Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Beta type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beta types are those with Ti-Fe & Se-Ni as their oscillation pairs. Beta types often develop as smoothtalkers and persuaders. From the articulate and empathic FeNi, to the hypnotic NiFe, to the affable SeTi and the cool geek TiSe, we are drawn to their tailored presentation and confident aura.

Alpha-beta type titanium alloy

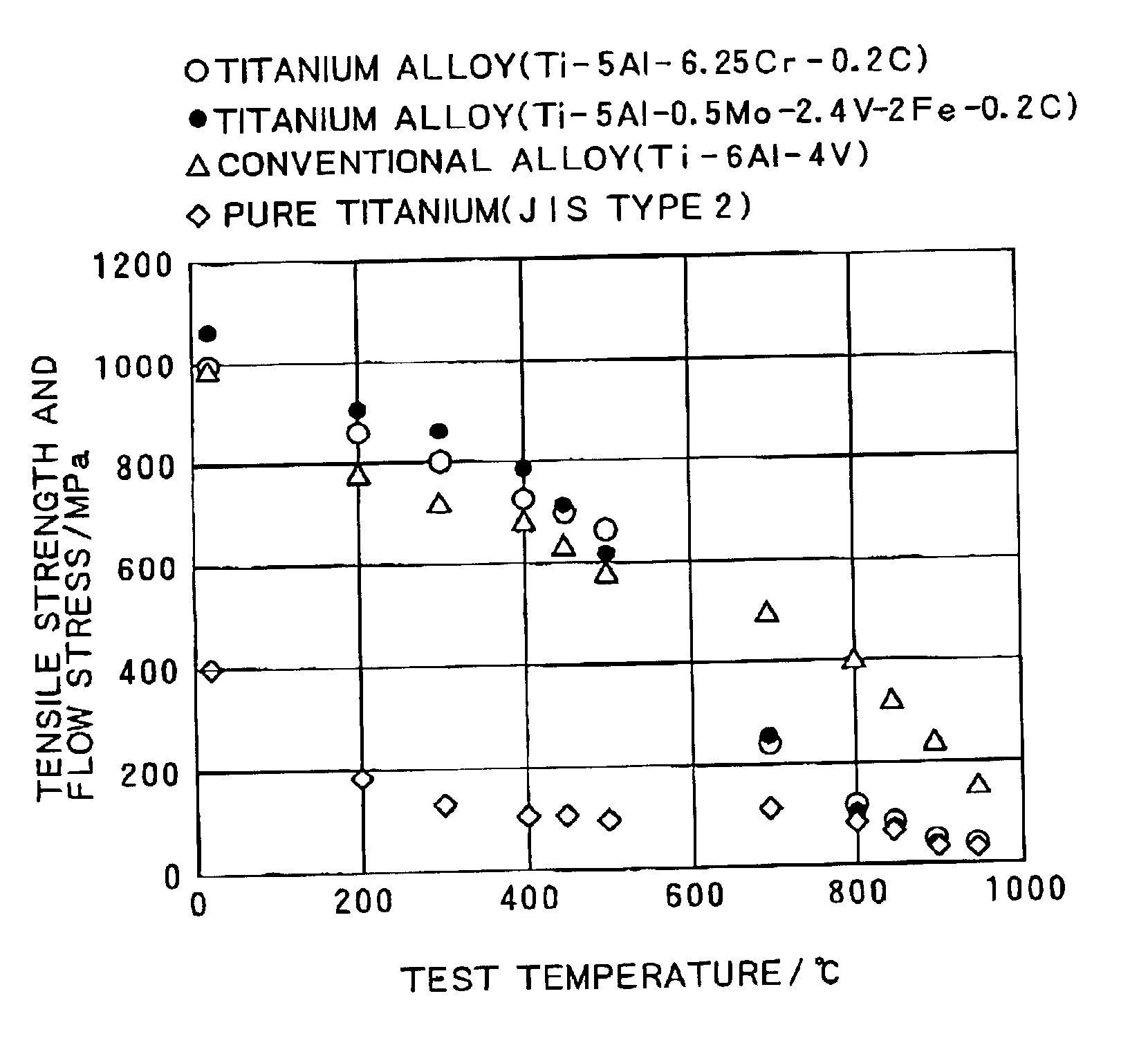

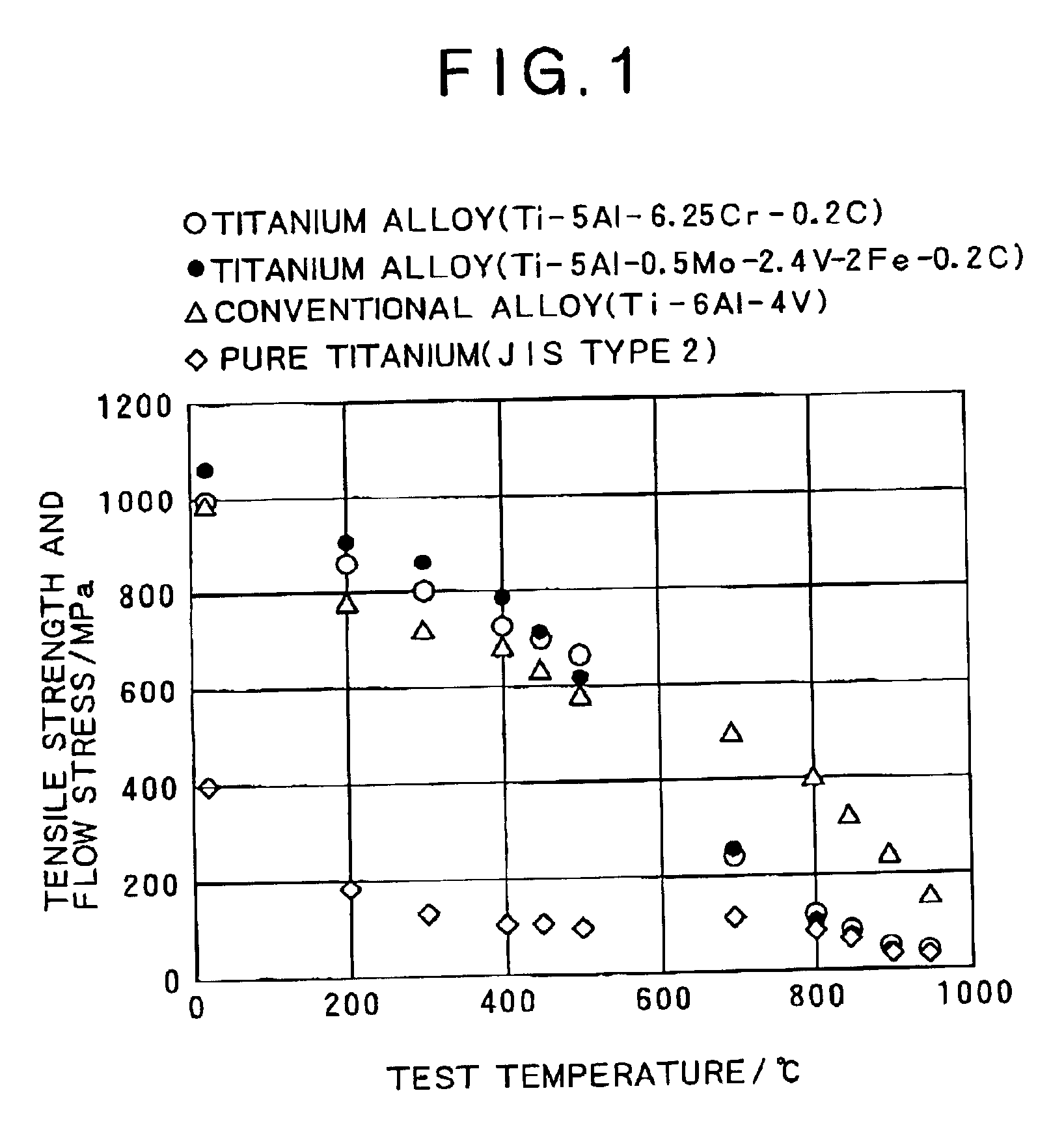

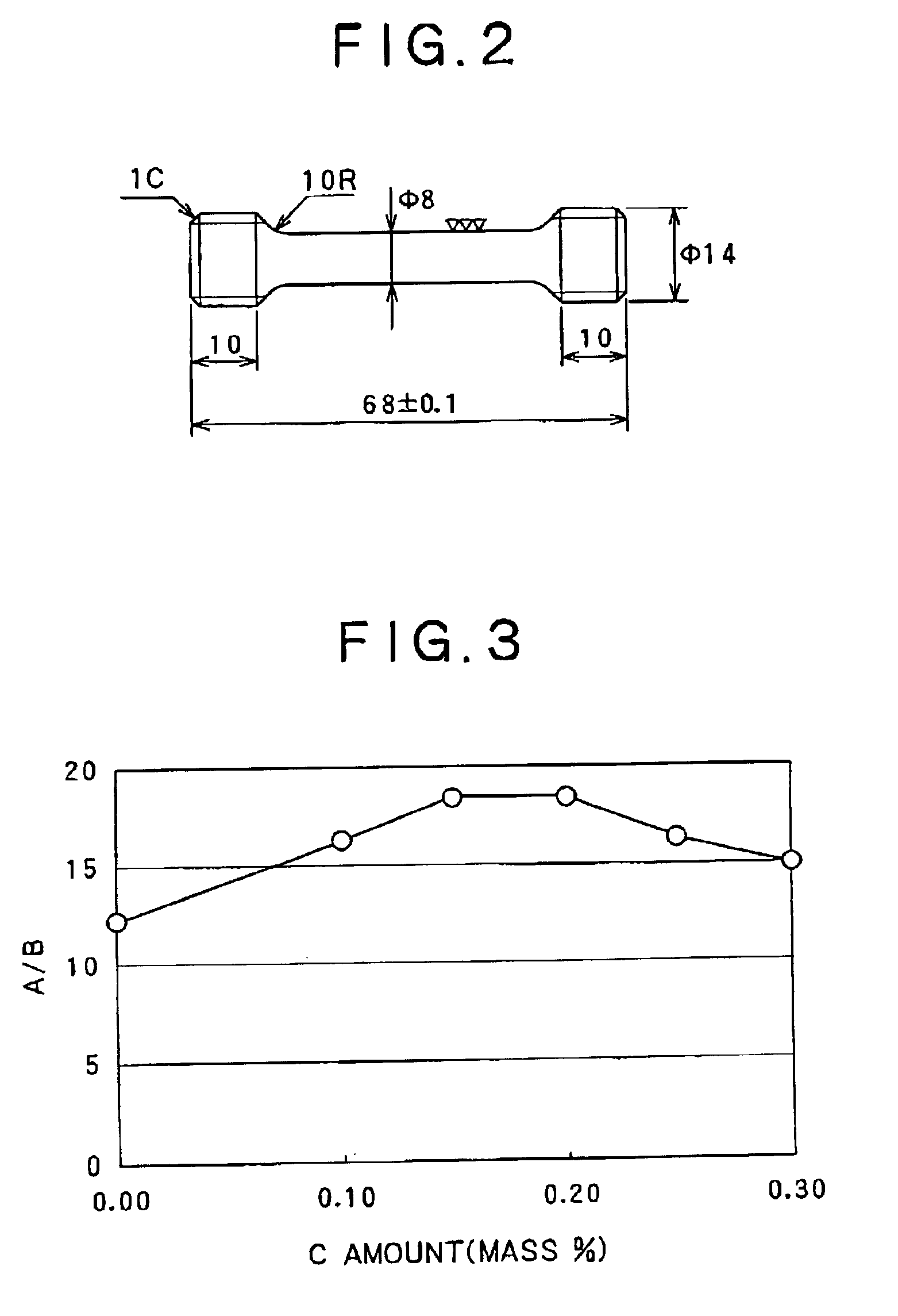

There is provided an α-β type titanium alloy having a normal-temperature strength equivalent to, or exceeding that of a Ti-6Al-4V alloy generally used as a high-strength titanium alloy, and excellent in hot workability including hot forgeability and subsequent secondary workability, and capable of being hot-worked into a desired shape at a low cost efficiently. There is disclosed an α-β type titanium alloy having high strength and excellent hot workability wherein 0.08-0.25% C is contained, the tensile strength at room temperature (25° C.) after annealing at 700° C. is 895 MPa or more, the flow stress upon greeble test at 850° C. is 200 MPa or less, and the tensile strength / flow stress ratio is 9 or more. A particularly preferred α-β type titanium alloy comprises 3-7% Al and 0.08-025% C as α-stabilizers, and 2.0-6.0% Cr and 0.3-1.0% Fe as β-stabilizers.

Owner:KOBE STEEL LTD

Type II TGF-beta receptor/immunoglobulin constant region fusion proteins

InactiveUS20050203022A1Prevent overproductionPreventing postradiation fibrosisFungiSenses disorderDiseaseImmunoglobulin Constant Region

Owner:BIOGEN MA INC

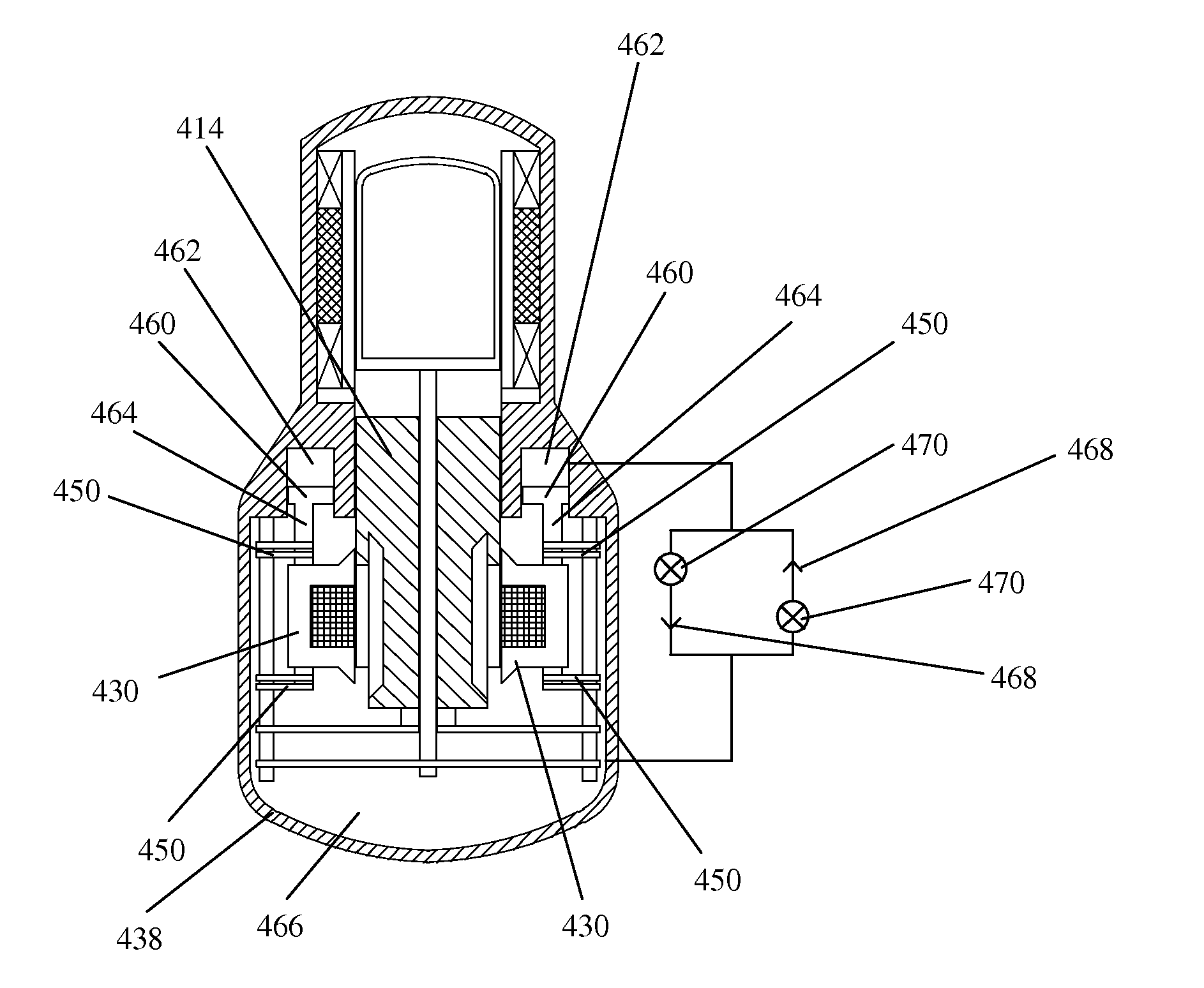

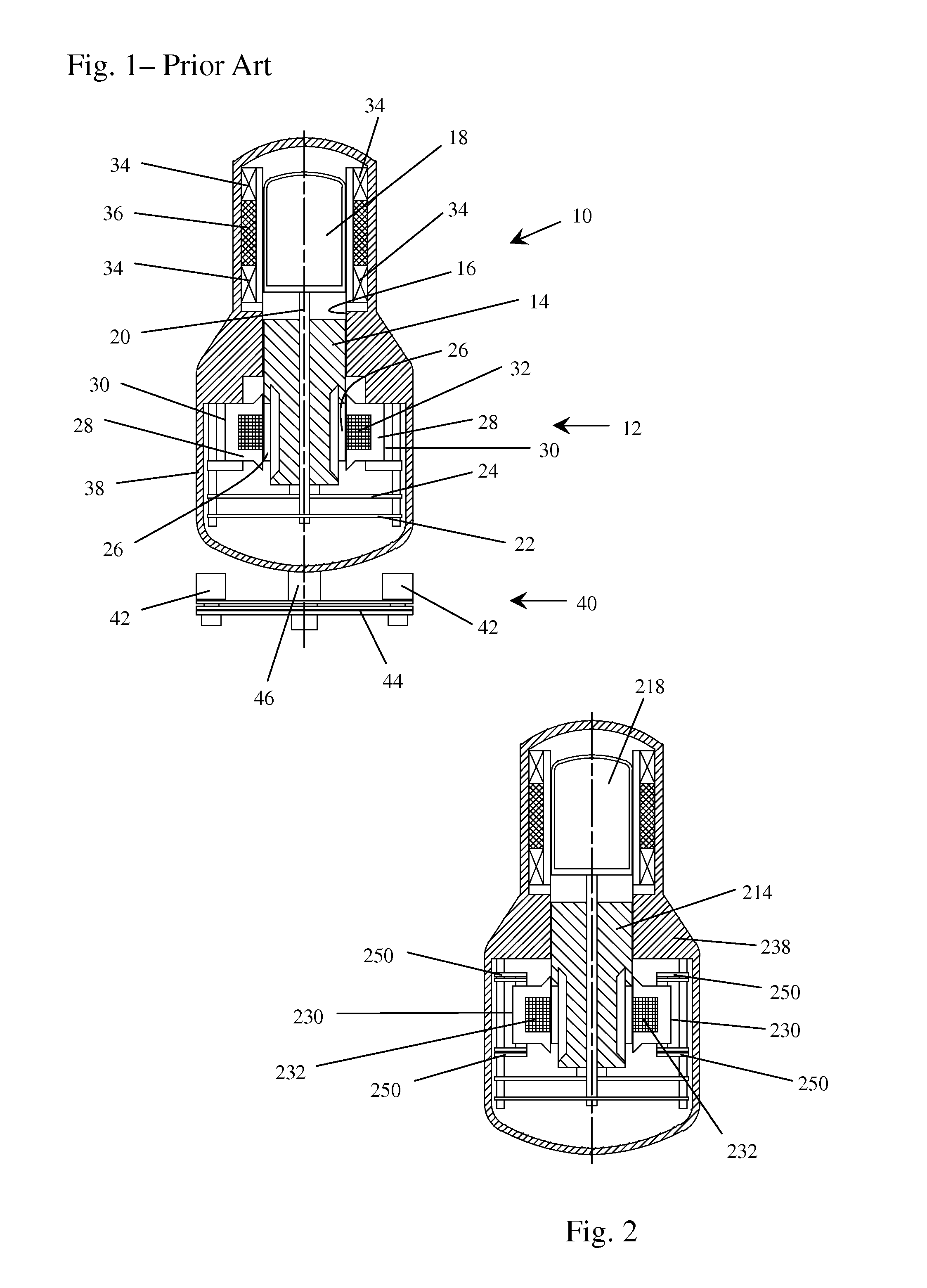

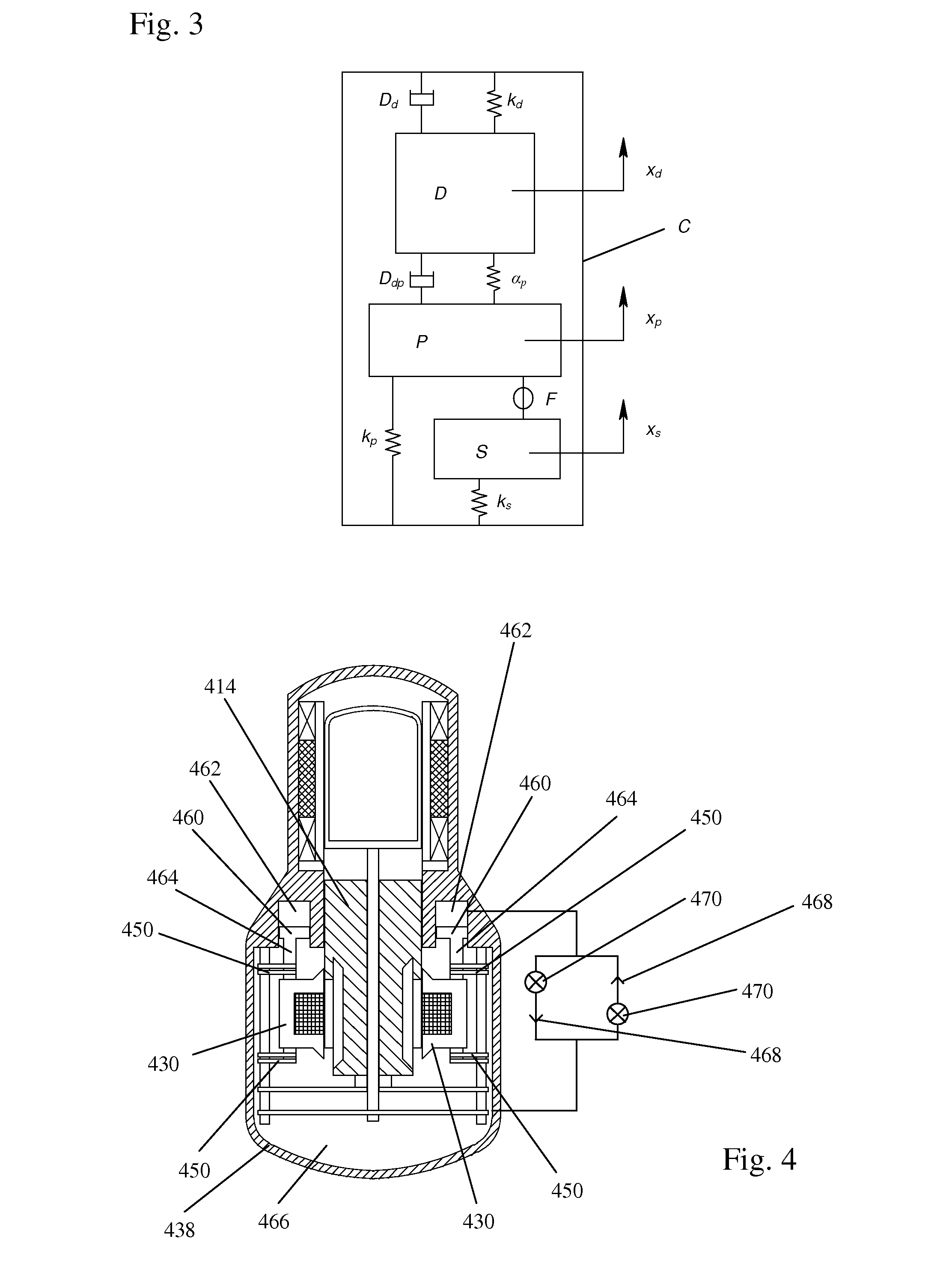

Resonant stator balancing of free piston machine coupled to linear motor or alternator

ActiveUS20090039655A1Vibration is reduced and minimized and eliminatedEliminate needSafety/regulatory devicesMechanical energy handlingEngineeringOperating frequency

A beta-type free-piston Stirling cycle engine or cooler is drivingly coupled to a linear alternator or linear motor and has an improved balancing system to minimize vibration without the need for a separate vibration balancing unit. The stator of the linear motor or alternator is mounted to the interior of the casing through an interposed spring to provide an oscillating system permitting the stator to reciprocate and flex the spring during operation of the Stirling machine and coupled transducer. The natural frequency of oscillation, ωs, of the stator is maintained essentially equal to ωpωp1-αpkpand the natural frequency of oscillation of the piston, ∩p, is maintained essentially equal to the operating frequency, ωo of the coupled Stirling machine and alternator or motor. For applications in which variations of the average temperature and / or the average pressure of the working gas cause more than insubstantial variations of the piston resonant frequency ωp, various alternative means for compensating for those changes in order to maintain vibration balancing are also disclosed.

Owner:GLOBAL COOLING

Beta type titanium alloy and method for producing same

The invention discloses a beta-Ti alloy, which comprises the components by weight percentage as follows: molybdenum is 9 to 15 percent, niobium is 6 to 10 percent, tantalum is 2 to 6 percent, zirconium is 2 to 6 percent, aluminum is 1 to 3 percent, ferrum is less than or equal to 1.0 percent, carbon is less than or equal to 0.1 percent, nitrogen is less than or equal to 0.05 percent, hydrogen is less than or equal to 0.015 percent, oxygen is less than or equal to 0.02 percent, and titanium is in the balancing amount. A preparation method comprises the steps as follows: sponge titanium, pure aluminium, sponge zirconium, Ti-Mo (the Mo is 31 percent), Ti-Nb (Nb is 53 percent) and Al-Ta (Ta is 80 percent) are mixed and made into a consumable electrode; the consumable electrode is smelted through a vacuum consumable electrode arc furnace to obtain a primary cast ingot; the primary cast ingot is used as the consumable electrode and is smelted to obtain a secondary cast ingot; the secondary cast ingot is used as the consumable electrode and is processed through vacuum consumable smelting to obtain finished products that is titanium alloy ingot. The beta-Ti alloy not only has high hardness, but also has higher unit extension and plasticity, and not only satisfies the intensity of application requirement, but also is easy to manufacture and mold and reduces the energy consumption.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

Beta type Ti Nb Zr alloy with low modulus of elasticity, preparation method and application

This invention discloses a beta-type Ti alloy with low elastic modulus for mrdical application. The Ti alloy comprises: Nb 30-37%, Zr 0-20%, and Ti. The cast structure of the Ti alloy is beta phase. The Ti alloy has moderate strength, and can satisfy the strength requirement for clinical bearing material. The elastic modulus of the Ti alloy is only 45-55% that of Ti-6Al-4V alloy. The alloy is a casting alloy, and has no noble metals added such as Ta, thus effectively lowering the cost. Besides, all the added elements have biocompatibility, and toxic elements are avoided. The Ti alloy has high biocompatibility and mechanical compatibility, and can be used to produce bone plates with reduced stress shielding effect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Low cost alpha and beta type titan alloy

The invention discloses a low-cost alpha plus beta type titanium alloy, which consists of 4.5-8 percent of aluminum, 0.3-3 percent of chromium, 0.3-2 percent of iron, and the rest of titanium and inevitable impurities by weight percent, wherein 0-3 percent of molybdenum, 0-3 percent of tin or 0-3 percent of zirconium can also be included. The alpha plus beta type titanium alloy of the invention has low cost of constituent elements and high comprehensive mechanical performance equivalent to Ti-6Al-4V, thus not only reducing the production cost of the titanium alloy, but also improving the cost performance. Therefore, the low-cost alpha plus beta type titanium alloy has wide market prospect.

Owner:北京正安广泰新材料科技有限公司

Low cost alpha and beta type titan alloy

The invention discloses a low-cost Alpha+Beta type titanium alloy, the titanium alloy contains, in weight percent: aluminum 4.5 to 8 percent, chromium 0.3 to 2 percent, iron 0.3 to 2 percent, molybdenum 0 to 1 percent, balance titanium and unavoidable impurities. The Alpha+Beta type titanium alloy of the invention contains no noble metal of vanadium, and has equivalent comprehensive mechanical properties compared with Ti-6Al-4V, thereby increasing the price performance ratio while reducing the titanium alloy manufacturing cost, and having the broad market prospect.

Owner:北京正安广泰新材料科技有限公司

Near Beta-Type Titanium Alloy

A near-beta titanium alloy having higher strength than ‘Ti-17’ is provided, while suppressing cost increase. Such a near-&bgr; titanium alloy consists of, in weight percent, 0.5-7% of V, 0.5-2.5% of Fe, 0.5-5% of Mo, 0.5-5% of Cr, 3-7% of Al, and the balance of Ti and impurities. When the weight % of V content is expressed as XV, the weight % of Fe content is expressed as XFe, the weight % of Mo content is expressed as XMo, and the weight % of Cr content is expressed as XCr; the value of XV+2.95XFe+1.5XMo+1.65XCr is 9-17%.

Owner:NIPPON STEEL CORP

Beta-type titanium alloy

Provided is a β-type titanium alloy having excellent cold workability and higher strength than Ti-20V-4Al-1Sn β-type titanium alloy, which contains: V: 5-15%, Fe: 0.5% by weight ~2.5%, Mo: 0.5~6%, Cr: 0.5~5%, and let the weight % of V contained be XV, the weight % of Fe contained be XFe, and the weight % of Mo contained be XMo When the weight % of Cr contained is XCr, the value of XV+2.95XFe+1.5XMo+1.65XCr is 15 to 23%, Al: 1.5 to 5%, and the balance is composed of Ti and impurities.

Owner:NIPPON STEEL CORP

Novel beta type titanium alloy with antibacterial and bone-healing-promoting functions

ActiveCN107630151AImprove performanceImprove mechanical propertiesProsthesisHuman bodyRare-earth element

The objective of the invention is to provide a novel beta type titanium alloy material with antibacterial and bone-healing-promoting functions and a preparation method thereof. According to the invention, proper amounts of copper, silver and rare earth elements are added into a Ti-Mo alloy. The novel beta type titanium alloy material comprises the following chemical components, by mass, 15 to 25%of Mo, 1 to 15% of Cu, 0.2 to 1% of Ag and 0.02 to 0.1% of La, with the balance being Ti. The novel beta type titanium alloy material is subjected to special heat treatment, so elemental copper is enriched on the surface of the titanium alloy and elemental silver is dissolved in a matrix in a solid solution manner; and thus, the novel beta type titanium alloy material is endowed with a biomedicalfunction and can be extensively applied to medical clinical fields such as orthopedics departments and stomatology departments using a variety of titanium alloy medical apparatuses and instruments. The novel beta type titanium alloy material overcomes the problems that conventional medical titanium alloys used in clinical practice has potential toxicity; the elastic moduli of the medical titaniumalloys are not matched with the modulus of the human body; the medical titanium alloys incur bacterial infection or are poor in osteogenesis states after implantation; etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

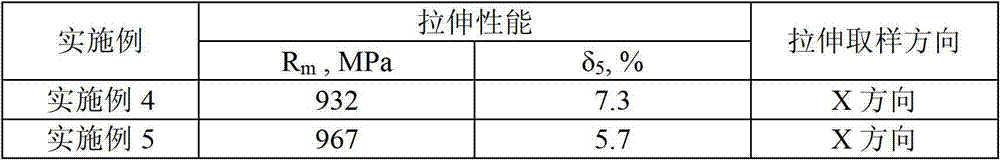

Alpha+beta type titanium alloy wire for 960MPa intensity level electron beam fused deposition rapid-forming members

The invention provides an alpha+beta type titanium alloy wire for 960MPa intensity level electron beam fused deposition rapid-forming members. The alpha+beta type titanium alloy wire is characterized by intensifying an alpha phase through adopting alloy elements Al, C and O and intensifying a beta phase through adopting alloy elements V, Fe and Si, the wire comprises the following components in percentage by weight: 6.2-7.2% of Al, 4.0-5.5% of V, 0.10-0.50% of Fe, 0.12-0.22% of O, 0.05-0.12% of Si, 0.03-0.08% of C, and the balance of Ti and inevitable impurity elements. The invention further provides a melting technology, a heating processing technology and a heating processing technology for electron beam rapid-forming members accordingly. The wire not only can meet the requirement on the electron beam fused deposition rapid-forming technology, but also enable the titanium alloy members to have excellent mechanical property. Therefore, the popularization and application of the alpha+beta type titanium alloy wire certainly create tremendous social benefits and economic benefits.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Beta-type titanium alloy and product thereof

The present invention provides a beta-type titanium alloy including, by weight %: Nb: 10 to 25%; Cr: 1 to 10%; at least one of Zr: 10% or less and Sn: 8% or less, satisfying Zr+Sn being 10% or less; and the balance of Ti and inevitable impurities, the alloy having Young's modulus of 100 GPa or less, a process for producing the beta-type titanium alloy, and a beta-type titanium alloy product.

Owner:DAIDO STEEL CO LTD

Beta-Type Titanium Alloy

Disclosed is a β-titanium alloy consisting of, in weight percent, 5-15% of V, 0.5-2.5% of Fe, 0.5-6% of Mo, 0.5-5% of Cr, 1.5-5% of Al, and the balance of Ti and impurities. When the weight % of V content is expressed as XV, the weight % of Fe content is expressed as XFe, the weight % of Mo content is expressed as XMo, and the weight % of Cr content is expressed as XCr; the value of XV+2.95XFe+1.5XMo+1.65 XCr is 15-23%. Such a β-titanium alloy has excellent cold workability, while having higher strength than Ti-20V-4Al-1Sn β-titanium alloy.

Owner:SUMITOMO METAL IND LTD

Near beta-type high-strength titanium alloy

The invention belongs to the technical field of materials sciences, and relates to a near beta-type high-strength titanium alloy. The alloy is characterized by comprising the following elements in percentage by weight: 2.5 to 3.5 percent of Al, 2.8 to 3.5 percent of V, 2.9 to 4.5 percent of Mo, 1.5 to 2.9 percent of Cr, 4.1 to 6 percent of Zr, 2 to 4 percent of Sn, 1 to 2 percent of Fe and the balance of Ti; and the alloy also comprises the following impurity elements: less than or equal to 0.04 percent of C, less than or equal to 0.15 percent of O, less than or equal to 0.04 percent of N, and less than or equal to 0.015 percent of H. Good mechanical property of the near beta-type titanium alloy is maintained, segregation of the components is not easily caused, and meanwhile, the production cost of the alloy is reduced to a certain degree; and the alloy can be widely applied in the industrial fields of aviation, aerospace, automobiles and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Alpha plus beta type titanium alloy

InactiveUS20090169416A1Ensure accuracy and uniformityConsistency of performanceRare-earth elementRoom temperature

A (α+β) type Ti alloy contains 7 wt % to 8.5 wt % of Al, 0.5 wt % to 1.5 wt % of V, 1 wt % to 3 wt % of Mo, 1 wt % to 3 wt % Cr, 0.3 wt % to 1 wt % of Fe, 0.05 wt % to 0.1 wt % of rare earth element, Ti, and unavoidable impurities. The Ti alloy can be produced by varmelting, forging, rolling and casting pressure processing or powder metallurgy. The total amount of impurities of C, H, O, and N is not higher than 0.25 wt %. V, Mo, and rare earth elements are added in forms of Al—V intermediate alloy, Al—Mo intermediate alloy, and La—Ce mixed rare earth, respectively. The room-temperature tensile strength and yield strength of the Ti alloy are higher than those of Ti—6Al—4V by more than 30%, the high-temperature strength is superior to that of Ti—6Al—4V, density and cost are lower than those of Ti—6Al—4V.

Owner:LI SHI QIONG

Low-elastic-modulus beta type titanium alloy for dental filling and production method thereof

ActiveCN108486408AImprove mechanical propertiesImprove corrosion resistanceImpression capsAdditive manufacturing apparatusYoung's modulusPhase volume

The invention provides a low-elastic-modulus beta type titanium alloy for dental filling. The low-elastic-modulus beta type titanium alloy is characterized by being prepared from alloy components according to the weight percent: 23 to 24 percent of Mo, 12 to 13 percent of Nb, 2.5 to 2.8 percent of Zr, 2.1 to 2.2 percent of Al, 1.1 to 1.7 percent of Cr, 0.5 to 0.6 percent of Ag, 0.2 to 0.3 percentof Fe, 0.4 to 0.7 percent of Ta, 0.15 to 0.2 percent of Cu, 0.3 to 0.45 percent of Hf, 0.2 to 0.4 percent of Sn, 0.05 to 0.08 percent of Er, less than or equal to 0.05 percent of O, less than or equalto 0.01 percent of H, less than or equal to 0.02 percent of C, less than or equal to 0.01 percent of N and the balance of Ti and unavoidable impurities; the beta type titanium alloy formed by heat treatment has the average crystallization grain diameter of 20 to 40mu m, the yield strength of 900 to 1000MPa, the tensile strength of 1020 to 1150MPa, the elongation percentage of 15 to 17 percent, the Young's modulus of 40 to 60GPa, the primary alpha-phase volume percent of 22 to 25 percent, the size of 2 to 3 microns and the secondary alpha-phase volume percent of 22 to 25 percent.

Owner:山东创瑞健康医疗科技有限公司

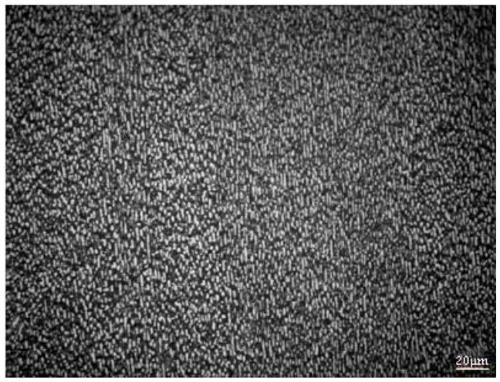

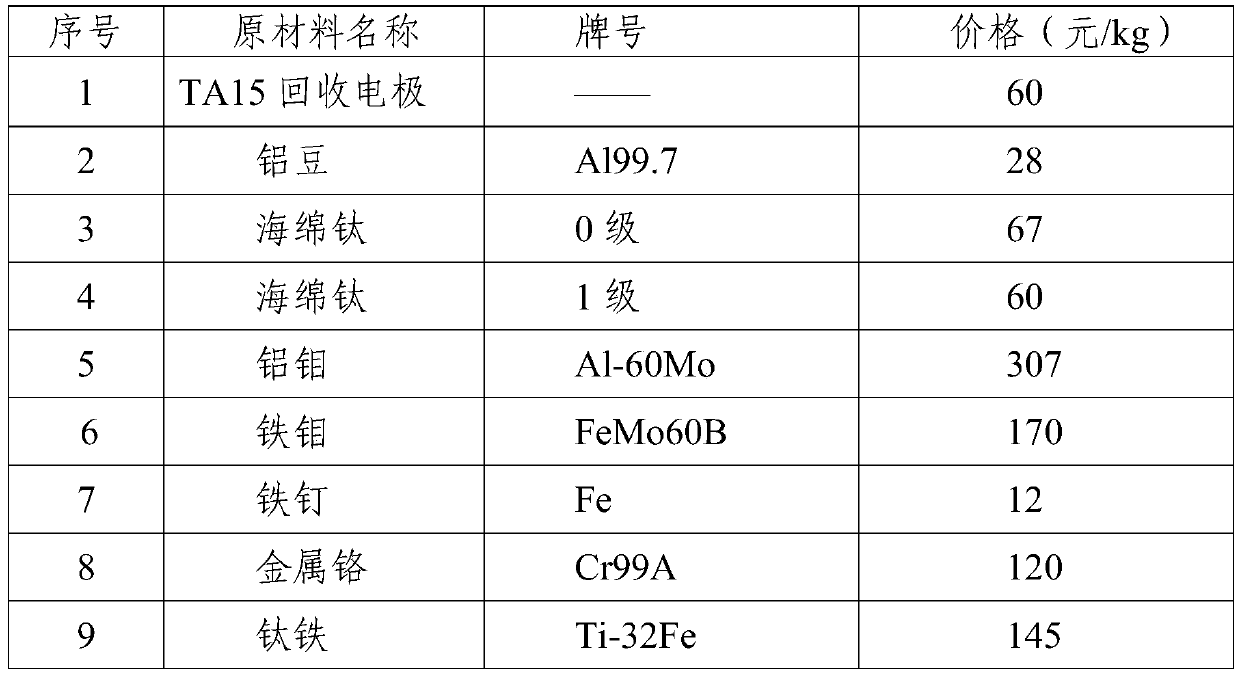

Nearly beta-type high-toughness titanium alloy and preparation method thereof

The invention discloses a nearly beta-type high-toughness titanium alloy. The nearly beta-type high-toughness titanium alloy comprises the following components in percentage by mass: 4.0%-5.5% of Al,0.8%-1.8% of Zr, 3.0%-4.5% of Mo, 1.0%-2.0% of V, 1.5%-2.5% of Fe, 2.5%-3.5% of Cr, no more than 0.12% of B, and the balance Ti and inevitable impurities. The invention also discloses a preparation method of the nearly beta-type high-toughness titanium alloy. According to the preparation method, a large amount of TA15 recycled material is adopted as a raw material; an Al-Zr system is adopted to reinforce an alpha phase in the titanium alloy, and a Mo-V-Cr-Fe system is adopted to reinforce a beta phase in the titanium alloy, so that the coupling reinforcement effect is enhanced; the titanium alloy has good strength and toughness matching; the aluminum equivalent and the molybdenum equivalent of the titanium alloy are controlled, so that the great strength and toughness of the titanium alloyis ensured; and the TA15 titanium alloy recycled material is used as a raw material, so that the preparation cost is greatly reduced.

Owner:WESTERN TITANIUM TECH

Beta type gamma-TiAl alloy and preparation method thereof

InactiveCN101880794AGood high temperature deformation abilityImprove antioxidant capacityNiobiumCrucible

The invention discloses a beta type gamma-TiAl alloy and a preparation method, relates to a TiAl alloy and a preparation method thereof and solves the problems of the high-temperature deformability and poor oxidation resistance of the traditional TiAl alloy. The beta type gamma-TiAl alloy comprises the following components in percentage by atom: 41-46 percent of Al, 9 percent of V and Nb, 0-0.3 percent of Y and the balance of Ti, wherein the specific value x of the V and the Nb is 0.5-5. The preparation method comprises the following steps: weighting raw materials of spongy titanium, high-purity aluminum, an aluminum-niobium intermediate alloy, an aluminum-vanadium alloy and an aluminum-yttrium alloy; and placing the raw materials into a water-cooled copper crucible vacuum medium frequency induction melting furnace for melting. By controlling the proportion of the V to the Nb, the beta type gamma-TiAl alloy with favorable high-temperature deformability and the oxidation resistance can be obtained and the forged surface has no crack phenomenon; and the weight is added by 25mg / cm<2> after circulating oxidation at 800DEG C for 80h, which is ten times of the oxidation resistance of a Ti-43Al-9V-0.3Y alloy. The preparation method is simple.

Owner:HARBIN INST OF TECH

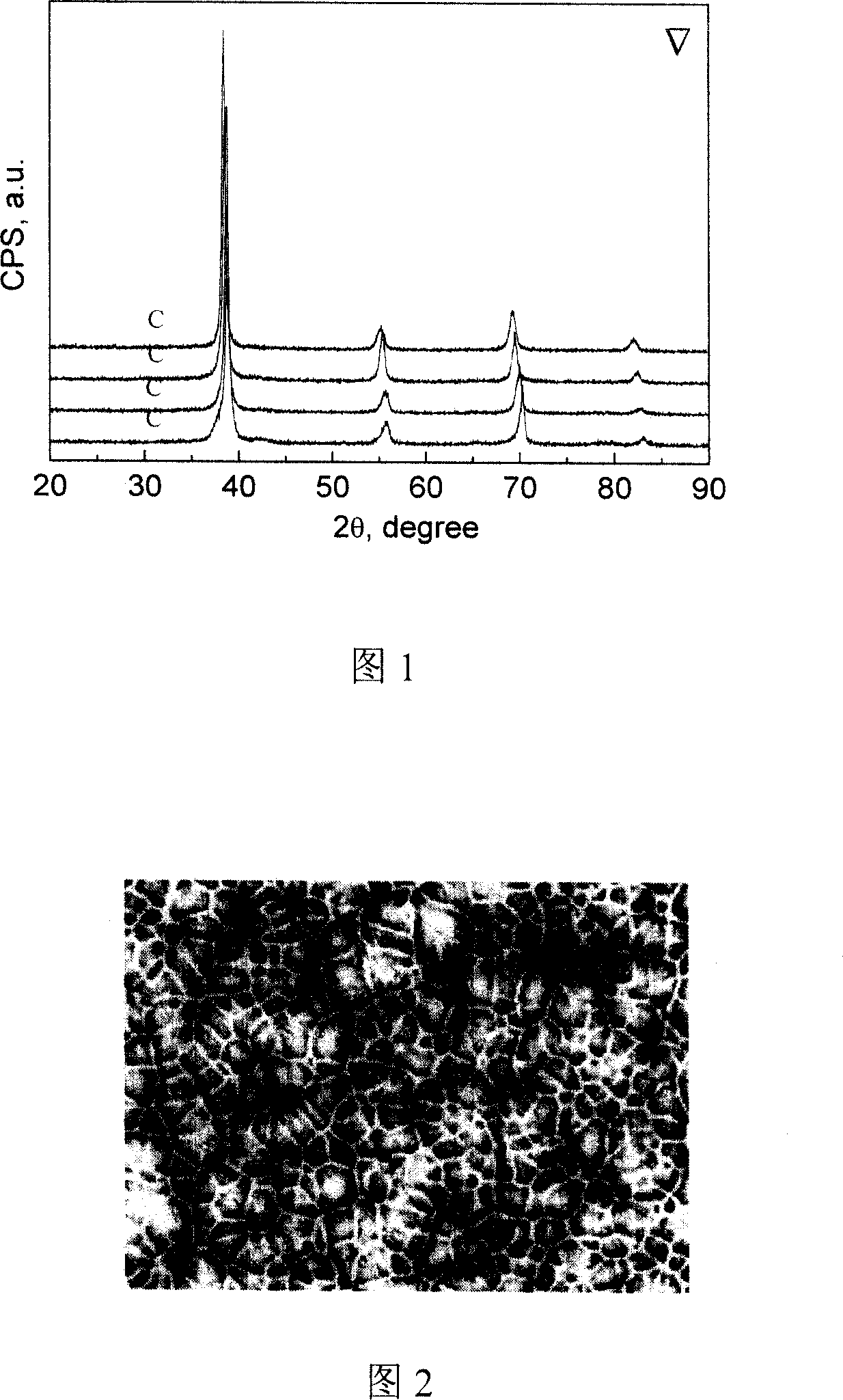

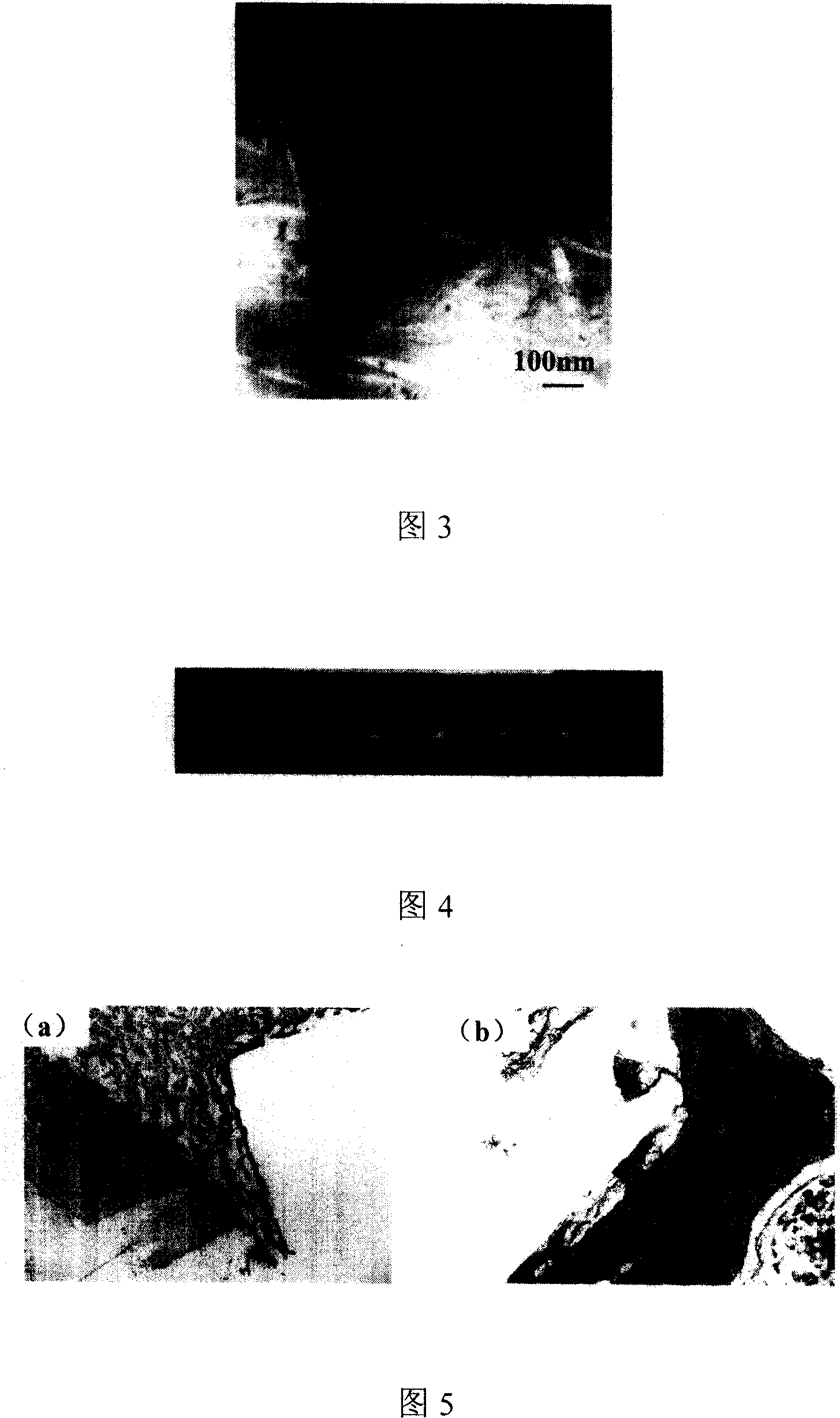

Method for enhancing work hardening capacity of beta-type amorphous alloy endogenous composite material

The invention discloses a method for enhancing work hardening capacity of a beta-type amorphous alloy endogenous composite material and belongs to the technical field of an amorphous alloy composite material. According to the method, content of beta-phase stable element in the chemical components of the beta-type amorphous alloy endogenous composite material is adjusted such that the beta-phase has proper structural metastability. Then, an obtained sample can undergo deformation-induced martensitic transformation and / or twinning so as to enhance work hardening capacity of the beta-type amorphous alloy endogenous composite material. The key of the method is to regulate and control structural metastability of the in-situ precipitated beta-phase. The method has important value for designing and developing the beta-type amorphous alloy endogenous composite material with excellent mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Alpha+beta type titanium alloy

The invention discloses an alpha plus beta type titanium alloy. The titanium alloy comprises the following components in percentage by weight: 7 to 8.5 percent of aluminum, 0.5 to 1.5 percent of vanadium, 1 to 3 percent of molybdenum, 1 to 3 percent of chromium, 0.3 to 1 percent of iron, 0.05 to 0.1 percent of rare earth element, the balance being titanium and inevitable impurities. The titanium alloy can be manufactured by common manufacturing methods for the titanium alloy such as the fusion casting pressure processing method and the powder metallurgic method. The total weight percentage of carbon, hydrogen, oxygen and nitrogen in the impurities is no more than 0.25 percent, and the vanadium is added in the form of aluminum-vanadium intermediate alloy, the molybdenum is added in the form of aluminum-molybdenum intermediate alloy, and the rare earth is added in the form of lanthanum-cerium mixed rare earth. Compared with Ti-6Al-4V, the room-temperature tensile strength and yield strength of the titanium alloy are improved by more than 30 percent, the high-temperature strength is also obviously enhanced, and the density and the cost are slightly lowered, so that the titanium alloy has more desirable performance-to-price ratio and wider market prospect.

Owner:李世琼

Heat treatment process for improving obdurability of near beta type or metastable beta type titanium alloy

The invention relates to a heat treatment process for improving obdurability of a near beta type or metastable beta type titanium alloy. The process comprises the following steps of: firstly, preserving heat at the temperature of T which is more than or equal to T beta-50 DEG C and less than or equal to T beta-10 DEG C, wherein the heat preservation time T (min) is eta * delta max, the delta max is the maximum section thickness of a forge piece, the unit is mm, the eta is a heating coefficient, and the value of the heating coefficient eta is 0.5 to 1.5min / mm; secondly, discharging the forge piece out of a furnace and cooling the forge piece to room temperature by air or water; thirdly, preserving heat of the cooled forge piece at the temperature of T which is more than or equal to 520 DEGC and less than or equal to 560 DEG C, wherein the heat preservation time T is more than or equal to 20min and less than or equal to 1.5h; fourthly, discharging the forge piece out of the furnace andcooling the forge piece to room temperature by air; fifthly, slowly heating the cooled forge piece to the temperature of T which is more than or equal to 480 DEG C and less than or equal to 540 DEG Calong with the furnace, wherein the heating rate is controlled to be within 5 DEG C / min, and the heat preservation time T is more than or equal to 6h and less than or equal to 12h; and finally, cooling the forge piece along with the furnace or discharging the forge piece out of the furnace and cooling the forge piece to room temperature by air. The process is suitable for heat treatment of the near beta type or metastable beta type titanium alloy with ultrahigh obdurability so as to obtain a tissue with high comprehensive performance and multi-scale precipitated phases, which has the requiredultrahigh strength (Rm is more than or equal to 1,500 MPa), high plasticity (A is more than or equal to 5 percent) and high obdurability (KIC is more than or equal to 45 MPa.m < 1 / 2 >), and meet important bearing structural members with ultrahigh obdurability matching required by airplanes.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method of preparing linear alkylbenzene

InactiveCN101058523AGood activity and stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention discloses a synthesizing method of straight-line alkyl benzene, which comprises the following steps: adopting straight-line olefin with carbon atom number between 2 and 20 and benzene as raw material; inputting in the reactor; reacting benzene and olefin with molar rate at 2-100:1 at 290-450 deg. c under 5-15Mpa hypercritical condition; setting the air speed at 0. 1-20h-1; making solid acid as catalyst; adopting one of loaded modified (1) SBA-15 typed molecular sieve, (2) HY typed molecular sieve, (3) USY typed molecular sieve, (4) H beta typed molecular sieve, (5) H-Moderite typed molecular sieve, (6) HZSM-20 typed molecular sieve as composite typed solid acid catalyst. The invention improves transmitting rate of olefin with stable operation, which possesses good using prospect.

Owner:ZHEJIANG UNIV OF TECH

A machining method for a metastable beta type titanium alloy TB16 cold rolled tube

The invention relates to a machining method for a metastable beta type titanium alloy TB16 cold rolled tube. The method includes blending raw materials of a TB16 titanium alloy, preparing a cast ingot, performing blooming forging, extruding a tube, performing sand blasting, performing acid washing, subjecting the tube to multi-pass rolling, subjecting a tube finished product to solution treatmentand ageing treatment, and other steps. Raw materials of the TB16 titanium alloy comprise 4.5-5.7 wt% of Mo, 4.5-5.7 wt% of V, 5.5-6.5 wt% of Cr, 2.5-3.5 wt% of Al, less than 0.30 wt% of Fe, less than0.05 wt% of C, less than 0.04 wt% of N, less than 0.015 wt% of H and less than 0.15 wt% of O, with the balance being titanium. The alloy has high tensile strength, toughness and good welding performance, and can be used in the fields of aviation, aerospace, oil, ships, chemical engineering, and the like.

Owner:GRIMAT ENG INST CO LTD

Multipurpose new type beta type titanium alloy

The present invention relates to the components and preparation process of new type multipurpose beta-type titanium alloy with high strength, high elasticity, high plasticity, excellent cold machining performance, and good welding performance. The beta-type titanium alloy consists of V 20-23 wt% and Al 3.5-4.5 wt%, except Ti and inevitable impurity, including Fe not more than 1.0 wt%, C not more than 0.1 wt%, N2 not more than 0.05 wt%, and O2 not more than 0.02 wt%. The beta-type titanium alloy may be used in producing spectacle frame, golf club head or its hit panel, various elastic parts, standard parts, etc.

Owner:西安赛特金属材料开发有限公司

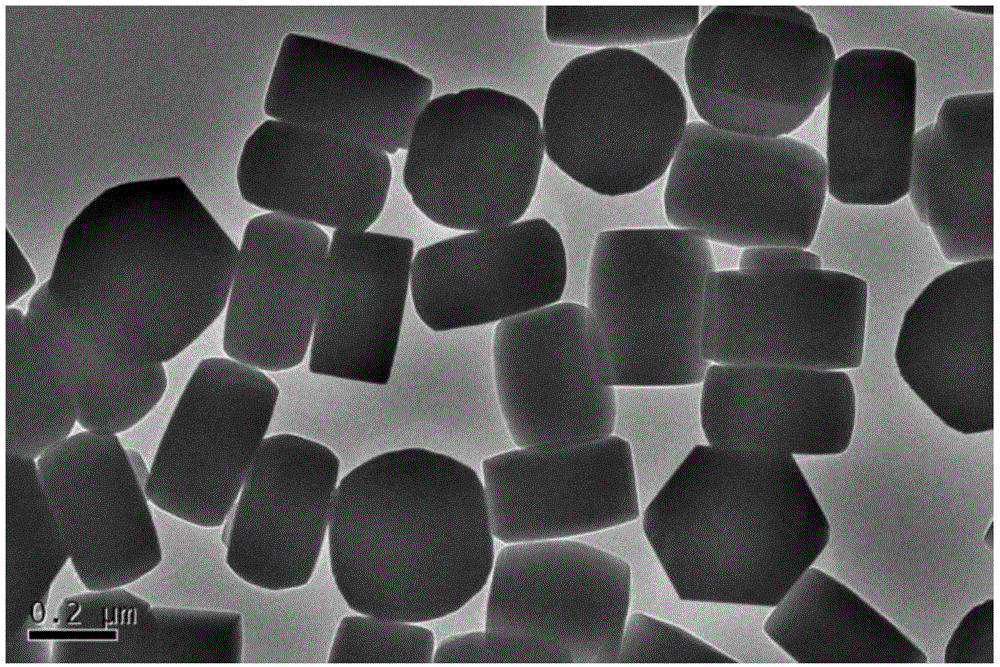

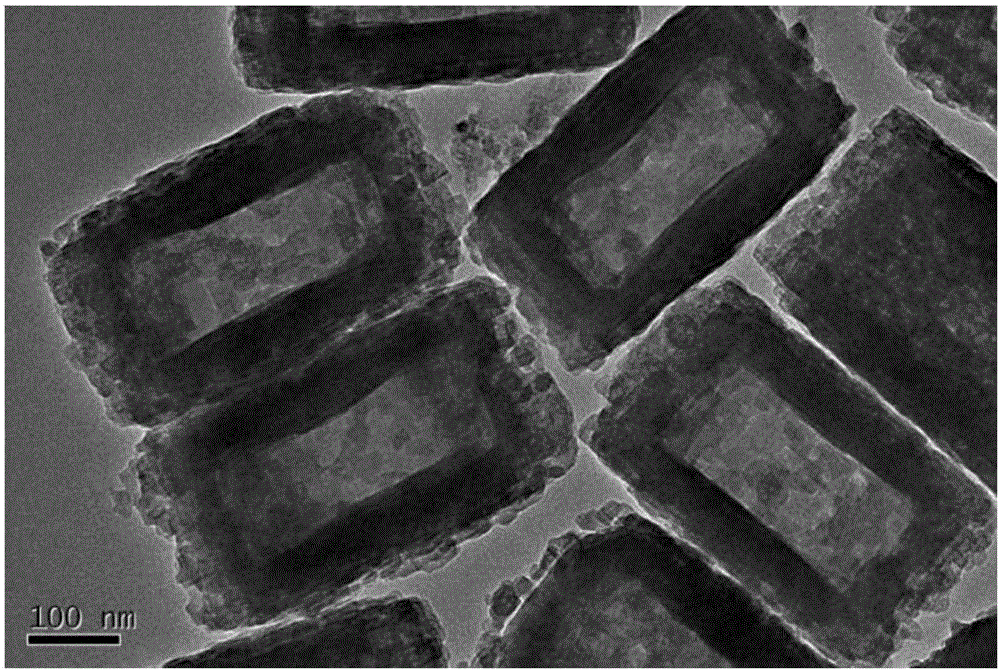

Hollow molecular sieve, and preparation method and application thereof

ActiveCN106082257AEasy to growResizeMolecular sieve catalystsMolecular sieve catalystBeta typePhotochemistry

The invention provides a hollow molecular sieve, and a preparation method and application thereof. The hollow molecular sieve has an external diameter of 50 nm to 10 [mu]m, an internal diameter of 20 nm to 9 [mu]m, and a specific surface area of 200 to 1000 m<2> / g; the shell of the hollow molecular sieve is composed of three layers of isomorphous molecular sieves with different Si / Al ratios; and the hollow molecular sieve may be one or more selected from a group consisting of a ZSM-5 type hollow molecular sieve, a beta type hollow molecular sieve and a Y type hollow molecular sieve. The hollow molecular sieve can effectively overcome the problem of diffusion in practical application; the size and shell thickness of the hollow molecular sieve can be regulated by changing a feed ratio and crystallization conditions; and a super-weak-solution-phase epitaxial growth method used in the invention is simple, has a wide application scope, can prepare three layers of isomorphous molecular sieve structures with different Si / Al ratios in a shell structure, is applicable to ZSM-5, beta and Y type molecular sieves and has low preparation cost.

Owner:TSINGHUA UNIV

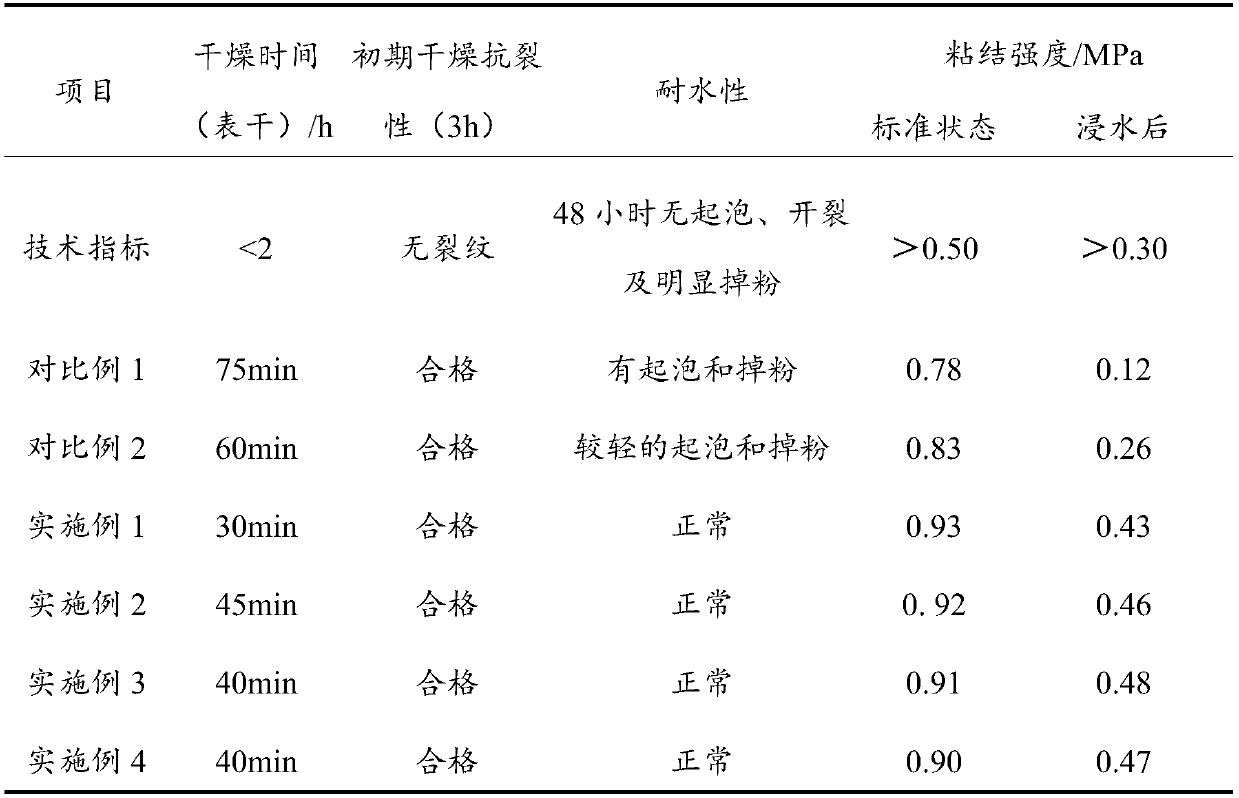

Gypsum-based putty

InactiveCN107936671AImprove mechanical propertiesImprove water resistanceFilling pastesCelluloseFiber

The invention discloses gypsum-based putty. The gypsum-based putty comprises the following components in parts by mass: 30-40 parts of beta-type hemihydrate gypsum, 3-7 parts of ash calcium, 2-3 partsof silica fume, 3-5 parts of mineral slag, 50-60 parts of triple superphosphate, 0.8-1.5 parts of redispersible latex powder, 0.3-0.4 part of cellulose ether, 0.03-0.05 part of starch ether, 0.2-0.5part of wood fiber, 0.1-0.5 part of a hydrophobic agent and 0.06-0.1 part of a retarder. The gypsum-based putty uses the beta-type hemihydrate gypsum as a main cementing material and uses the ash calcium, mineral slag and the silica fume as auxiliary cementing materials, and the components react with one another so as to improve the mechanical properties and the water resistance of the cementing system; the gypsum-based putty has excellent adhesion, water resistance and flexibility, and raw materials are wide in sources and low in cost; the 7d bonding strength of the gypsum-based putty reaches0.9MPa, and the flooding bonding strength thereof reaches 0.4MPa or above.

Owner:北京宝辰联合科技股份有限公司

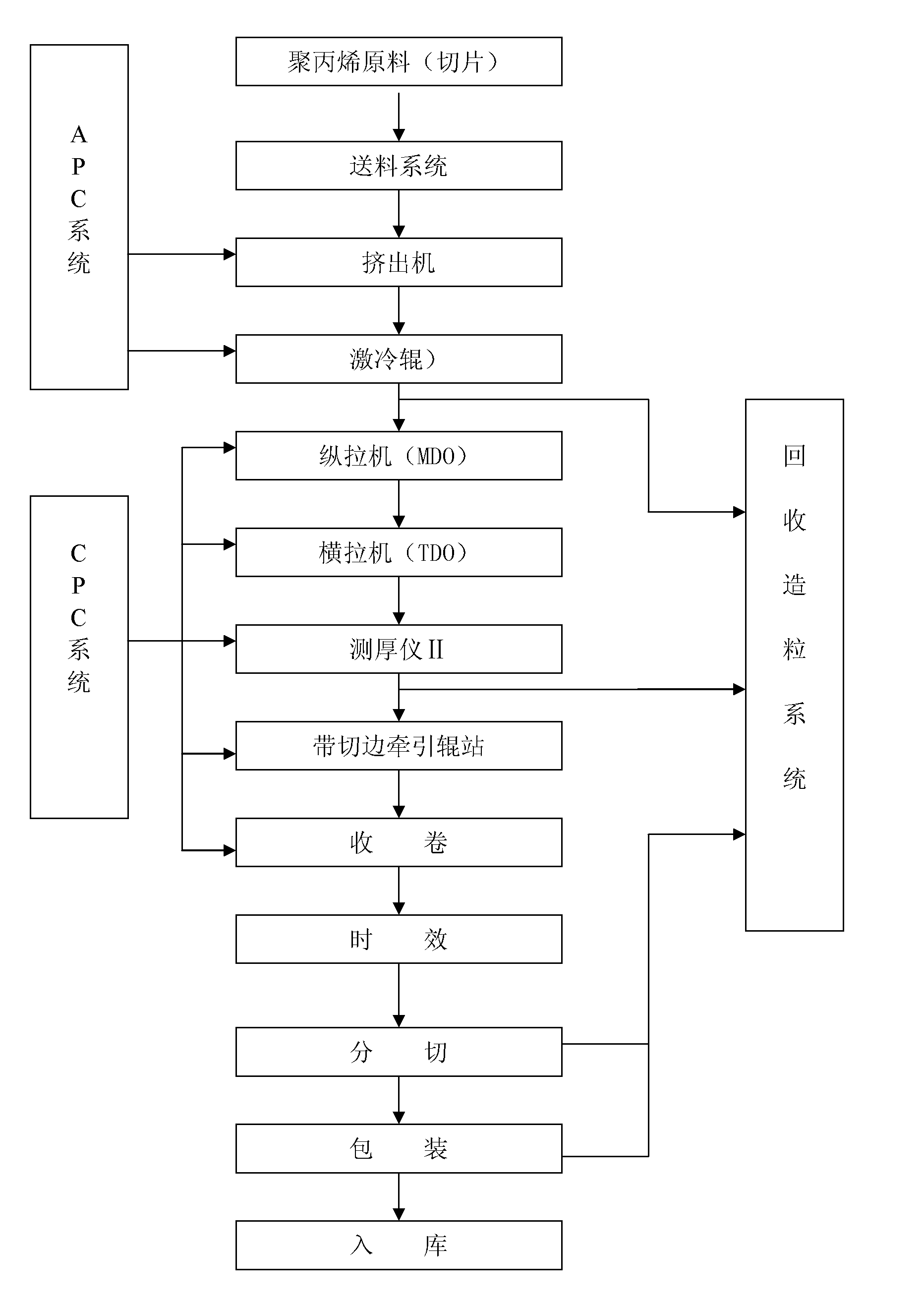

Production method of high-permeability low-density lithium battery polyolefin diaphragm

InactiveCN102403478AOvercoming performance deficienciesReduced mechanical propertiesCell component detailsPorosityPolyolefin

The invention discloses a production method of a high-permeability low-density lithium battery polyolefin diaphragm. The production method comprises the following steps of 1, preparing a nucleating agent, 2, mixing 50 to 80% of a metallocene-catalyzed polypropylene homopolymer, 20 to 50% of a metallocene-catalyzed polypropylene block copolymer and 1 to 4% of the nucleating agent, extruding the mixture by an extruder to obtain a diaphragm, cooling the diaphragm by a chilling roller at a temperature of 100 to 150 DEG C for 2 to 15 minutes so that a mass of beta-type crystals are produced and fully grows in the diaphragm, and cooling to obtain a casted sheet, and 3, carrying out vertical stretching and horizontal stretching of the casted sheet to obtain the high-permeability low-density lithium battery polyolefin diaphragm having density less than or equal to 0.55g / cm<3> and thickness of 12 to 60 micrometers, wherein a stretching temperature is in a range of 90 to 160 DEG C; and an area stretching ratio is in a range of 8 to 40. The high-permeability low-density lithium battery polyolefin diaphragm obtained by the production method has unique performances of high non-transparency, high gas permeability, low density (high porosity), high moisture permeability and high strength. A stretching ratio of the high-permeability low-density lithium battery polyolefin diaphragm is in a range of 8 to 40. The density of the high-permeability low-density lithium battery polyolefin diaphragm is less than 0.55g / cm<3>, and preferably, is 0.30g / cm<3>.

Owner:TONGLING JINGNENG ELECTRONICS

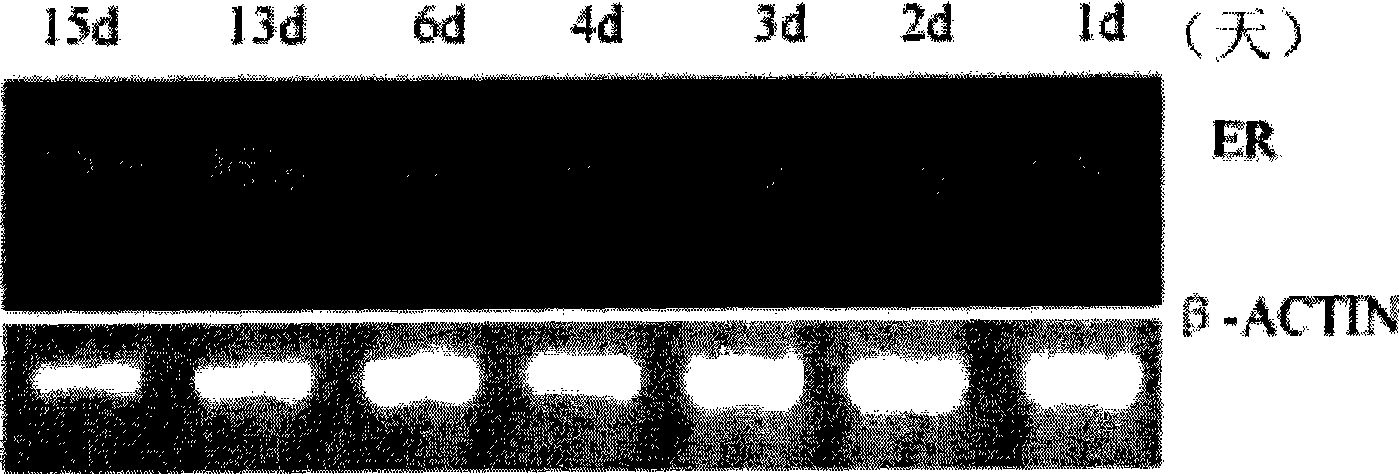

Rare minnow beta type estrogen receptor and use thereof

InactiveCN101469020ARegulation of reproductive capacitySimple and fast operationMicrobiological testing/measurementReceptors for hormonesMinnowCarp

The invention provides a rare golden carp beta type estrogen receptor and an encoded gene thereof. The invention also provides a method for detecting the chemical toxicity of an aquatic environment and a kit for diagnosing the diseases of aquatics. The method and the kit both relate to the detection of the expression level of the receptor. The invention is applied to detecting the chemical toxicity of the aquatic environment and diagnosing the diseases of aquatics, in particular the piscine genital system diseases, thereby realizing the aim of regulating the piscine reproductive ability. Experimental results show that: the expression of the GrER beta gene has a dosage-effect relationship with the estrogen effect; therefore the method has the advantage of simple, quick and correct operation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

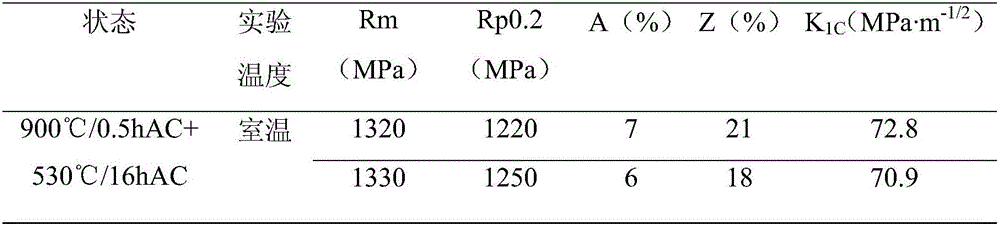

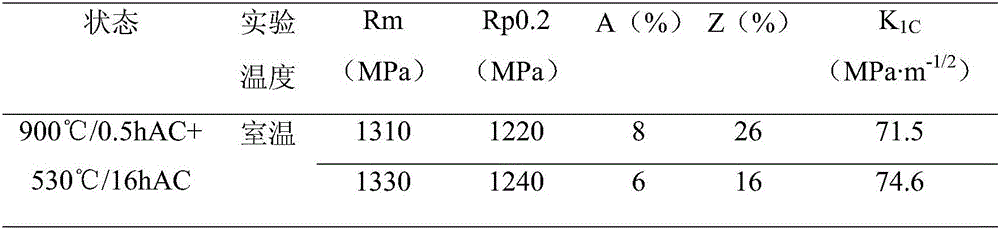

Beta-type similar high-strength and high-tenacity titanium alloy

The invention discloses a beta-type similar high-strength and high-tenacity titanium alloy. The beta-type similar high-strength and high-tenacity titanium alloy is characterized by comprising alloy elements, by weight percentage, including 2.5%-3.5% of Al, 4%-6% of Mo, 4%-6% of V, 3%-5% of Cr, 1.5%-3% of Nb and the balance titanium and unavoidable impurities. According to the beta-type similar high-strength and high-tenacity titanium alloy, the tensile strength Rm is larger than or equal to 1,300 MPa, the yield strength Rp0.2 is larger than or equal to 1,200 MPa, the breaking tenacity K1C is larger than or equal to 70 MPa.m<1 / 2>, and the alloy is a high-strength and high-tenacity beta-type similar titanium alloy.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com