Nearly beta-type high-toughness titanium alloy and preparation method thereof

A technology of tough titanium alloy and titanium alloy, which is applied in the field of nearly β-type high-strength and tough titanium alloy and its preparation, can solve the problems of waste of resources and other problems, and achieve the effects of reducing production cycle and cost, efficient coupling strengthening effect, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

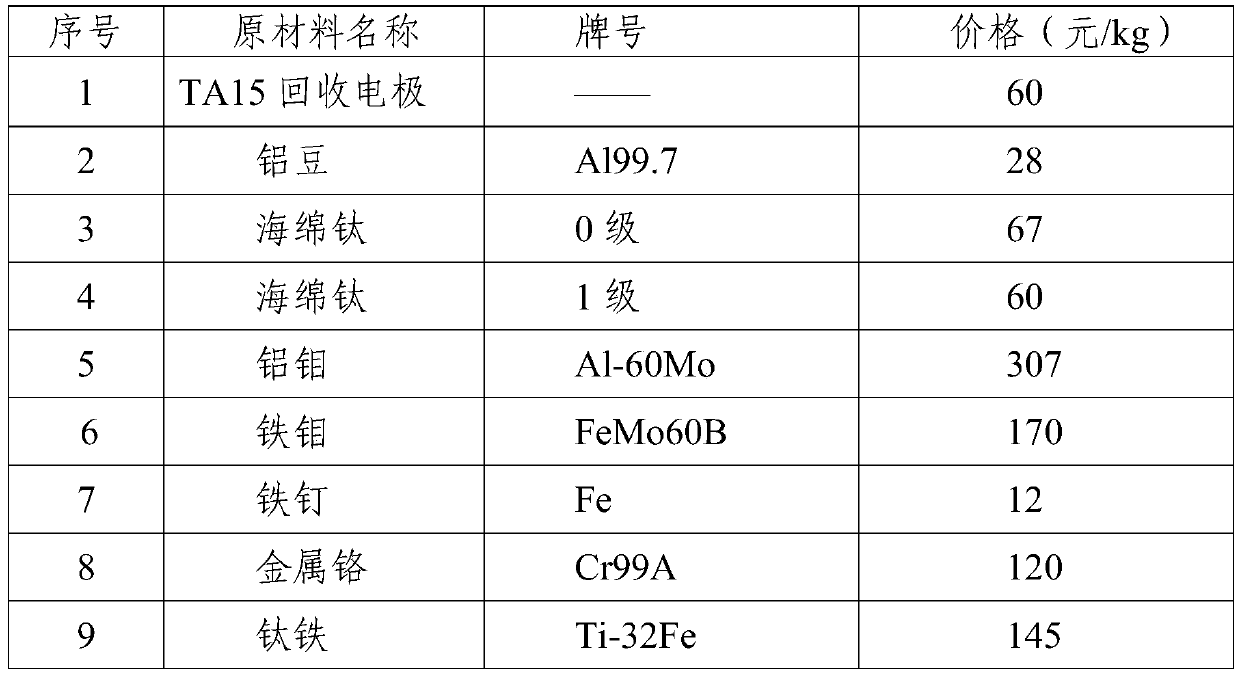

Embodiment 1

[0036] The nearly β-type high-strength and tough titanium alloy of this embodiment is composed of the following mass percentages: Al 5.0%, Zr 1.0%, Mo 3.5%, V 1.4%, Fe 2%, Cr 3%, and the balance is Ti and not Avoid impurities.

[0037] The preparation method of the near β-type high-strength and tough titanium alloy of this embodiment is: fully mix the electrode prepared by the TA15 titanium alloy reclaimed material with aluminum beans, iron nails, metal chromium, 0-grade sponge titanium, and iron-molybdenum intermediate alloy and then press it. The electrodes are assembled and welded to prepare a smelting electrode, wherein the mass percentage of the electrode prepared from the TA15 titanium alloy recycled material in the smelting electrode is 60%, and then undergo three vacuum consumable arc melting to obtain a titanium alloy ingot; the titanium alloy ingot is passed through After mechanical processing and subsequent thermal processing, a titanium alloy rod with a diameter of...

Embodiment 2

[0041] The nearly β-type high-strength and tough titanium alloy of this embodiment is composed of the following mass percentages: Al 4.5%, Zr 1.8%, Mo 4.5%, V 1.2%, Fe 1.5%, Cr 3%, B 0.05%, and the balance For Ti and unavoidable impurities.

[0042] The preparation method of the near β-type high-strength and tough titanium alloy of this embodiment is: fully mix the electrode prepared by the TA15 titanium alloy reclaimed material with aluminum beans, iron nails, metal chromium, boron powder, first-grade sponge titanium, and iron-molybdenum master alloy Afterwards, the pressed electrodes are assembled and welded to prepare smelting electrodes, wherein the mass percentage of electrodes prepared from TA15 titanium alloy recycled materials in the smelting electrodes is 70%, and then undergo three vacuum consumable arc melting to obtain titanium alloy ingots; titanium alloy After the ingot is mechanically processed and followed by thermal processing, it is prepared into a near-β-typ...

Embodiment 3

[0046] The nearly β-type high-strength and tough titanium alloy of this embodiment is composed of the following mass percentages: Al 4.2%, Zr 1.4%, Mo 4.1%, V 1.9%, Fe 2%, Cr 3.5%, B 0.12%, and the balance For Ti and unavoidable impurities.

[0047] The preparation method of the near β-type high-strength and tough titanium alloy in this embodiment is as follows: the electrode prepared from the recycled TA15 titanium alloy is fully mixed with the electrode made of aluminum beans, iron nails, metal chromium, first-grade sponge titanium, and FeMo60B master alloy, and then pressed. Welding is carried out to prepare a smelting electrode, wherein the mass percentage of the electrode prepared from TA15 titanium alloy recycled materials in the smelting electrode is 70%, and then undergoes three vacuum consumable arc melting to obtain a titanium alloy ingot; the titanium alloy ingot is machined After processing and subsequent thermal processing, a near-β-type titanium alloy rod with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com