Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and thermal treatment process thereof

A β-titanium alloy and ultra-high-strength technology, applied in the field of alloy materials, can solve problems such as plasticity decline and application limitations, and achieve the effects of reducing temperature sensitivity, high strength, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the ultra-high-strength β-titanium alloy of the present invention includes the following steps: different from the vacuum consumable arc furnace (VAR) used in conventional titanium alloy smelting, the present invention adopts an advanced cold crucible suspension melting method (CCLM). Select the type of raw material according to the actual needs, calculate the ratio of raw materials according to the alloy composition and mix them evenly, load the raw materials into the furnace in bulk and carry out 3 times of suspension melting to obtain ingots. After the ingot is peeled and riser is cut, the billet is opened, high-temperature forging and post-forging heat treatment are obtained to obtain ultra-high-strength alloy plates.

[0030] Specifically, the raw materials involved in the alloy smelting include: Al-Mo, Ti-Mo master alloy, pure Cr, pure aluminum beans, 0-grade sponge titanium and sponge zirconium. First of all, according to the design comp...

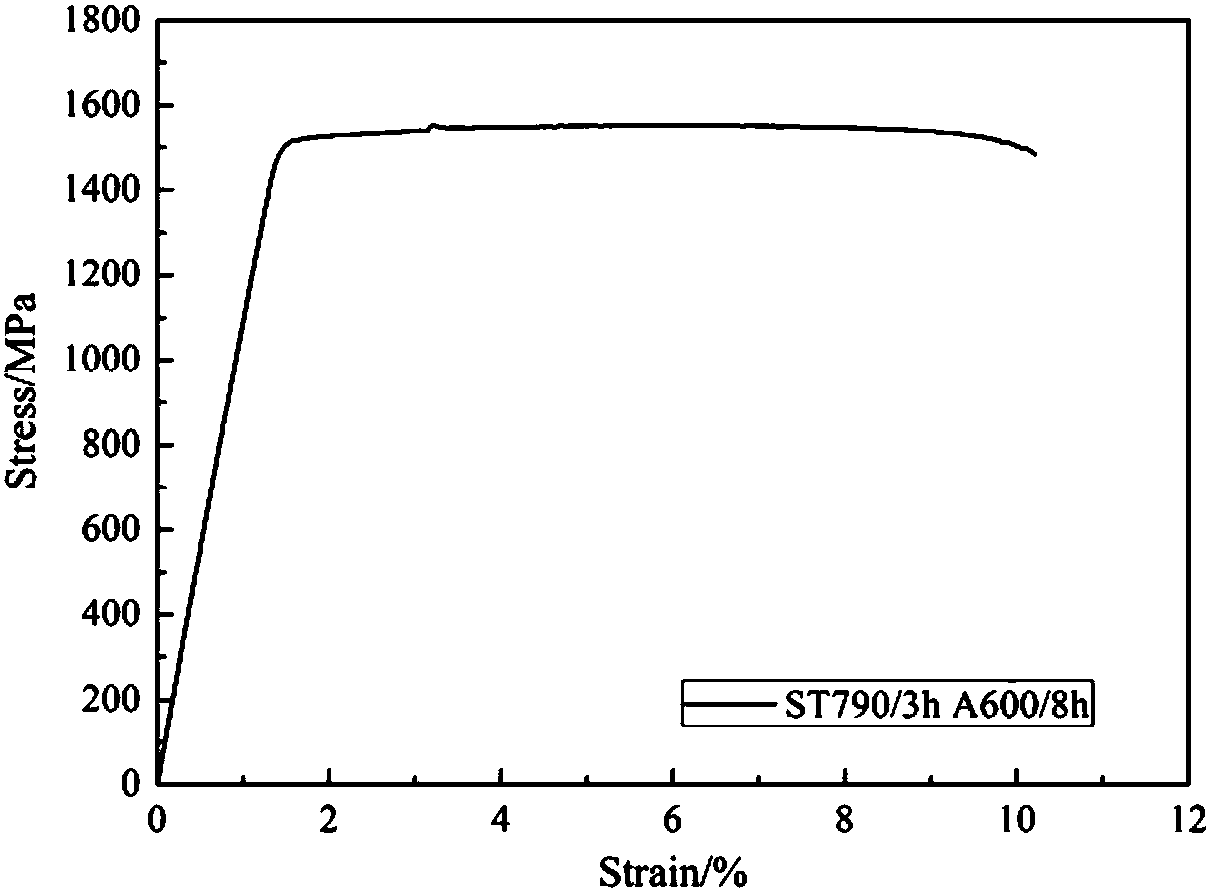

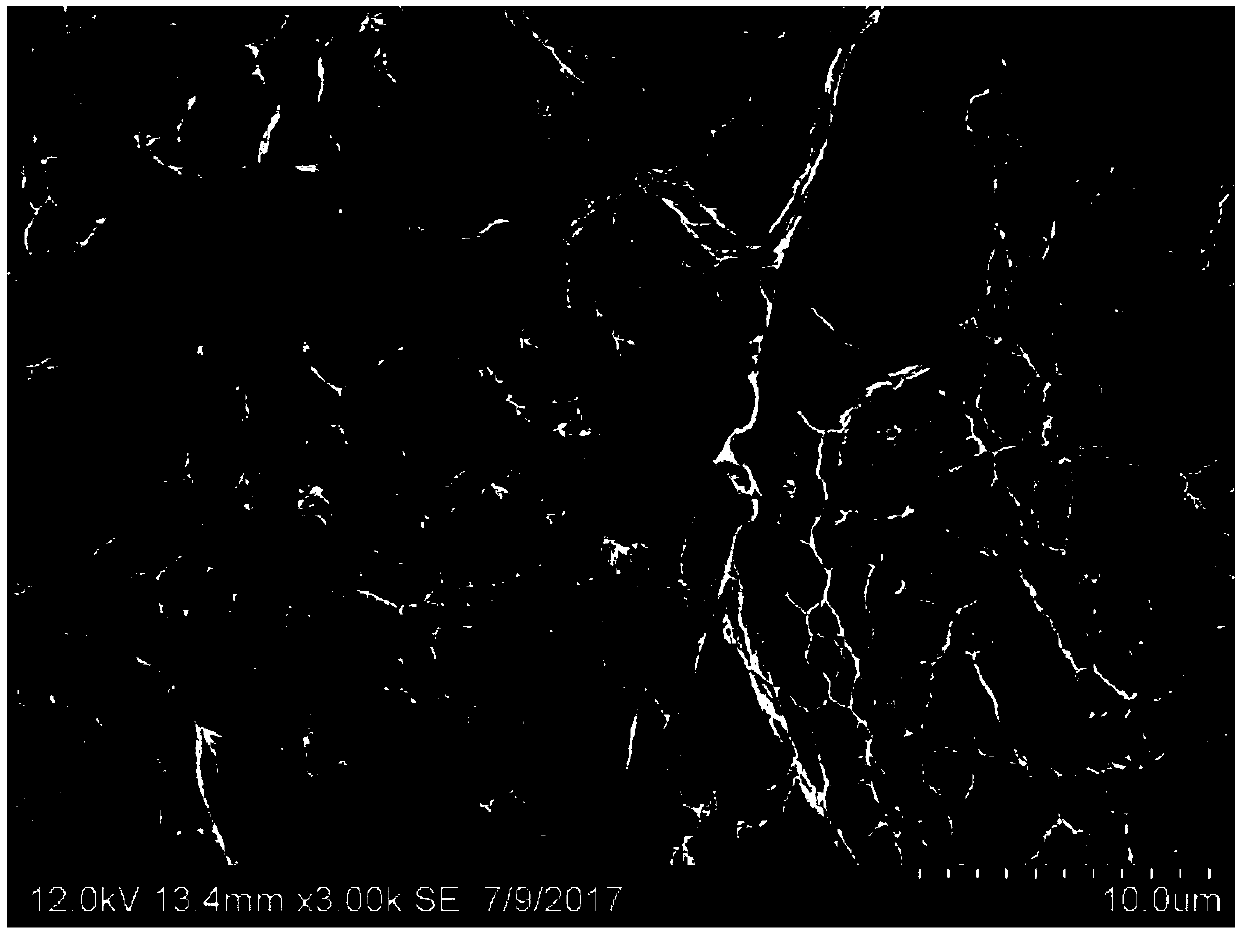

Embodiment 1

[0032] Ti-Al-Zr-Mo-Cr series β-titanium alloy is composed of the following components by weight percentage: 5-5.1% Al, 4.06-4.15% Zr, 9.8%-10% Mo, 3.03-3.15% Cr, The balance is Ti and unavoidable impurity elements.

[0033]According to the above design composition, Ti-32Mo, Al-62Mo master alloy, pure Cr, pure Al sponge titanium and sponge zirconium are mixed evenly according to the ratio and loaded into the furnace in bulk, followed by CCLM melting, and 400MPa high-purity argon gas is introduced during the melting process , the induction current is 350-400A, the current frequency is 20-25KHz, and it is kept for 3 minutes after the alloy is completely melted. In order to ensure uniform composition, the alloy was smelted three times, and the ingot was turned upside down and loaded into the furnace during the second and third smelting. The alloy composition and impurity content were measured by ICP-AES and elemental analyzer, as shown in Table 1. Using metallographic method and...

Embodiment 2

[0041] Ti-Al-Zr-Mo-Cr series β-titanium alloy is composed of the following components by weight percentage: 5-5.1% Al, 4.06-4.15% Zr, 9.8%-10% Mo, 3.03-3.15% Cr, The balance is Ti and unavoidable impurity elements.

[0042] According to the above design composition, Ti-32Mo, Al-62Mo master alloy, pure Cr, pure Al sponge titanium and sponge zirconium are mixed evenly according to the ratio and loaded into the furnace in bulk, followed by CCLM melting, and 400MPa high-purity argon gas is introduced during the melting process , the induction current is 350-400A, the current frequency is 20-25KHz, and it is kept for 3 minutes after the alloy is completely melted. In order to ensure uniform composition, the alloy was smelted three times, and the ingot was turned upside down and loaded into the furnace during the second and third smelting. The alloy composition and impurity content were measured by ICP-AES and elemental analyzer, as shown in Table 1. Using metallographic method an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com