Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about How to "Plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

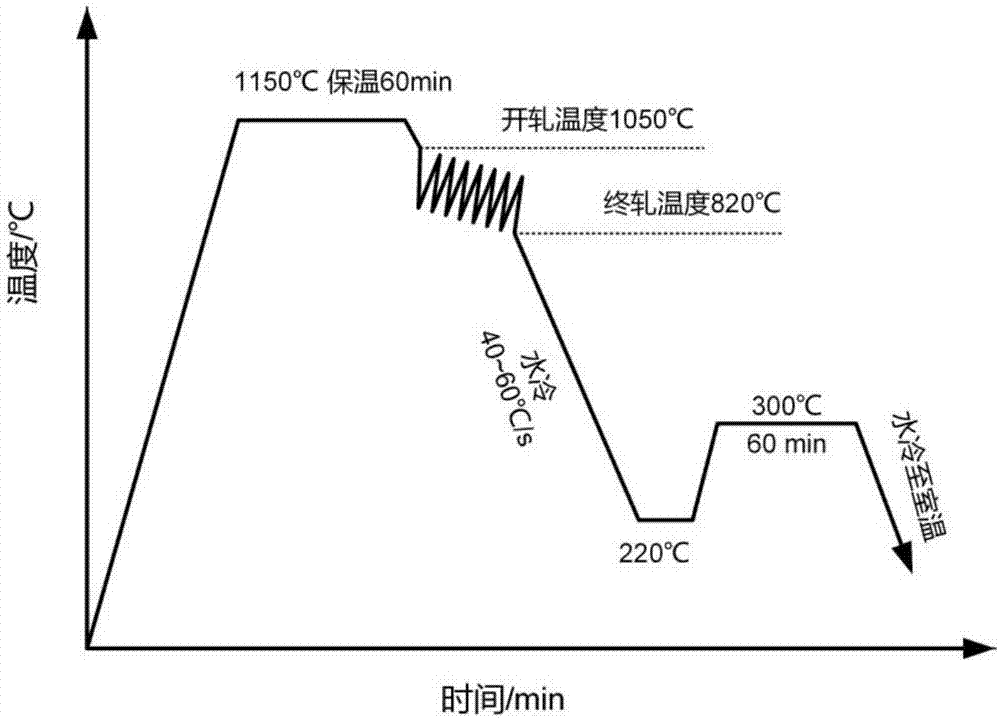

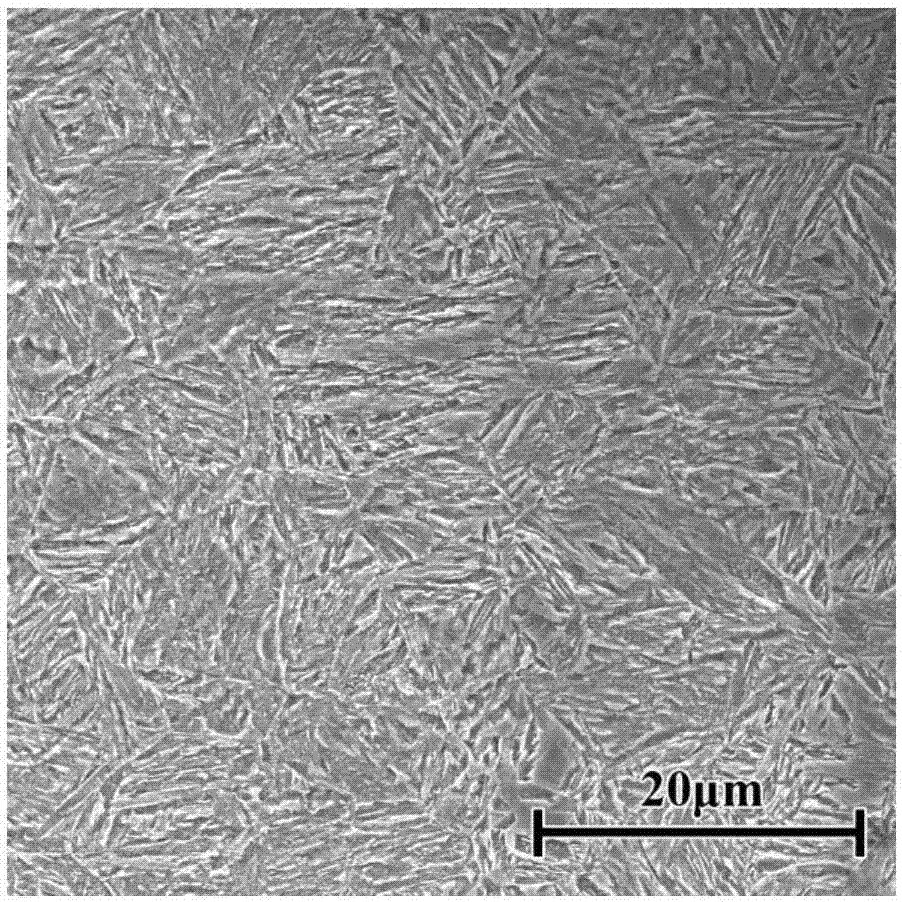

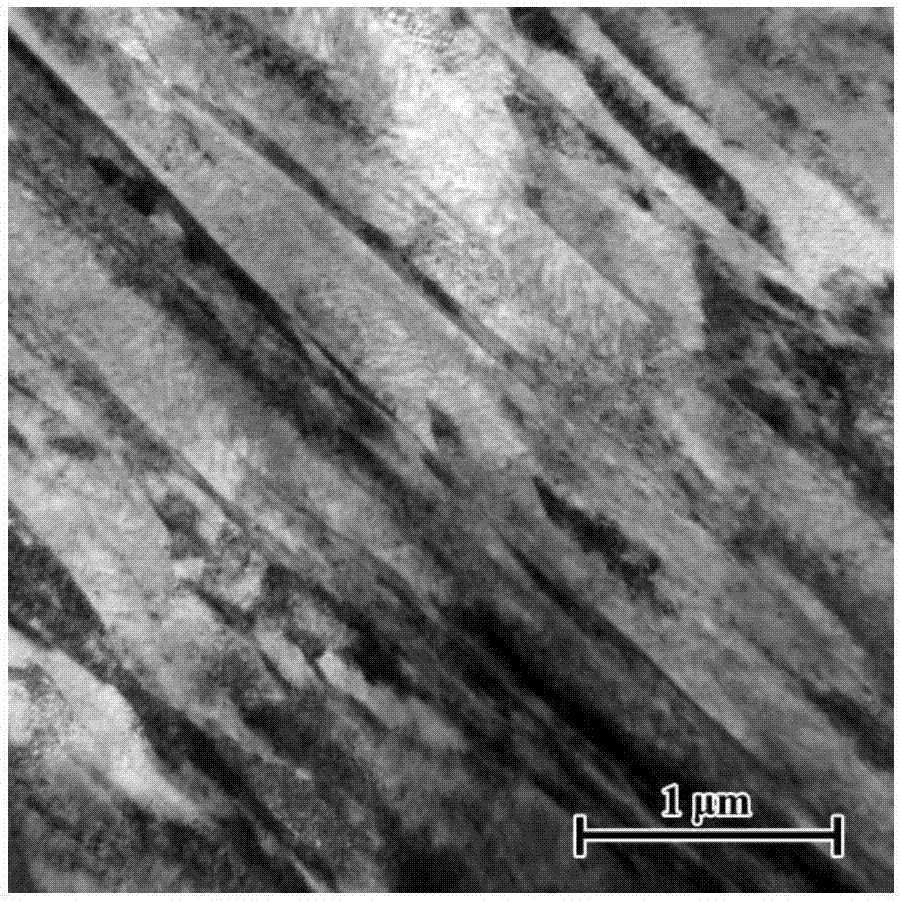

Low-density and high-toughness automobile-used steel board and preparation process

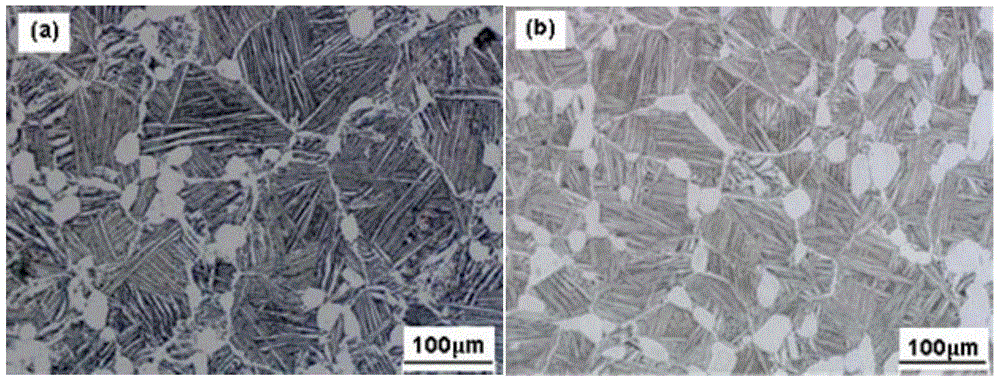

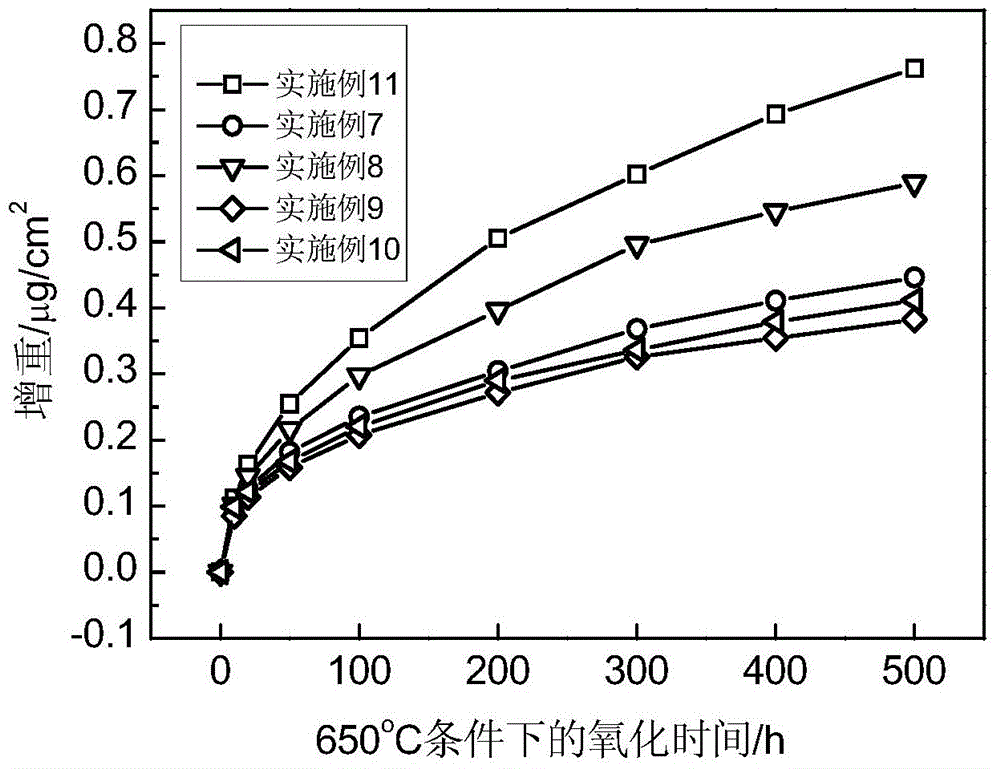

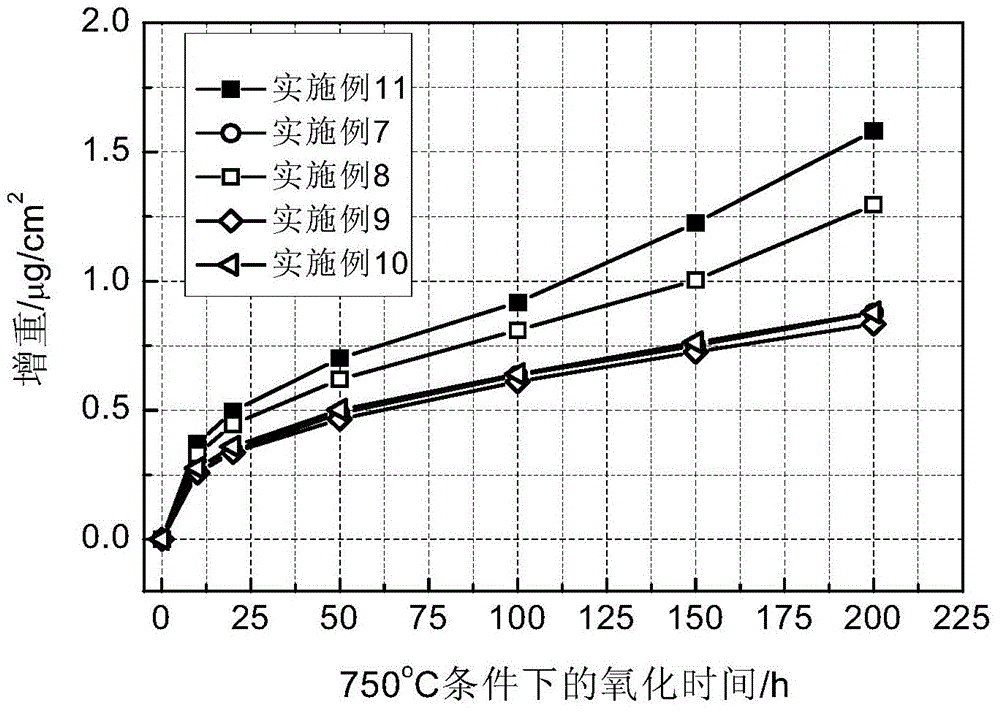

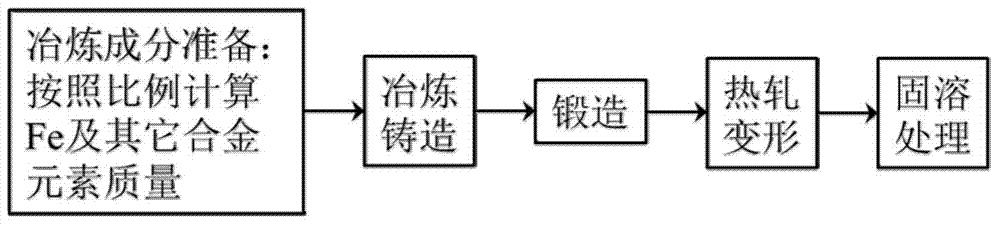

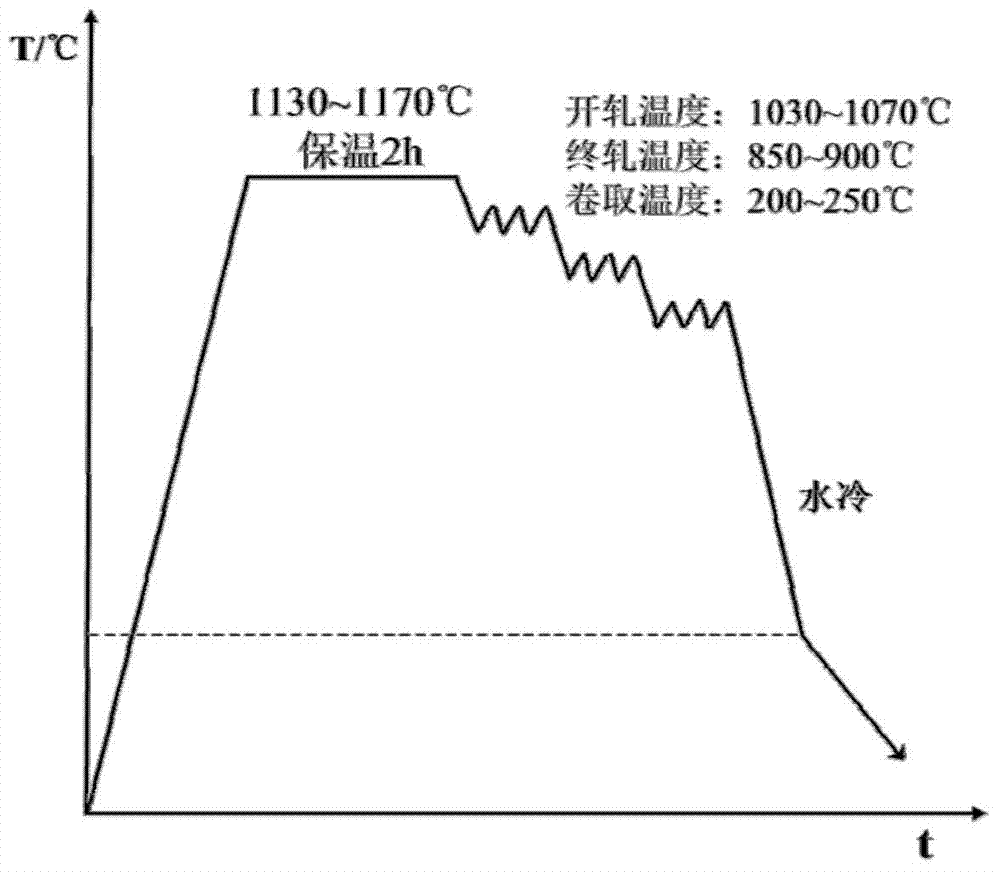

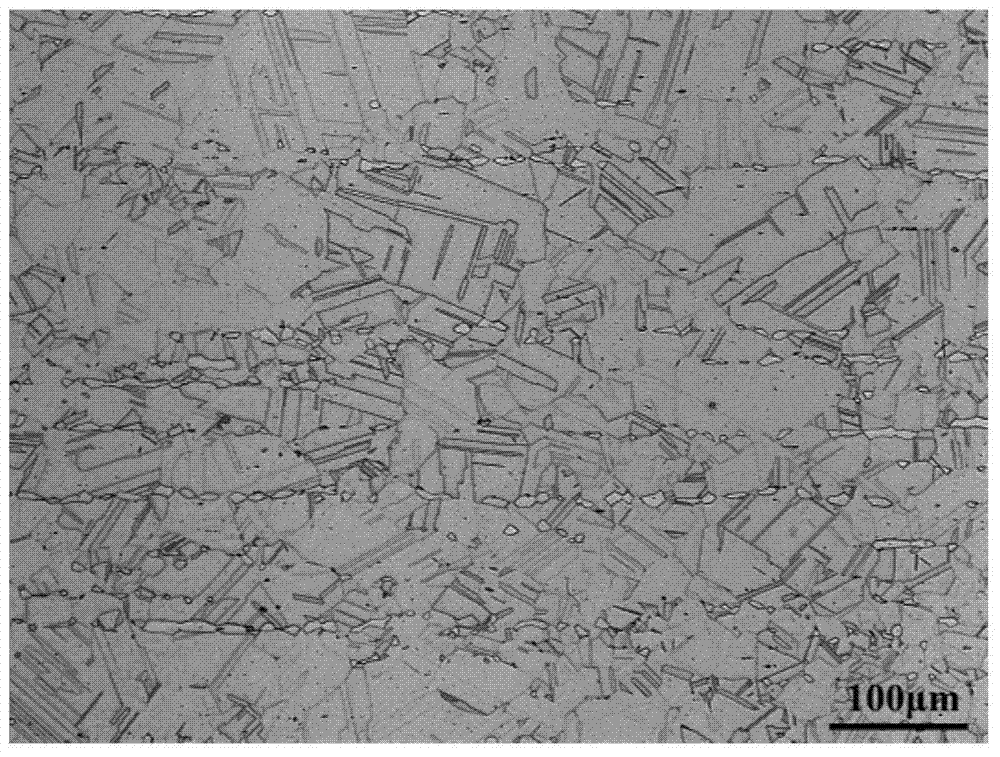

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

3D printed digital artificial bone and preparation method thereof

ActiveCN105031737AFast preparationStable uniform sizeAdditive manufacturing apparatusProsthesisPorosityPolyester

The invention discloses a 3D printed digital artificial bone. The artificial bone consists of a cortical bone, a cancellous bone and a marrow cavity, wherein the cortical bone is composed of poly-L-lactic acid or polyester-ester-ketone; the cancellous bone is formed by mixing poly-L-lactic acid and hydroxyapatite; the molecular weight of the poly-L-lactic acid of which the cortical bone is composed higher than that of which the cancellous bone composed; the cortical bone and the cancellous bone are simultaneously prepared by a 3D printing technology. The invention also discloses a 3D printing method for the digital artificial bone. According to the artificial bone disclosed by the invention, in micrometer and millimeter scales, the porosity of the cortical bone is 10 percent; the porosity of the cancellous bone is 60-80 percent, and the pore size of the cancellous bone is 120-220 micrometers. The 3D printed digital artificial bone has the porosity, the pore size and the mechanical property as those of a bone structure of human beings.

Owner:上海浦卫生物科技有限公司

Processing process of automobile engine crank shaft

The invention provides a processing process of an automobile engine crank shaft. The process comprises the following processing steps of (1) blank forging; (2) coarse tuning: coarse turning of a main shaft neck and a connecting rod neck is carried out; (3) coarse drilling: coarse drilling of a main oil hole is carried out; (4) annealing heat treatment; (5) semi-finish turning: semi-finish turning is carried out on the main shaft neck and the connecting rod neck; (6) tempering; (7) fine turning: fine turning is carried out on the main shaft neck and the connecting neck; (8) coarse and fine grinding: coarse and fine grinding is carried out on the main shaft neck and the connecting rod neck; (9) hole drilling: coarse drilling, expanding and reaming of balance block installing holes and inclined oil holes are carried out; (10) compounding reinforcing; (11) rolling processing: each processed hole is subjected to rolling pressing processing; (12): the main shaft neck and the connecting rod neck are subjected to polishing processing; (13) anti-rust processing; (14) inspection and packaging. The process solves three problems of low rigidity intensity, poor wear resistance and good lubrication performance in the existing automobile engine crank shaft production process, so that the finally produced crank shaft has the sufficient rigidity and intensity, good impact load bearing capability and good abrasion resistance and lubrication performance.

Owner:ANHUI JINQINGLONG MACHINERY

Mesothermal copper based solder without cadmium, and preparation method

ActiveCN1759974AShort processImprove product qualityWelding/cutting media/materialsSoldering mediaIntermediate frequencySoldering

A medium-temp non-Cd Cu-based soldering wire contains Cu (74.9-82.96 Wt%), Ni (1-5.5), Sn (10-12), P (6-7), Ce (0.02-0.3) and La (0.02-0.3). Its preparing process features that after the electrolytic Cu and Ni in the graphite crucible of MF induction furnace is heated to 600-800 deg.C, the covering agent is added. Its advantages are low smelting temp, narrow smelting zone, better wet spreading performance and certain plasticity.

Owner:浙江信和科技股份有限公司

Rubber-plastic blended high-flame-retardant heat-insulating heat-preserving material

ActiveCN104927216AImprove flame retardant performanceHigh tensile strengthFoaming agentThermal insulation

The invention discloses a rubber-plastic-blended high-flame-retardant thermal-insulation material. The material is composed of a rubber-plastic blended material, a stabilizer, a filler, a plasticiser, a foaming agent, an active agent, a vulcanizing agent, an antiaging agent and a flame retardant. The heat-preserving material provided by the invention has weatherability and aging resistance of rubber, strength and plasticity of plastic, excellent flame retardant property and capability of being used as a heat-preserving, heat-insulating and sound-insulating material and applied in the engineering fields of building, transportation vehicles, ships, aerospace, etc.

Owner:HEBEI SHENZHOU THERMAL INSULATION BUILDING MATERIAL GRP CO LTD

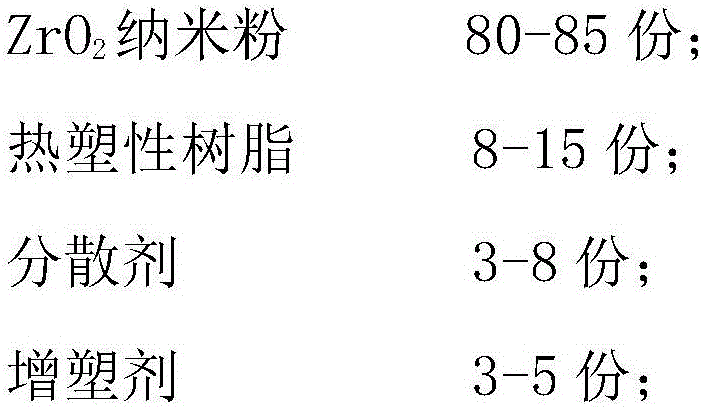

Cement-based compound material used for mobile phone shell and ceramic-based compound material mobile phone shell

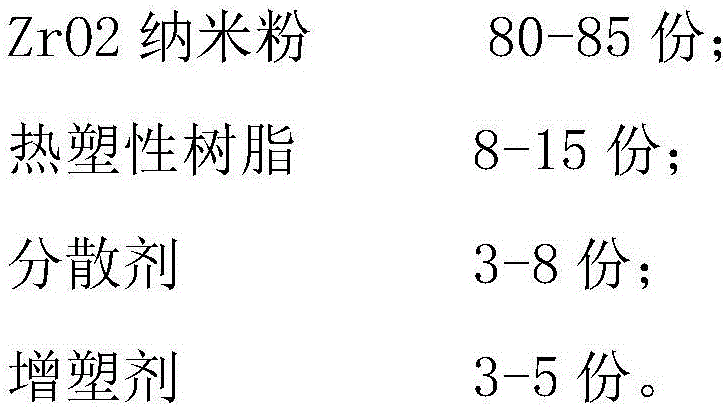

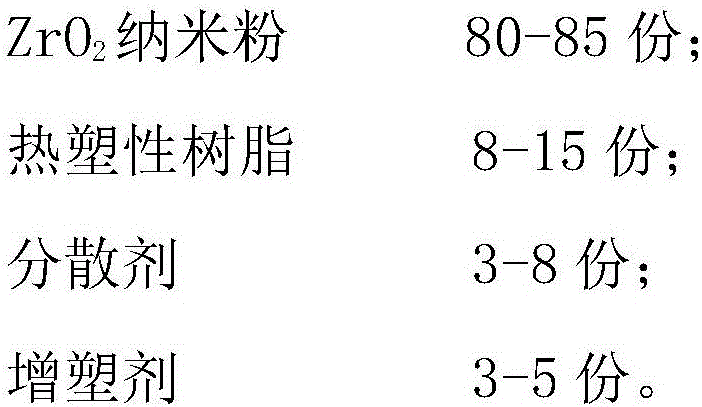

The invention provides a cement-based compound material used for a mobile phone shell and a ceramic-based compound material mobile phone shell and a preparation method thereof. The cement-based compound material used for the mobile phone shell is prepared from, by weight, 80-85 parts of ZrO2 nano powder, 8-15 parts of thermoplastic resin, 3-8 parts of a dispersing agent and 3-5 parts of a plasticizer. The cement-based compound material used for the mobile phone shell integrates noble texture of ceramics and toughness and plasticity of macromolecules, and can be machined. Leftover materials can be conveniently recycled, and the cement-based compound material is low in cost and suitable for large-scale industrial production.

Owner:SHENZHEN PENGHUI FUNCTIONAL MATERIAL CO LTD

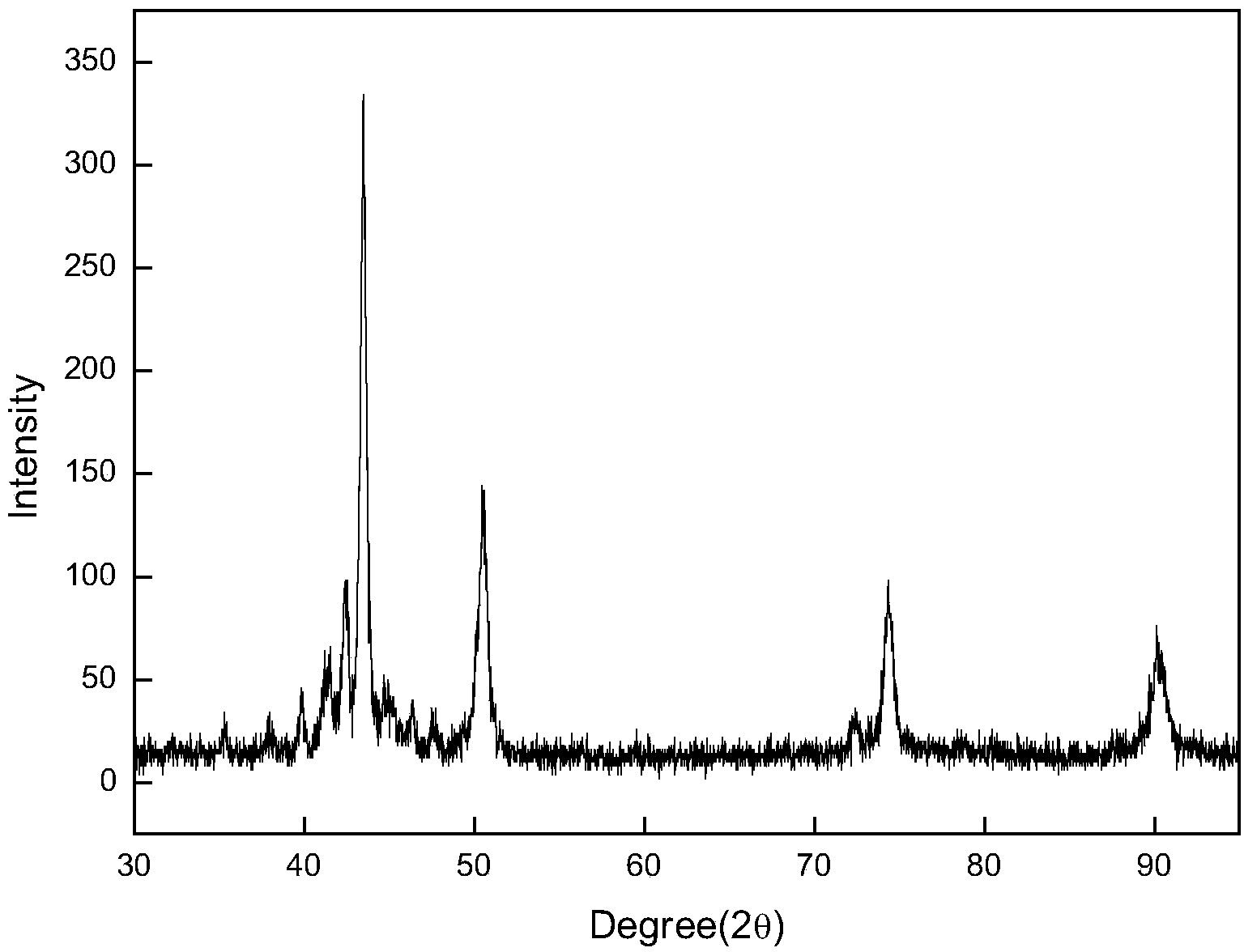

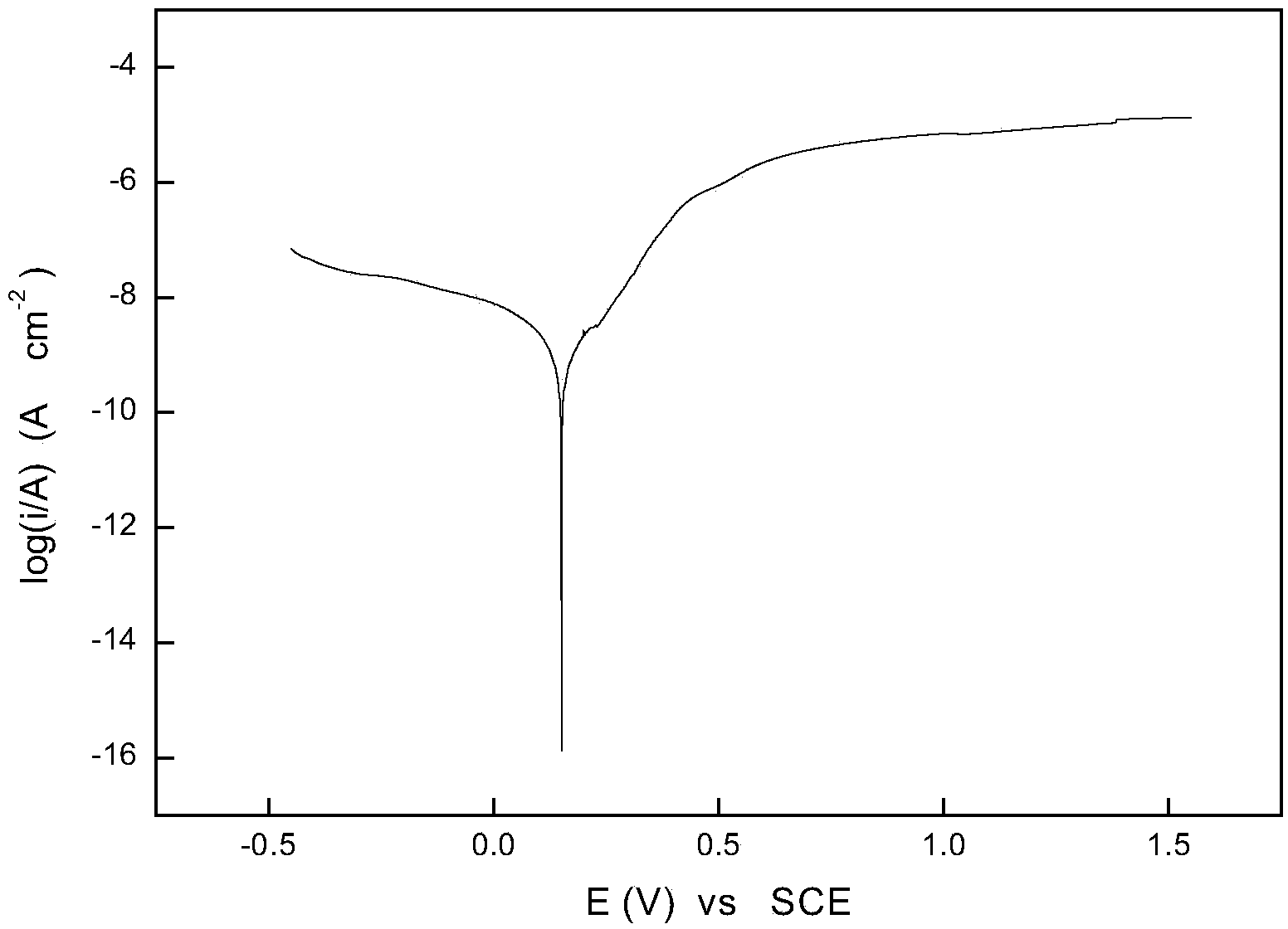

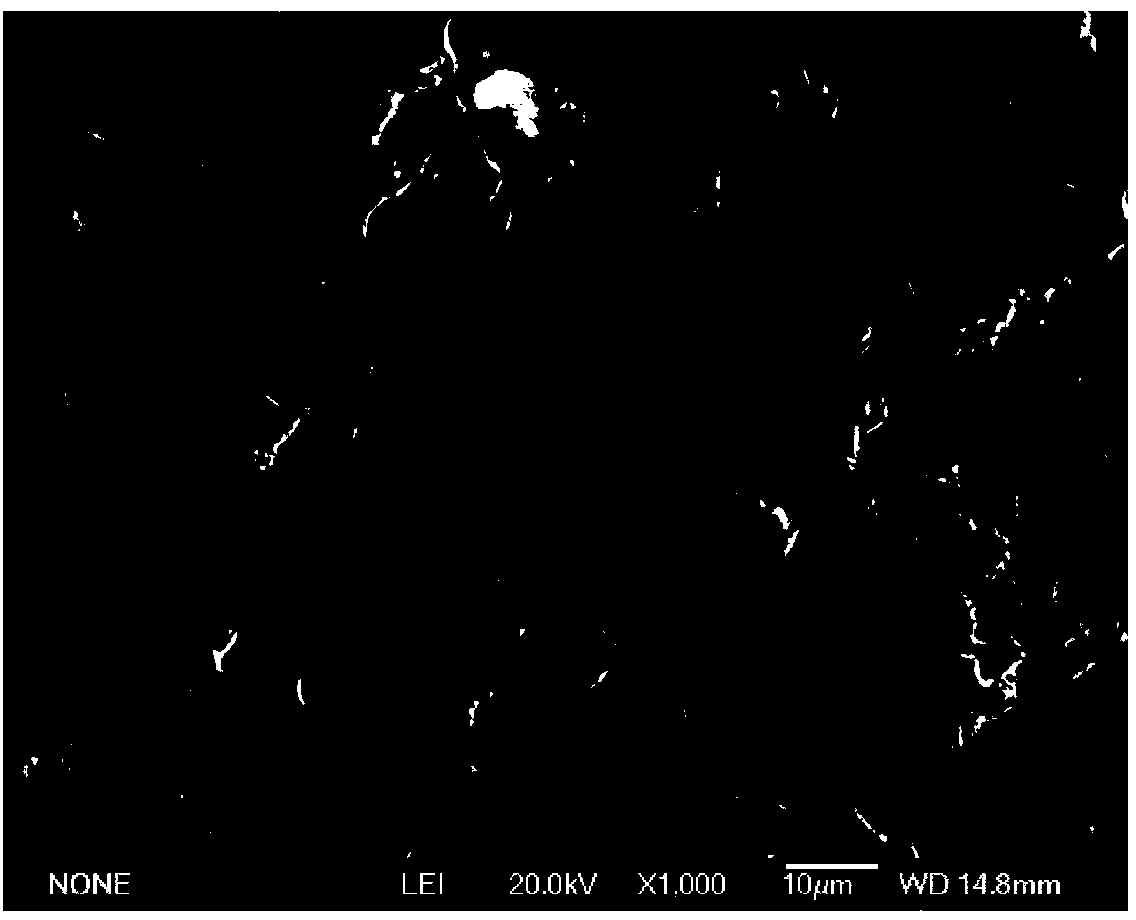

High-entropy alloy and preparation method thereof

InactiveCN104099509AGood resistance to electrochemical corrosionGood passivationCompression moldingHigh entropy alloys

The invention discloses high-entropy alloy. The high-entropy alloy is formed by aluminum, chromium, iron, nickel, copper and molybdenum and the mole ratio of the above is 1 to 1.1 to 1 to 1.05 to 1 to 1.05 to 1 to 1.05 to 1 to 1.05 to 1 to 1.05. The high quality as-cast high-entropy alloy is obtained by compression molding of powder material and vacuum sintering. The high-entropy alloy is good in hardness, high in compression strength, prominent in corrosion resistance and can satisfy some environment with specific requirements.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

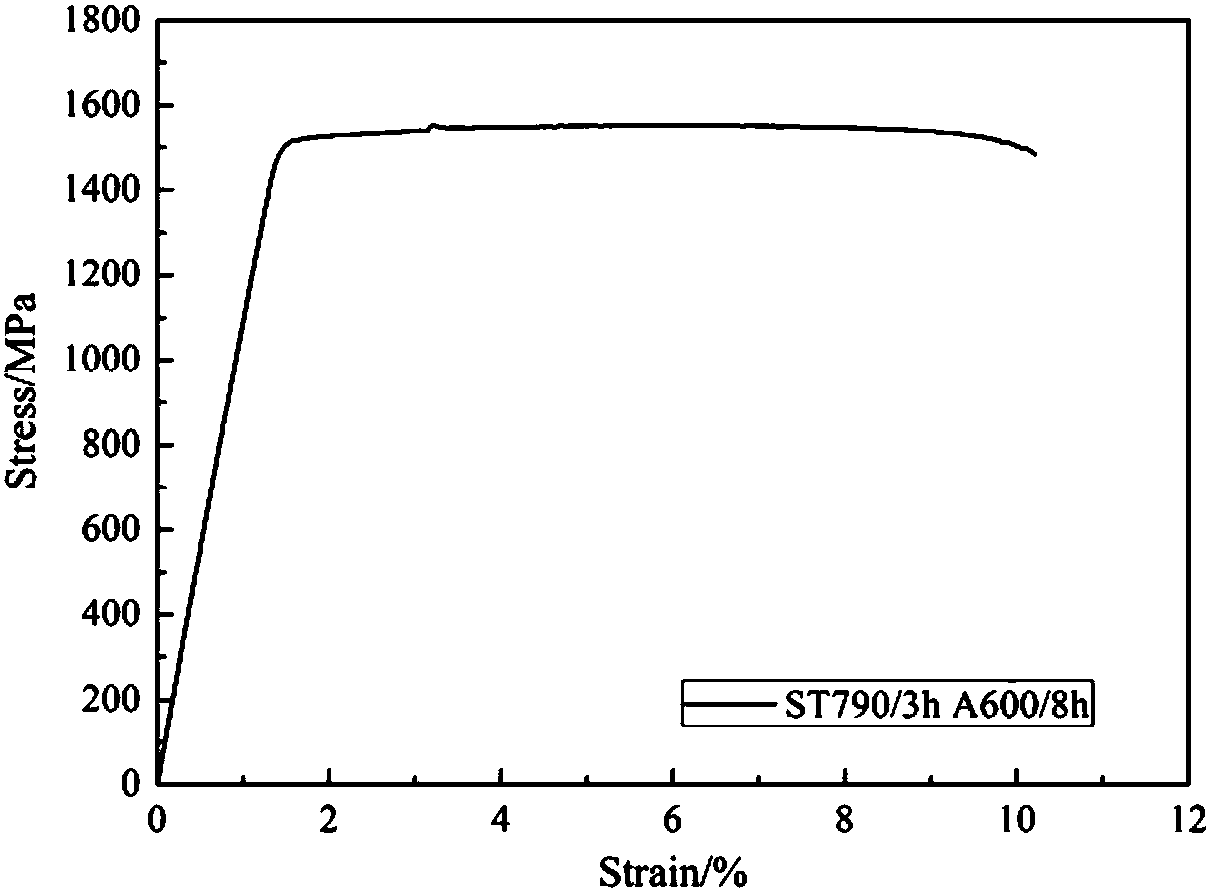

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and thermal treatment process thereof

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and a thermal treatment process thereof. The thermal treatment includes steps of performing solution treatment to Ti-Al-Zr-Mo-Cr-series beta titanium alloy and then performing aging treatment. The Ti-Al-Zr-Mo-Cr-series beta titanium alloy includes, by weight, 4.5-5.5% of Al, 3.5-4.5% of Zr, 9.5-10.5% of Mo, and 2.5-3.5% of Cr, the balanced being Ti. The alloy, after smelting, forging and toughening thermal treatment, has ultrahigh strength and plasticity. The alloy includes aluminum and also a certain amount of a neutral element, zirconium, so that alpha-phase is further reinforced; by adding the molybdenum at high mass percentage, a beta-matrix is reinforced; in addition, due to the low diffusion rate of molybdenum, temperaturesensitivity of the alloy in a two-phase zone during forging is reduced, thus enlarging processing window of the alloy.

Owner:XI AN JIAOTONG UNIV

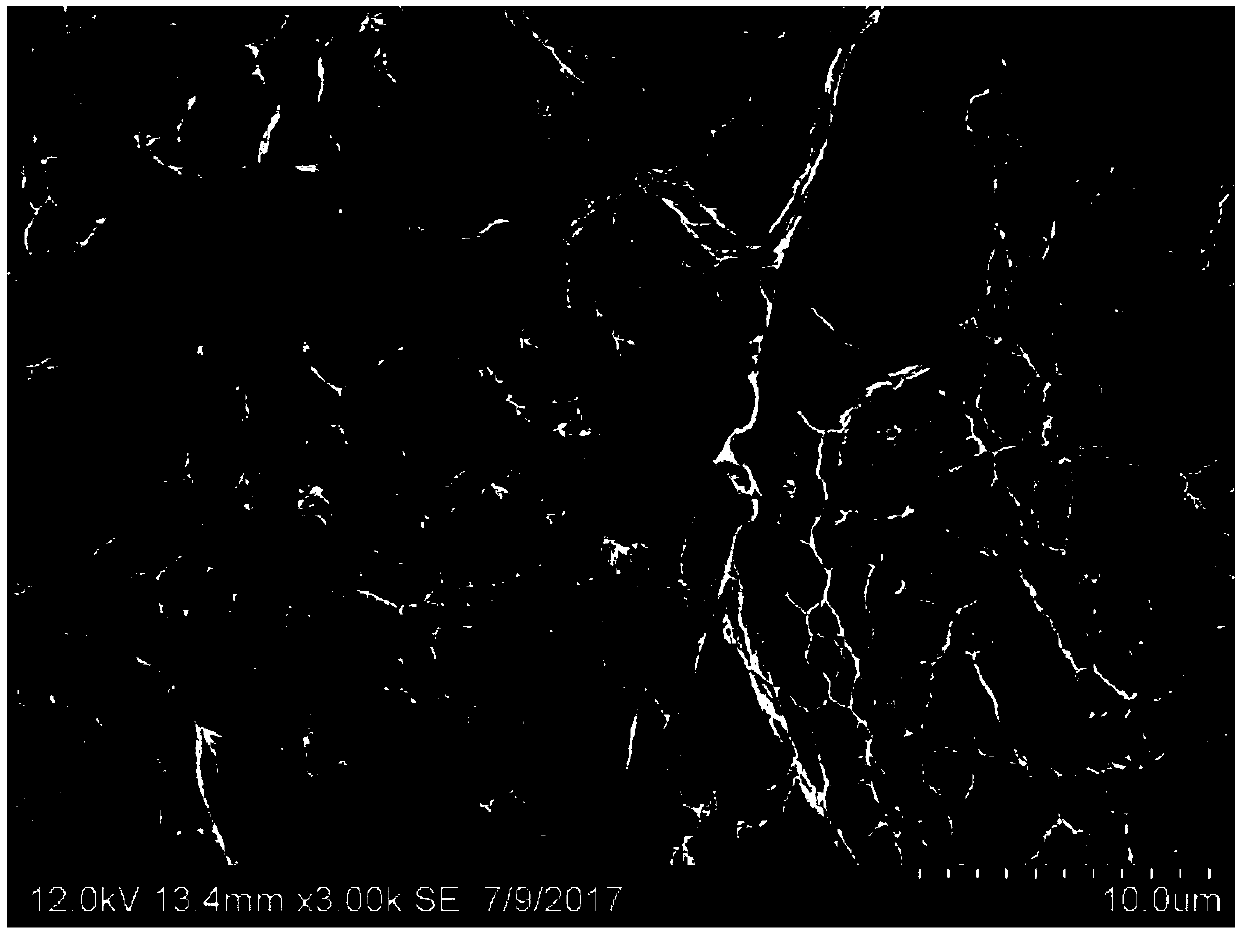

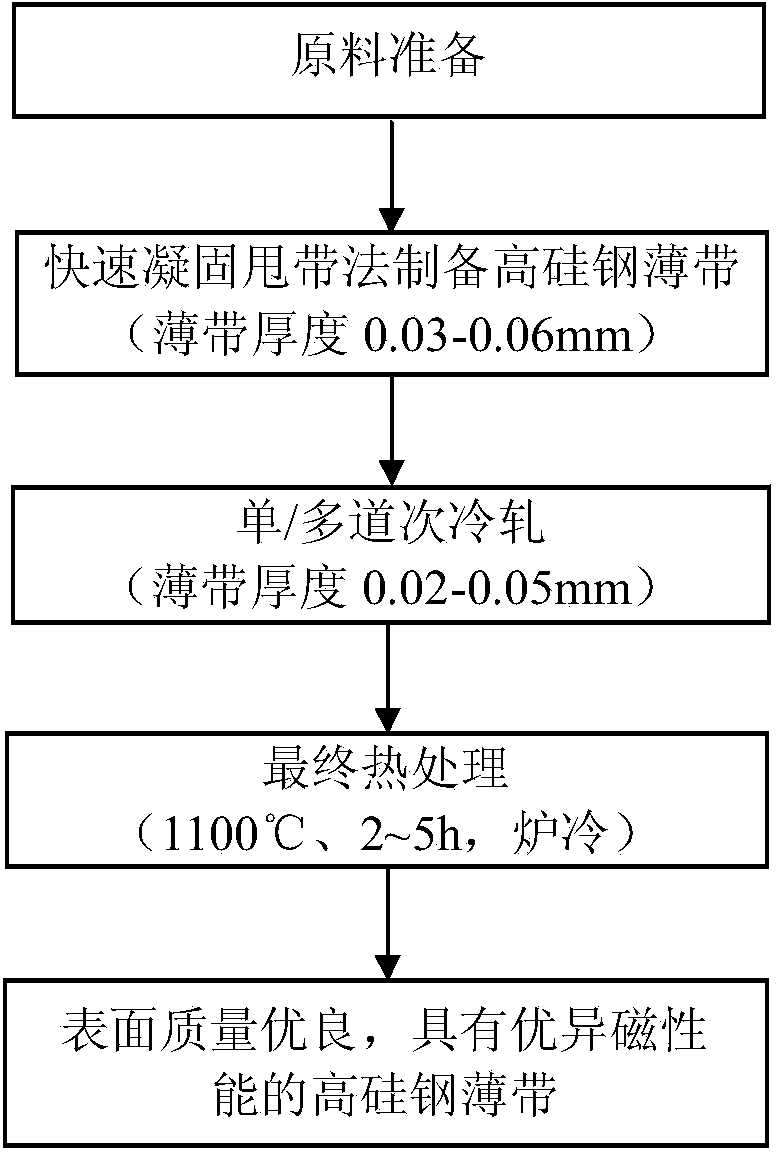

Short-process efficient cold-rolling preparation method of high-silicon steel thin strip

The invention aims at providing a short-process efficient cold-rolling preparation method of a high-silicon steel thin strip. The preparation method is characterized in that the high-silicon steel thin strip is prepared by using a rapid solidification method, and the thickness of the high-silicon steel thin strip is reduced by using a cold rolling method, the surface quality is improved, and the high-frequency magnetic performance is improved; due to rapid solidification, the plasticity of high-silicon steel can be improved, and the thin strip with certain plasticity is obtained and can be wound into a coil; then, cold rolling is carried out, so that the degree of order of the high-silicon steel is further lowered, the plasticity of the high-silicon steel is improved, and a high-silicon steel thin strip coil is obtained; the thin strip obtained through rapid solidification has the advantages that the crystal grain size is obviously reduced, the degree of order is obviously lowered, and the microhardness change is not great, so that next-step cold rolling is facilitated; during cold rolling, the rolling reduction of first-time rolling is controlled, and then, the plasticity is further improved, so that the thin strip with the thinnest thickness of 0.02mm can be obtained. According to the preparation method, the production efficiency of the prepared high-silicon steel thin strip is high, and the product quality of the prepared high-silicon steel thin strip is good, so that the method can be widely implemented industrially and accordingly has a broad application prospect.

Owner:UNIV OF SCI & TECH BEIJING

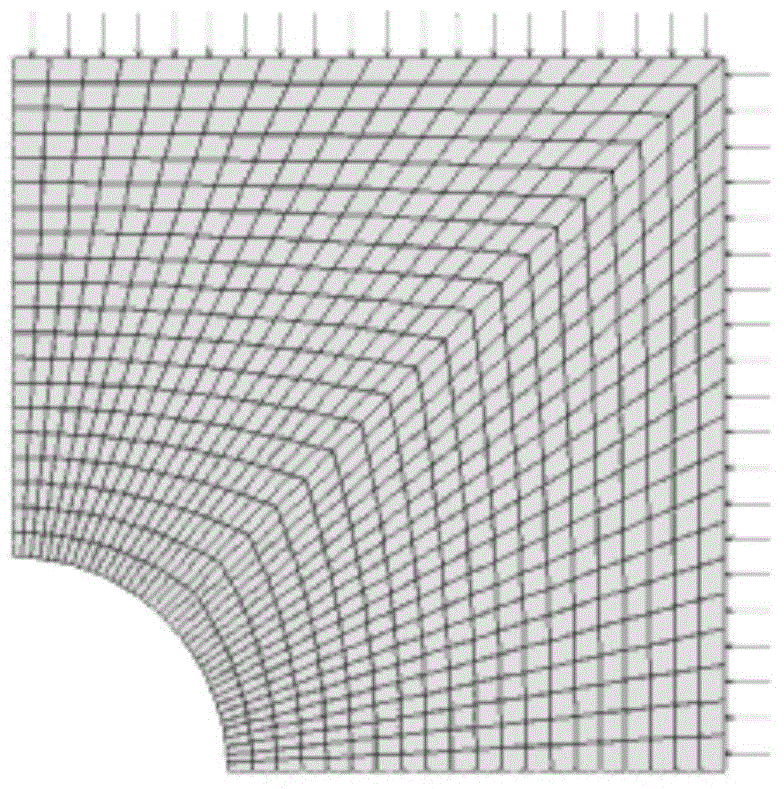

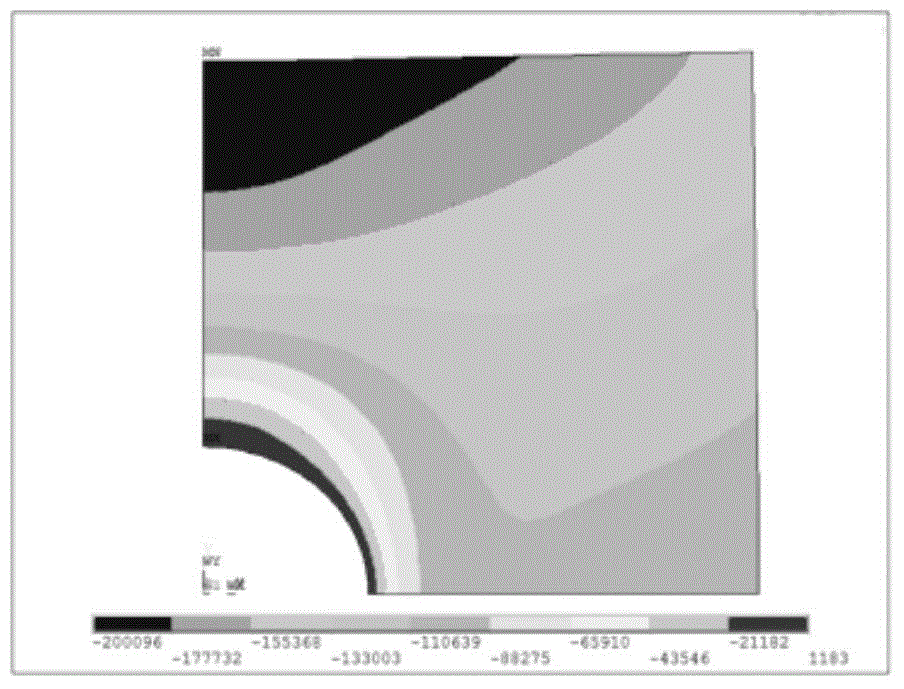

Stress distribution acquisition method after excavation of shield tunnel

InactiveCN104021254AMake up for the lack of industry normsEasy to createSpecial data processing applicationsStress distributionElement model

The invention discloses a stress distribution acquisition method after excavation of a shield tunnel. The method comprises the following steps: S1, establishing a finite element model according to related parameters of the tunnel to be excavated; S2, acquiring stress values and stress distribution condition of position nodes around the tunnel and the tunnel surrounding rock in the finite element model; S3, acquiring stress theoretical values at different position nodes around the tunnel and the tunnel surrounding rock after excavation according to the planar stress of the finite element model; and S4, comparing the stress theoretical values at different position nodes around the tunnel and the tunnel surrounding rock after excavation with the stress values at the corresponding position nodes around the tunnel and the tunnel surrounding rock in the finite element model, and determining the correctness of the stress theoretical values around the tunnel and the tunnel surrounding rock after excavation according to compare result. The method disclosed by the invention verifies and analyzes correctness and feasibility of the stress values acquired by the theoretical method through the comparative result so as to obtain the stress distribution condition of the shield tunnel after excavation.

Owner:JINAN UNIVERSITY

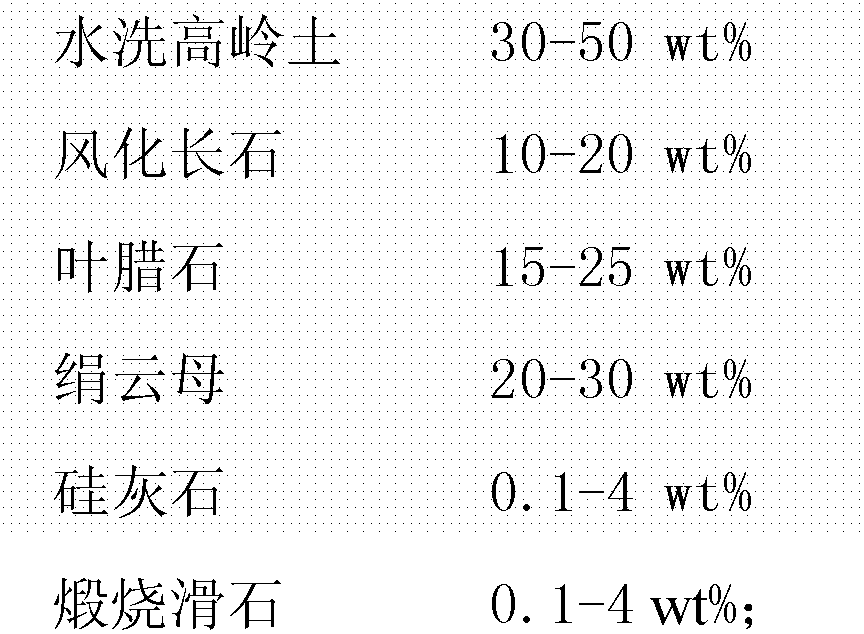

Mud for sanitary ceramics and mud preparation process

InactiveCN102603268ASmall coefficient of thermal expansionLess free quartz contentClaywaresPyrophylliteGranularity

The invention discloses mud for sanitary ceramics and a mud preparation process. The mud is mainly made of multiple raw materials and water by means of mixing and ball milling. The raw materials include 30-50wt% of water washed kaolin, 10-20wt% of weathered feldspar, 15-25wt% of pyrophyllite, 20-30wt% of sericite, 0.1-4wt% of wollastonite and 0.1-4wt% of calcined talc, and usage of water is 40-45wt% of the amount of the raw materials. The pyrophyllite, the water washed kaolin, the wollastonite and the calcined talc which have low-temperature sintering characteristics and the sericite and the weathered feldspar which have high high-temperatuare fusibility are used as the raw materials, and by means of the reasonable proportion, high-temperature components SiO2+Al2O3 of mud can be controlled within a low range, MgO, CaO,K2O and Na2O which are high in fusibility are increased, and the components with granularity smaller than 10um in the mud account for 65wt%-70wt%, so that the mud can be easily sintered. Compared with the prior art, the mud has the advantages that the mud can be formed by sintering at a low temperature (1150 DEG C), so that energy saving and consumption reduction are realized.

Owner:HUIHUANG PLUMBING GROUP

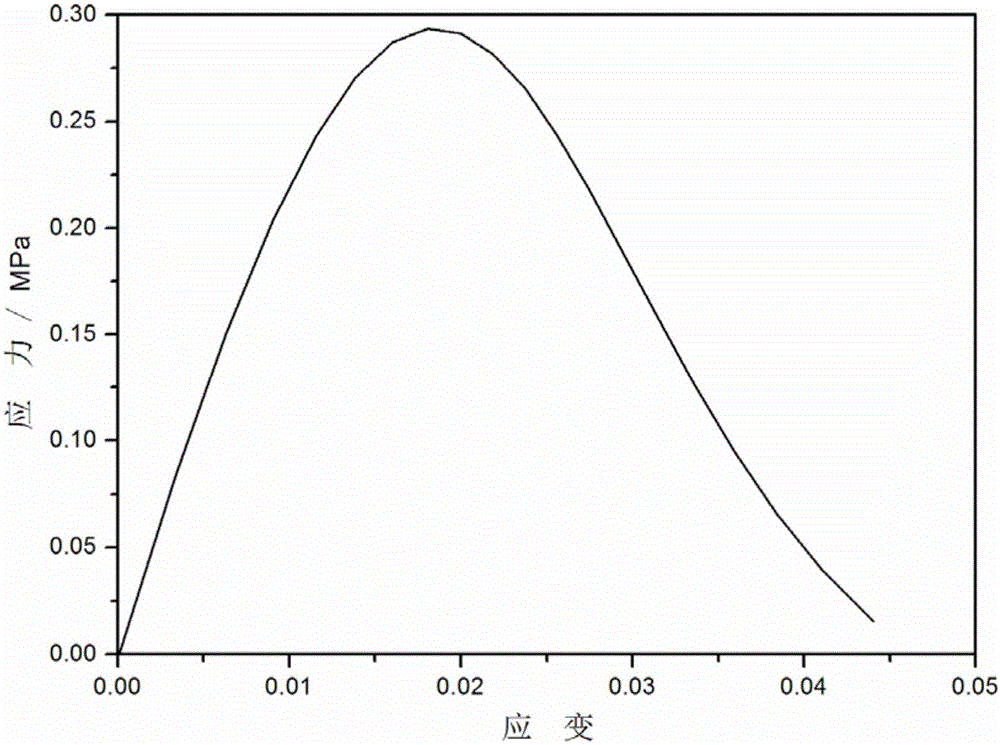

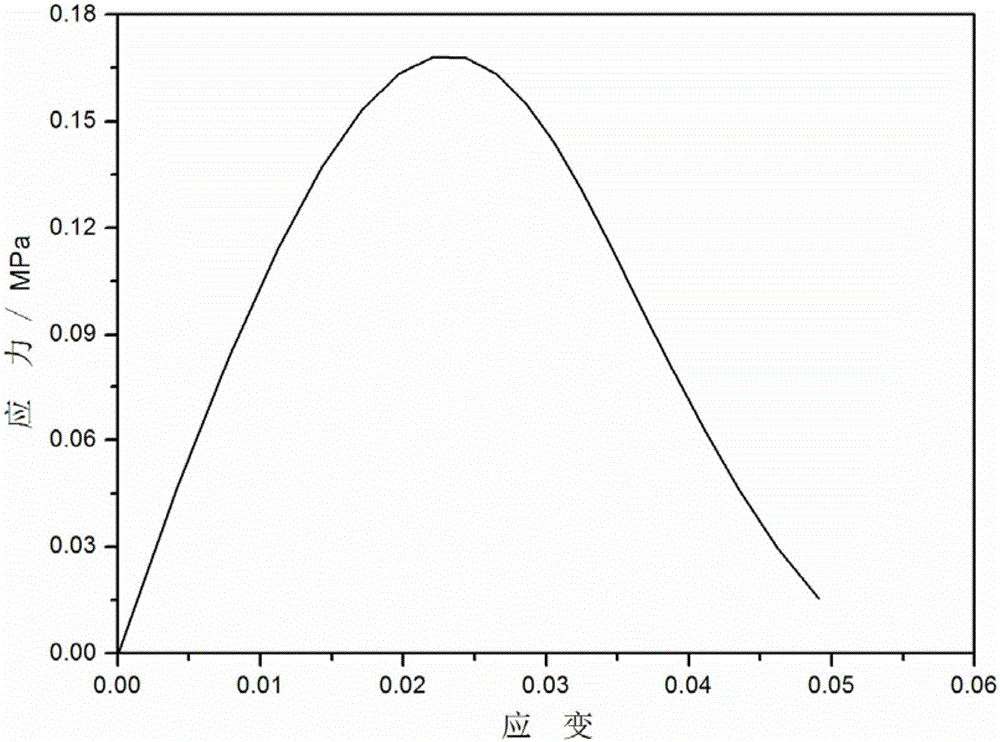

Fluid-solid coupling simulation material for coal series pressure-bearing fault activation water inrush similarity test and preparation method

ActiveCN105784945AGuaranteed plasticityGuaranteed StrengthPreparing sample for investigationGypsumCoal

The invention relates to a fluid-solid coupling simulation material for a coal series pressure-bearing fault activation water inrush similarity test. The fluid-solid coupling simulation material for the coal series pressure-bearing fault activation water inrush similarity test consists of three parts, i.e., a coal seam, a fault and surrounding rock; the coal seam consists of coal powder, talcum powder, gypsum, Vaseline, silicon oil and mixing water, the fault consists of coarse sand, talcum powder, gypsum, kaolin, Vaseline, silicon oil, soybeans and mixing water, and the surrounding rock consist of fine sand, talcum powder, gypsum, kaolin, cement, Vaseline, silicon oil and mixing water, wherein the gypsum, the cement and the Vaseline are used as cementing agents, the properties that the soybeans are expanded while absorbing water and the kaolin is granulated while meeting with water are combined, the fault surrounding rock similar material is guaranteed to have certain plasticity and strength and not to be softened and collapsed when meeting with water, simultaneously the purposes of producing a fracture with displacement when the fault similar material meets with water, reducing the strength, gradually increasing the permeability, causing seepage washing and slow collapse to form a water inrush passage are realized, and the difference between fluid-solid coupling properties of the fault and the surrounding rock in the same similarity test is inversed to enable test results to be more compliant with the reality.

Owner:ANHUI UNIV OF SCI & TECH

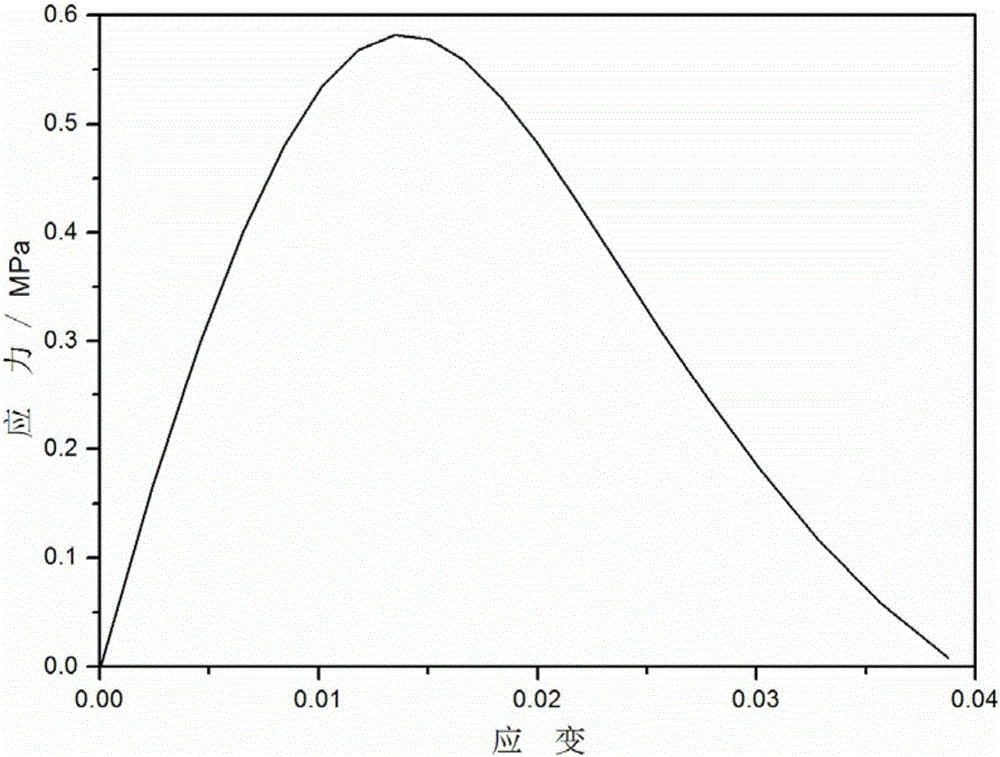

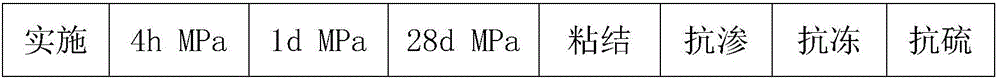

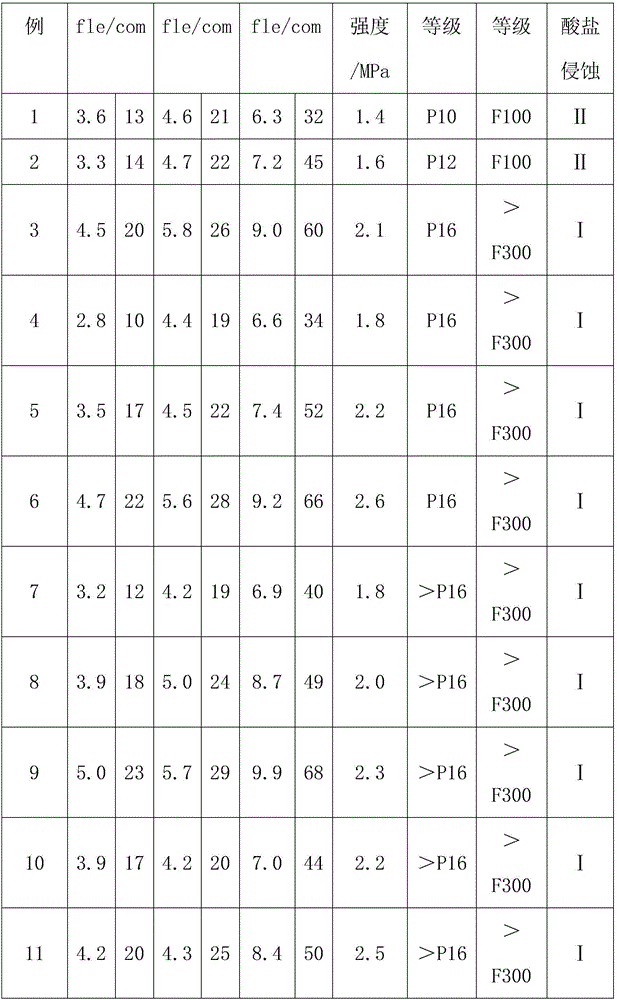

Quick-setting early strength inorganic polymer mortar and production method thereof

The invention discloses a quick-setting early strength inorganic polymer mortar and a production method thereof, and relates to the technical field of building material application. The quick-setting early strength inorganic polymer mortar comprises, by mass, 20-50 parts of slag powder, 35-60 parts of quartz sands, 0-10 parts of silica fume, 2-10 parts of an alkali exciting agent, 0.1-0.3 parts of a superplasticizer, 14-15 parts of tap water, 0-5 parts of sulfoaluminate cement, 0-10 parts of gypsum powder, 0-2 parts of EVA, and 0-0.5 parts of polymer fibers. The production method comprises the following steps: proportioning above raw materials, stirring the raw materials, carrying out heating stirring, and cooling the raw materials to obtain the mortar with the advantages of good workability, high early strength, high impermeability, good flexibility, high durability, high bonding strength and good corrosion resistance. The mortar is a beneficial supplement to present gelling material systems, and is produced from high-aluminum slag, fly ash, silica fume, gypsum and other solid wastes. The quick-setting early strength inorganic polymer mortar has the advantages of no high temperature calcining in the production process, suitableness for being used in the fields of engineering with special requirements, and good development prospect.

Owner:河南普利泰新材料研究院有限公司

Machining method for aluminum alloy turbine blade of aero-engine

The invention discloses a machining method for an aluminum alloy turbine blade of an aero-engine, and belongs to the technical field of machining for turbine blades of aero-engines. The machining method comprises the following steps: casting the aluminum alloy turbine blade, carrying out film hole machining through a machining method of ultrafast laser annular cutting and spiral scanning, and removing a remelted layer through abrasive particle flow machining and a melted layer removal solution. According to the machining method disclosed by the invention, the film hole machining is carried outthrough the machining method of ultrafast laser annular cutting and spiral scanning, so that the heat effect can be greatly reduced and the surface integrity is improved, the machined film hole has few burrs, grooves and micro-cracks, and the maximum thickness of the remelted layer is not greater than 25[mu]m. Abrasive particles uniformly grind the surface or the corners of a channel under a pressure effect, so that allowance can be removed, the effects of deburring, chamfering and polishing can also be acted, the remelted layer can also be effectively reduced, a hole diameter increment is controlled to be 0.02mm to 0.04mm, and the remelted layer and the micro-cracks can be effectively controlled. The remelted layer is further removed through the remelted layer removal solution, so that no remelted layer residue at the inlet-outlet of the film hole can be achieved.

Owner:安徽恒利增材制造科技有限公司

Low alloy high tenacity Q-P-T wear-resistant steel plate and manufacturing method thereof

The invention relates to the field of material heat treatment, and discloses a low alloy high tenacity Q-P-T wear-resistant steel plate and a manufacturing method thereof. The low alloy high tenacityQ-P-T wear-resistant steel plate comprises, by mass, 0.2-0.4% of C, 0.1-0.5% of Si, 0.5-1.5% of Mn, 0.5-1.2% of Cr, 0.1-0.3% of Mo, 0.02-0.08% of Ni, 0.04-0.1% of Cu, 0.001-0.008% of V, 0.01-0.04% ofTi, 0.01-0.05% of Nb, 0.001-0.003% of B, less than 0.015% of P, less than 0.005% of S, less than 0.006% of N, and the balance Fe and inevitable impurities. The low alloy high tenacity Q-P-T wear-resistant steel plate adopts the technique of Q-P-T heat treatment to manufacture the high tenacity wear-resistant steel. Microstructures are martensite, bainite, and retained austenite. Microalloy elements of V, Ti and Nb have effects of fine grain strengthening and precipitation strengthening. Therefore, the wear-resistant steel is good in abrasion performance, and high in tenacity.

Owner:UNIV OF SCI & TECH BEIJING

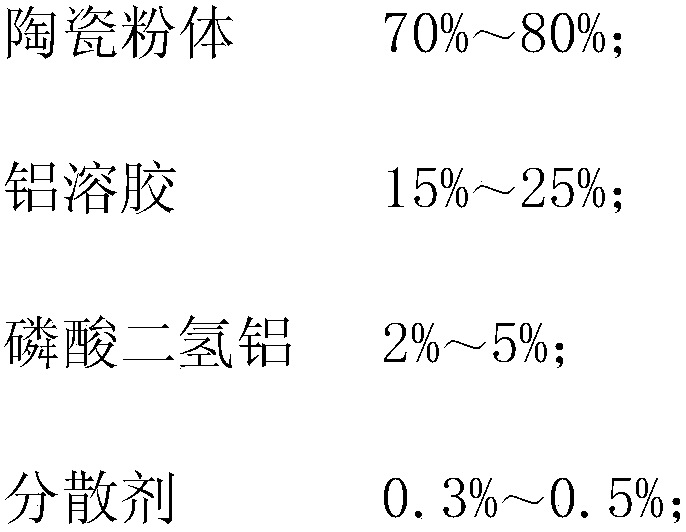

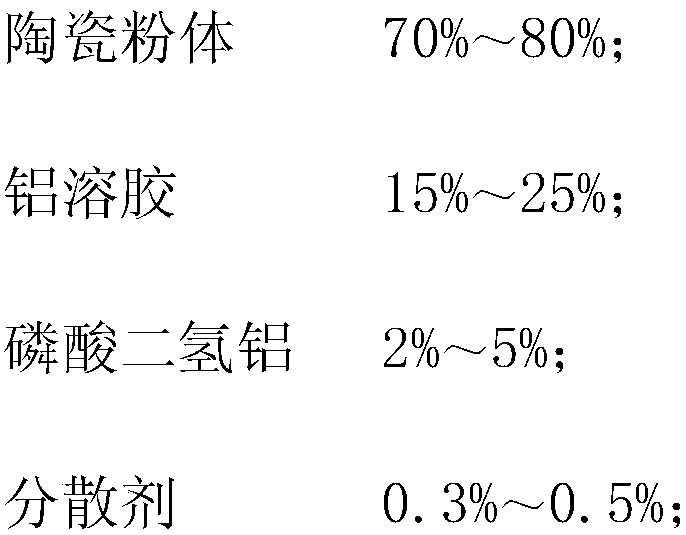

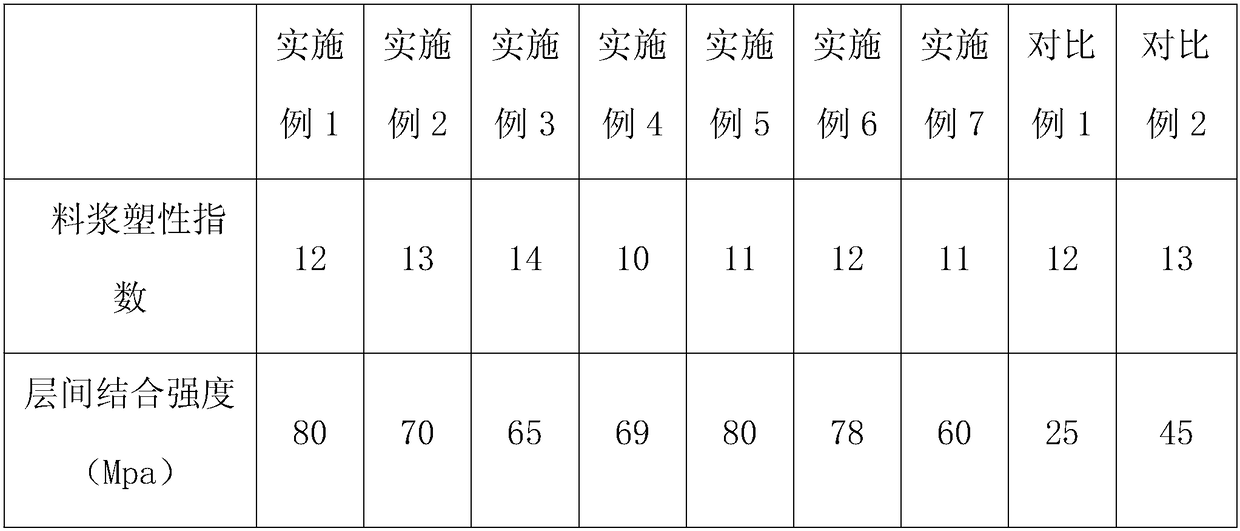

Alumina ceramic slip suitable for 3D printing, preparation method and application thereof

The invention provides an alumina ceramic slip suitable for 3D printing, a preparation method and an application thereof. The alumina ceramic slip comprises the following raw materials by mass percentage: 70-80% of ceramic powder, 15-25% of aluminium sol, 2-5% of aluminium dihydrogen phosphate, and 0.3-0.5% of a dispersant, wherein the ceramic powder contains alumina. By using the technical scheme, the technical problems of large amount of required plasticizer used for the ceramic slip, environment pollution, low intensity of prepared ceramic part, and high required sintering temperature in the prior art can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

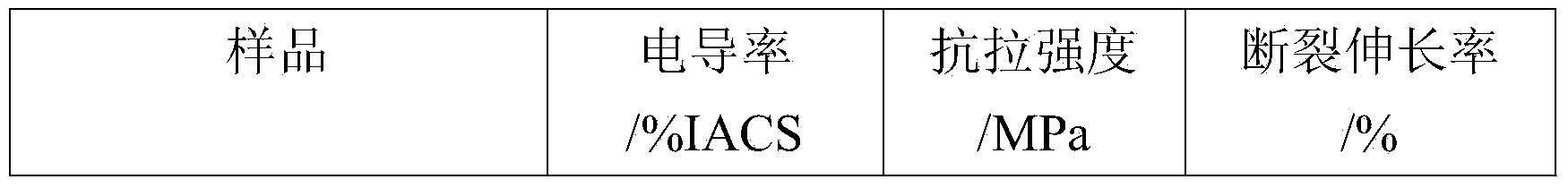

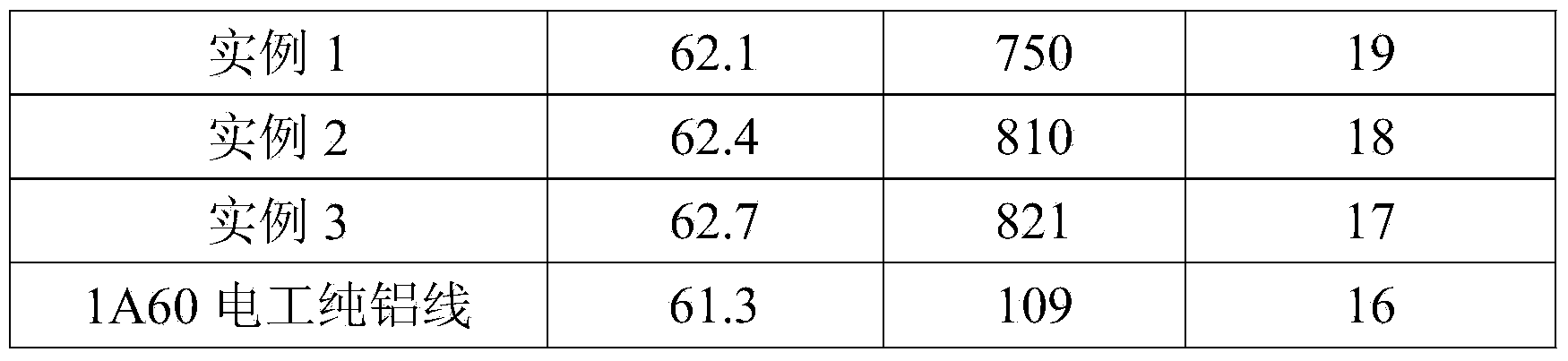

Carbon nano tube reinforced aluminum alloy core aluminum stranded wire and preparation method thereof

ActiveCN103632751AReduce weightLower resistanceNon-insulated conductorsPower cablesCarbon nanotubeMagnesium

The invention discloses a carbon nano tube reinforced aluminum alloy core aluminum stranded wire and a preparation method thereof. A core layer of the carbon nano tube reinforced aluminum alloy core aluminum stranded wire is made of a carbon nano tube reinforced aluminum alloy material which is composed of, by weight, 1-8% of carbon nano tubes, 0.1-1% of magnesium, 0.1-1% of manganese, smaller than or equal to 0.1% of chromium, smaller than or equal to 0.1% of titanium, smaller than or equal to 0.1% of copper, smaller than or equal to 0.01% of impurities and the rest aluminum. A light-weight high-strength carbon nano tube modified alumium alloy material is prepared through nano-modification technology, enabled to reach the level of steel in strength while to be one third of steel in density and taken as a load-bearing core material, and a hard aluminum wire is stranded on an outer layer to prepare the aluminum stranded wire. The carbon nano tube reinforced aluminum alloy core aluminum stranded wire and the preparation method thereof have the advantages that the aluminum stranded wire is light in weight, small in resistance, nonmagnetic and small in sag, loss of a power transmission line can be substantially reduced, electric energy can be saved, transmission capacity can be improved, height of a power transmission tower can be reduced, steel consumption can be reduced, and the objectives of energy conservation and capacity improvement can be achieved.

Owner:STATE GRID CORP OF CHINA +4

Silicon carbide honeycomb ceramic pug and pugging method

The invention relates to a silicon carbide ceramic material, in particular to a silicon carbide honeycomb ceramic pug and a pugging method. Silicon carbide with different grain diameters is adopted as a main material, and then a binder, a pore-forming agent, a lubricating agent, a high polymer release agent, water and a plasticizer are added, after the pugging steps like mixing materials and twice ageing, the pug with high plasticity and high viscidity and used for producing silicon carbide honeycomb ceramics is obtained. According to the silicon carbide honeycomb ceramic pug and the pugging method, provided by the technical scheme of the invention, various technical indices of the produced honeycomb ceramic products are obviously improved when compared with that of the prior art.

Owner:NINGXIA MACHINERY RES INST

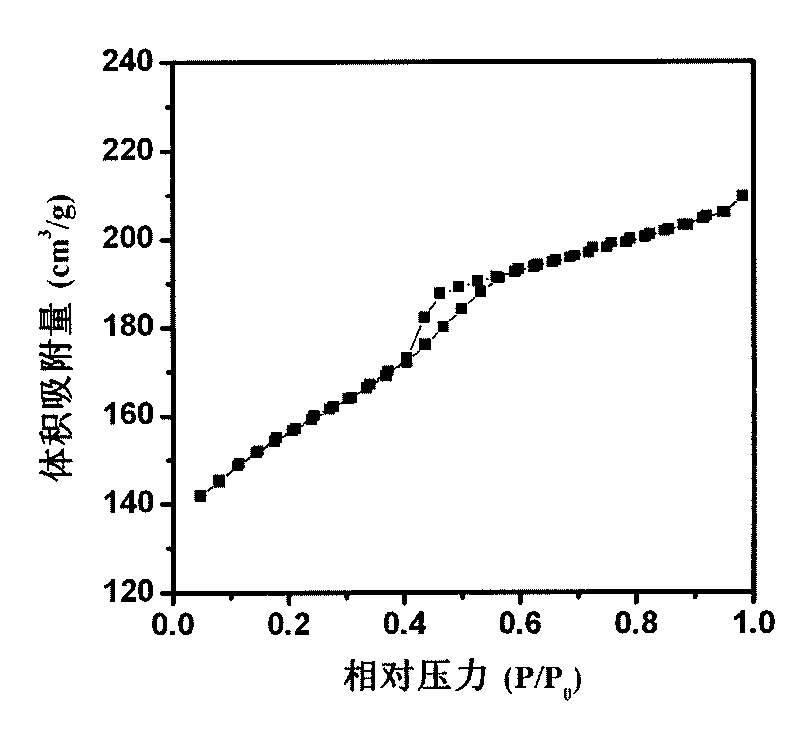

Polymer composite with plasticity, ordered mesoporous polymer of multi-level structure and ordered mesoporous carbon material

The invention relates to the material field and provides a polymer composite with plasticity. The polymer composite with plasticity and with plasticine characteristic is synthesized through evaporation-induced self-assembly of a solvent by mixing a mixed surfactant and an organic polymer. The polymer composite is further roasted and the surfactant is removed to obtain an ordered mesoporous polymer of multi-level structure, and the ordered mesoporous polymer is carbonized at high temperature to obtain an ordered mesoporous carbon material of multi-level structure. Being plastic, the shape of the polymer composite is not damaged before and after roasting, the mesoporous polymers and carbon materials of different shapes can be obtained after carrying out post-forming on the polymer composite, and the macro shapes of the mesoporous polymers and carbon materials are not damaged. The obtained carbon materials have the characteristics of open multi-level pore channel structures, high specific surface, large pore volume, uniform mesopore diameter and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

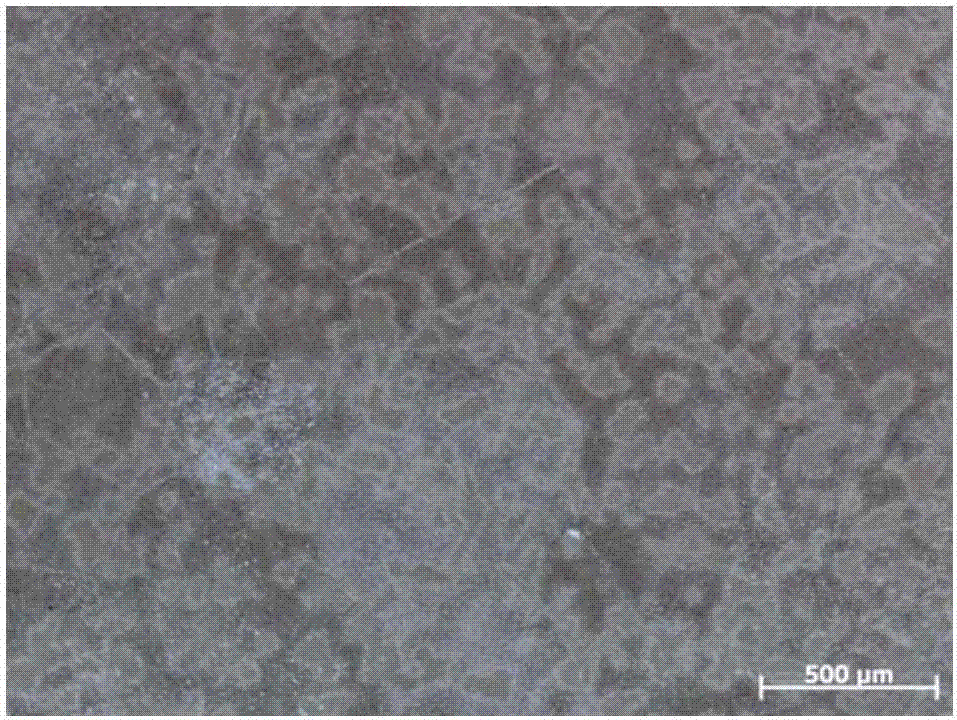

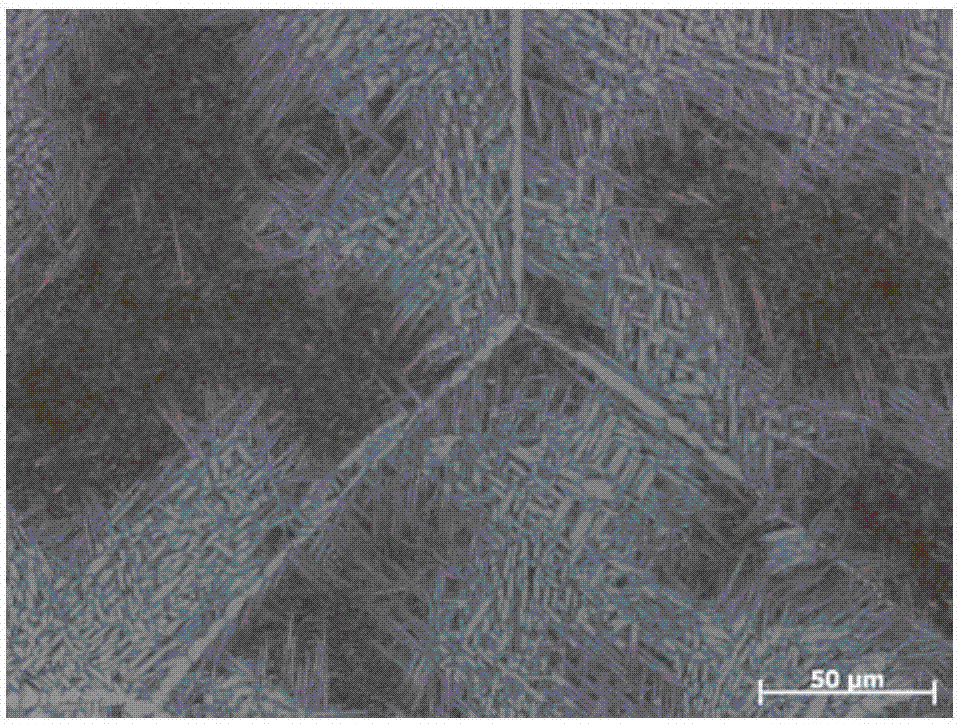

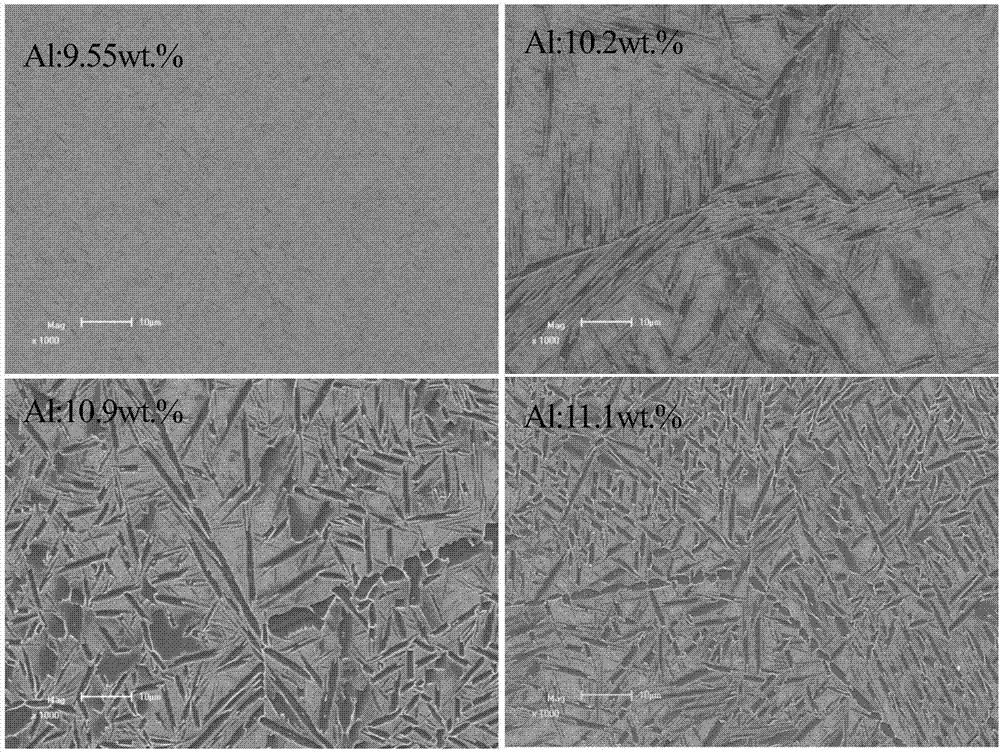

Cast toughened Ti3Al intermetallic compound as well as preparation method and application thereof

The invention belongs to the field of Ti-Al intermetallic compounds, and in particular relates to a cast toughened Ti3Al intermetallic compound as well as a preparation method and application thereof. The cast toughened Ti3Al intermetallic compound comprises constitution factors such as alloy components, smelting, precise casting and thermal treatment. The alloy components comprise 10.2-11.8 percent by weight of Al, 26.0-29.0 percent by weight of Nb, 1.0-3.0 percent by weight of Mo, and the balance of Ti and inevitable impurity elements, wherein the inevitable impurity elements comprise Fe, Si, O, N and H; Fe is less than or equal to 0.3%; Si is less than or equal to 0.3%, O is less than or equal to 0.15%; N is less than or equal to 0.04%; and H is less than or equal to 0.01%. Therefore, with the combination of the component optimization process and the thermal treatment processes, different matches between tensile strength and plasticity and between fatigue strength and thermal stability can be achieved, and the compound can be also used for manufacturing precise cast parts such as high-temperature parts of aero-engines, and can be used for a long time at 600-700 DEG C; and the alloy can be also used for manufacturing high-temperature resistant structural parts of aerospace crafts, and can be used for a short time at 650-750 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Titanium diaphragm for loudspeaker

InactiveCN101478713AImprove sound qualityWith stamping propertiesElectrical transducersRoll mill control devicesSound filmPunching

The present invention provides a titanium sound film for loudspeaker. The invention is characterized in that the titanium foil is manufactured through the following processes: processing titanium strip material through a multi-roller foil mill or executing more than two times of rolling to a thickness of 0.02mm-0.1mm, cleaning for degreasing after aligning and leveling, annealing through a vacuum annealing oven in the temperature of 530-640 DEG C, keeping the temperature for 2-4 hours, facilitating the vacuum degree to above 10, and taking the titanium sound film out from the furnace. The finished product is obtained after taking out. The acoustic quality of titanium sound film according to the invention is excellent. The punching capability, plasticity and material hardness can totally obtain the using requirement.

Owner:常荣波

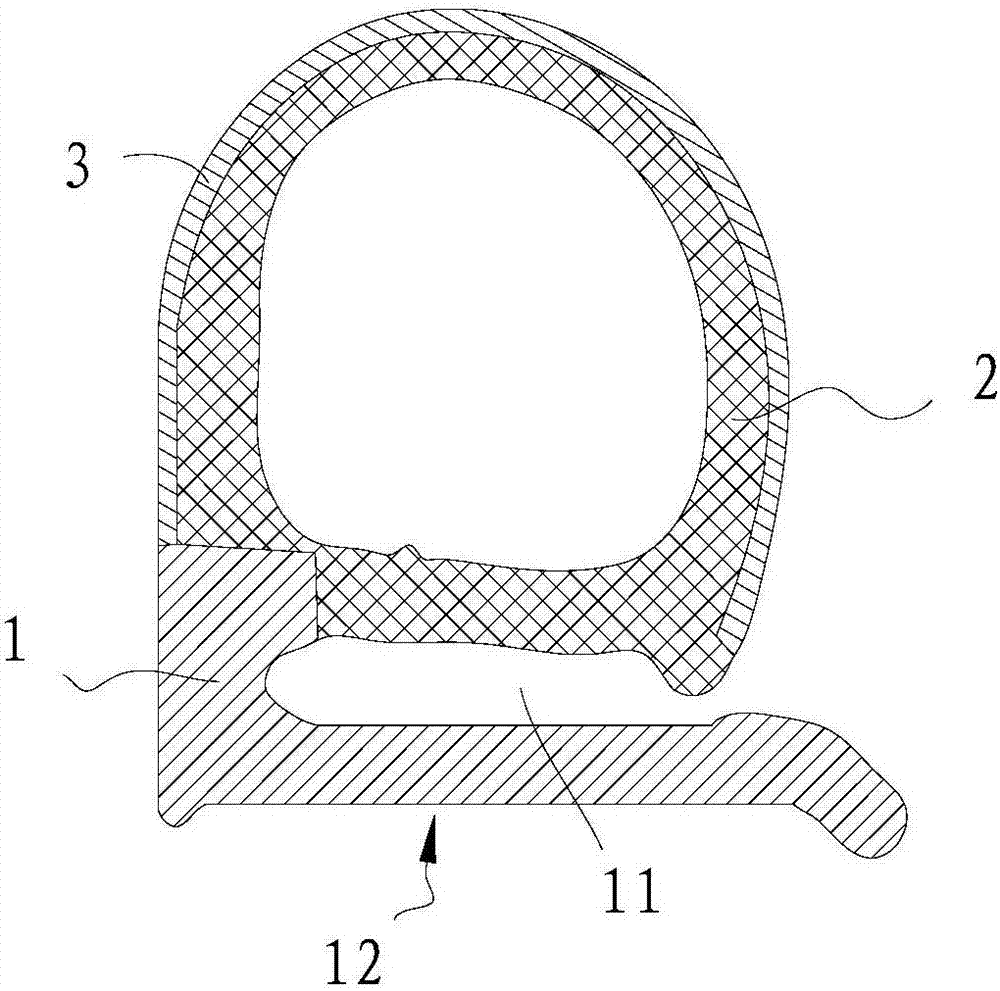

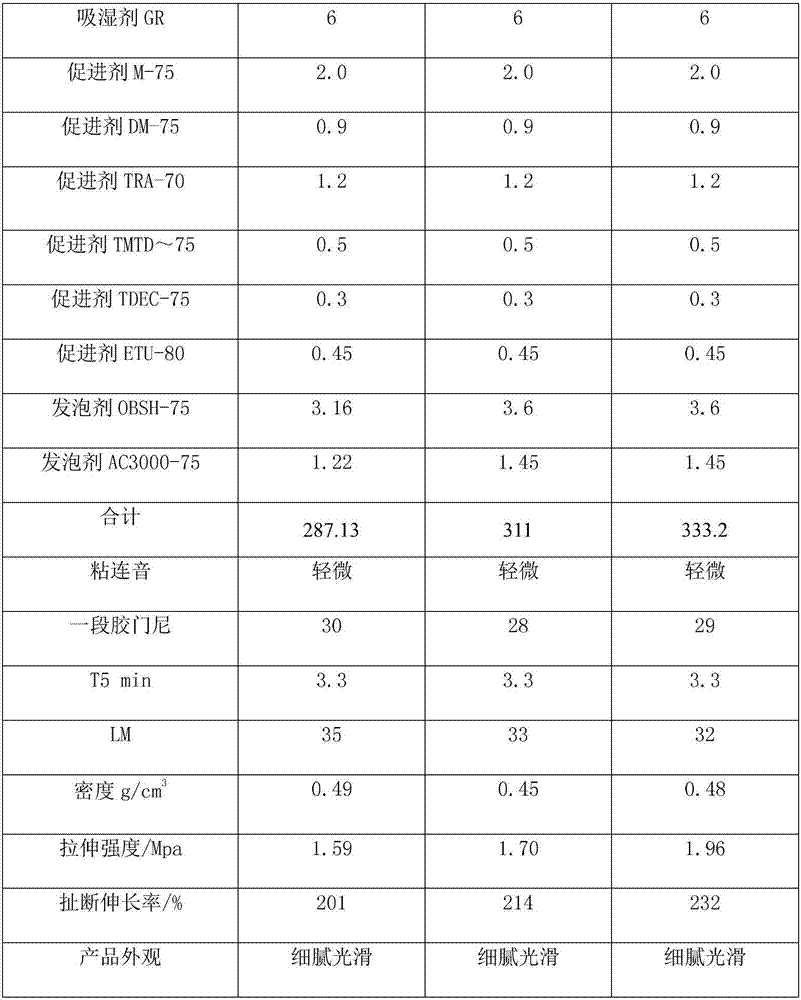

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

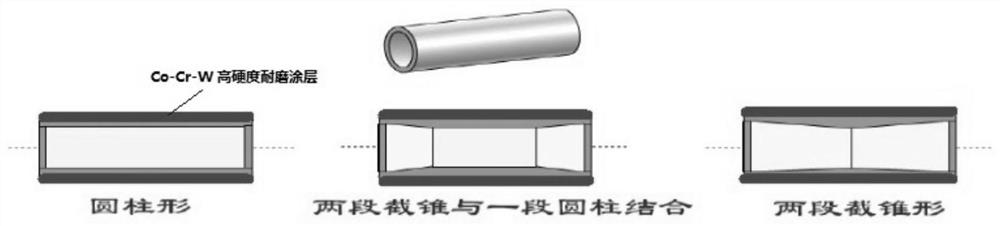

High-hardness wear-resistant piston pin and preparation method thereof

The invention discloses a high-hardness wear-resistant piston pin and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively mixing matrix material powder and Co-Cr-W alloy powder with a binder, and performing granulation to obtain a matrix material feed and a high-hardness wear-resistant coating material feed; then, sequentially injecting the matrix material feed and the Co-Cr-W alloy coating material feed into a mold cavity by using an injection molding technology to obtain a product green body; removing the binder in the green body through catalytic debinding and thermal debinding processes; and finally, performing co-sintering densification to obtain the Co-Cr-W series high-hardness wear-resistant piston pin. The process is simple, the bonding performance of a coating layer and a matrix is good, and the piston pin has the characteristics of high hardness and wear resistance.

Owner:湖南英捷高科技有限责任公司

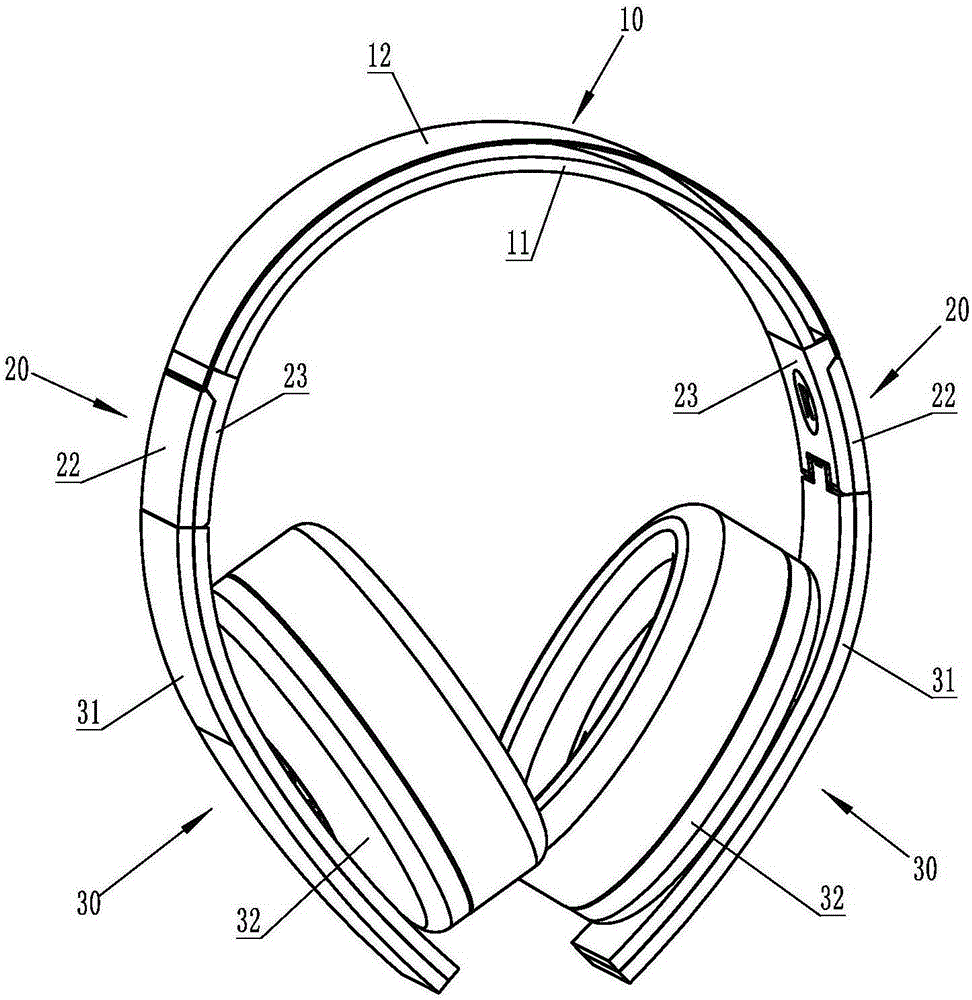

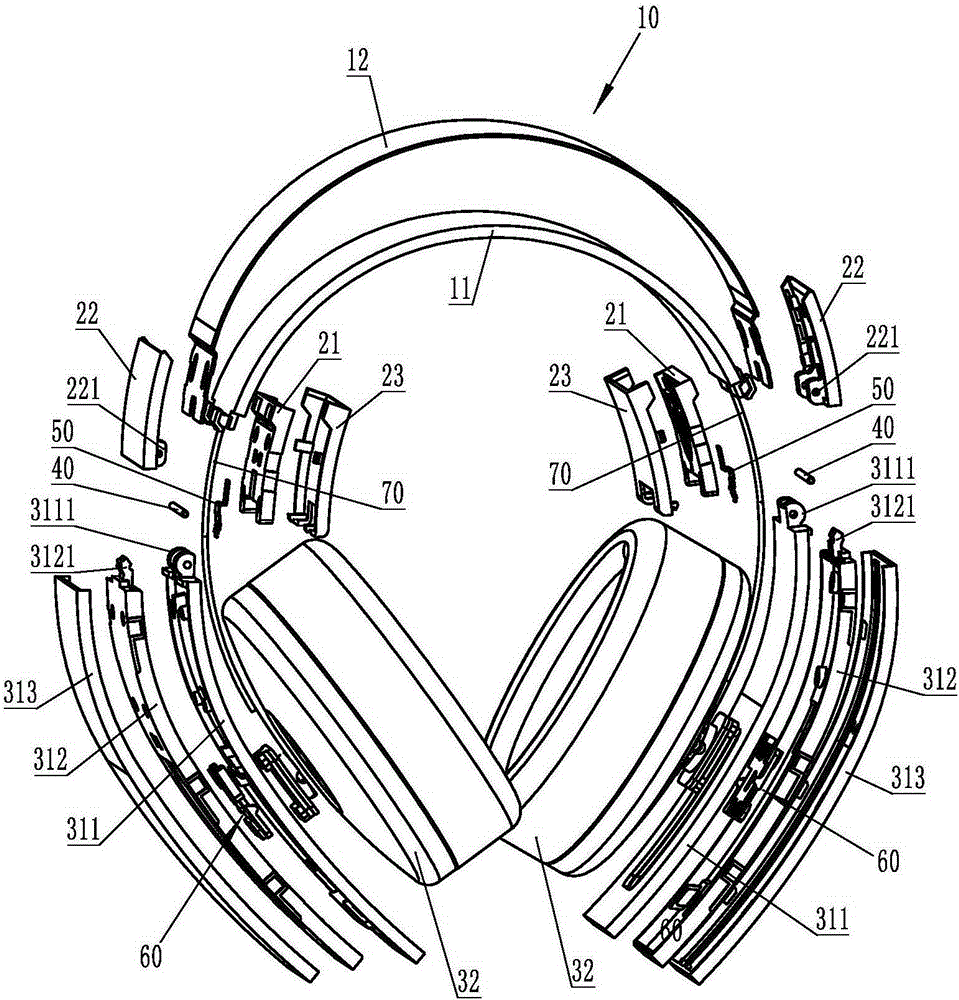

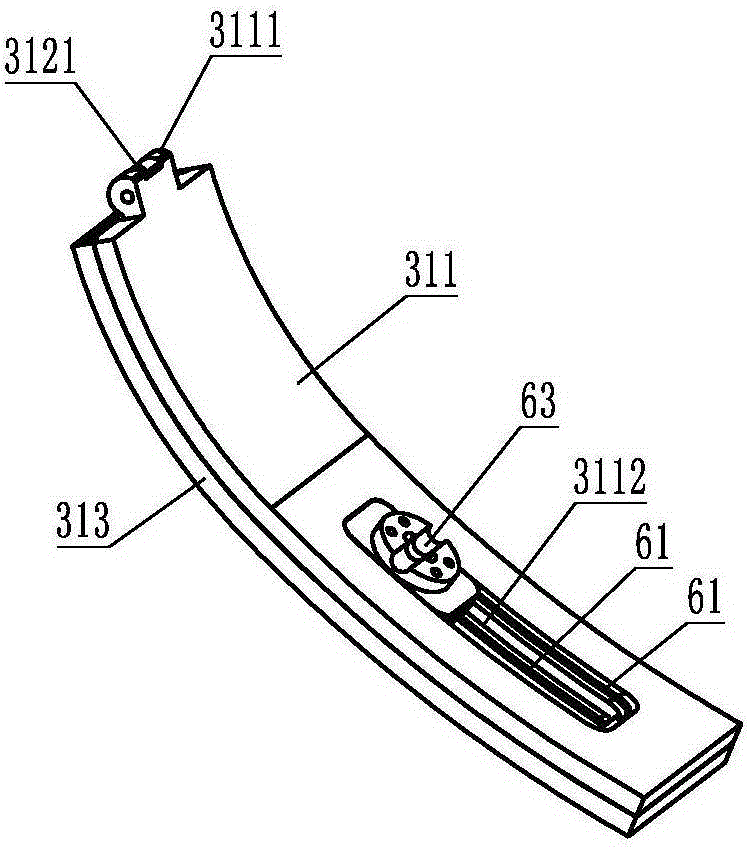

Foldable headphone

ActiveCN105163214AGuaranteed bending strengthPlasticEarpiece/earphone attachmentsEngineeringHeadphones

The invention belongs to the technical field of headphones, and particularly relates to a foldable headphone. The foldable headphone includes an arc-like head band, earphone units arranged on two sides of the head band, two end parts of the head band are each provided with a connecting structure, and each earphone unit is rotatably connected with the connecting structure of the same side and can rotate towards an area that the head band surrounds; the head band includes a flexible head strip at an inner side and a steel sheet at an outer side, distance is reserved between a middle position of the flexible head strip and a middle position of the steel sheet, an end part of the steel sheet is fixedly connected with the connecting structure, and an end part of the flexible head strip is hinged to the connecting structure in a width direction. Each earphone unit includes a support one end of which is rotatably connected with the end part of the connecting structure, an earphone arranged on an inner side face of the support and an electrical connecting line, and the electrical connecting line is embedded in the flexible head strip. The foldable headphone can ensure bending strength and can also ensure wearing comfort of a head top part, and volume space can be effectively reduced when the headphone is folded, and thus the headphone is convenient to carry.

Owner:QINGDAO GOERTEK

2.3 GPa strength grade Co-Ni-Cr-based alloy and preparation method thereof

The invention discloses a 2.3 GPa strength grade Co-Ni-Cr-based alloy and a preparation method thereof. The alloy comprises the following components of, in percentage by mass, 42%-45% of Co, 30%-33% of Ni, 18%-21% of Cr, 0.8%-1.2% of W, 1.8%-2.2% of Mo, 0.3%-0.7% of V and 0.15%-0.3% of C. The preparation method of the alloy comprises the steps of casting, homogenization treatment, solution treatment, cold deformation treatment and aging heat treatment. The tensile strength of the alloy can reach 2.30 GPa or above, the alloy has certain plasticity, the preparation process is simple, and the alloy can be produced through conventional casting and cold and hot machining processes.

Owner:SHENYANG AEROSPACE UNIVERSITY

Expanded quartz sand water-permeable colored brick

InactiveCN101913809AEasy to adjust temperatureSolve the problem of floodingCovering/liningsSolid waste managementSlagThermal insulation

The invention relates to an expanded quartz sand water-permeable colored brick which solves the problems of poor wear resistance, poor compression resistance, low water permeability, high specific gravity and high cost of a clay kiln-fired brick and a machine-made brick for the pavement of urban sidewalks, public squares and residence communities as well as the exterior wall decoration of buildings. The brick is manufactured from expanded quartz sand disused in the production process in the firebrick production industry and is manufactured by the following steps: screening the expanded quartz sand, crushing, filtering impurities, carrying out fine grinding, mixing with cement, slag, thermal insulation beads, water, mortar hardener and pigments according to a composition ratio, uniformly blending in a blender, carrying out secondary extrusion forming in a machine-made brick forming machine, and carrying out aeration-drying to obtain final products. The invention has the advantages of scientific prescription, easy material selection, beautiful appearance of products, light weight, wear resistance, compression resistance, good water permeability and low manufacturing cost, thereby having wide market prospects.

Owner:湘潭昭华建材厂(普通合伙)

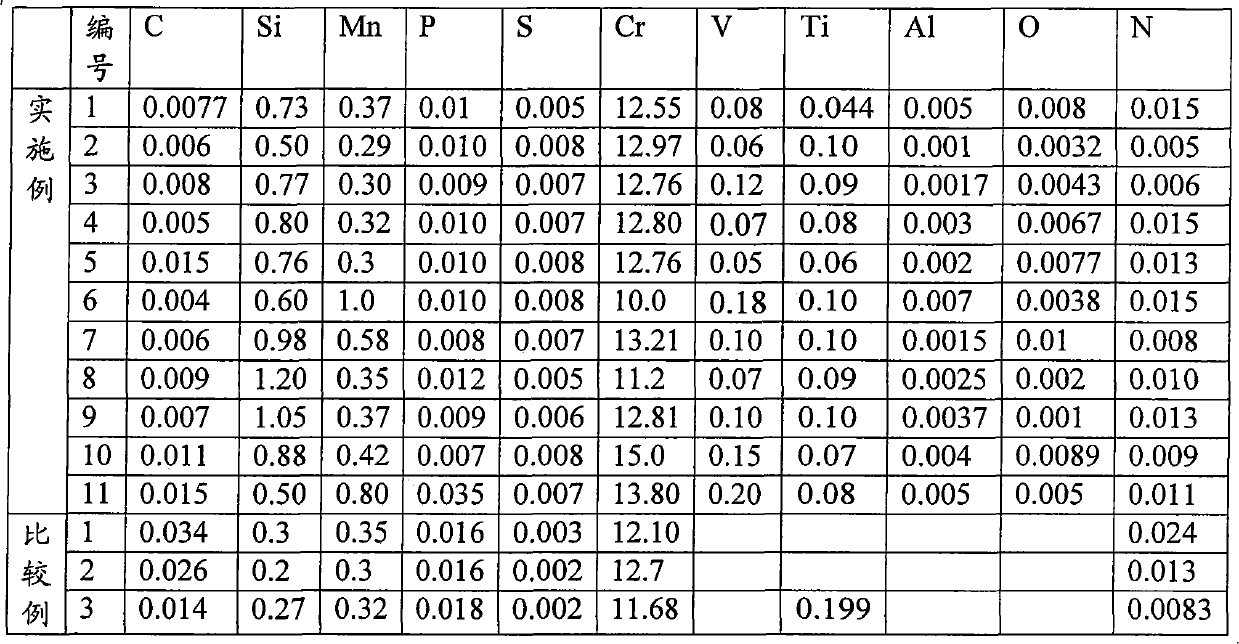

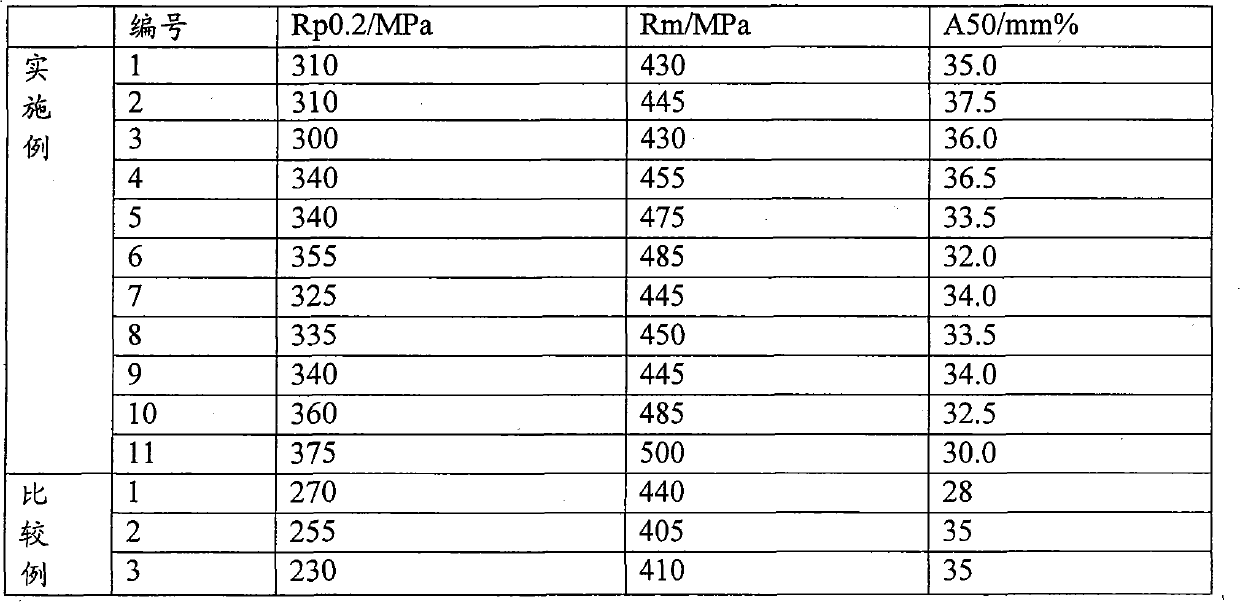

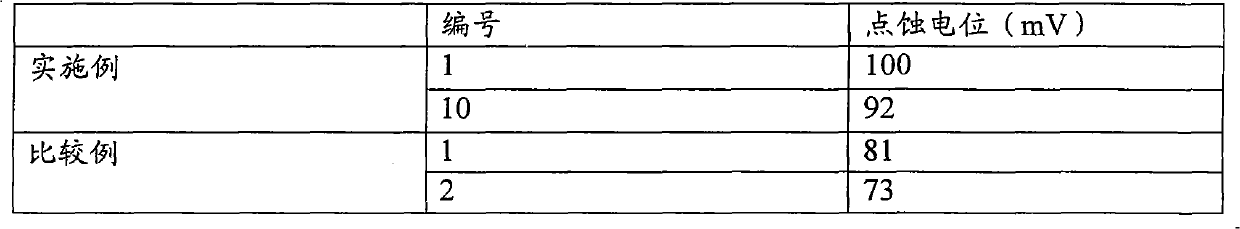

Low-chromium ferritic stainless steel and manufacturing method thereof

ActiveCN102021480AHigh strengthImprove corrosion resistanceTemperature control deviceProcess efficiency improvementChromiumCorrosion

The invention relates to low-chromium ferritic stainless steel and a manufacturing method thereof. The low-chromium ferritic stainless steel comprises the following components in percentage by mass: 0.005 to 0.015 percent of C, 0.005 to 0.015 percent of N, 0.50 to 1.20 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percent of S, 10 to 15 percent of Cr, 0.05 to 0.20 percent of V, less than or equal to 0.10 percent of Ti, less than or equal to 0.005 percent of Al, less than or equal to 0.005 percent of O and the balance of Fe and inevitable impurities. The low-chromium ferritic stainless steel has higher yield strength and tensile strength and has certain plasticity and excellent corrosion resistance. Therefore,the low-chromium ferritic stainless steel can be used in the industries for manufacturing frames of televisions, computers, mobile phones and other electronic products, and the like.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

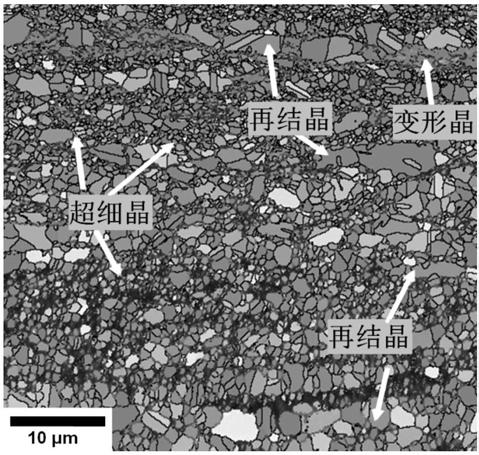

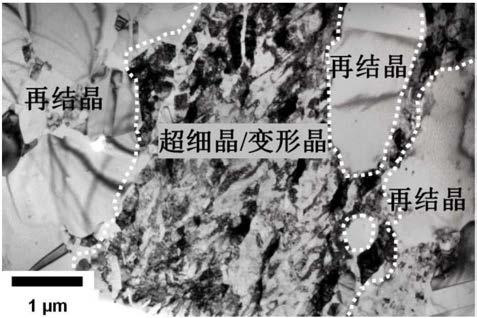

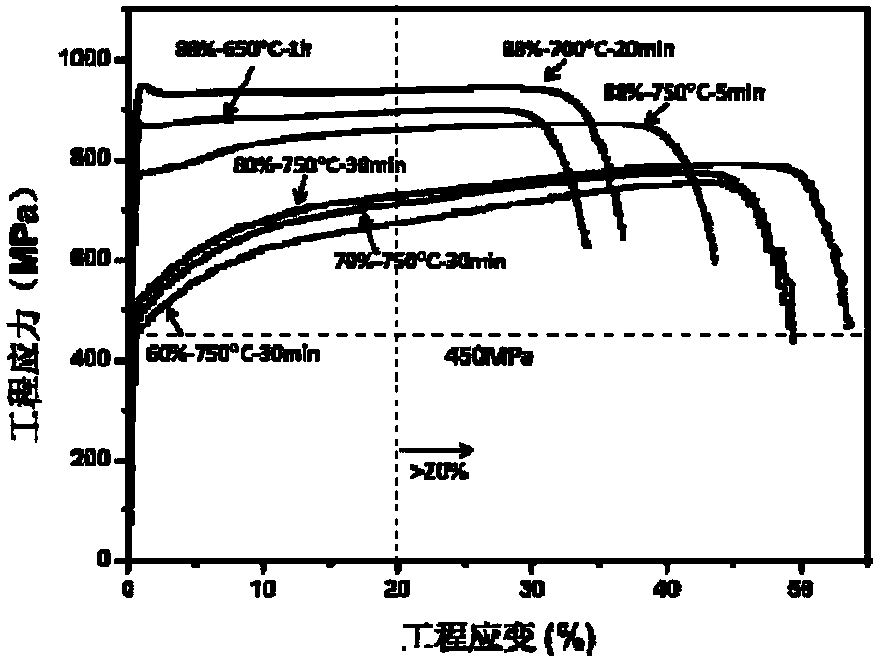

Preparation method of heterogeneous-layered-structure 304L stainless steel

The invention discloses a preparation method of a heterogeneous-layered-structure 304L stainless steel, and belongs to the field of stainless steel preparation. According to the method, firstly, solidsolution treatment is carried out on the 304L stainless steel with the thickness being 3-30 mm to obtain uniform austenite structures with the average grain size being 40-120 microns; then, cold rolling treatment is carried out on the 304L stainless steel with the total rolling reduction being 60-90% to form traditional strip-shaped cold-rolled structures; and finally, incomplete recrystallization annealing treatment is carried out on the 304L stainless steel for 5-60 minutes at the condition being 650-750 DEG C, and thus the heterogeneous-layered-structure 304L stainless steel is prepared. The mechanical experiment result shows that the stainless steel has the yield strength being 450-1000 MPa and the tensile strength being 750-1000 MPa, and it is worth noting that the uniform elongationrate of the 304L stainless steel can reach greater than or equal to 20%. The method is easy to operate and suitable for industrial production.

Owner:NANJING UNIV OF SCI & TECH

Uvioresistant textile finishing agent

InactiveCN102409529AHigh refractive indexGood UV shielding functionFibre treatmentCeramic particleTextile processing

The invention relates to an uvioresistant textile finishing agent which is characterized by comprising the following components in concentration: 10-50 g / L nano ceramic particles, 1.0-3.0 g / L chitosan, 1.5-2.5 g / L sodium sulfate and 0.5-1.5 wt% of glacial acetic acid. The textile processed by the finishing agent has a good ultraviolet shielding function, and the textile processing procedure is simple.

Owner:WUJIANG RUIFENG WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com