Preparation of ductility cement product by utilizing lead zinc tail mineral powder

A technology of cement products and tailings powder, which is applied in the field of environment and building materials, and achieves the effects of simple operation process, improved brittleness and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The weight ratio of the raw material formula: cement clinker 60wt%, lead-zinc tailings 30wt%, gypsum 10wt%, weigh the three raw materials according to the formula, and pour them into the same ball mill tank for ball milling for 2 hours to obtain a well-mixed mixture And pass through a 300 mesh sieve, add the screened mixture to deionized water with 10% of the total mass of raw materials, stir for 30 minutes to obtain a plastic mixture, put the obtained plastic mixture into a mold, and press it into segments, then at temperature It is cured at 20~25°C to obtain ductile cement products.

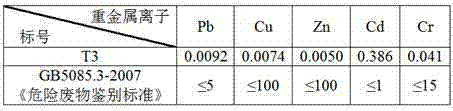

[0028] Test its compressive strength at different ages according to GB1 / 7671-1999 "Cement Mortar Strength Test Method (ISO)", and test according to GB / T1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" The results of the setting time of the ductile cement products are shown in Table 1-1. According to the solid waste leaching toxicity test met...

Embodiment 2

[0034] The weight ratio of the raw material formula: cement clinker 59wt%, lead-zinc tailings 31wt%, gypsum 10wt%, weigh the three raw materials according to the formula, and pour them into the same ball mill tank for ball milling for 2 hours to obtain a well-mixed mixture And pass through a 300 mesh sieve, add the screened mixture to deionized water with 10% of the total mass of raw materials, stir for 30 minutes to obtain a plastic mixture, put the obtained plastic mixture into a mold, and press it into segments, then at temperature It is cured at 20~25°C to obtain ductile cement products.

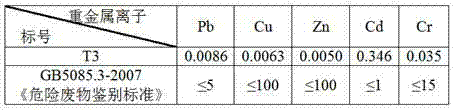

[0035]Test its compressive strength at different ages according to GB1 / 7671-1999 "Cement Mortar Strength Test Method (ISO)", and test according to GB / T1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" The results of the setting time of the ductile cement products are shown in Table 2-1. According to the solid waste leaching toxicity test meth...

Embodiment 3

[0041] The weight ratio of the raw material formula: cement clinker 58wt%, lead-zinc tailings 32wt%, gypsum 10wt%, weigh the three raw materials according to the formula, and pour them into the same ball mill tank for ball milling for 2 hours to obtain a well-mixed mixture And pass through a 300 mesh sieve, add the screened mixture to deionized water with 10% of the total mass of raw materials, stir for 30 minutes to obtain a plastic mixture, put the obtained plastic mixture into a mold and press into segments, and then It is cured at 20~25°C to obtain ductile cement products.

[0042] Test its compressive strength at different ages according to GB1 / 7671-1999 "Cement Mortar Strength Test Method (ISO)", and test according to GB / T1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" The results of the setting time of the ductile cement products are shown in Table 3-1. According to the solid waste leaching toxicity test method (HJ / T 299-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com