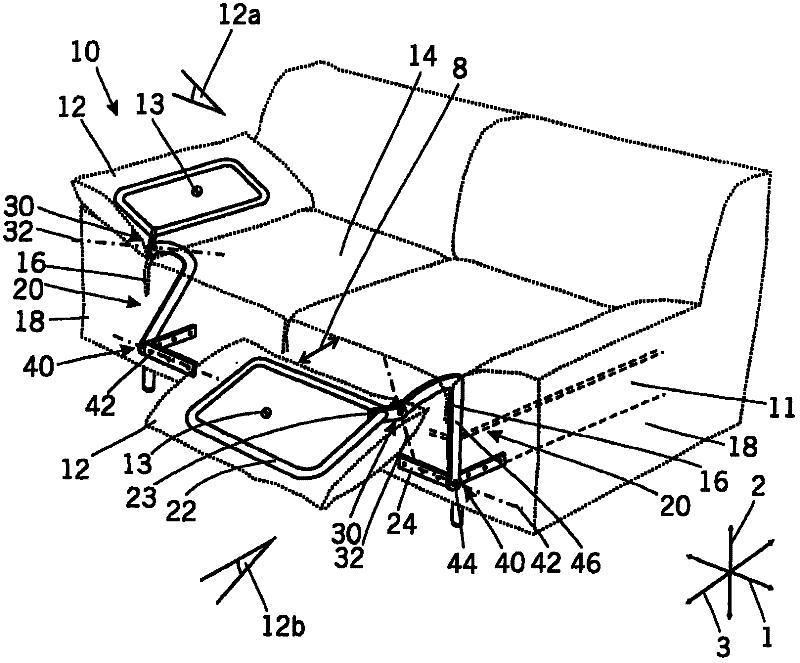

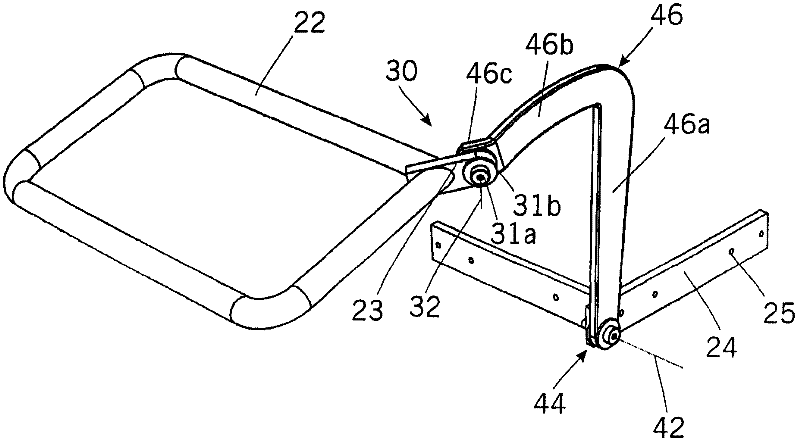

Piece of furniture and fitting for a piece of furniture

InactiveCN102188116AWide range of market applicationsEasy to stand upStoolsChairsEngineeringMechanical engineering

Owner:VEL VEGA DESIGN E TECHA IND UNIP LDA

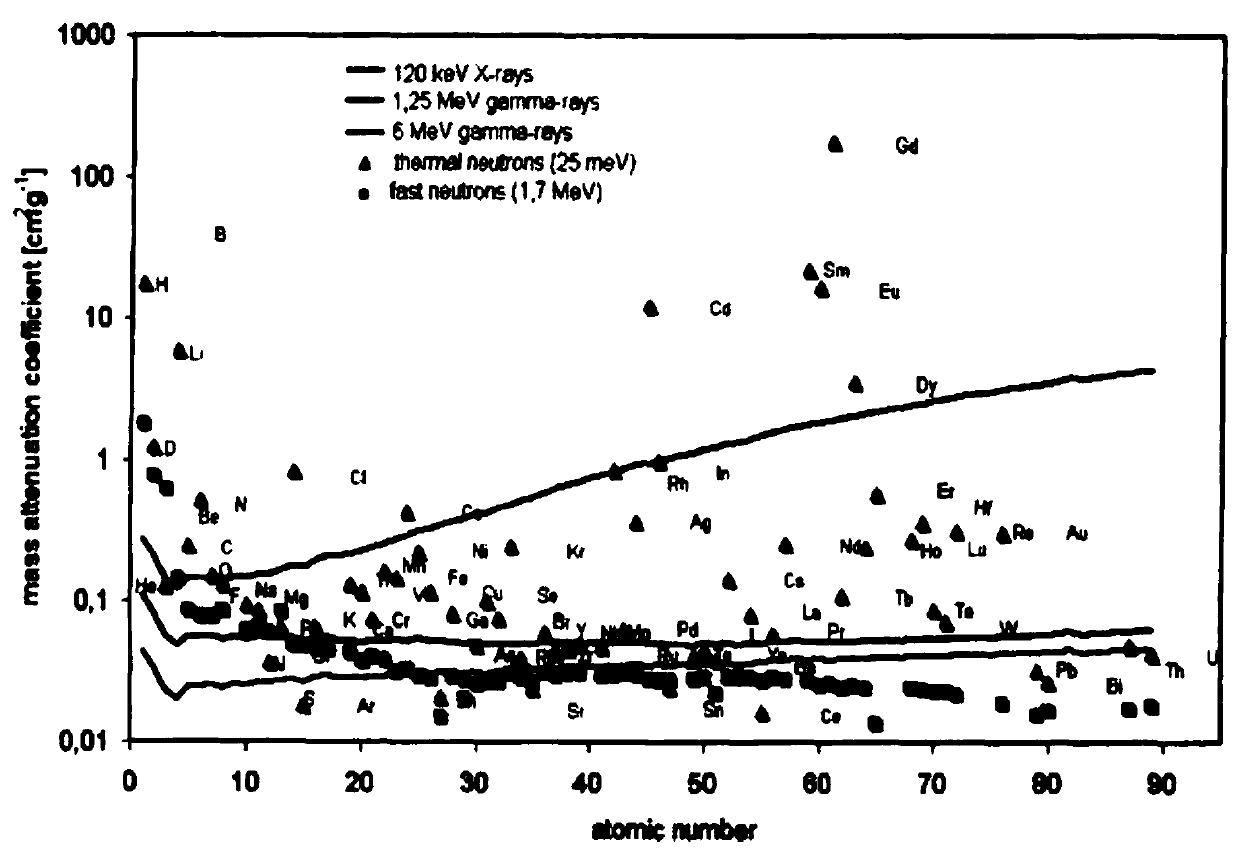

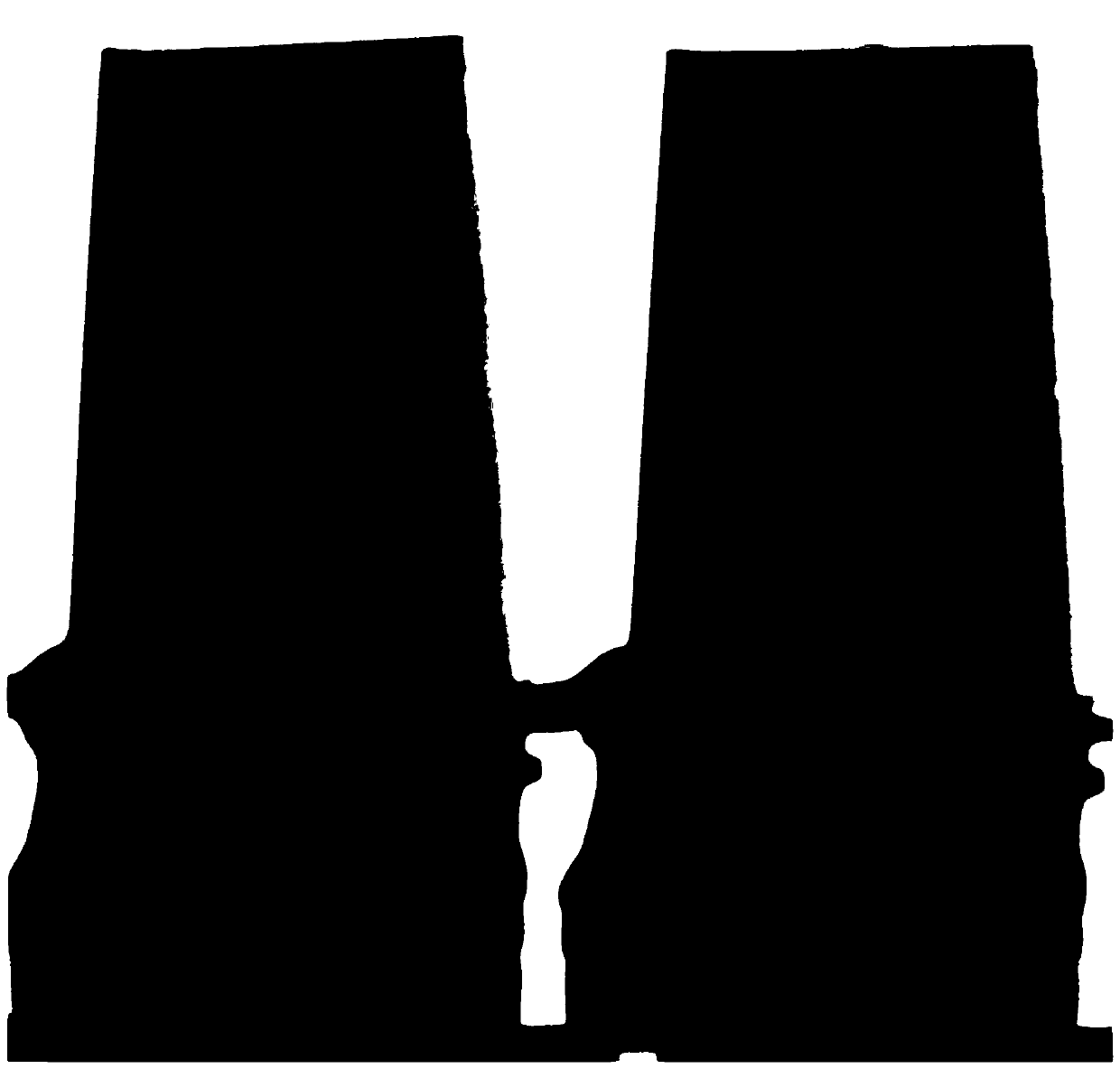

Hollow blade intracavitary residue detection method

InactiveCN110426255AWide range of market applicationsLow costPreparing sample for investigationMaterial analysis by transmitting radiationIron powderGadolinium

The invention belongs to the technical field of nondestructive detection, and discloses a hollow blade intracavitary residue detection method which is applied in neutron radiography, and includes thefollowing main steps: (1) preparing 10%-20% of a gadolinium nitrate aqueous solution; (2) placing a to-be-detected hollow blade into the gadolinium nitrate aqueous solution, soaking the to-be-detectedhollow blade at a vacuum degree of 0.07-0.09 atm for 6-8 hours; (3) continuously washing the to-be-detected hollow blade in a 24-64KHZ ultrasonic tank for 5-15 minutes; and (4) drying the be-detectedhollow blade at 80-100 degrees by baking. The to-be-detected hollow blade processed by the method is subjected to neutron radiography, and intracavitary residues of the hollow blade, including a residual core, residual iron powder produced after powder filling detection, and impurities sucked by the blade after long working hours, can be removed effectively. The method is simple in process, low in cost and accurate in detection results, and avoids erroneous judgement and missed judgment caused by other detection methods.

Owner:GUIYANG AVIC POWER PRECISION CASTING

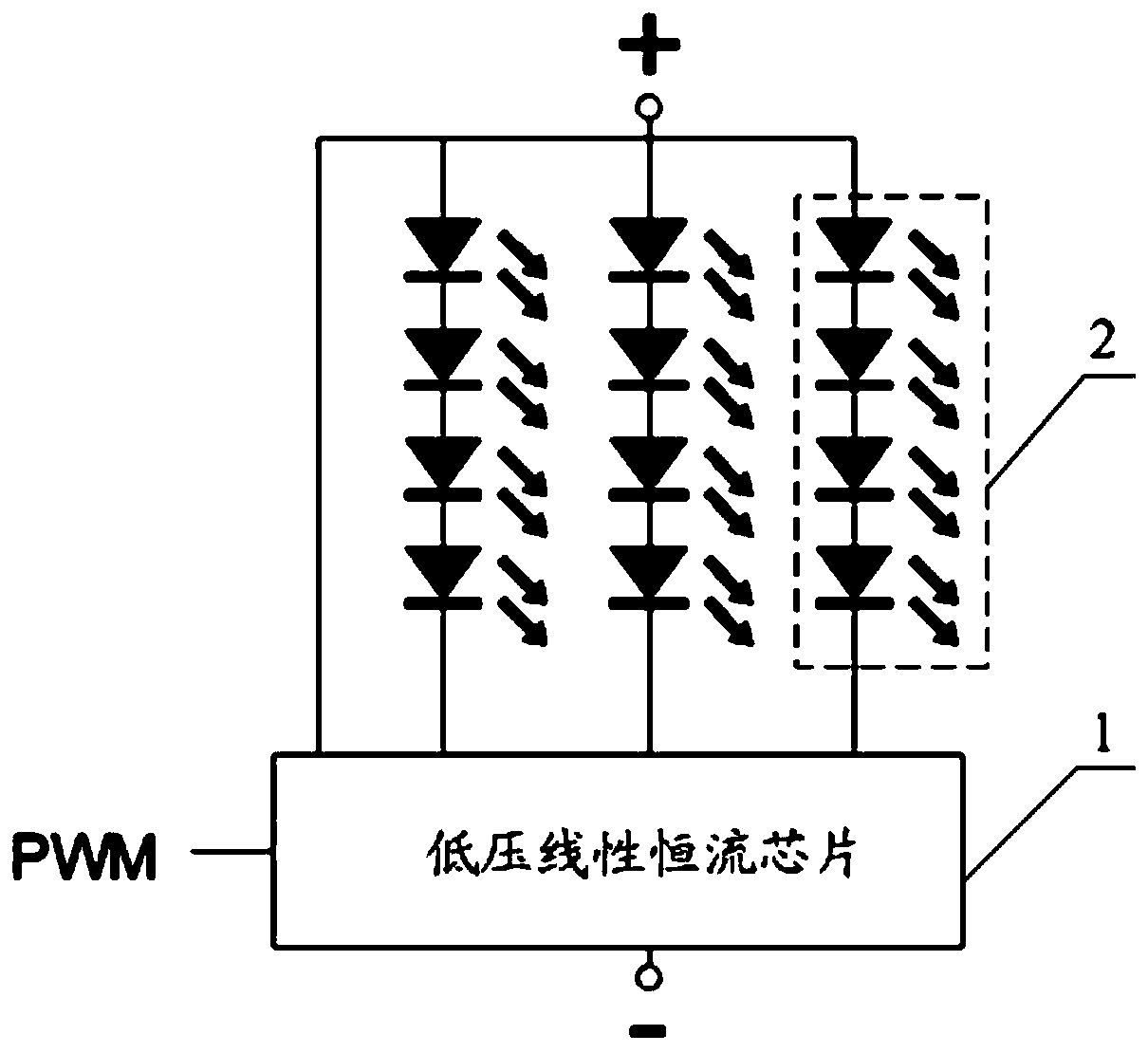

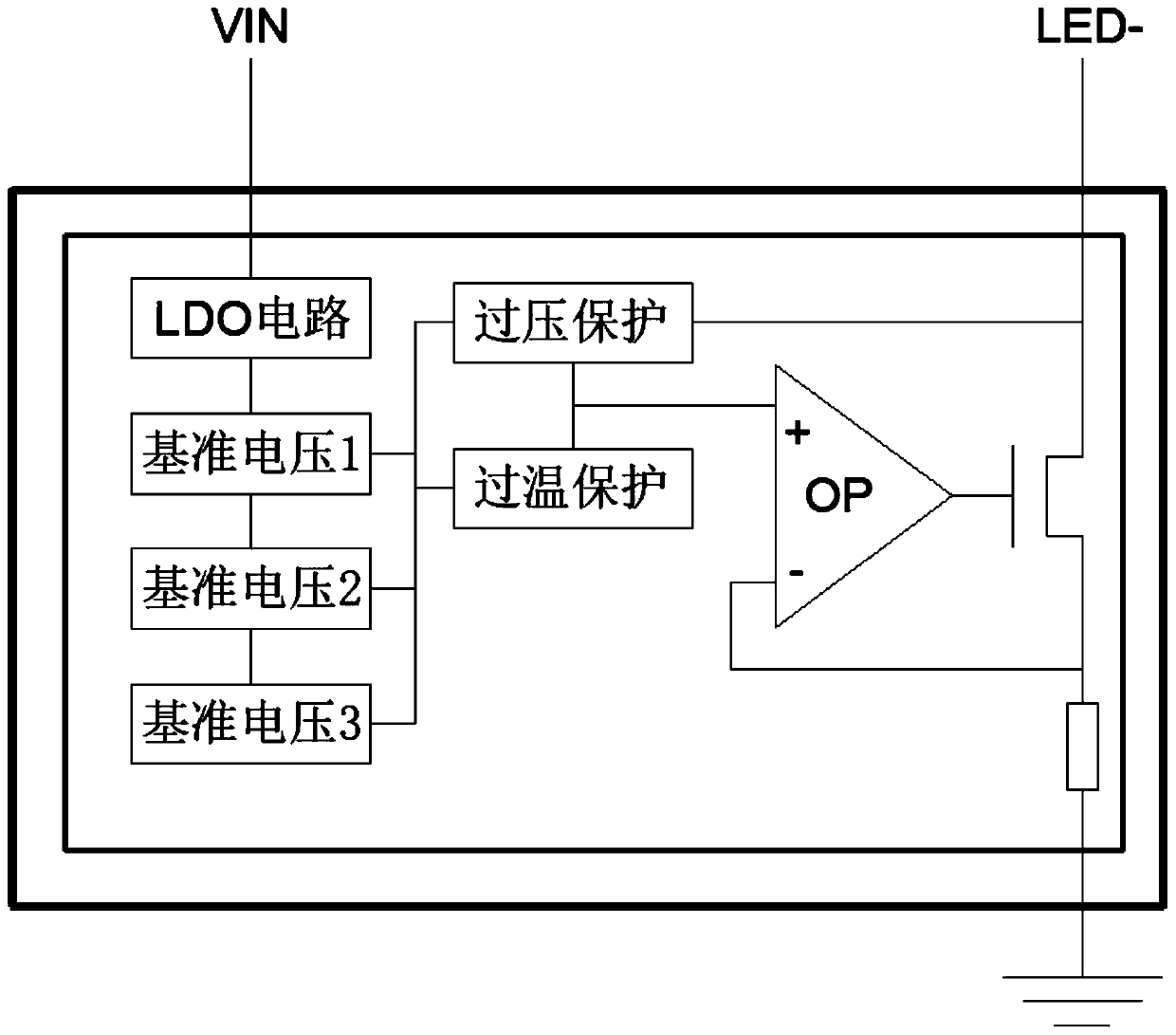

Constant-voltage driven COB light source

PendingCN110671616AConducive to concentrated useReduce installationElectrical apparatusElectric circuit arrangementsEngineeringMaterials science

The invention discloses a constant-voltage driven COB light source. The constant-voltage driven COB light source comprises a COB substrate and at least one group of light-emitting modules packaged onthe COB substrate, wherein each light-emitting module comprises an LED module and a low-voltage linear constant-current chip which are in one-to-one correspondence; each LED module comprises at leastone LED chip; the LED chips and the low-voltage linear constant-current chips are integrally packaged on the COB substrate in a die manner; the positive electrode of each LED module is connected withan external power supply; the external power supply is used for providing a 12-42V low-voltage direct-current power supply for the LED chips; the negative electrode of each LED module is connected inseries with the corresponding low-voltage linear constant-current chip; and the low-voltage linear constant-current chips are used for converting the low-voltage direct-current power supply output bythe external power supply into a constant-current power supply to drive the LED chips to work. By adopting the light source, the constant-voltage power supply output by the external power supply can be converted into the constant-current power supply, and the light-emitting modules are driven in a low-voltage linear driving mode, so that centralized use of a lamp is better facilitated.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

A kind of low-energy curing ultraviolet light curing coating and preparation method thereof

InactiveCN105567063BHigh solid contentLow viscosityEpoxy resin coatingsPolyester coatingsPolyesterEpoxy

Owner:HUNAN JINHAI SCI & TECH

Strength-toughness waterproof coating applied in indoor decoration and manufacturing method thereof

InactiveCN109207027AWide variety of sourcesManufacturing process detailsEpoxy resin coatingsChitinKetone

The invention discloses a strength-toughness waterproof coating applied in indoor decoration and a manufacturing method thereof. The waterproof coating comprises two parts, one part is a viscous suspension obtained from heating concentration of a suspension composed of acidified modified methacryloxy light curing resin, chitin micro-powder, lignin decomposed polysaccharide, trace useless organic matters and minerals and water, wherein the acidified modified methacryloxy light curing resin is obtained from lobster shells, methacryloxy light curing resin and sawdust under the combined action oflysase, ligninase and dilute hydrochloric acid; the other part is a hydroxylated bisphenol A epoxy acrylate and hydroxylated 2-hydroxyl-1,2-diphenyl ethyl ketone aqueous solution obtained by dissolving bisphenol A epoxy acrylate and 2-hydroxy-1,2-diphenyl acetone in absolute ethyl alcohol, then undergoing a reaction with sodium hydroxide and then carrying out heating evaporation to remove ethyl alcohol. The strong-tough waterproof coating has the advantages of wide source, detailed and easily realized manufacturing process, quick effect, lasting effect, green and environmental protection, no pollution, high strength, good toughness and self-hydrophobicity.

Owner:山东天汇防水股份有限公司

Recycle technology of plastic lunchboxes

InactiveCN104559280AReduce pollutionWide range of market applicationsPlastic recyclingAmmonium sulfatePotassium persulfate

The invention discloses a recycle technology of plastic lunchboxes and belongs to the field of plastic. The recycle technology comprises the following steps: (1) collection and leaching; (2) crushing; (3) removal of impurities; (4) cracking: cleaned fine granules are put into a reaction pot and undergo hydrocracking at 800 DEG C in presence of an initiator and under the stirring condition for 50 min so as to obtain 80% of a micromolecular liquid, wherein the initiator is a mixture of ammonium persulfate and potassium persulphate; (5) joint recombination; (6) vacuum cleaning; and (7) drying and shaping. After a series of treatments of plastic lunchboxes, wastes are reutilized, the environment is purified, and pollution is reduced. The technology provided by the invention has a wide market application range.

Owner:丹阳恒安化学科技研究所有限公司

A kind of led-uv ultraviolet light curing wood nano coating and preparation method thereof

ActiveCN107513344BHigh solid contentLow viscosityPolyurea/polyurethane coatingsPolyester coatingsPolyesterMeth-

The invention discloses an LED-UV ultraviolet light curing wood nano-coating and a preparation method thereof, which is composed of the following raw materials in weight percent: 25-30% of polyurethane acrylate crosslinked with pentaerythritol triacrylate and polyisocyanate, Fatty acid modified polyester acrylate resin 10‑15%, ethoxylated modified trimethylolpropane triacrylate 20‑25%, dipropylene glycol diacrylate 10‑20%, wetting and dispersing agent 0.2-1.0%, nano-barium sulfate powder is 10-15%, UV UV curable monomer dispersion of nano wear-resistant particles is 2-5%, hydrogen abstraction type photoinitiator is 2-4%, active amine is 1‑3%, cracking photoinitiator is 2‑4%, leveling agent is 0.2‑0.5%, defoamer is 0.2‑0.5%, and polymerization inhibitor is 0.1‑0.3%. The UV-curable coating of the present invention only needs 50-60mj / cm2 of LED-UV ultraviolet light energy to reach the required curing degree, which greatly reduces the energy required for coating curing, improves construction efficiency, and reduces wood surface coating. The possibility of quality defects in fabric construction.

Owner:SHANDONG UNIV +1

Circular clean production method for preparing yellow phosphorus, potassium salt, alumina, molecular sieve, slag cement and building profiles from potassium-containing phosphate rock

ActiveCN105197902BReduce manufacturing costTake advantage ofSolid waste managementChemical industryFiltrationMolten slag

The invention relates to a recycling and clean production method for preparing yellow phosphorus, sylvite, aluminum oxide, molecular sieves, slag cement and architectural profiles through potassium-bearing phosphorite. The method utilizes two routes, for the first route, high quality yellow phosphorus is produced by the potassium-bearing phosphorite and coke nuts through an electrothermal method, water quenching is conducted on yellow phosphorus slags, KAlO2 is dissolved out, filtration is conducted, CO2 is introduced, Al(OH)3 is settled, first filtrate is obtained, and the Al(OH)3 is converted through temperature control to obtain Al2O3. For the second route, orthoclase power and Na2CO3 are evenly mixed, roasting is conducted through yellow phosphorus tail gas, water leaching is conducted through water, the CO2 is introduced to settle out silicon-aluminum colloid, and second filtrate is obtained. Crystallization and drying are conducted on the first filtrate and the second filtrate, and K2CO3 and Na2CO3 are obtained. The Na2CO3 returns to the second route to be recycled. The content of K2O, Na2O, SiO2 and Al2O3 is adjusted for partial silicon-aluminum colloid which is not subjected to sedimentation and the filtrate, hydrothermal crystallization reaction is conducted, and the molecular sieves are obtained; settled silicon-aluminum colloid is mixed with the yellow phosphorus slags to prepare the slag cement and / or the architectural profiles.

Owner:黄钰雪

Graphene-based polyester fiber capable of absorbing moisture, releasing sweat and rapidly dissipating heat and preparation method thereof

PendingCN113622047AWide range of market applicationsExtend the mixing timeMonocomponent polyesters artificial filamentArtifical filament manufacturePhosphoric acidPolyester

The invention discloses a preparation method of graphene-based polyester fiber capable of absorbing moisture, releasing sweat and rapidly dissipating heat. The method comprises the following steps of firstly, intercalating natural flake graphite by using a mixed acid of sulfuric acid and phosphoric acid with the mass fraction of 50-98%, performing stripping by using an oxidation method to obtain graphene oxide, and preparing the graphene oxide and PET into master batches; and then preparing the master batches and polyester particles into the polyester fiber by adopting a melt spinning method, wherein the polyester particles are PET or PET mixed PBT, and the mass ratio of the polyester particles to the master batches is (75-85): 20. The graphene is deeply oxidized to obtain a high O / C ratio, a complete single crystal structure is kept, and the graphene is an excellent heat dissipation material, so that heat can be quickly removed. By combining the characteristics of a large number of hydrophilic groups, a moisture absorption condition is formed, so that the polyester fiber capable of absorbing moisture, releasing sweat and rapidly dissipating heat is prepared; the polyester fiber can be prepared into a fabric capable of absorbing moisture, releasing sweat and rapidly dissipating heat on the basis; and the market application range is wide.

Owner:GAOBEIDIAN LONGTAI FENGBO GRAPHENE PROCESSING CO LTD

Anti-sticky packing bottle

InactiveCN102363456AConvenient for daily lifeWide range of market applicationsDispensing apparatusBottlesHand washingEngineering

The invention discloses an anti-sticky packing bottle. The anti-sticky packing bottle is provided with a bottle body for accommodating liquid and a cover positioned at the top and used for covering the bottle opening of the bottle body. The anti-sticky packing bottle is characterized in that: the bottom of the anti-sticky packing bottle is provided with a second bottle opening, and the bottle body is provided with a push switch for squeezing the liquid out of the second bottle opening. According to the anti-sticky packing bottle, the liquid can be randomly squeezed to any position and can be completely squeezed out; and the anti-sticky packing bottle can be operated by a single hand, brings convenience to daily life, can be used for reforming hand washing solution, cleanser essence, toilet shampoo and sesame oil bottles and replacing the conventional package, can be directly produced into a kitchen and bathroom bottle and separately sold, and is wide in market application and strong in practicability.

Owner:NANTONG XINYING DESIGN SERVICE

Energy-saving method for preparing yellow phosphorus, potassium salt, sodium carbonate and alumina from potassium-containing phosphate rock

ActiveCN105197901BReduce manufacturing costTake advantage ofChemical industryAlkali metal carbonatesFiltrationBlast furnace smelting

Owner:黄钰雪

A kind of water-soluble alginate antibacterial fiber and preparation method thereof

ActiveCN109252246BIncrease manufacturing costNot easy to fall offBiochemical fibre treatmentConjugated cellulose/protein artificial filamentsSodium bicarbonateSoluble fiber

The invention relates to a water-soluble alginate antibacterial fiber and a preparation method thereof. The preparation method comprises: weighing a water-soluble polymer and dissolving the water-soluble polymer in distilled water, and then adding nano-silver-loaded zirconium phosphate and / or nano-zinc oxide, and carrying out uniform ultrasonic dispersion; weighing sodium alginate and dissolving sodium alginate in the mixed liquor, stirring and heating to obtain a spinning solution; defoaming the spinning solution, metering and ejecting from a spinneret plate into a coagulating bath by a metering pump; preparing a sodium ethylene diamine tetracetate solution; squeezing fiber to remove water, and immersing in the sodium ethylene diamine tetracetate aqueous solution; adding sodium carbonateand sodium bicarbonate and fully mixing, and continuously immersing; preparing a chitosan solution; squeezing fiber to remove water, and immersing in the chitosan solution; squeezing fiber to remove water, drying, and winding. The invention has the advantages as follows: the product is soluble in water; active ingredients are easy to absorb, and the antibacterial effect is good; the disadvantage that traditional water-soluble fiber has low strength and is easy to fracture is dissolved; and the product has a wide application prospect.

Owner:青岛海赛尔新材料科技有限公司

Energy-saving method for co-production of potassium salt, sodium carbonate and alumina from yellow phosphorus

ActiveCN105217589BReduce manufacturing costTake advantage ofChemical industryAlkali metal carbonatesSlagFiltration

Owner:黄钰雪

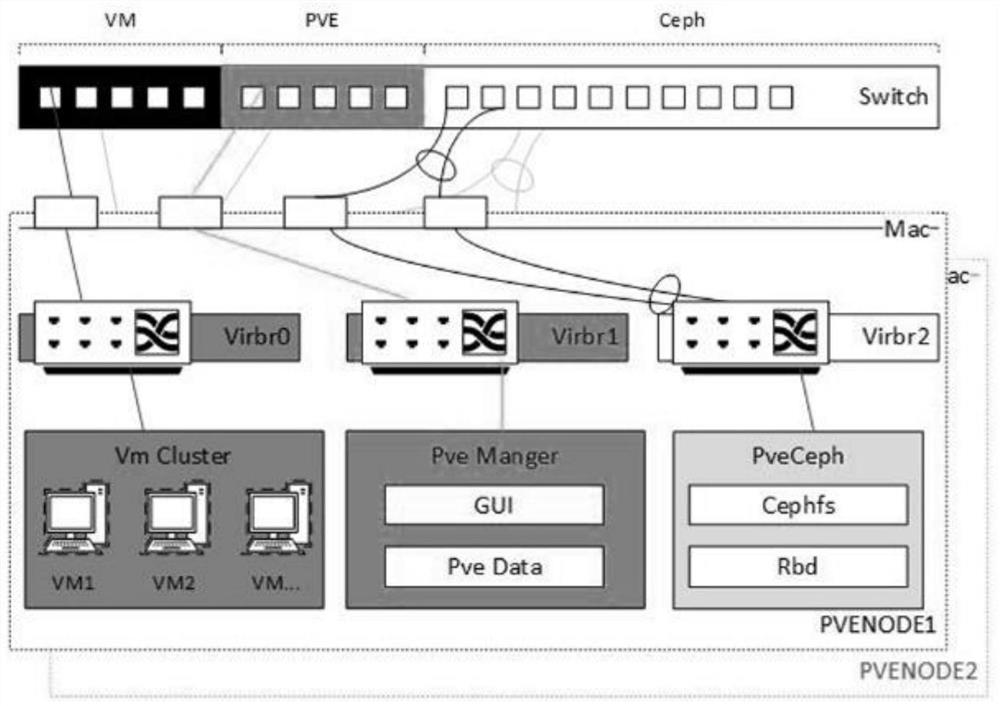

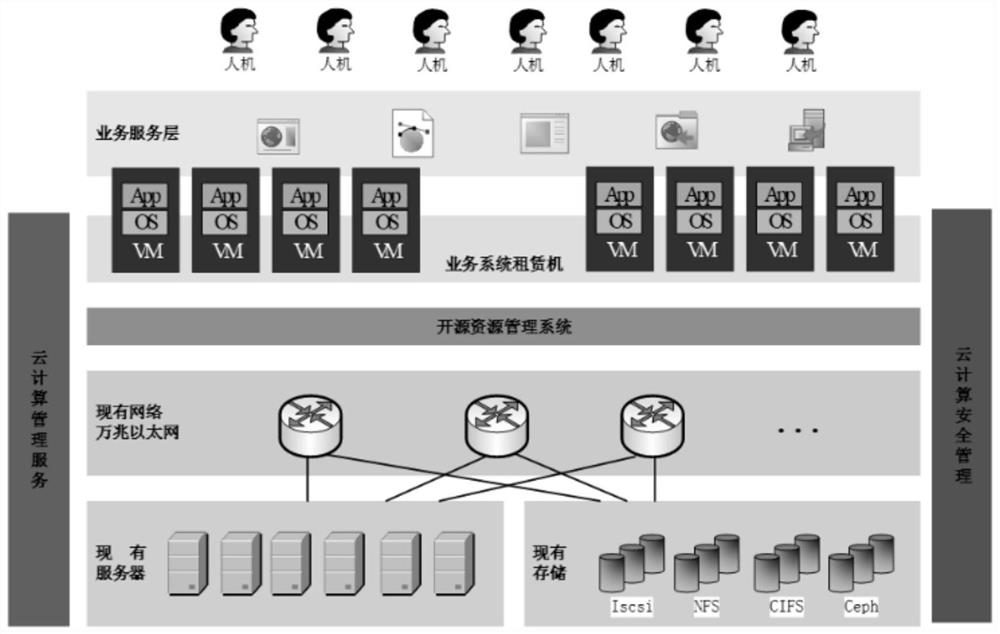

Cloud data system constructed based on PVE virtual technology and integration method

PendingCN113961310AReduce in quantityImprove operational efficiencyResource allocationSoftware simulation/interpretation/emulationResource poolVirtual technology

The invention discloses a cloud data system constructed based on a PVE virtual technology and an integration method. A cloud data platform comprises a resource pool, resource management, service management and cloud data security management. The resource pool comprises computing resources, storage resources and network resources; the computing resource is composed of a server, undertakes a data computing function and serves as a node machine of cloud data; the storage resources adopt a file system interface and a block storage interface, and a unified distributed storage system Ceph is adopted for the importance of service system data; the network resources utilize the original exchange board to ensure the safety and reliability of a data service link, and network card binding and link aggregation technologies are used; according to the invention, the original architecture is divided into different layers and functions again, so that the operation efficiency of the system is improved, and the operation cost is reduced; according to the invention, a green concept is advocated, new network equipment is not purchased, and an original switching board is utilized; according to the invention, zero-cost construction of the cloud data platform is really realized.

Owner:安慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com