Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

287 results about "Beta titanium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beta-titanium. Beta titanium alloys exhibit the BCC allotropic form of titanium (called beta). Elements used in this alloy are one or more of the following other than titanium in varying amounts. These are molybdenum, vanadium, niobium, tantalum, zirconium, manganese, iron, chromium, cobalt, nickel, and copper.

Processing of titanium-aluminum-vanadium alloys and products made thereby

InactiveUS20040221929A1Expensive to produceHigh energy input requirementMetal rolling arrangementsNitrogenTitanium

A method of forming an article from an alpha-beta titanium including, in weight percentages, from about 2.9 to about 5.0 aluminum, from about 2.0 to about 3.0 vanadium, from about 0.4 to about 2.0 iron, from about 0.2 to about 0.3 oxygen, from about 0.005 to about 0.3 carbon, from about 0.001 to about 0.02 nitrogen, and less than about 0.5 of other elements. The method comprises cold working the alpha-beta titanium alloy.

Owner:ATI PROPERTIES

Process for production of titanium alloy

InactiveUS6918942B2Inexpensive and reliable in qualityElectric furnaceBeta titanium alloyTitanium aluminum alloy

Owner:TOHO TITANIUM CO LTD

Method of straightening wire rods of titanium and titanium alloy

InactiveUS6077369ALow costImprove production yieldFurnace typesHeat treatment furnacesWire rodTitanium

PCT No. PCT / JP95 / 01897 Sec. 371 Date Mar. 19, 1997 Sec. 102(e) Date Mar. 19, 1997 PCT Filed Sep. 20, 1995A method of straightening a wire rod of titanium or titanium alloy wherein the rod is hot-straightened to a straight rod at the straightening temperature T and elongation epsilon satisfying the expression (1) or (2). The method includes hot rolling a titanium billet of beta titanium alloy, ( alpha + beta ) titanium alloy or a near alpha titanium alloy into a wire rod, winding the hot rolled wire rod into a coil, cold drawing the wire rod, cutting the wire rod to obtain a bent wire rod, heating the bent wire rod to a straightening temperature T while both end portions of the bent wire rod are fixed, applying a predetermined elongation epsilon to the wire rod, maintaining a straightening temperature T, hot-straightening the wire in accordance with the expression (2) epsilon (T-400)> / =400(1) epsilon (T-500)> / =200(2) and cooling the wire rod while applying tension. The method is suitable for preparing a straight rod for use in an engine valve.

Owner:NIPPON STEEL CORP

Methods of beta processing titanium alloys

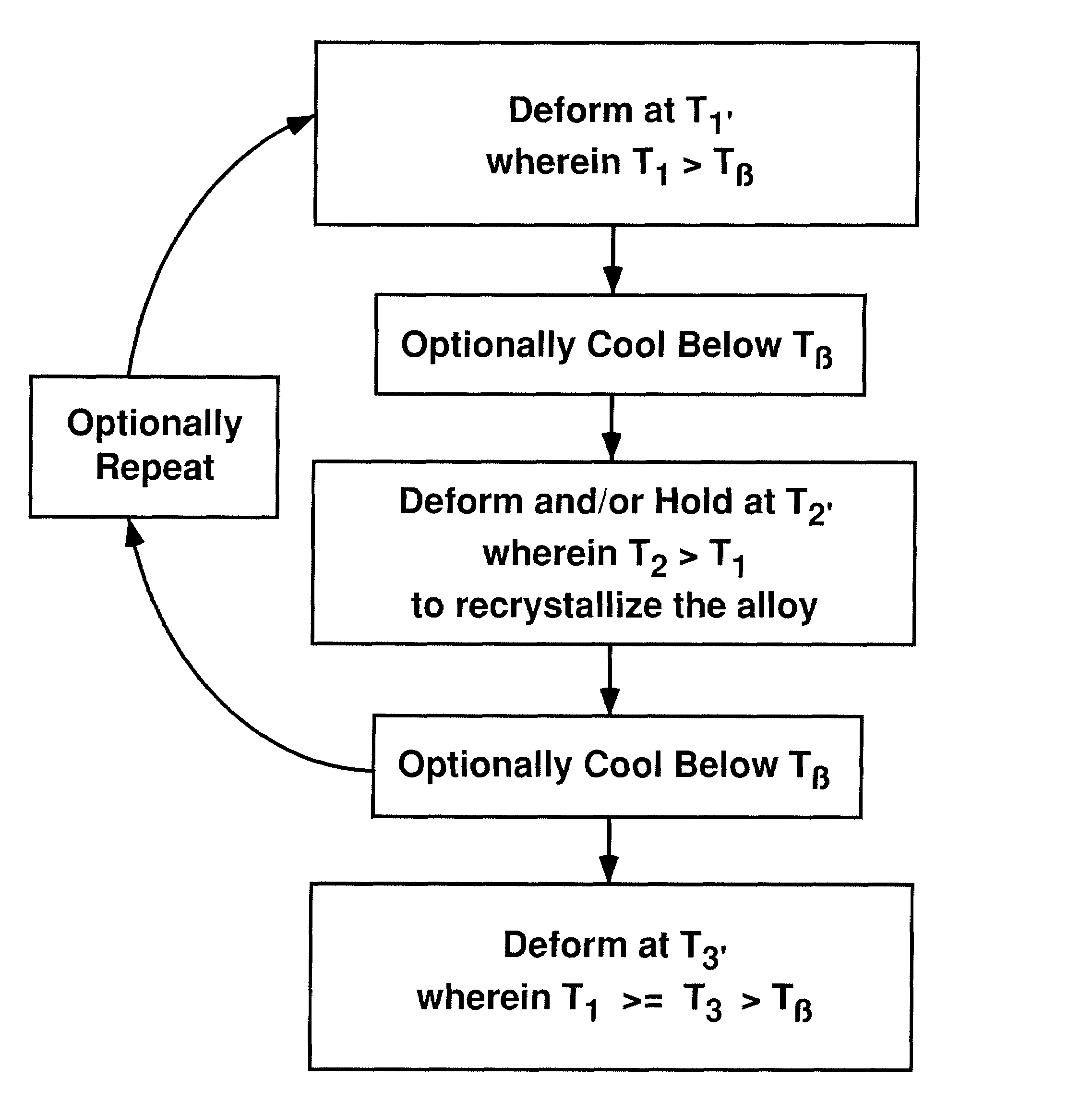

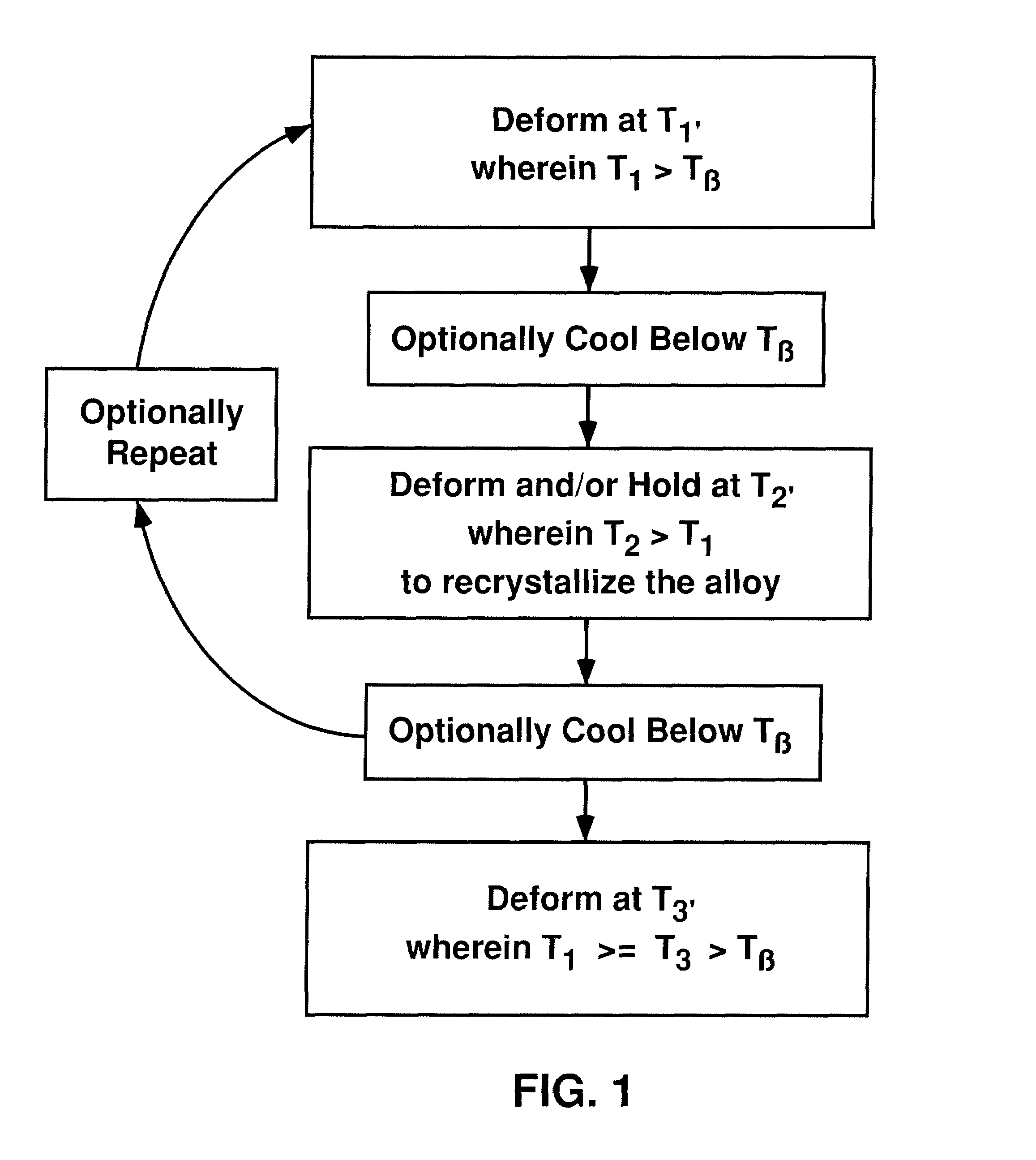

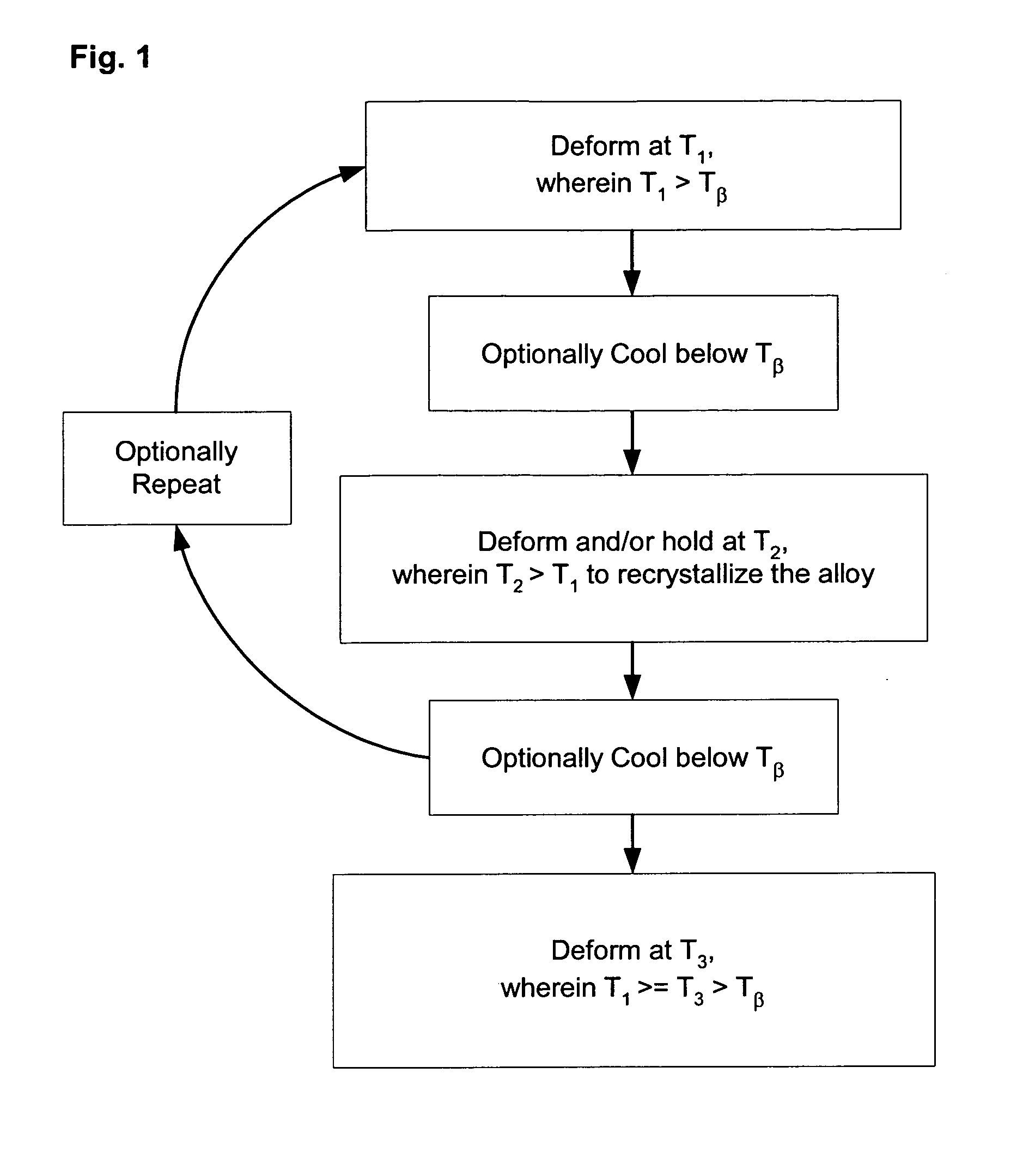

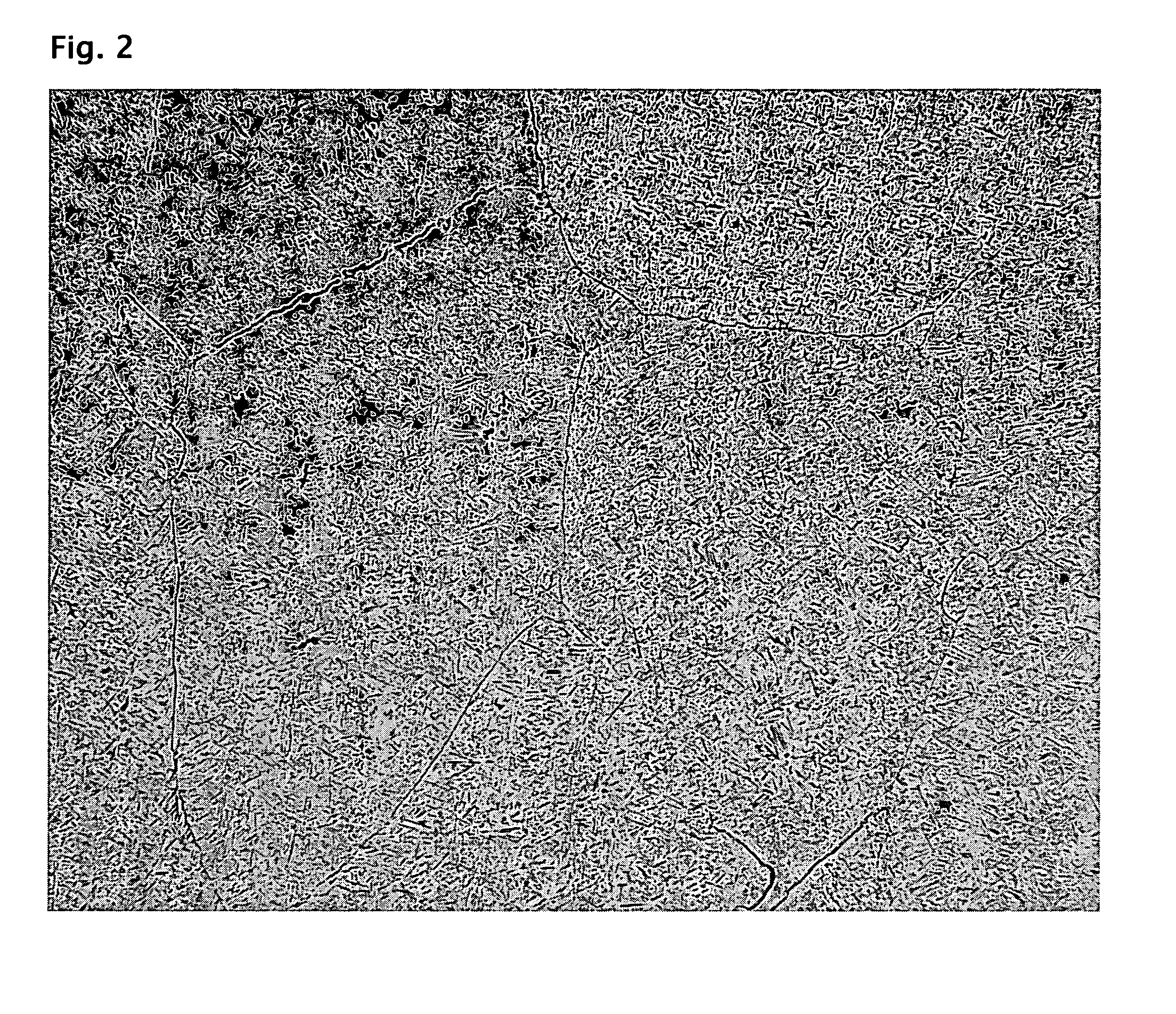

Various non-limiting embodiments of the present invention relate to methods of processing titanium alloys wherein the alloys are subjected to deformation above the beta transus temperature (Tβ) of the alloys. For example, one non-limiting embodiment provides a method of processing an alpha+beta or a near-beta titanium alloy comprising deforming a body of the alloy at a first temperature (T1) that is above the Tβ of the alloy; recrystallizing at least a portion of the alloy by deforming and / or holding the body at a second temperature (T2) that is greater than T1; and deforming the body at a third temperature (T3), wherein T1≧T3>Tβ; wherein essentially no deformation of the body occurs at a temperature below Tβ during the method of processing the titanium alloy.

Owner:ATI PROPERTIES

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

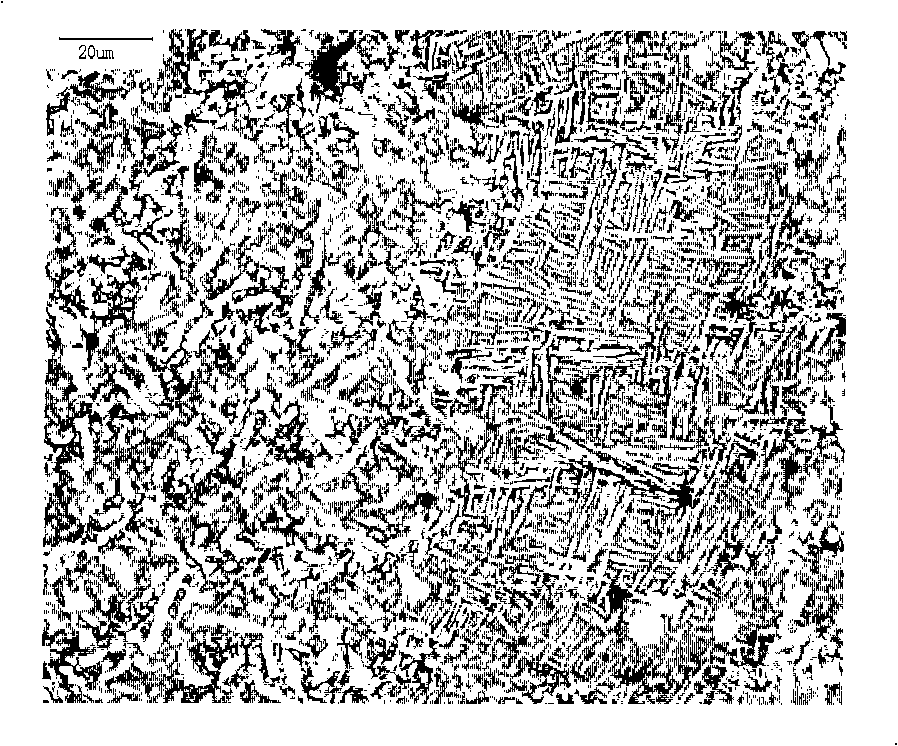

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS7264682B2High wear and corrosion and oxidation resistanceResistance to galling and seizureSolid state diffusion coatingMetal boridesBorideTitanium surface

Owner:UNIV OF UTAH RES FOUND

Process for preparing biomedical beta-titanium alloy

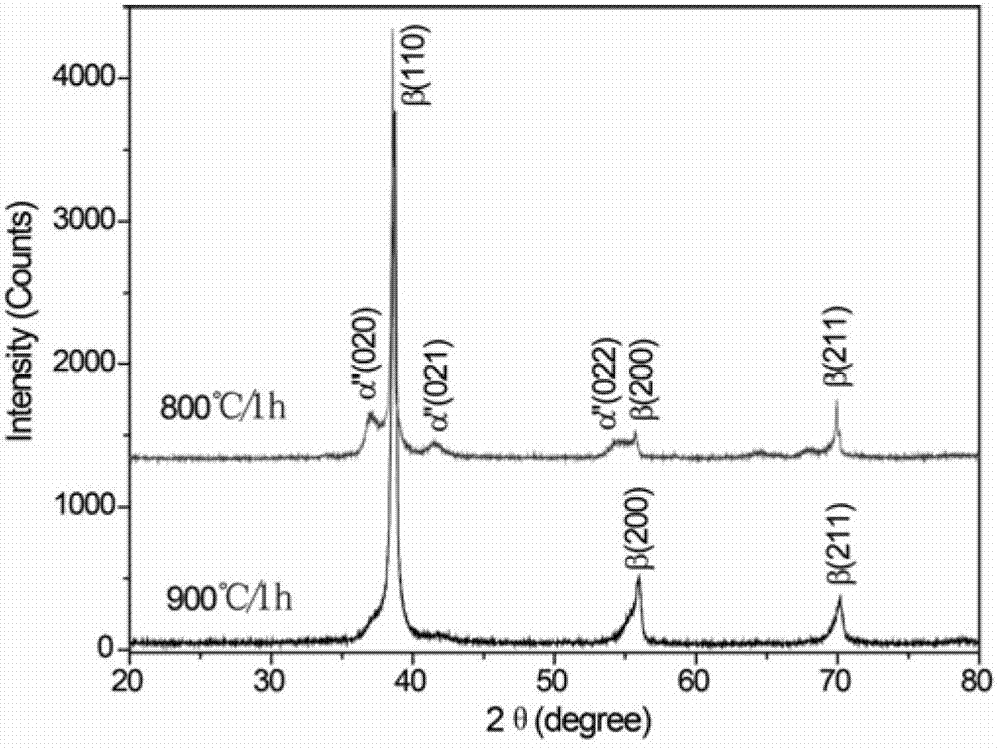

InactiveCN101724764AImprove performanceHigh strengthImpression capsFurnace typesMaterials processingQuenching

The invention discloses a process for preparing a biomedical beta-titanium alloy. The process comprises the following steps: A) alloy preparation; B) surface coating; C) hot forging and cogging; D) hot rolling; E) cold rolling and molding; and F) heat treatment. In the process, the material is manufactured to a 2mm plate after the beta-titanium alloy is subjected to high vacuum electric arc melting, repeated stirring, casting, phase transformation point measuring, homogenization under the protection of vacuum and argon, coating, hot forging, hot rolling, cold rolling, solid solution, water quenching, artificial aging and water cooling so as to prepare the biomedical beta-titanium alloy with excellent comprehensive performance. The process is a biomedical beta-titanium preparation process capable of improving the material strength, abrasion resistance and corrosion resistance, reducing the elasticity modulus of the material, and maintaining excellent manufacturing and molding performance of the material.

Owner:CENT SOUTH UNIV

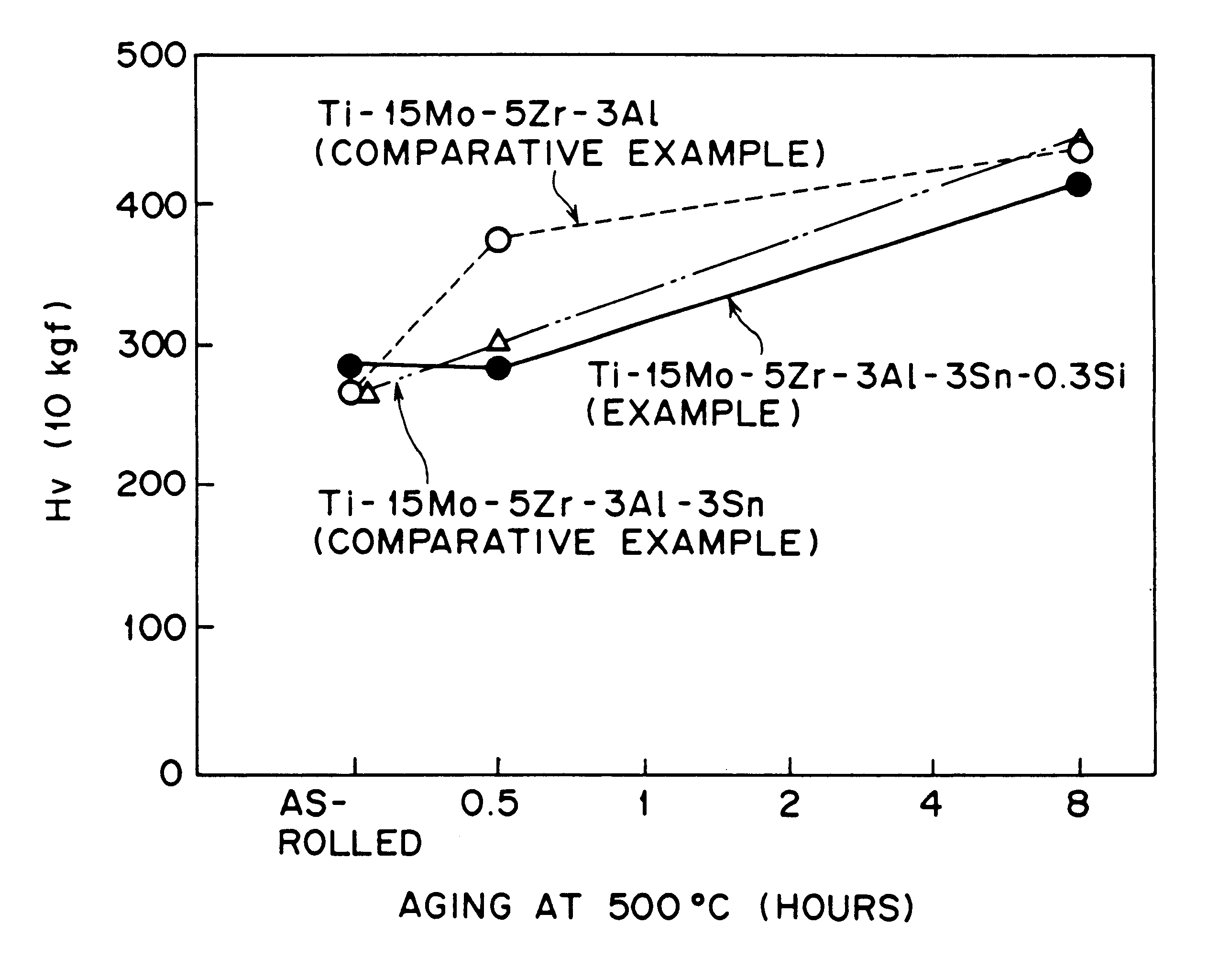

Titanium alloy and production thereof

A near-beta or beta titanium alloy having high strength, high ductility, and high toughness which is capable of coil rolling at a high temperature and recoiling for high productivity, and a process for producing said titanium alloy. The titanium alloy contains not more than 1.0% (excluding 0%) of Si alone or in combination with not more than 10% of Sn. The process comprises heating a beta alloy or near-beta alloy containing not more than 1.0% (excluding 0%) of Si alone or in combination with not more than 10% of Sn and subjecting said alloy to plastic deformation while keeping silicides solved in it at a temperature above the beta-transus, so that silicides precipitate in the form of fine particles, with recrystallization suppressed. The resulting titanium alloy is good in workability and has high strength after aging treatment.< / PTEXT>

Owner:LG PHILIPS LCD CO LTD +1

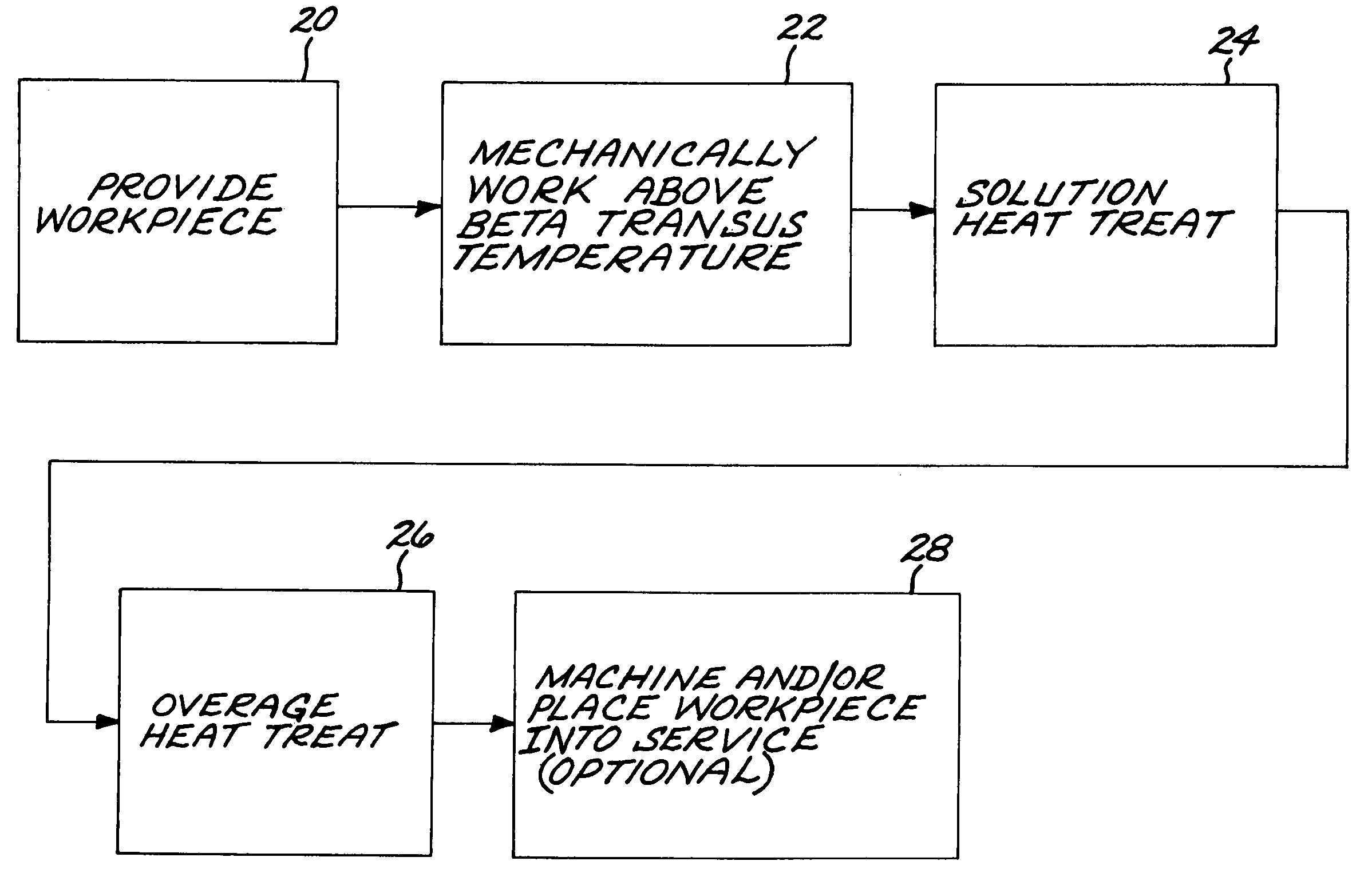

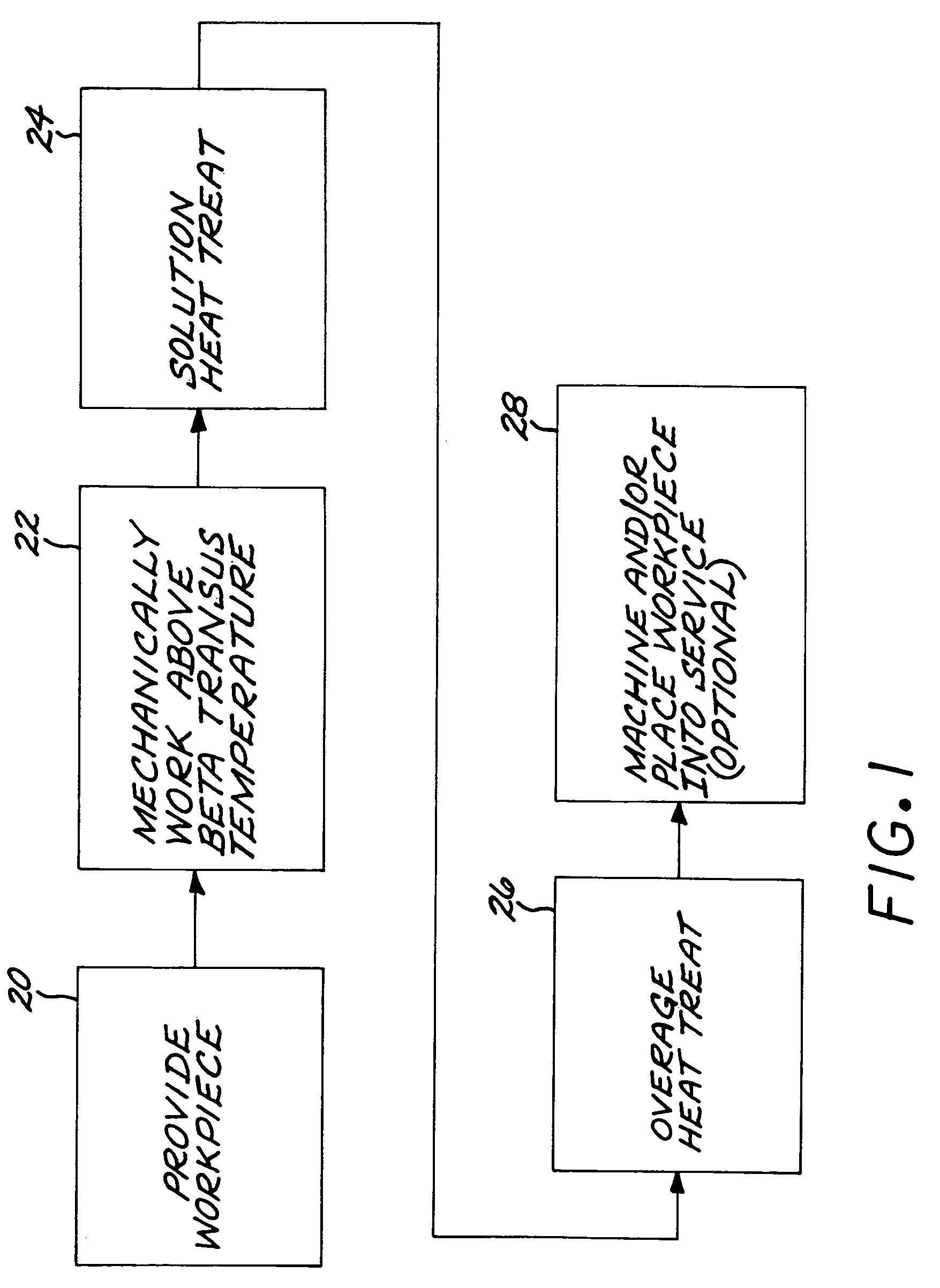

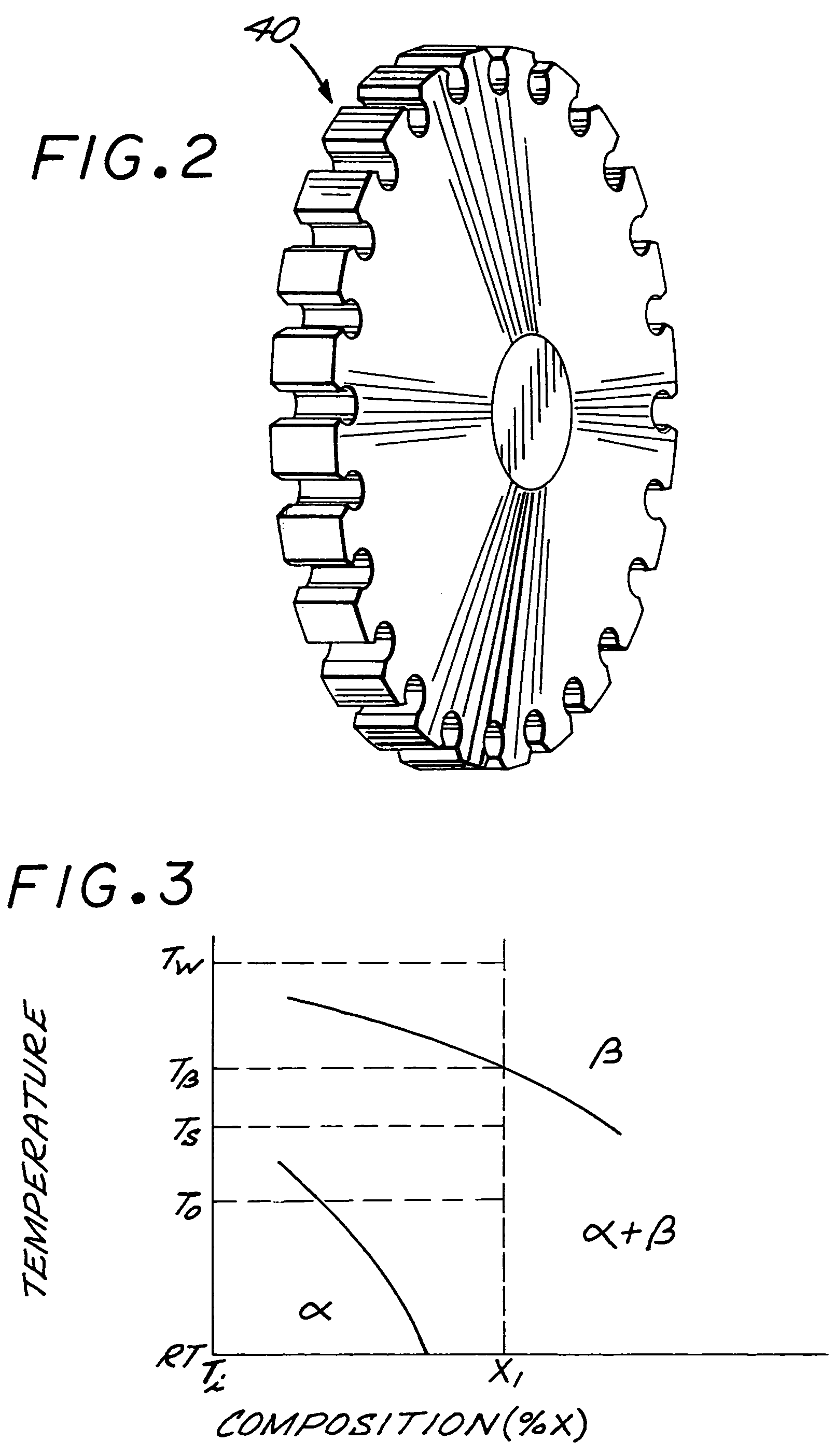

Method for producing a beta-processed alpha-beta titanium-alloy article

InactiveUS7449075B2Improve mechanical propertiesReduce anisotropyGreek letter betaWorking temperature

A titanium-alloy article is produced by providing a workpiece of an alpha-beta titanium alloy having a beta-transus temperature, and thereafter mechanically working the workpiece at a mechanical-working temperature above the beta-transus temperature. The mechanically worked workpiece is solution heat treated at a solution-heat-treatment temperature of from about 175° F. below the beta-transus temperature to about 25° F. below the beta-transus temperature, quenched, overage heat treated at an overage-heat-treatment temperature of from about 400° F. below the beta-transus temperature to about 275° F. below the beta-transus temperature, and cooled from the overage-heat-treatment temperature.

Owner:GENERAL ELECTRIC CO

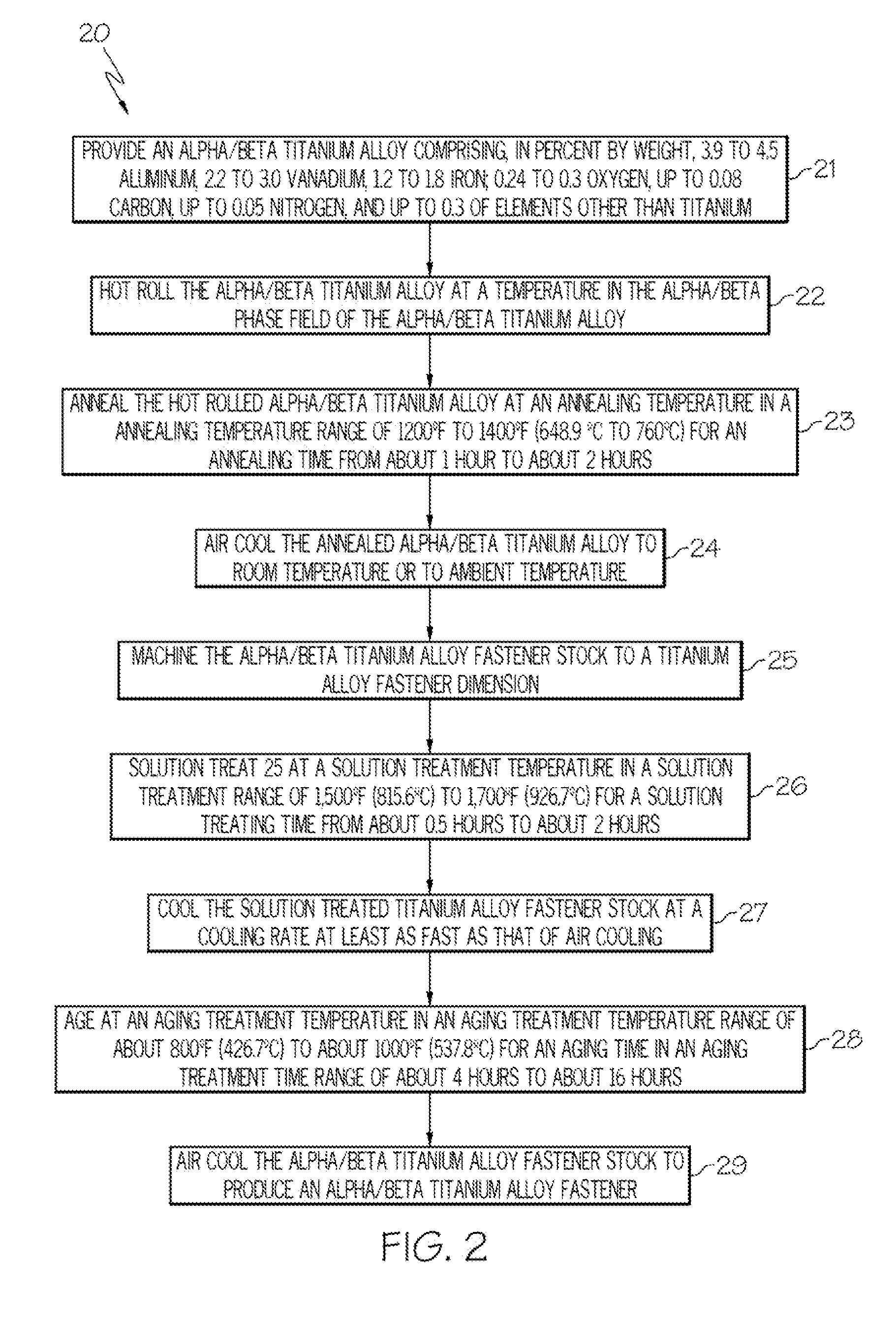

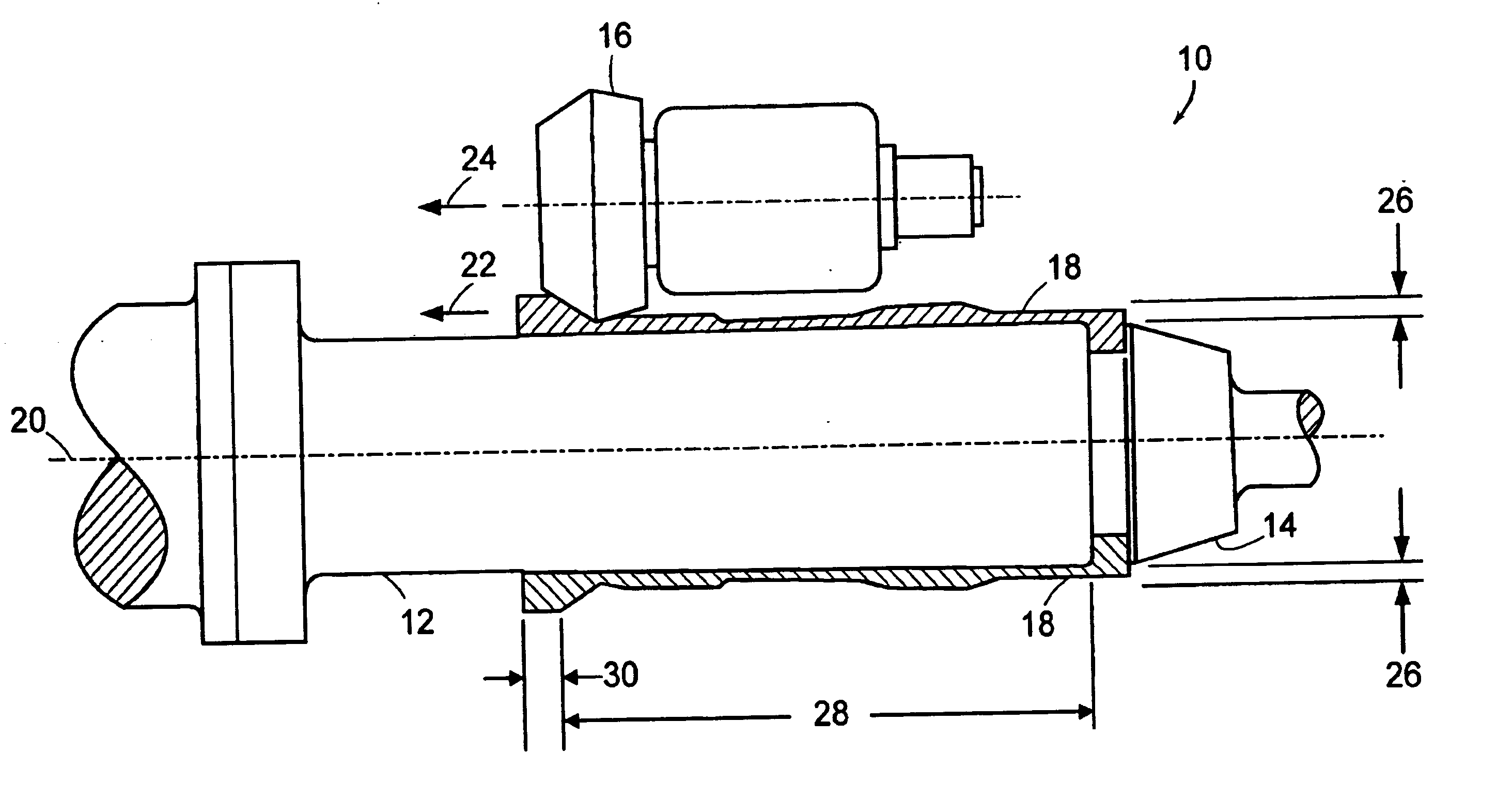

High strength alpha/beta titanium alloy fasteners and fastener stock

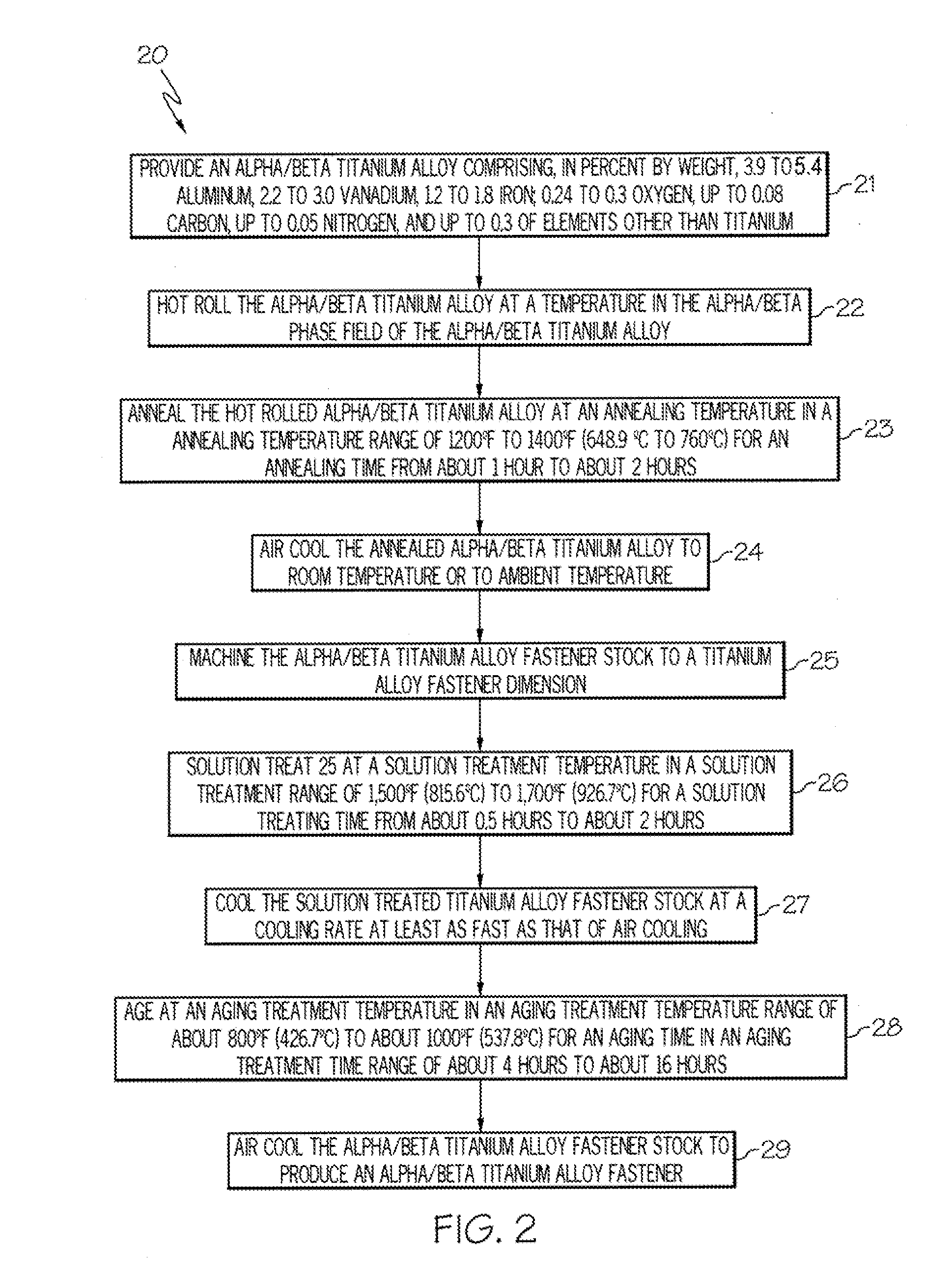

An article of manufacture selected from a titanium alloy fastener and a titanium alloy fastener stock including an alpha / beta titanium alloy comprising, in percent by weight: 3.9 to 4.5 aluminum; 2.2 to 3.0 vanadium; 1.2 to 1.8 iron; 0.24 to 0.3 oxygen; up to 0.08 carbon; up to 0.05 nitrogen; titanium; and up to a total of 0.3 of other elements. In certain embodiments, article of manufacture has an ultimate tensile strength of at least 170 ksi (1,172 MPa) and a double shear strength of at least 103 ksi (710.2 MPa). A method of manufacturing a titanium alloy fastener and a titanium alloy fastener stock comprising the alpha / beta alloy is disclosed.

Owner:ATI PROPERTIES LLC

High Strength Alpha/Beta Titanium Alloy Fasteners and Fastener Stock

An article of manufacture selected from a titanium alloy fastener and a titanium alloy fastener stock including an alpha / beta titanium alloy comprising, in percent by weight: 3.9 to 5.4 aluminum; 2.2 to 3.0 vanadium; 1.2 to 1.8 iron; 0.24 to 0.3 oxygen; up to 0.08 carbon; up to 0.05 nitrogen; titanium; and up to a total of 0.3 of other elements. In certain embodiments, article of manufacture has an ultimate tensile strength of at least 170 ksi (1,172 MPa) and a double shear strength of at least 103 ksi (710.2 MPa). A method of manufacturing a titanium alloy fastener and a titanium alloy fastener stock comprising the alpha / beta alloy is disclosed.

Owner:ATI PROPERTIES

Titanium alloy and production thereof

A near-beta or beta titanium alloy having high strength, high ductility, and high toughness which is capable of coil rolling at a high temperature and recoiling for high productivity, and a process for producing said titanium alloy. The titanium alloy contains not more than 1.0% (excluding 0%) of Si alone or in combination with not more than 10% of Sn. The process comprises heating a beta alloy or near-beta alloy containing not more than 1.0% (excluding 0%) of Si alone or in combination with not more than 10% of Sn and subjecting said alloy to plastic deformation while keeping silicides solved in it at a temperature above the beta-transus, so that silicides precipitate in the form of fine particles, with recrystallization suppressed. The resulting titanium alloy is good in workability and has high strength after aging treatment.

Owner:LG PHILIPS LCD CO LTD +1

Methods of beta processing titanium alloys

ActiveUS20070193018A1Reduce eliminate occurrenceMetal rolling stand detailsMetal working apparatusGreek letter betaTitanium

Various non-limiting embodiments of the present invention relate to methods of processing titanium alloys wherein the alloys are subjected to deformation above the beta transus temperature (Tβ) of the alloys. For example, one non-limiting embodiment provides a method of processing an alpha+beta or a near-beta titanium alloy comprising deforming a body of the alloy at a first temperature (T1) that is above the Tβ of the alloy; recrystallizing at least a portion of the alloy by deforming and / or holding the body at a second temperature (T2) that is greater than T1; and deforming the body at a third temperature (T3), wherein T1≧T3>Tβ; wherein essentially no deformation of the body occurs at a temperature below Tβ during the method of processing the titanium alloy.

Owner:ATI PROPERTIES

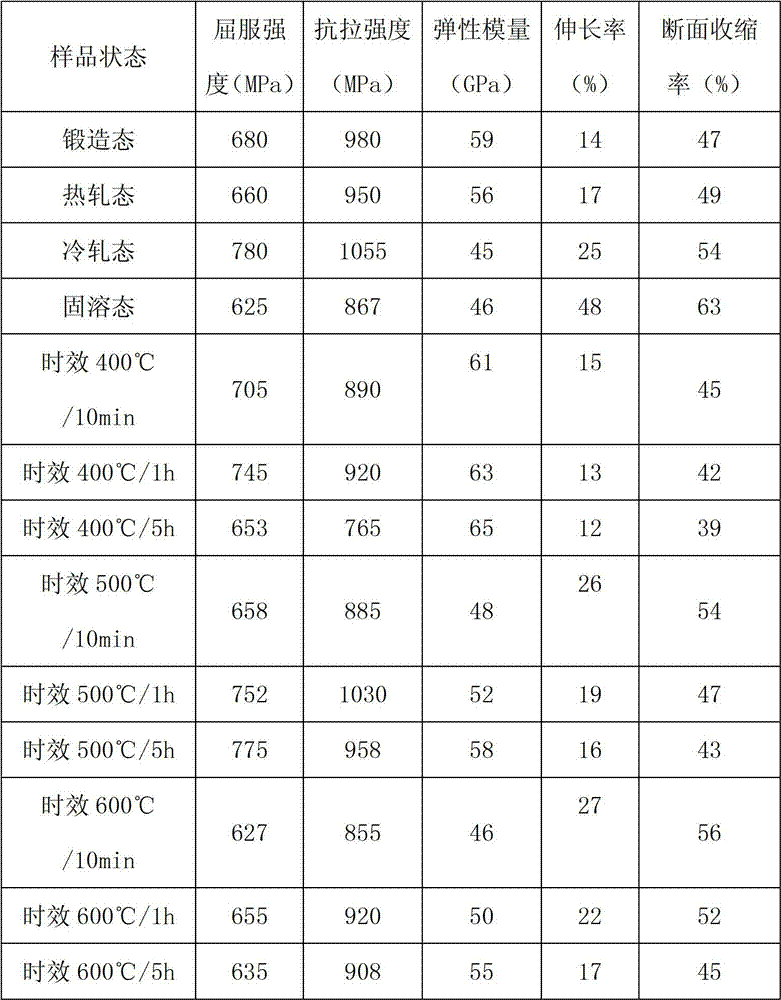

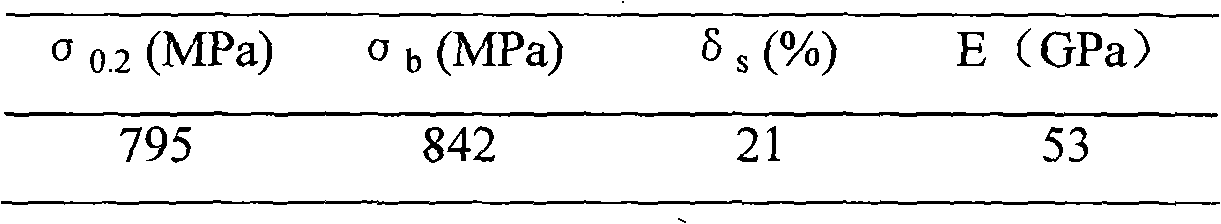

Biomedical beta-titanium alloy material and preparation method

The invention relates to a biomedical beta-titanium alloy material and a preparation method, and belongs to the technical field of preparation of titanium alloy materials with high niobium content. The alloy comprises the following components in percentage by mass: 30-40 percent of Nb, 5-15 percent of Zr, 1-10 percent of Sn, 0.1 and 0.3 percent of O and the balance of Ti. The titanium alloy has high comprehensive performance, and the strength and the elastic modulus of the alloy can be modulated and controlled by different heat treatment processes; the elastic modulus E of the alloy is 40-68GPa; the yield strength sigma 0.2 is 580-800MPa; the tensile strength sigma b is 750-1120MPa; the elongation ratio epsilon is 12-48 percent; and the section shrinking percentage is 36-65 percent. The titanium alloy does not contain toxic elements, has excellent corrosion resistance, biocompatibility and cold treating performance, and can perform cold rolling in a large deformation amount. The titanium alloy is wide in use, so that the titanium alloy can be used for manufacturing tissue recovery or replacement materials of a human body of mouth rehabilitation, artificial bone, joint prosthesis and the like, and also can be used for manufacturing machines in sports and industry.

Owner:BAOJI TITANIUM IND +1

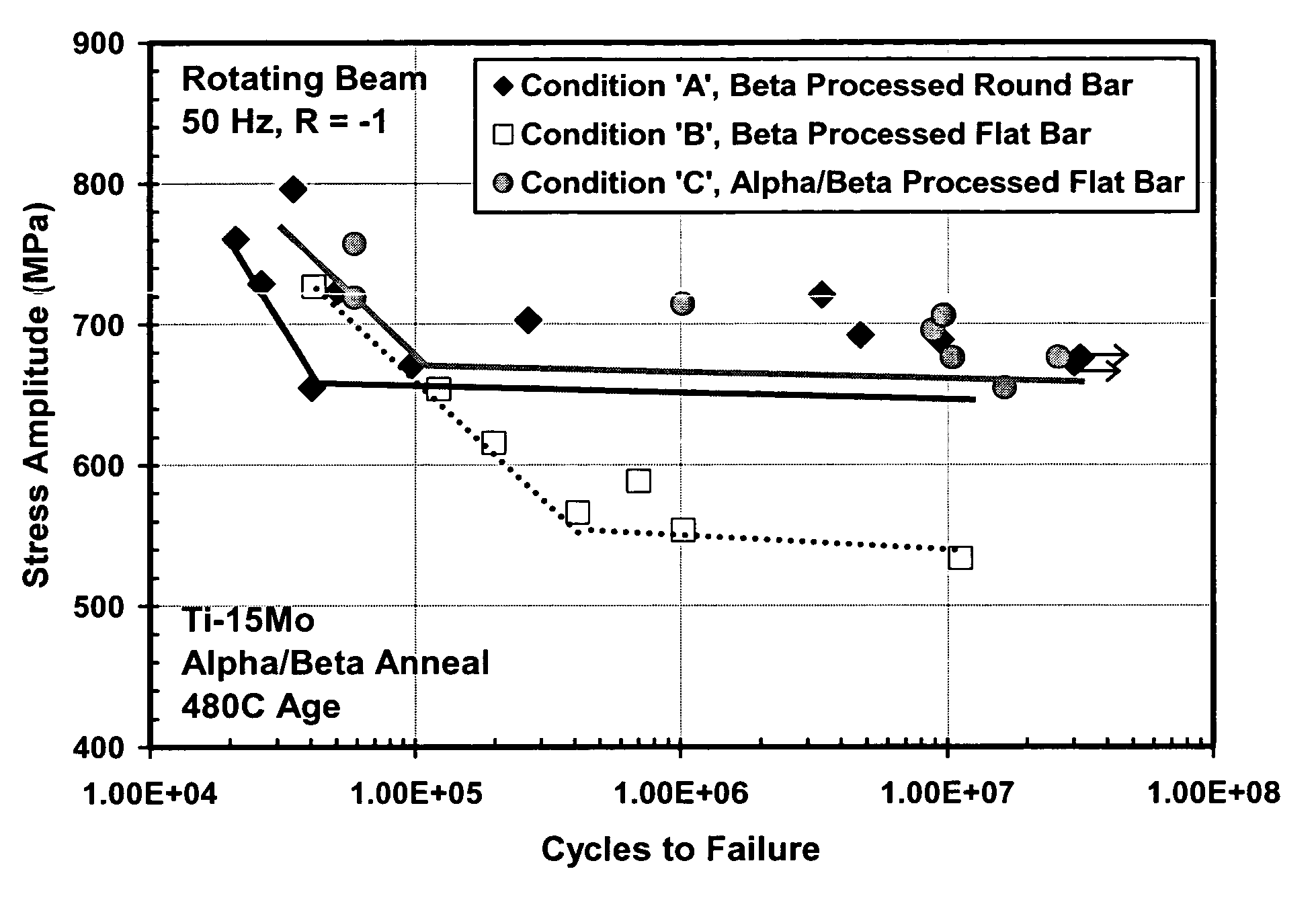

Metastable beta-titanium alloys and methods of processing the same by direct aging

Owner:ATI PROPERTIES LLC

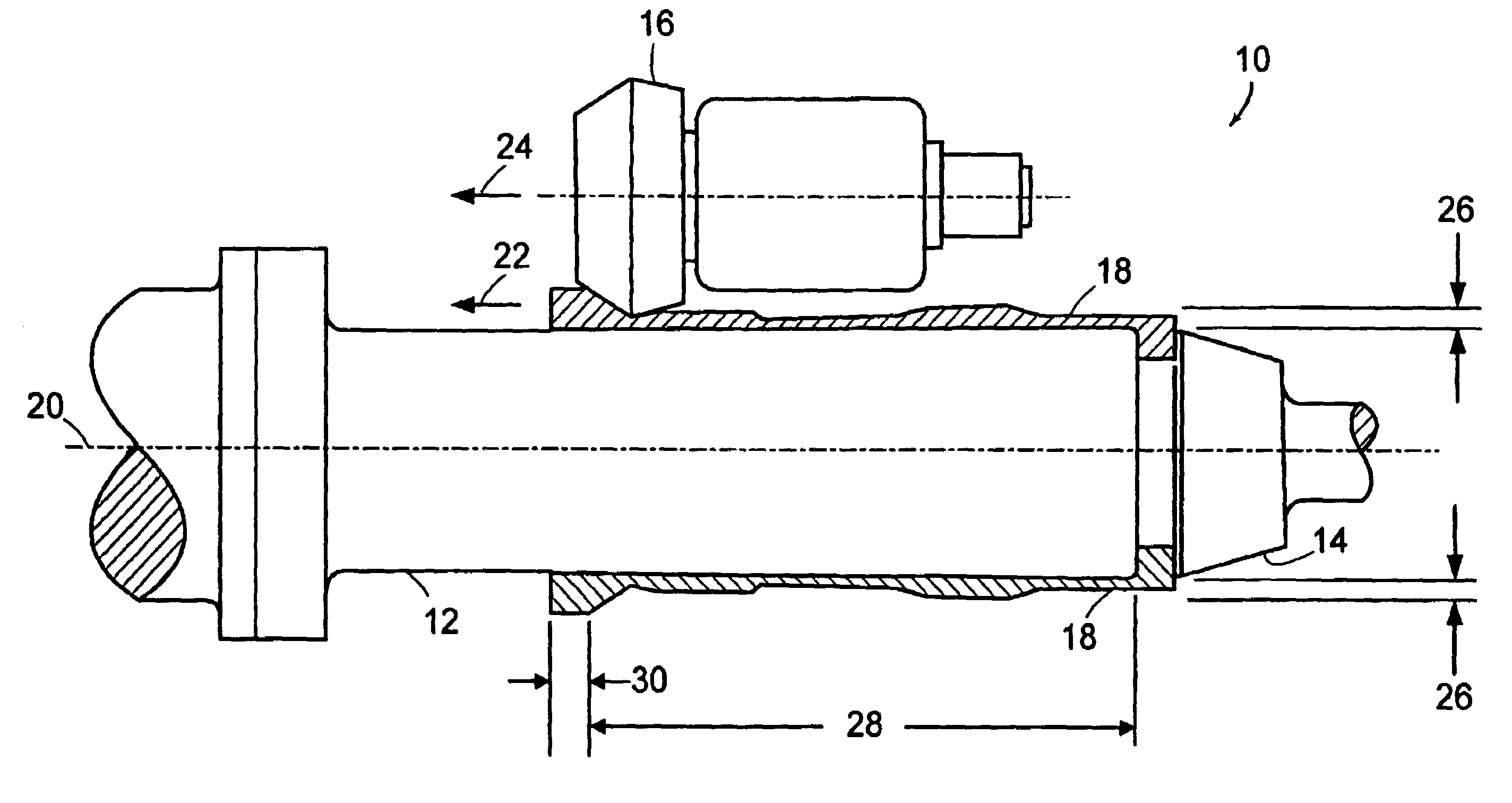

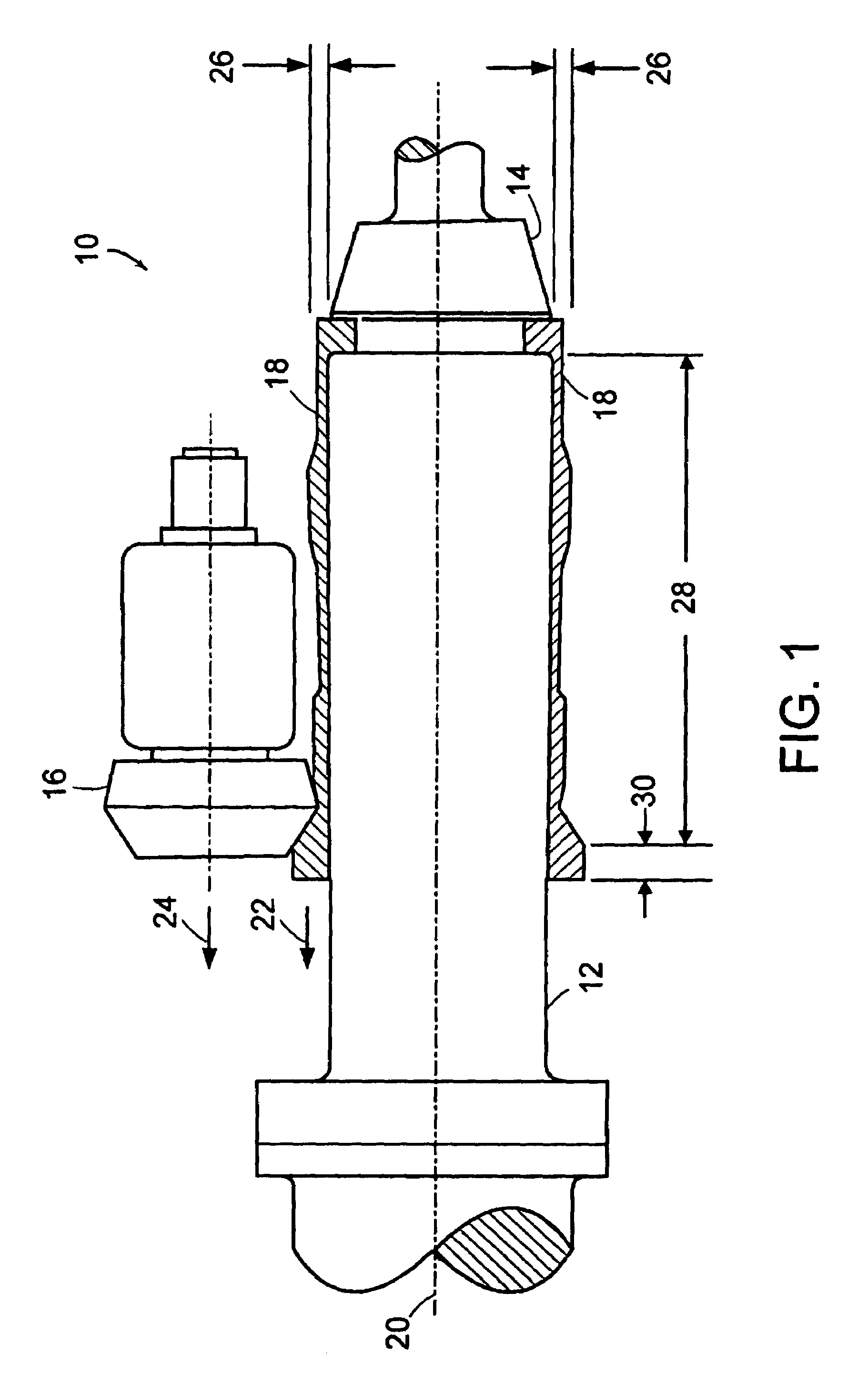

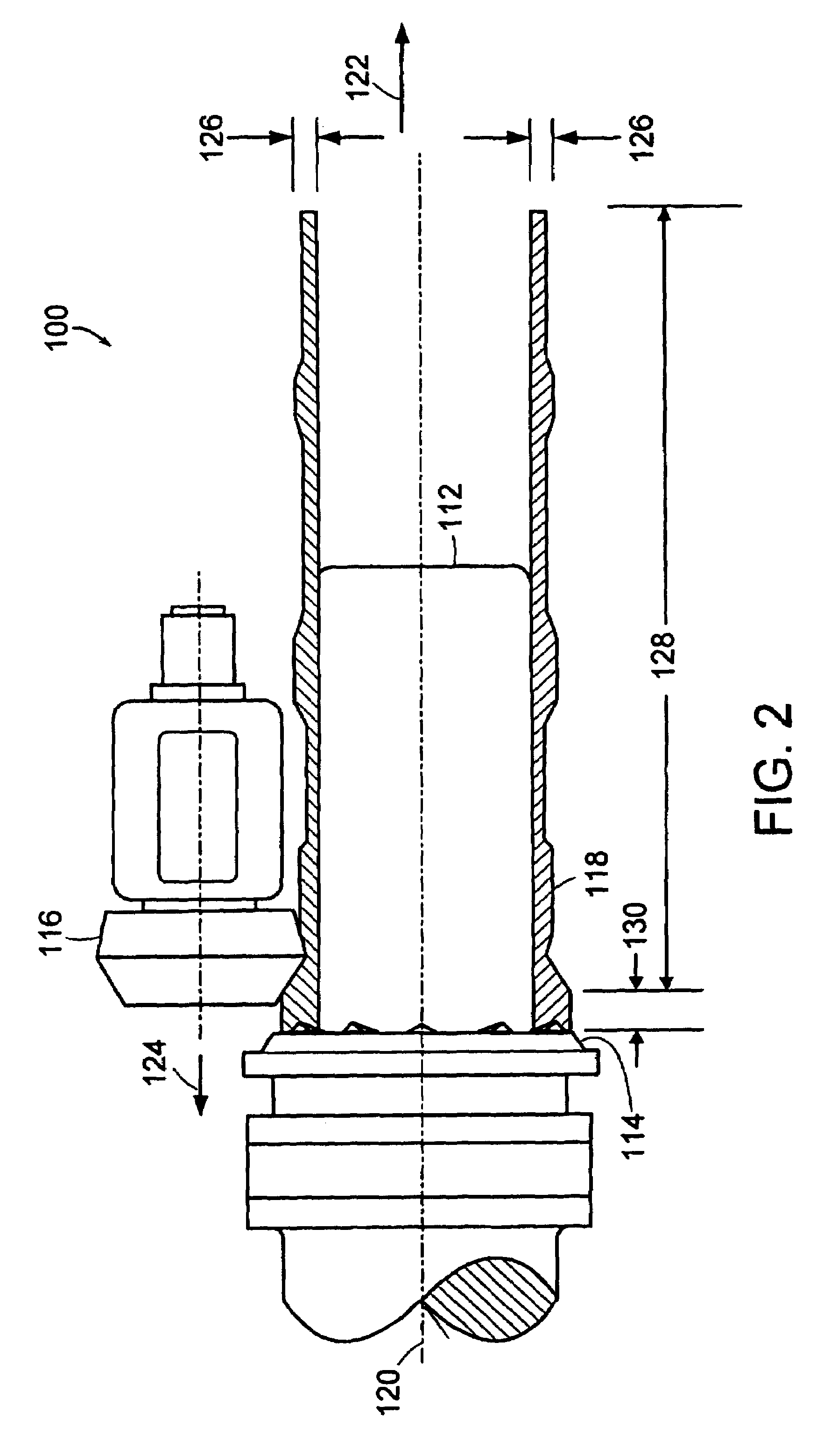

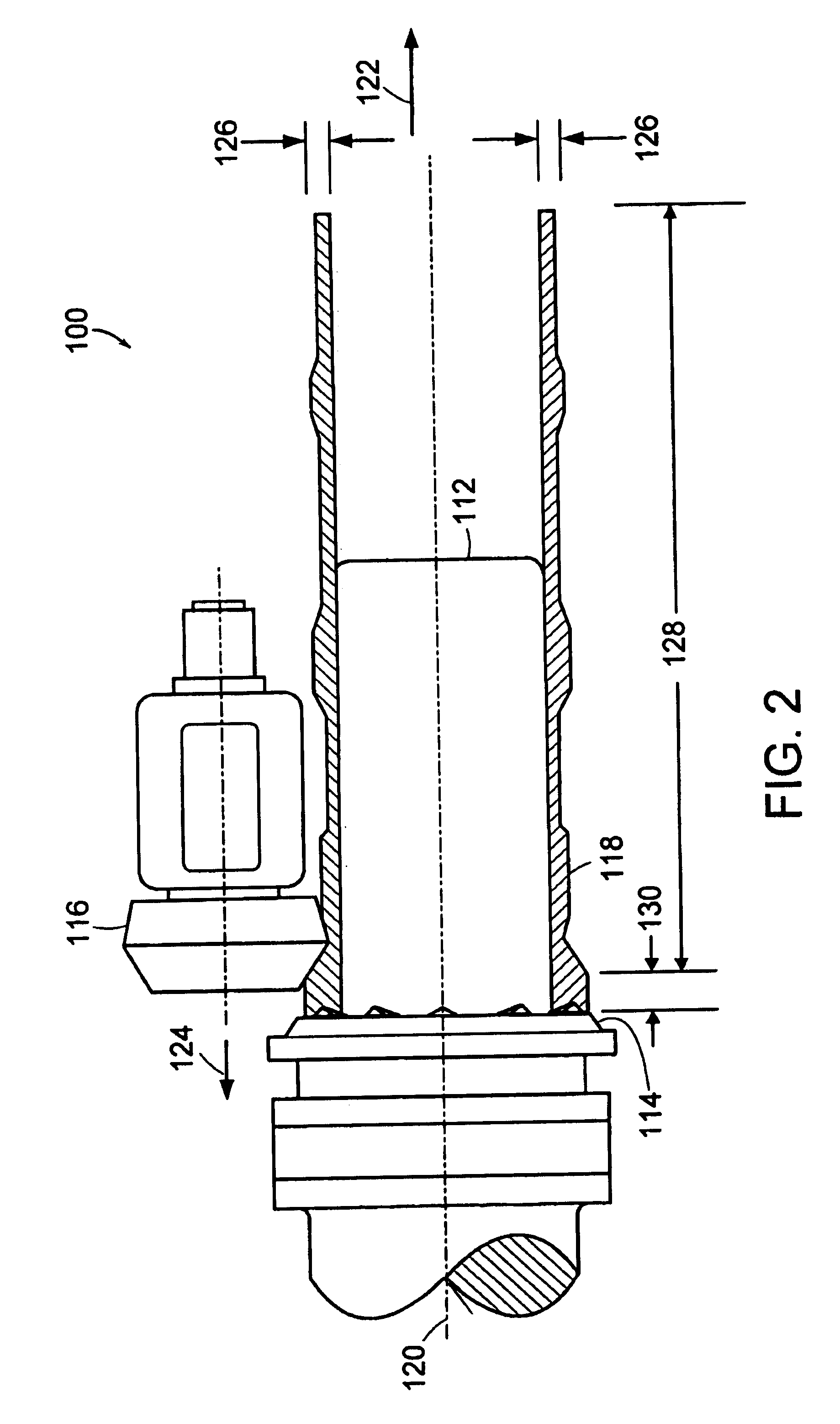

Alpha-beta titanium alloy tubes and methods of flowforming the same

Described herein are methods for forming titanium alloy tubes having an α-β grain structure. The methods include the steps of hot-working a titanium alloy workpiece at a temperature below the β-transus temperature of the workpiece and above the recrystallization temperature of the workpiece to produce an α-β titanium alloy preform hollow. Subsequently, the α-β titanium alloy preform hollow is flowformed, thereby forming a α-β titanium alloy tube.

Owner:ATI FLOWFORM PROD

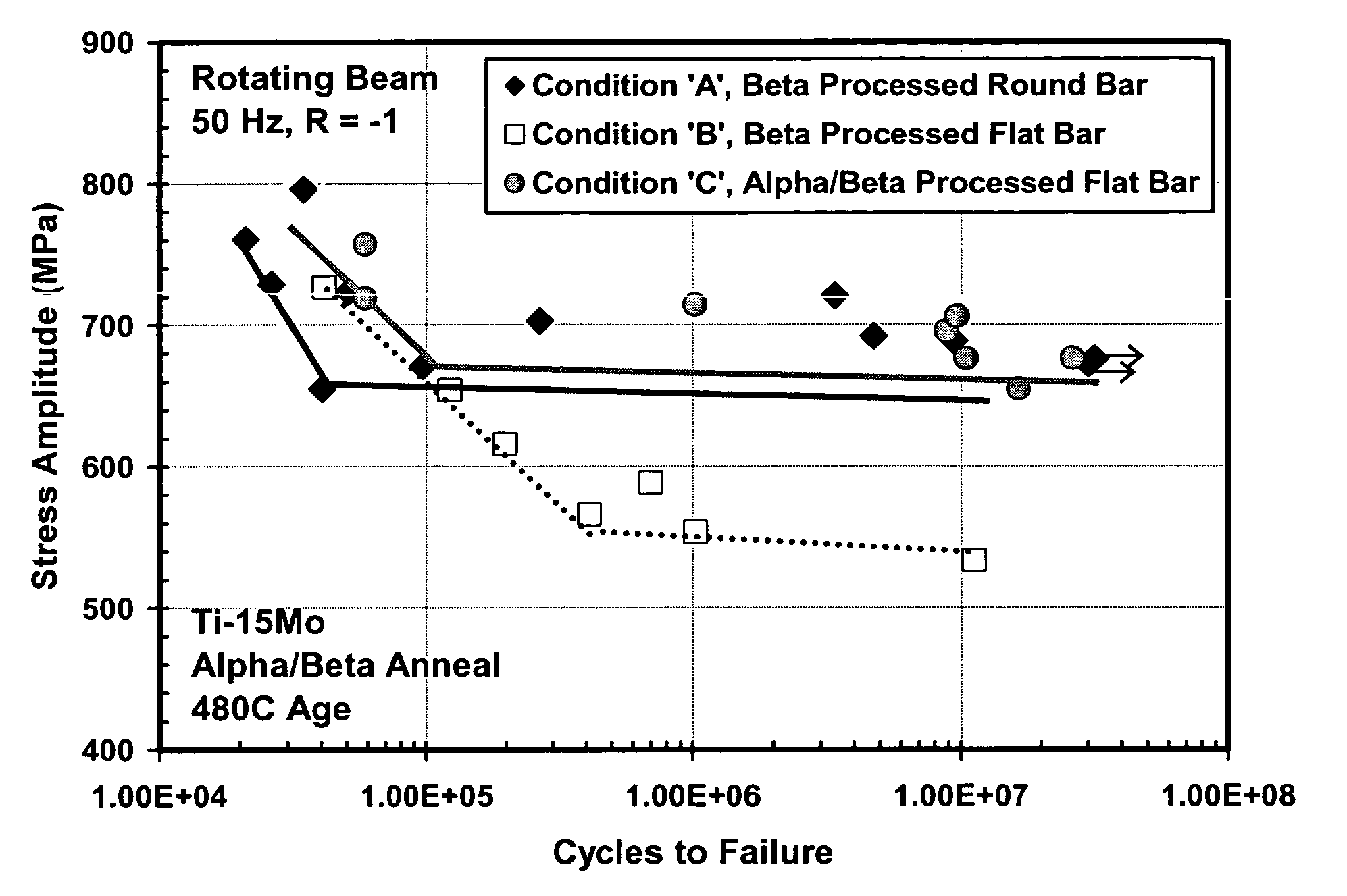

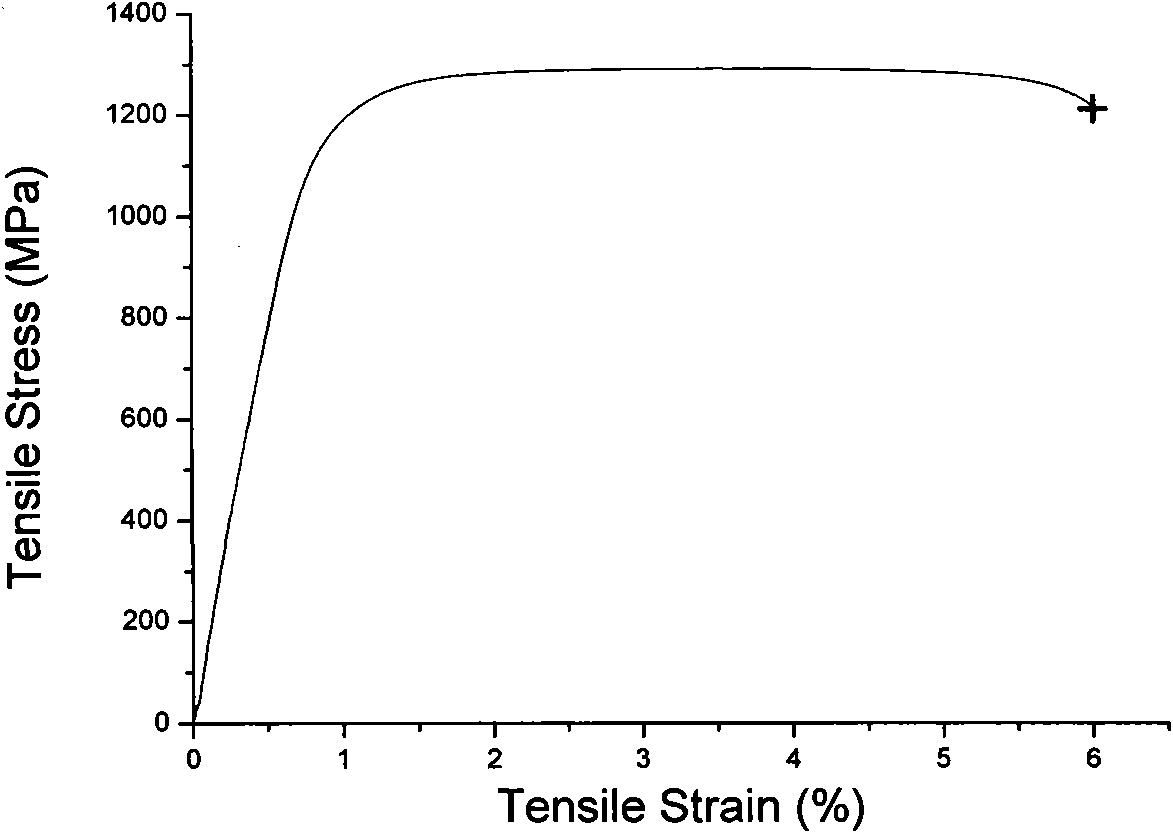

Metastable beta-titanium alloys and methods of processing the same by direct aging

Metastable beta titanium alloys and methods of processing metastable β-titanium alloys are disclosed. For example, certain non-limiting embodiments relate to metastable β-titanium alloys, such as binary β-titanium alloys comprising greater than 10 weight percent molybdenum, having tensile strengths of at least 150 ksi and elongations of at least 12 percent. Other non-limiting embodiments relate to methods of processing metastable β-titanium alloys, and more specifically, methods of processing binary β-titanium alloys comprising greater than 10 weight percent molybdenum, wherein the method comprises hot working and direct aging the metastable β-titanium alloy at a temperature below the β-transus temperature of the metastable β-titanium alloy for a time sufficient to form α-phase precipitates in the metastable β-titanium alloy. Articles of manufacture comprising binary β-titanium alloys according to various non-limiting embodiments disclosed herein are also disclosed.

Owner:ATI PROPERTIES LLC

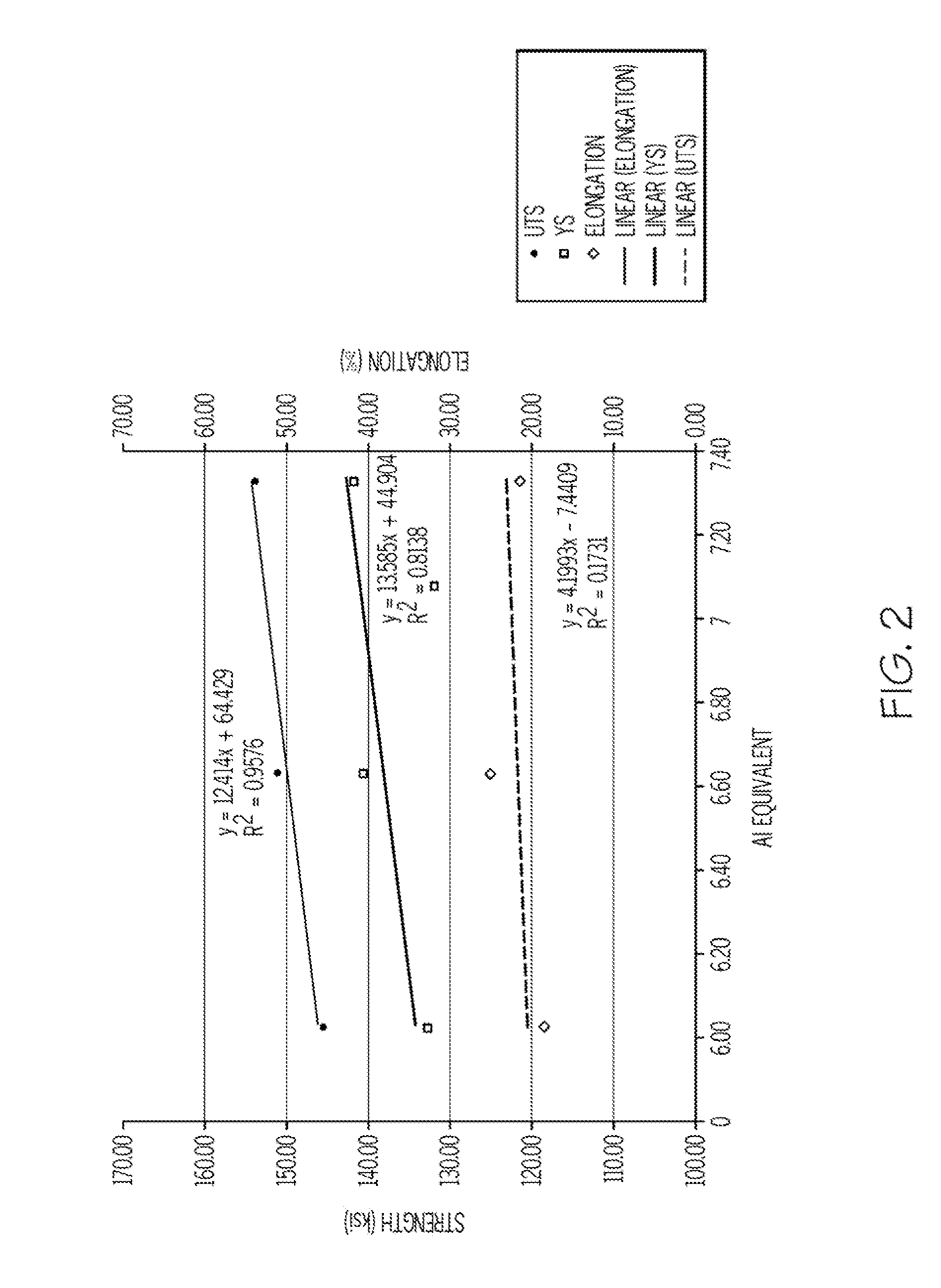

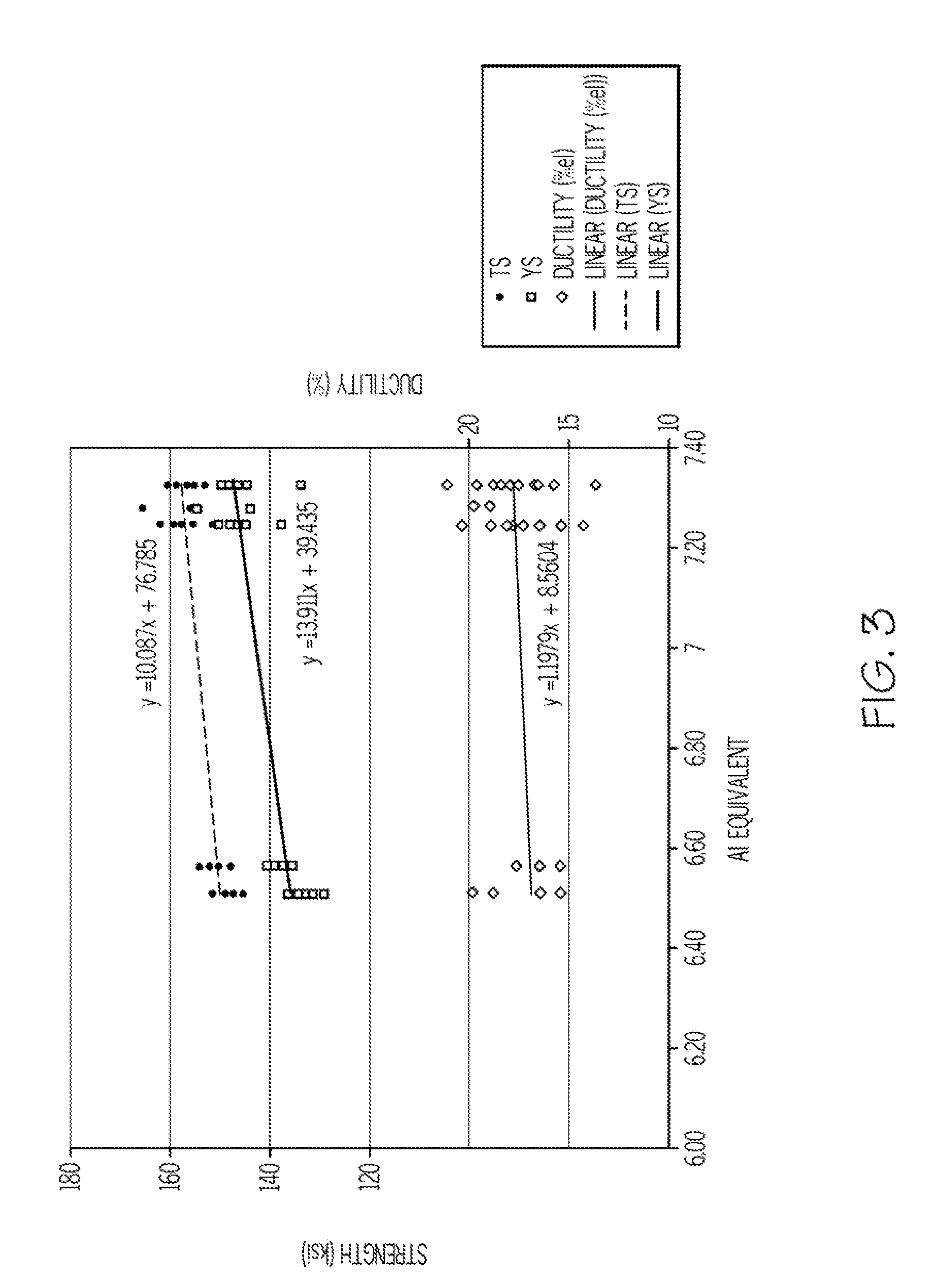

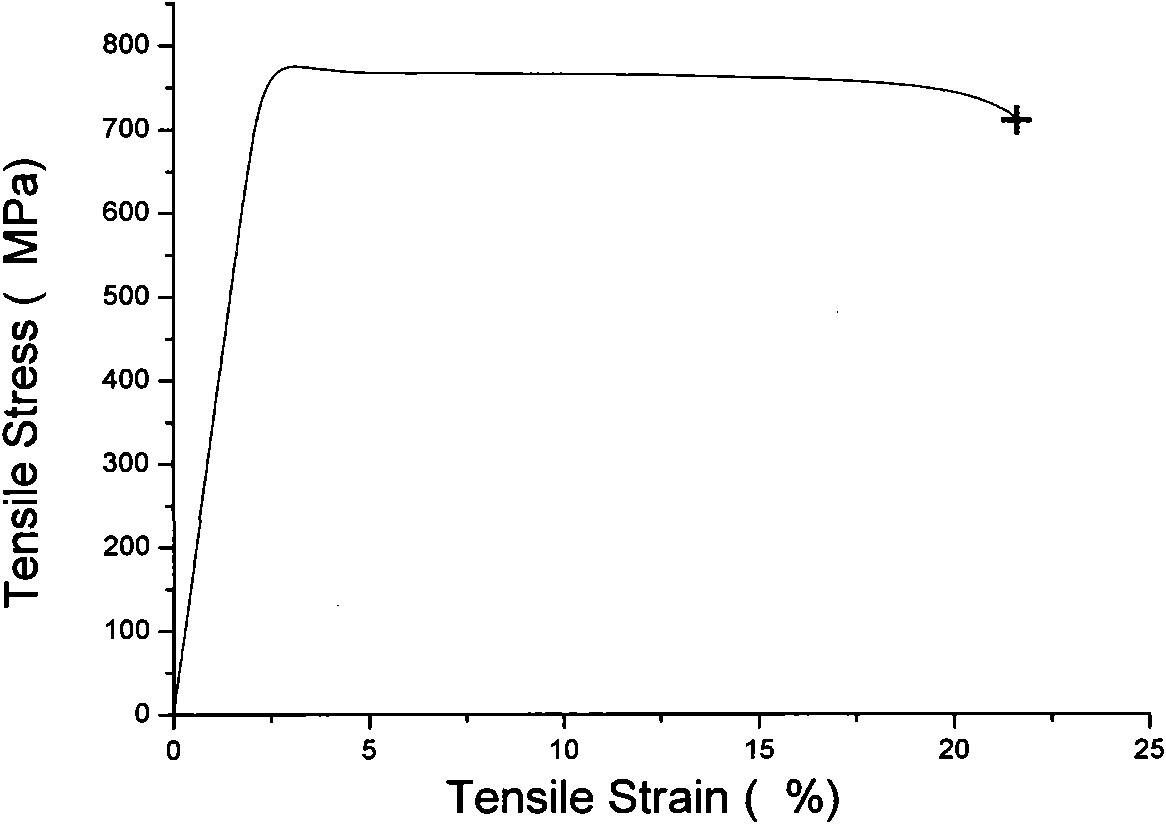

High strength alpha/beta titanium alloy

An alpha / beta titanium alloy comprising, in percent by weight based on total alloy weight: 3.9 to 4.5 aluminum; 2.2 to 3.0 vanadium; 1.2 to 1.8 iron; 0.24 to 0.30 oxygen; up to 0.08 carbon; up to 0.05 nitrogen; up to 0.015 hydrogen ; titanium; and up to a total of 0.30 of other elements. A non-limiting embodiment of the alpha / beta titanium alloy comprises an aluminum equivalent value in the range of 6.4 to 7.2, exhibits a yield strength in the range of 120 ksi (827.4 MPa) to 155 ksi (1,069 MPa), exhibits an ultimate tensile strength in the range of 130 ksi (896.3 MPa) to 165 ksi (1,138 MPa), and exhibits a ductility in the range of 12 to 30 percent elongation.

Owner:ATI PROPERTIES LLC

Processing of titanium-aluminum-vanadium alloys and products made thereby

A method of forming an article from an α−β titanium including, in weight percentages, from about 2.9 to about 5.0 aluminum, from about 2.0 to about 3.0 vanadium, from about 0.4 to about 2.0 iron, from about 0.2 to about 0.3 oxygen, from about 0.005 to about 0.3 carbon, from about 0.001 to about 0.02 nitrogen, and less than about 0.5 of other elements. The method comprises cold working the α−β titanium alloy.

Owner:ATI PROPERTIES LLC

Beta titanium alloy and preparation method thereof

The invention discloses a beta titanium alloy and a preparation method thereof, relates to a titanium alloy, and provides a beta titanium alloy with excellent combination property and a preparation method thereof. The beta titanium alloy comprises the following components by mass percent: 6-10% of vanadium, 2-4% of aluminum, 2-4% of chromium, 0-13% of niobium, 0-3% of tin, 0-5% of zirconium, 0-4% of molybdenum, 0-0.05% of boron and the balance titanium. The preparation method comprises the following steps: putting the titanium and zirconium in a sponge state into an arc furnace; vacuumizing and then charging argon for smelting; smelting the smelted titanium and zirconium with vanadium, aluminum, chromium, niobium, tin, molybdenum and boron to obtain a beta titanium alloy pig material; carrying out homogenizing heat treatment on the beta titanium alloy pig material, and cooling along with the furnace; rolling the beta titanium alloy pig material after the heat treatment into a schistose alloy material; slicing the obtained schistose alloy material into a sample; and quenching with icy water after the solution treatment, and then carrying out aging to obtain the beta titanium alloy.

Owner:XIAMEN UNIV

Alpha-beta titanium alloy tubes and methods of flowforming the same

Described herein are methods for forming titanium alloy tubes having an α-β grain structure. The methods include the steps of hot-working a titanium alloy workpiece at a temperature below the β-transus temperature of the workpiece and above the recrystallization temperature of the workpiece to produce an α-β titanium alloy preform hollow. Subsequently, the α-β titanium alloy preform hollow is flowformed, thereby forming a α-β titanium alloy tube.

Owner:ATI FLOWFORM PROD

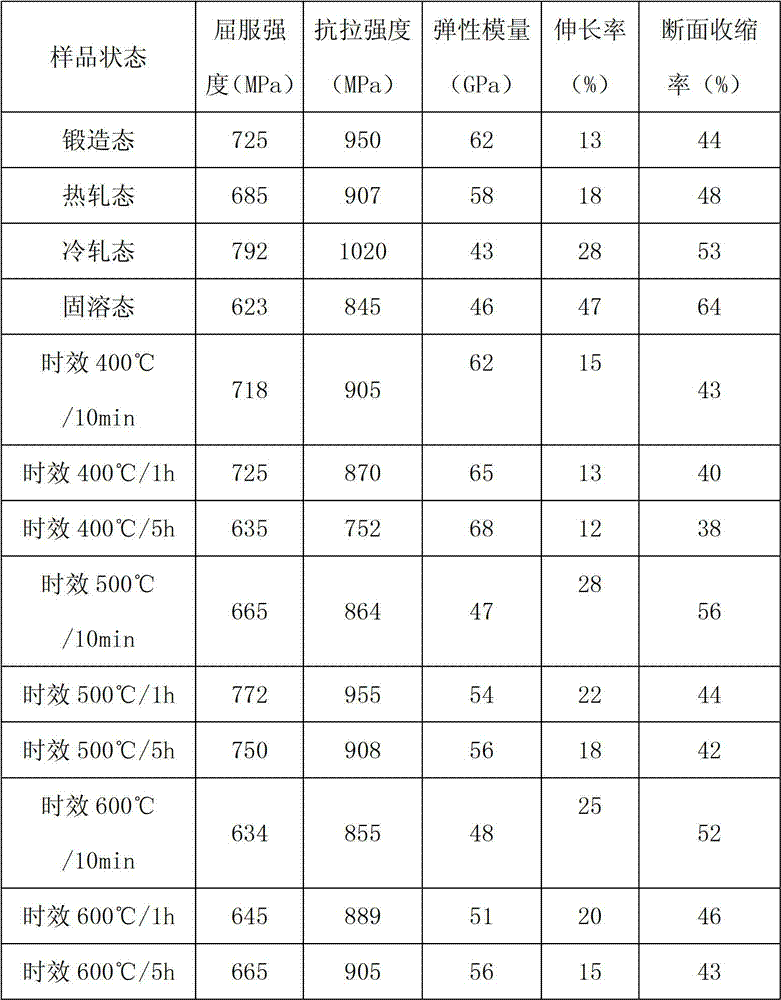

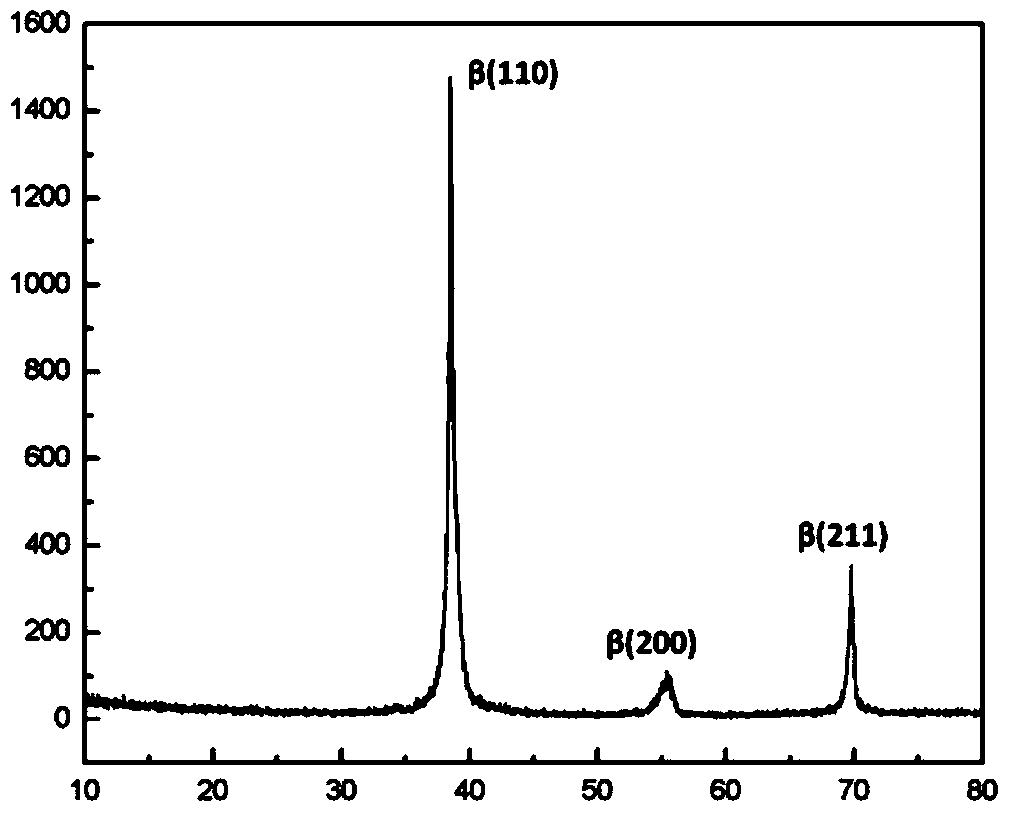

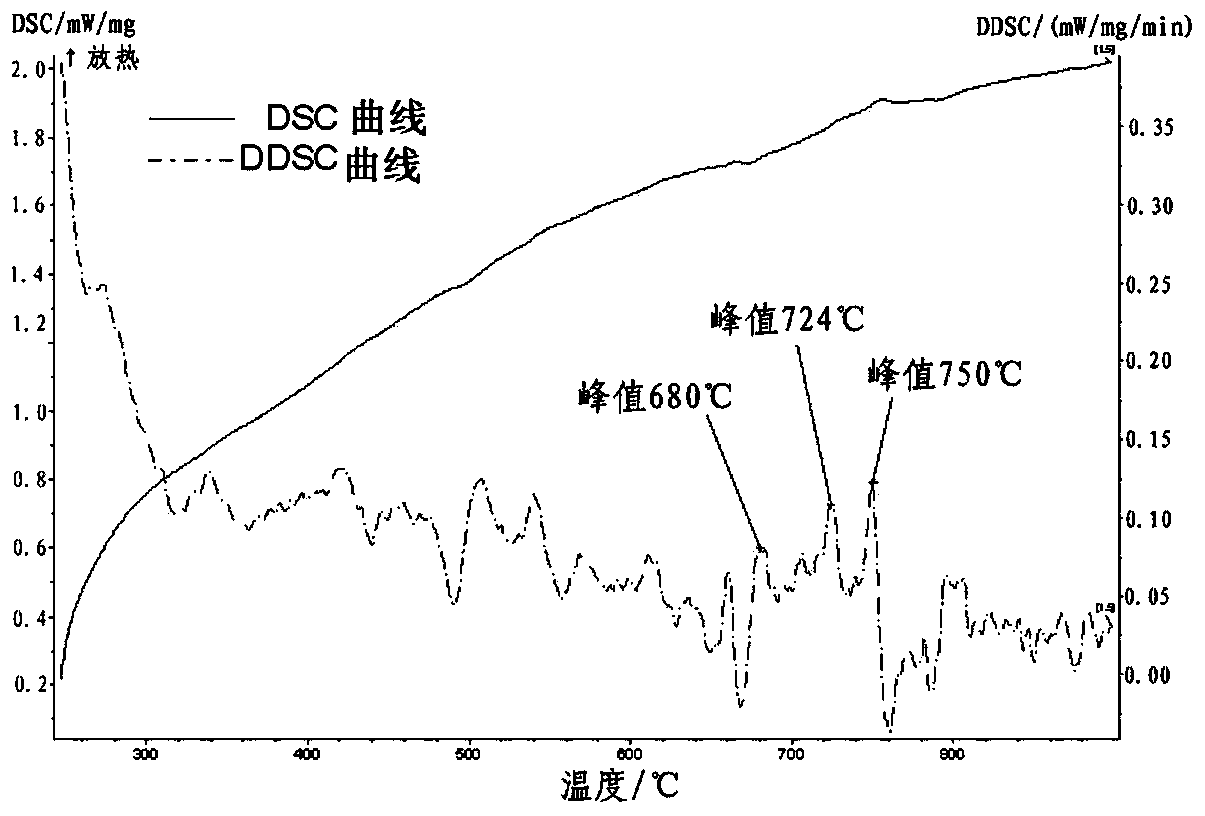

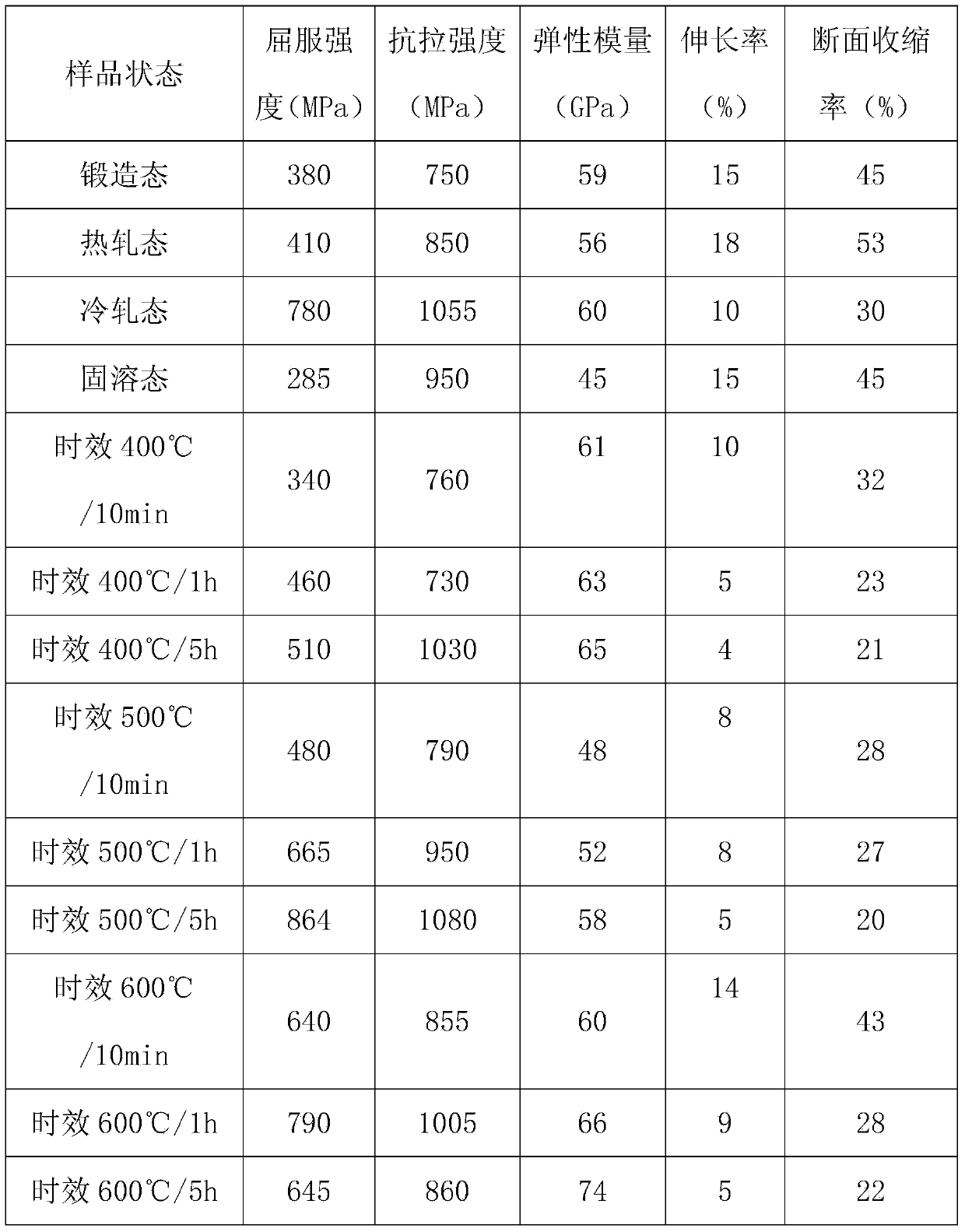

Metastable beta titanium alloy with low elastic modulus and preparing method thereof

The invention relates to a titanium alloy material, in particular to a multi-functional biomedical metastable beta titanium alloy material with excellent processing performance, and belongs to the technical field of titanium alloy material preparation. The alloy contains the following ingredients by mass: 18-27% of Nb, 0.5-2% of Mo, 3-5% of Zr, 7-9% of Sn, 0.1-0.3% of O and the balance of Ti. The titanium alloy has excellent comprehensive performance, and the strength and the elastic modulus of the alloy can be regulated through different thermal treatments. The elastic modulus E of the alloy is 40-7 3GPa, the yield strength sigma 0.2 is 260-864 MPa, the tensile strength sigma b is 686-1094 MPa, the elongation rate epsilon = 4-20%, and the facture surface shrinkage rate is 20-52%. The titanium alloy does not contain toxic elements, such as Al and V, and has excellent corrosion resistance, biocompatibility and cold processing performance. The titanium alloy can be used for manufacturing tissue repairing or substituting materials, such as artificial bones, artificial joints and bone plates.

Owner:BAOJI TITANIUM IND +1

Processing of alpha-beta titanium alloys

A method for increasing tensile strength of a cold workable alpha-beta titanium alloy comprises solution heat treating a cold workable alpha-beta titanium alloy in a temperature range of Tβ-106° C. to Tβ-72.2° C. for 15 minutes to 2 hours; cooling the alpha-beta titanium alloy at a cooling rate of at least 3000° C. / minute; cold working the alpha-beta titanium alloy to impart an effective strain in the range of 5 percent to 35 percent in the alloy; and aging the alpha-beta titanium alloy in a temperature range of Tβ-669° C. to Tβ-517° C. for 1 to 8 hours. Fastener stock and fasteners including solution treated, quenched, cold worked, and aged alpha-beta titanium alloys are also disclosed.

Owner:ATI PROPERTIES LLC

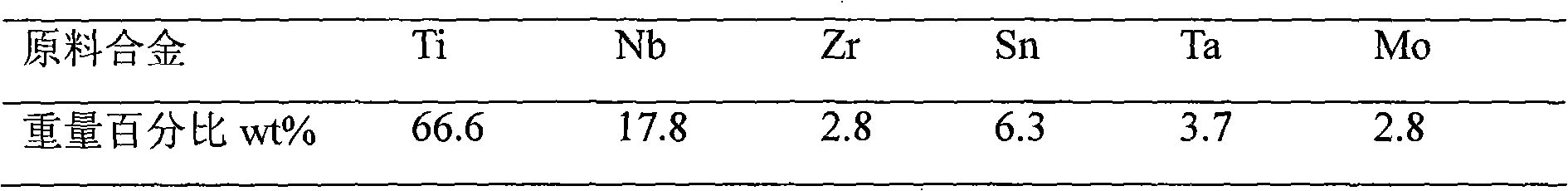

Biomedical beta-titanium alloy material and preparation method thereof

The invention relates to a biomedical beta-titanium alloy material with low elastic modulus. The preparation method for the material comprises the steps of raw material preparation, raw material smelting, cogging, forging and the like, namely the method comprises the following steps: preparing a raw material alloy of Nb, Zr, Sn, Ta, Mo and Ti according to a certain proportion, mechanically stirring and mixing the alloy, then pressing the alloy on a hydraulic press to form electrodes, and later smelting the electrodes in a vacuum consumable electro-arc furnace to obtain cast ingots of the beta-titanium alloy material; taking out the cast ingots with certain diameter, heating the cast ingots in a vacuum furnace and then preserving the heat, upsetting and drawing out the heated cast ingots on the hydraulic press or a forging device, and repeating the step twice to thrice to obtain a forging stock of the beta-titanium alloy material; heating the forging stock in the vacuum furnace and then preserving the heat, drawing out the heated forging stock on the hydraulic press or the forging device to obtain the biomedical beta-titanium alloy material with the elastic modulus E of 50 to 80GPa. The alloy has the characteristic of low elastic modulus, has good combination properties such as tensile strength, yield strength, corrosion resistance and the like, and does not contain toxic elements to human body.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

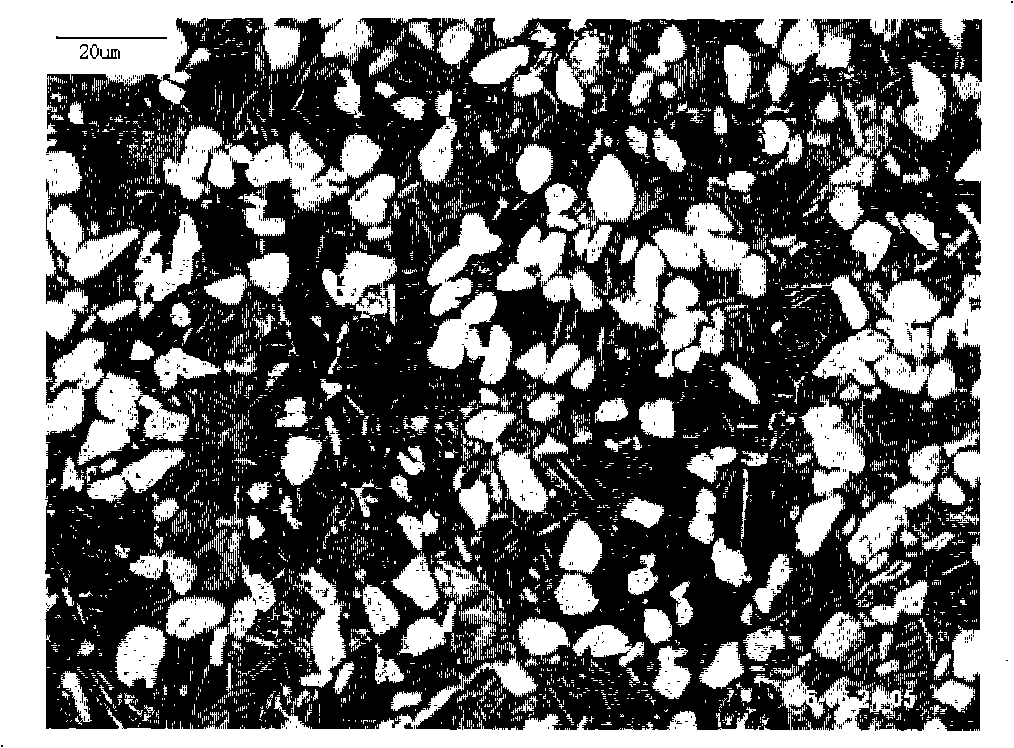

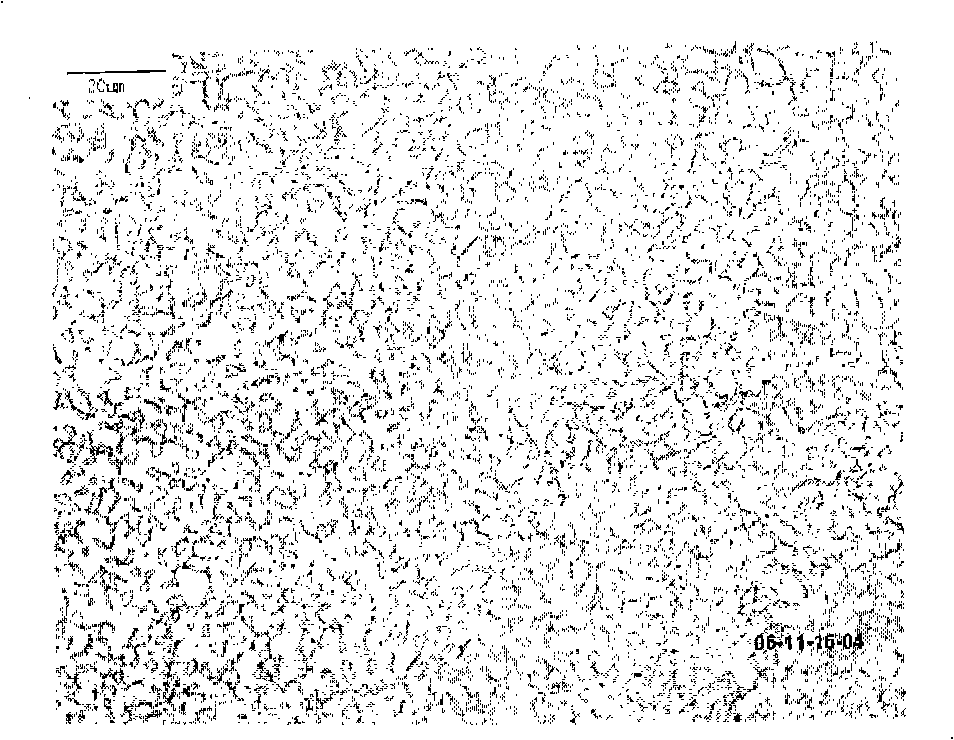

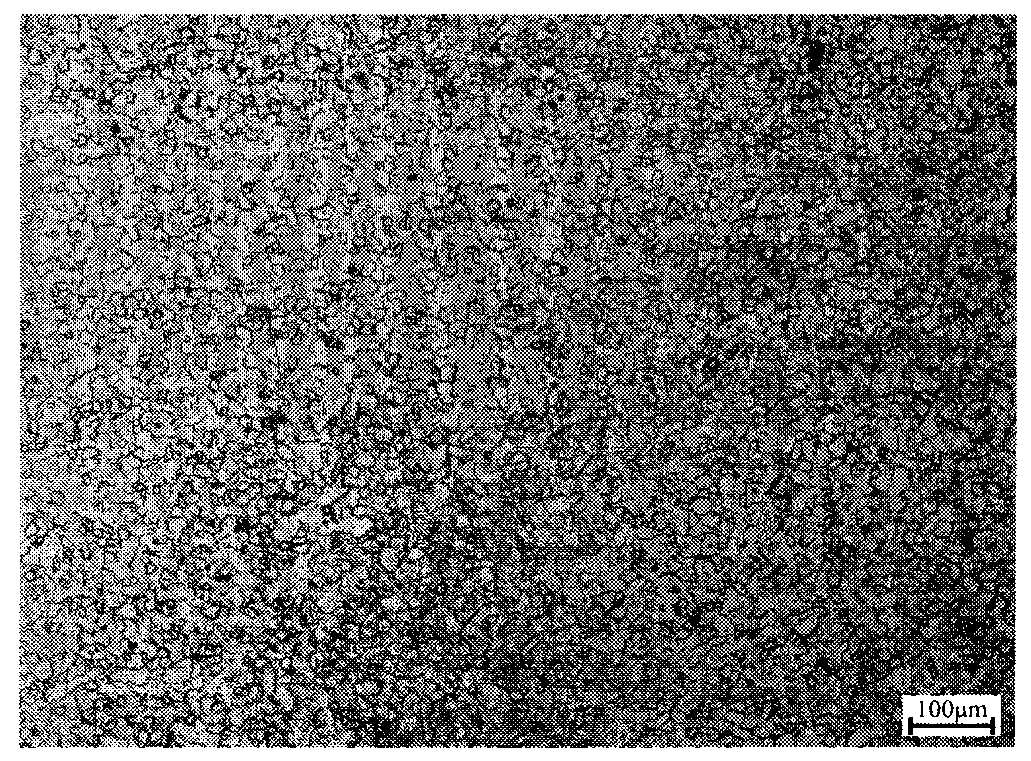

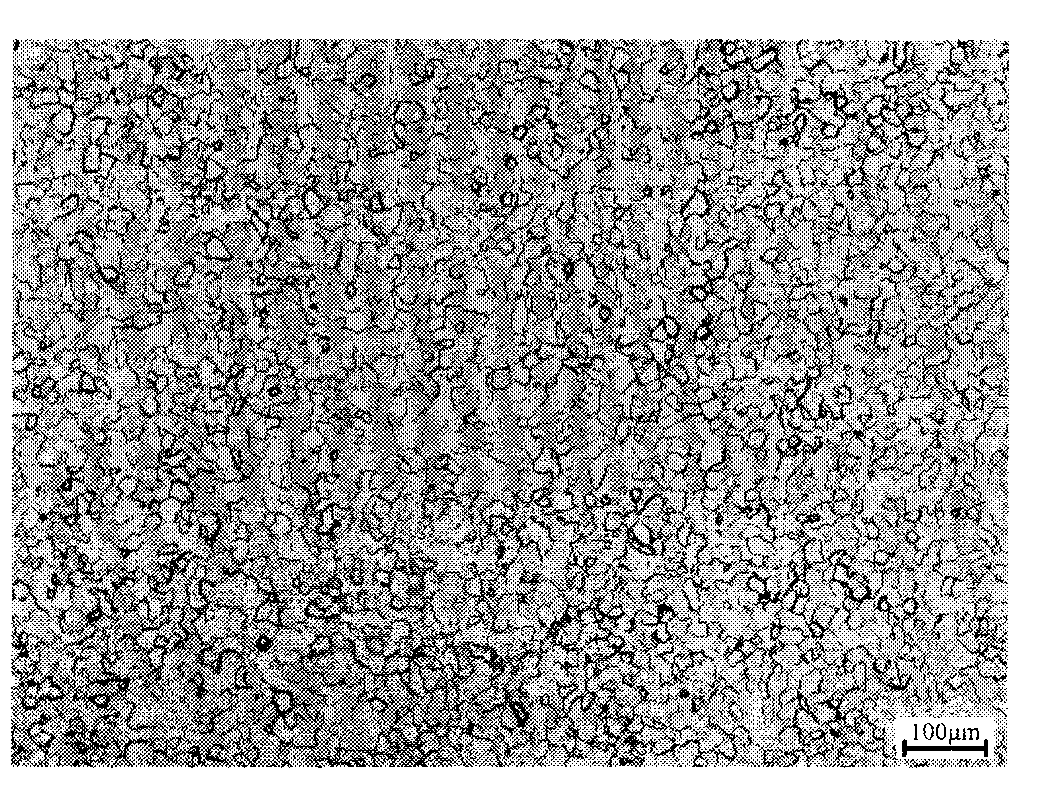

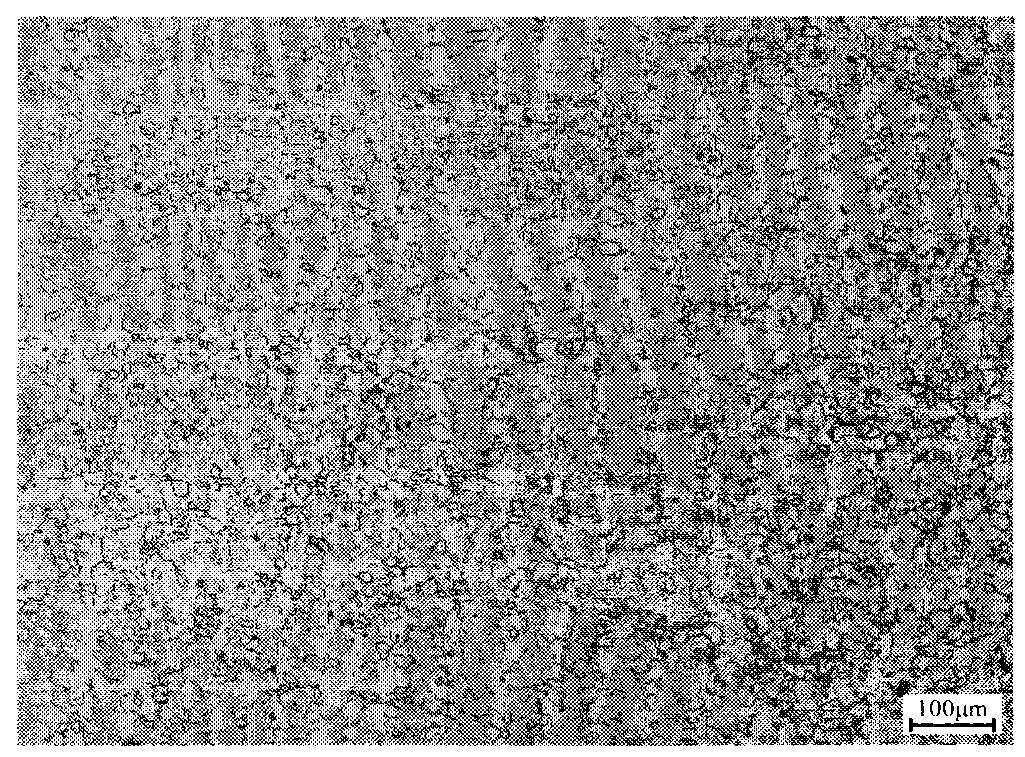

Metallographic etchant and metallographic etching method for pure titanium and beta titanium alloy

InactiveCN102808179AAccelerated corrosionFast corrosionPreparing sample for investigationHydrofluoric acidEtching

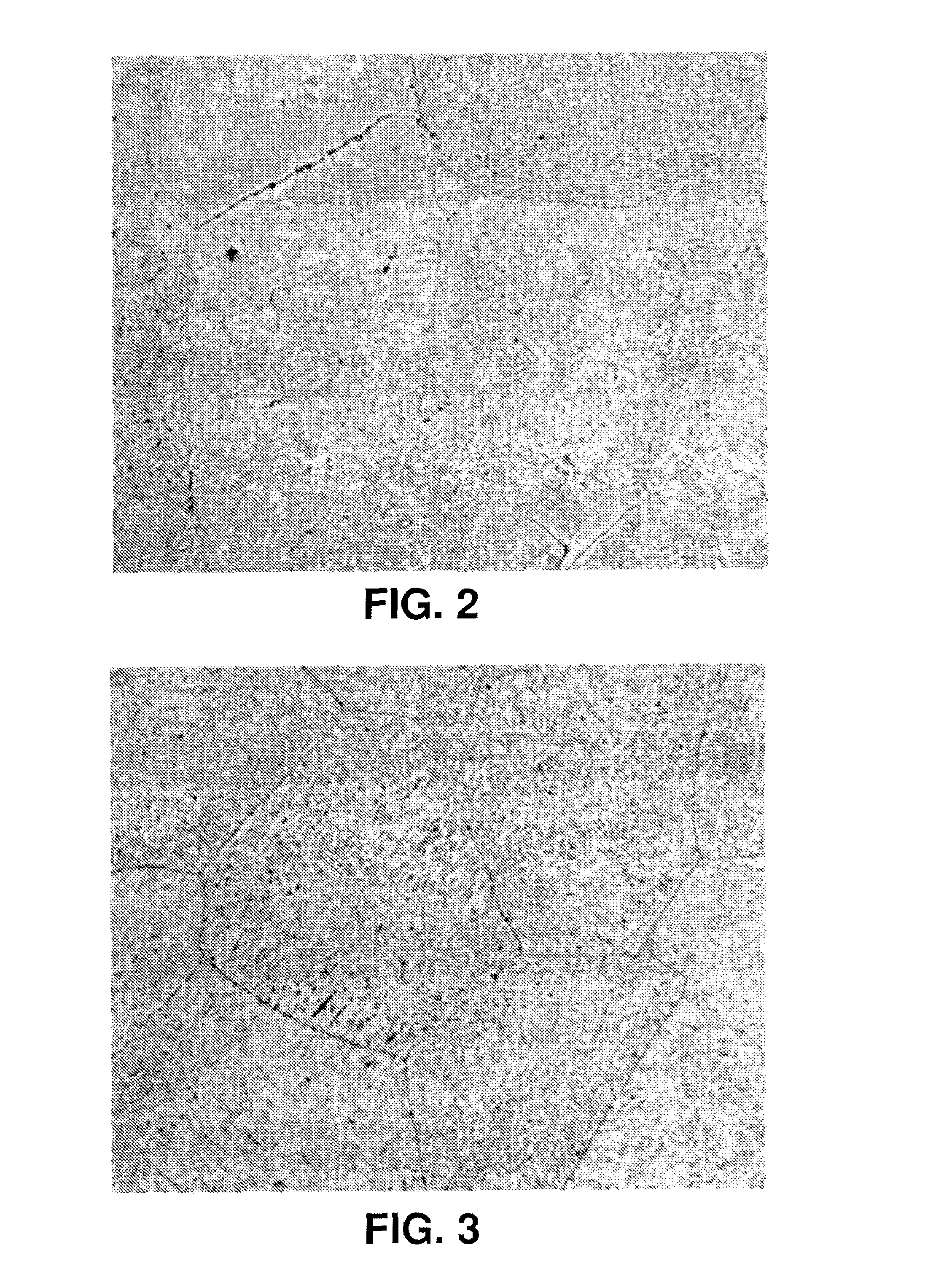

The invention relates to the field of metallographic etching of titanium and titanium alloy and discloses metallographic etchant and a metallographic etching method for pure titanium and beta titanium alloy. The metallographic etchant and the metallographic etching method are mainly used for metallographic etching of the pure titanium and the beta titanium alloy. The etchant consists of 10 to 40 volume parts of nitric acid, 5 to 10 volume parts of hydrofluoric acid, and 30 to 100 volume parts of water. The method comprises the following steps of: soaking a ground and polished metallographic specimen in the etchant for a certain period of time, then placing the metallographic specimen in warm absolute ethanol at the temperature of between 30 and 50 DEG C for a moment, polishing again to ensure that the etching layer is polished completely, and etching the metallographic specimen for the second time by using etchant which is similar to the etchant used in the first-time etching to obtain a single-phase metallographic structure. By the method, processing-state and annealing-state pure titanium and beta titanium alloy bars, wires and plates are subjected to metallographic etching, and the obtained single-phase metallographic structure is clear and complete in crystal boundary, and abnormal etching pits or plaques in a single crystal grain can be avoided.

Owner:西安赛特新材料科技股份有限公司

Beta-titanium alloy material in biology medical application

InactiveCN101081311AHigh strengthImprove wear resistanceSurgeryProsthesisBreaking strengthThick plate

The present invention discloses one kind of biomedicine beta-titanium alloy material comprising Ti-Nb 25-30 wt%, Zr 1-5 wt%, Fe 0.2-1 wt%, and Ta 10-15 wt%. The beta-titanium alloy material is produced through vacuum arc melting, casting, vacuum homogenizing under the protection of argon, cold rolling, forming solid solution, water quenching, artificial ageing, water cooling and other steps. It is produced into 2 mm thick plate, and has excellent comprehensive performances, including elastic modulus 40-60 GPa, breaking strength 600-910 MPa, yield strength 480-650 MPa, elongation 14-18 % and reduction of area 40-52 %. It has simple and reliable production process.

Owner:CENT SOUTH UNIV

Titanium alloy

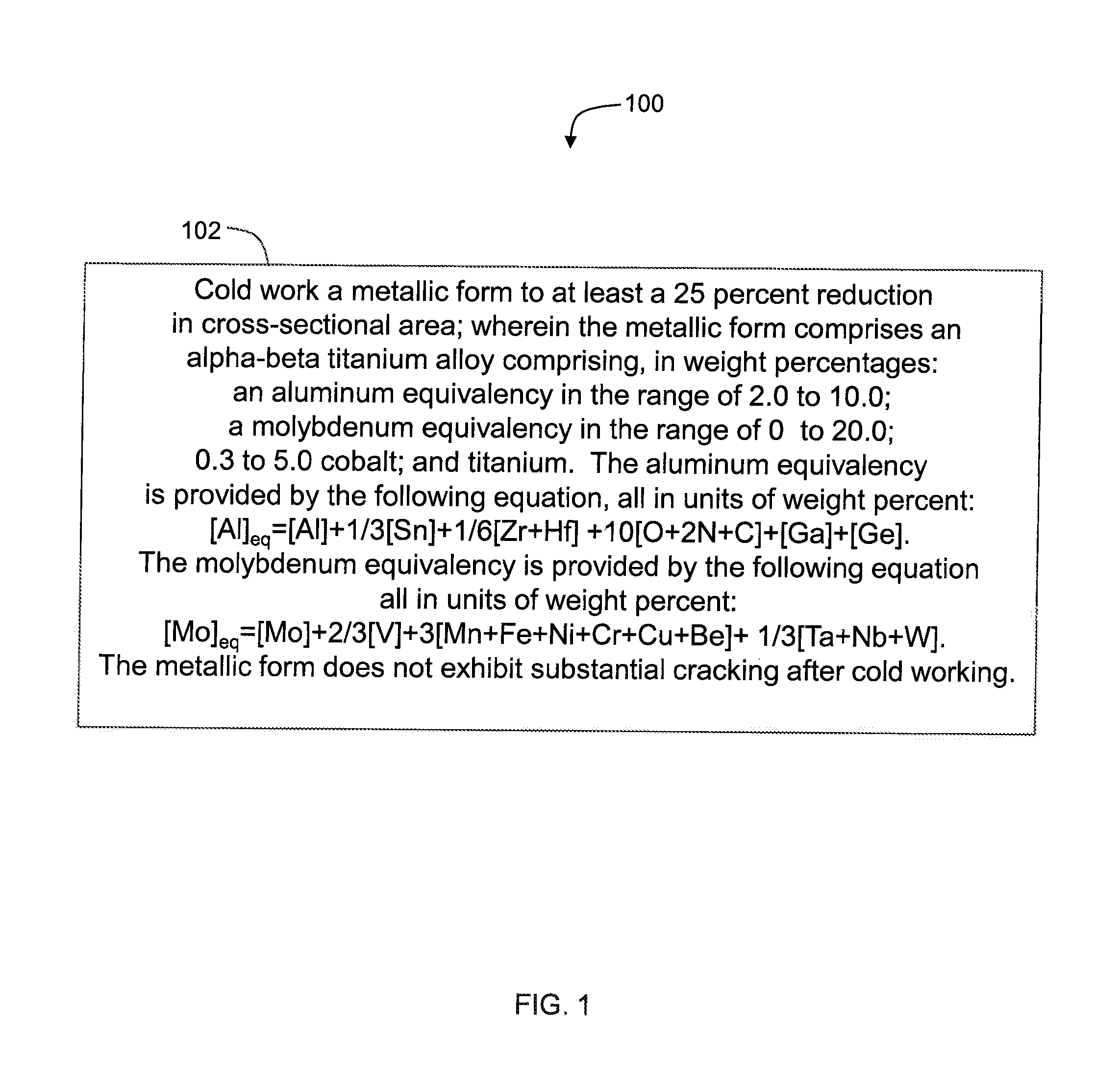

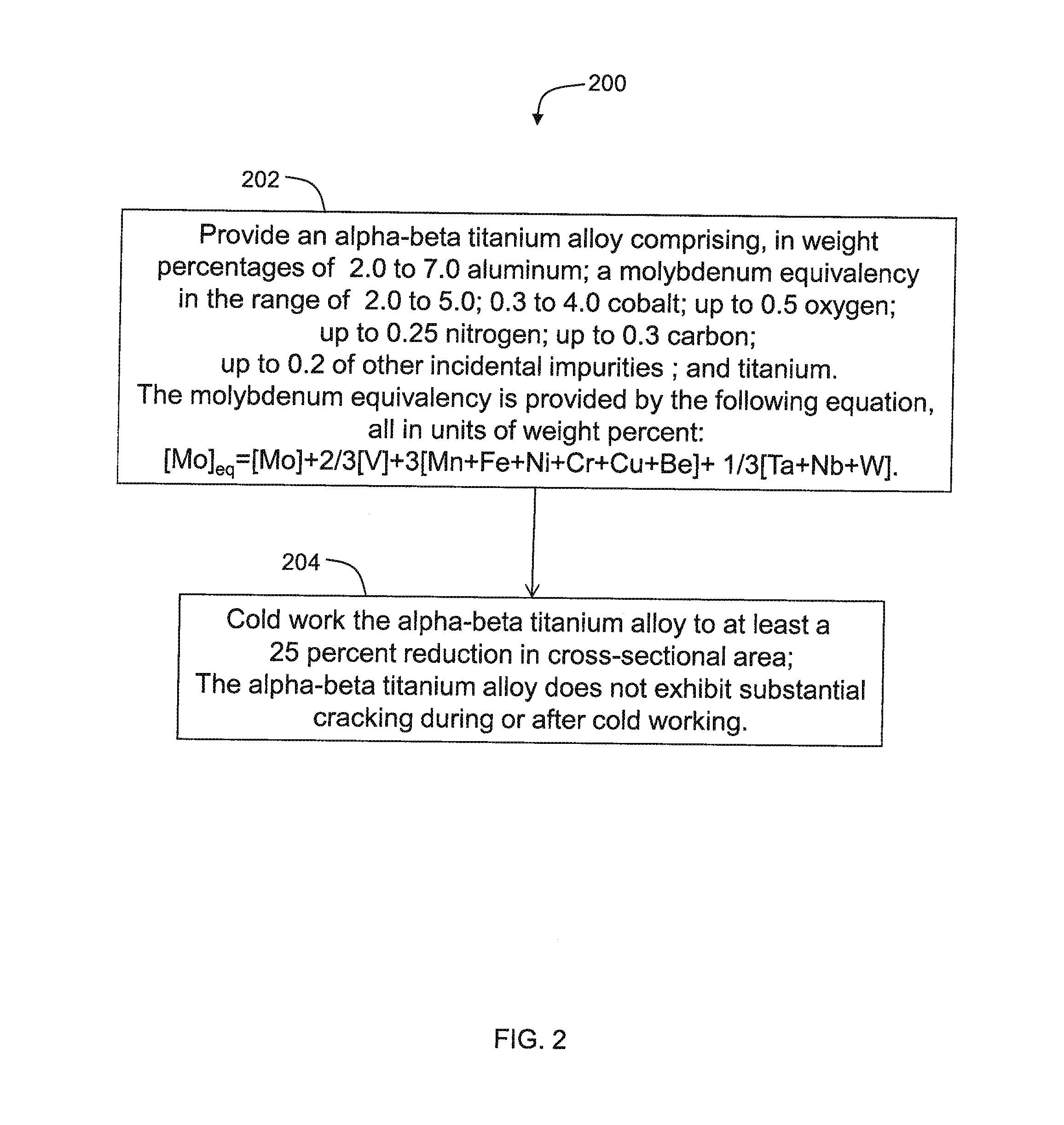

An alpha-beta titanium alloy comprises, in weight percentages: an aluminum equivalency in the range of 2.0 to 10.0; a molybdenum equivalency in the range of 0 to 20.0; 0.3 to 5.0 cobalt; and titanium. In certain embodiments, the alpha-beta titanium alloy exhibits a cold working reduction ductility limit of at least 25%, a yield strength of at least 130 KSI (896.3 MPa), and a percent elongation of at least 10%. A method of forming an article comprising the cobalt-containing alpha-beta titanium alloy comprises cold working the cobalt-containing alpha-beta titanium alloy to at least a 25 percent reduction in cross-sectional area. The cobalt-containing alpha-beta titanium alloy does not exhibit substantial cracking during cold working.

Owner:ATI PROPERTIES LLC

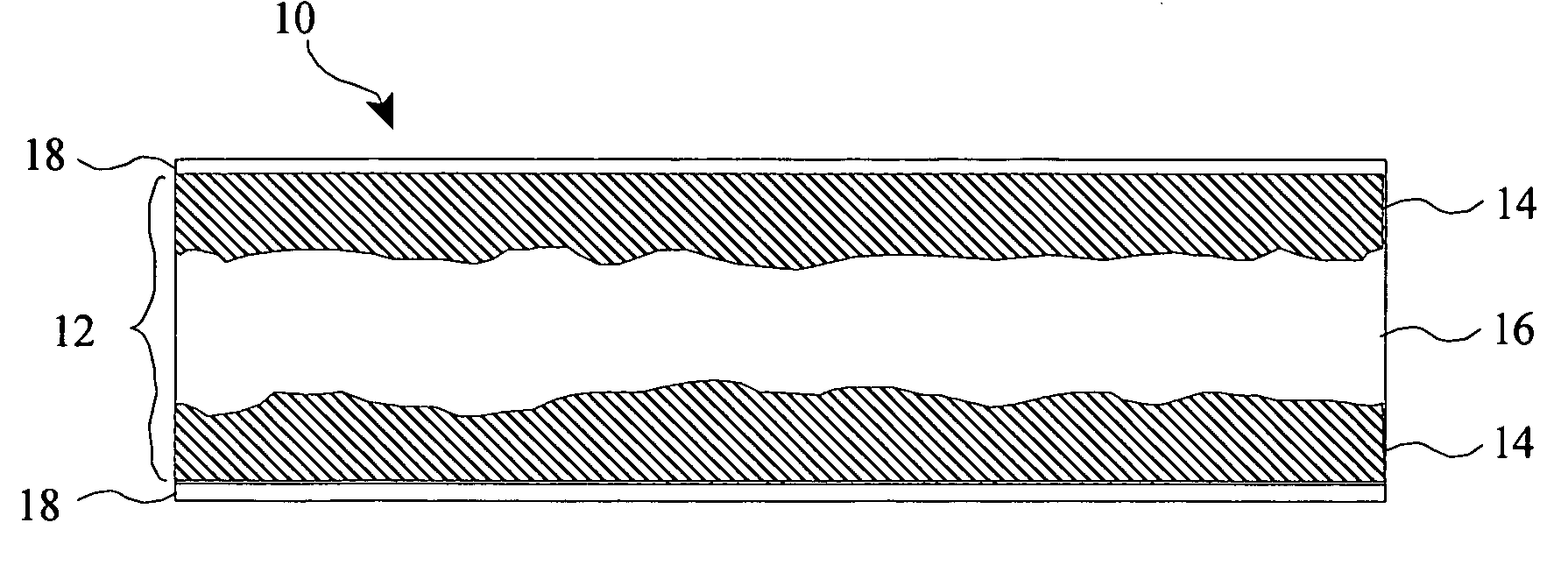

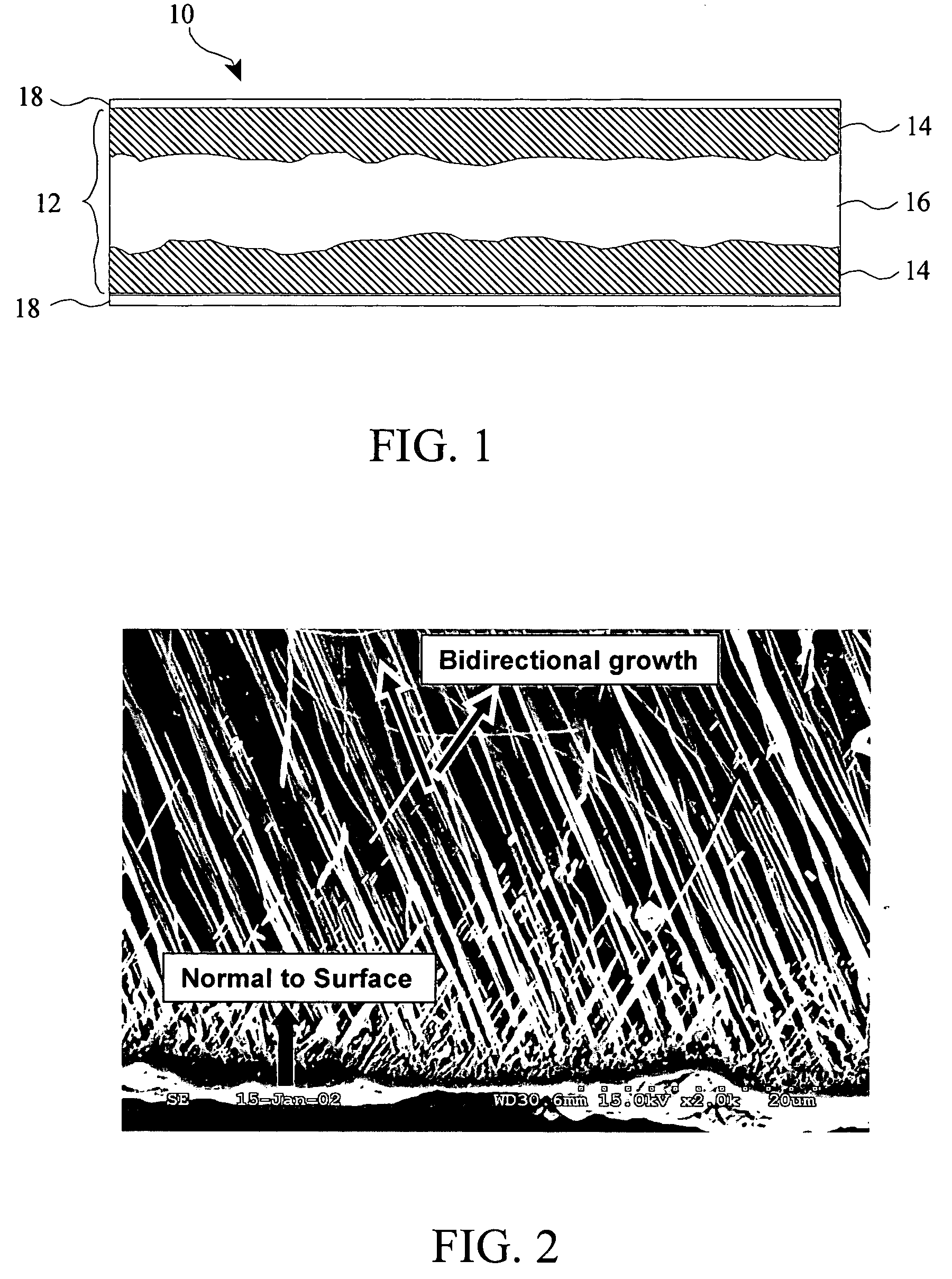

Thin parts made of beta or quasi-beta titanium alloys; manufacture by forging

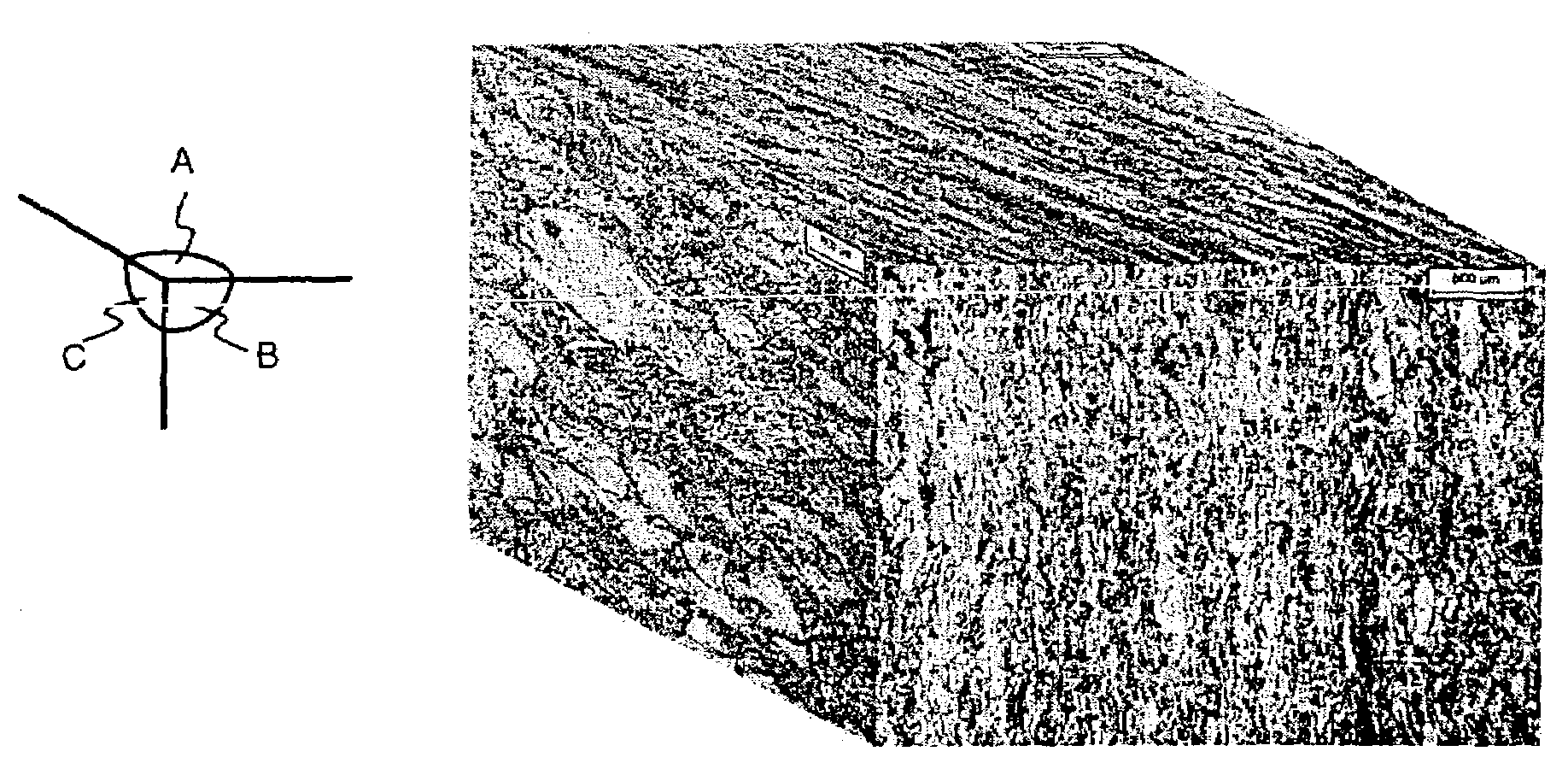

The present invention provides non-axially symmetrical manufactured parts of thickness less than 10 mm, made of β or quasi-β titanium alloy, having a core microstructure constituted by whole grains presenting a slenderness ratio greater than 4 and an equivalent diameter lying in the range 10 μm to 300 μm. The invention also provides a method of manufacturing the parts by forging.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Preparation method of beta titanium alloy tube

ActiveCN103436735AGood strength and plasticity matchingImprove fracture toughnessOne passAbrasive blasting

The invention provides a preparation method of a beta titanium alloy tube. The method comprises the following steps of: 1, performing one-pass cogging and rolling on the beta titanium alloy tube by using a cold pilger mill to obtain a rough rolled tube blank; 2, performing first solution treatment on the rough rolled tube blank; 3, removing defects on the inner and outer surfaces of the rough rolled tube blank, and then performing multi-pass precision rolling by using the cold pilger mill, and orderly performing second solution treatment, sandblasting treatment and acid pickling treatment after each pass of precision rolling to obtain a finish-rolled tube blank; and 4, performing aging treatment to obtain the beta titanium alloy tube having the outer diameter of 20 mm to 133 mm and the wall thickness of 1 mm to 5 mm. The preparation method provided by the invention is simple in preparation process, high in material utilization rate, low in production cost and short in production period; the beta titanium alloy tube prepared by using the preparation method provided by the invention is even in structure; the crystalline grains of the beta titanium alloy tube are fine and dispersed; and the beta titanium alloy tube is excellent in mechanical properties, and can be widely applied to the fields such as war industry, civilian use and the like.

Owner:西安秦钛智造科技有限公司

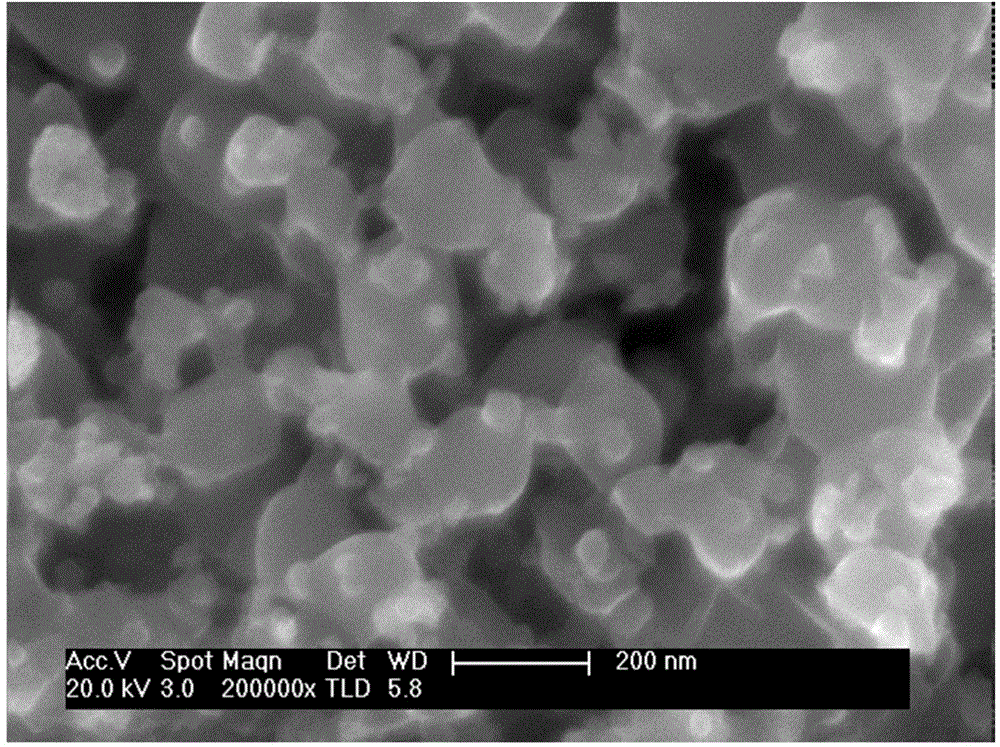

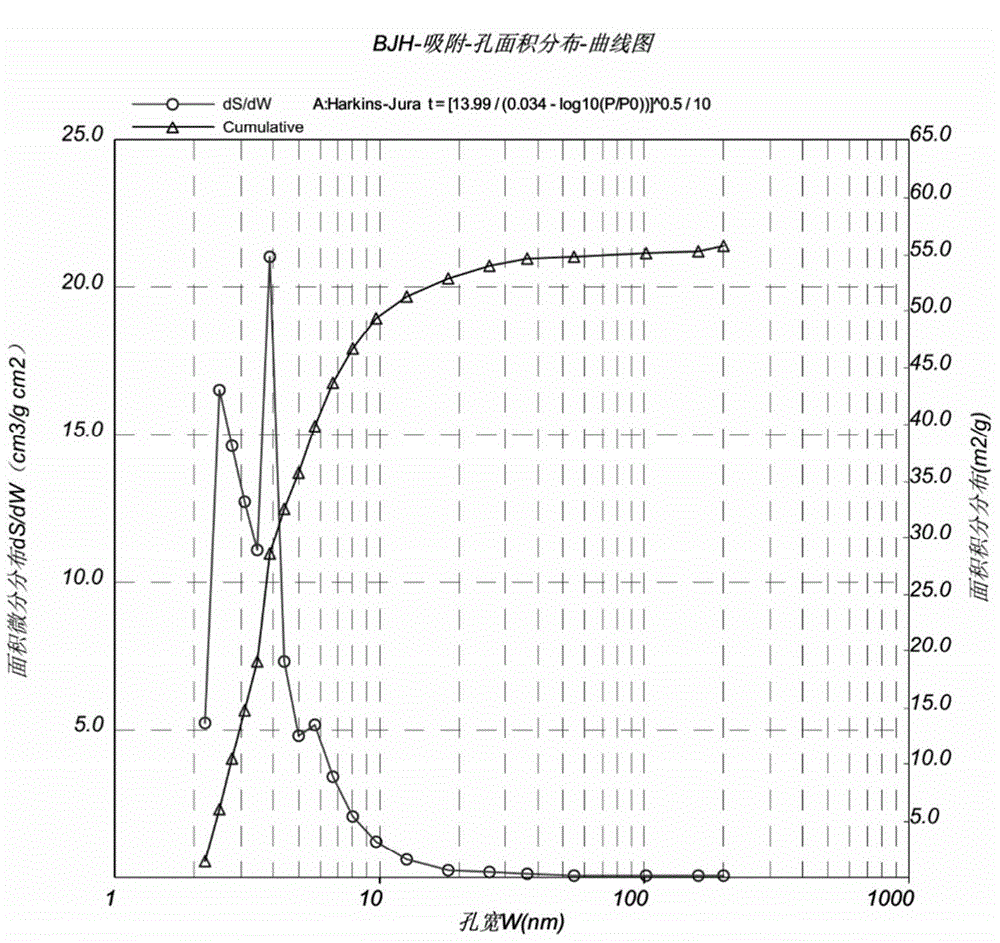

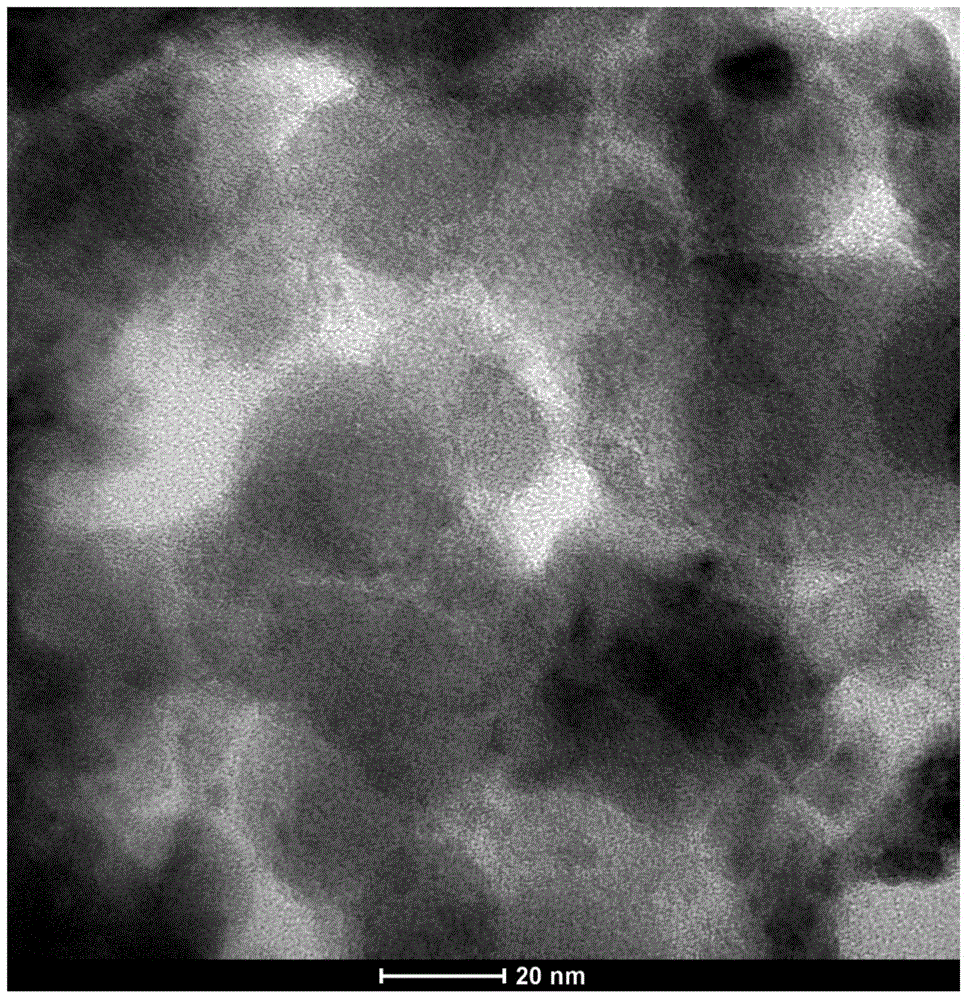

Preparation method of three dimensional nanometer porous titanium and alloy thereof

The invention provides a preparation method of three dimensional nanometer porous titanium and alloy thereof. The method adopts a powder coated solid phase sintering technology, and comprises the following steps: coating a mother alloy block with a dealloying medium material with magnesium metal or magnesium alloy powder as the dealloying medium material, and carrying out heat insulation sintering; and dissolving the surface coating dealloying medium material to prepare nanometer porous pure alpha titanium with a three dimensional block structure or nanometer porous beta titanium alloy. A powder metallurgy magnesium powder coated titanium alloy sintering dealloying technology is adopted, a solid phase dealloying technology adopting the magnesium-based powder as the dealloying medium is used to prepare the nanometer porous pure alpha titanium and beta titanium alloy, so the use amount of the magnesium powder can be stoichiometrically controlled according to the mass of a titanium alloy sample, the porosity of the prepared nanometer alpha titanium and beta titanium alloy is above 60%, and the aperture dimension is 1-100nm.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com