Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145 results about "Ti 6al 4v" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ti-6Al-4V (UNS designation R56400 ), also sometimes called TC4, is an alpha-beta titanium alloy with a high strength-to-weight ratio and excellent corrosion resistance. It is one of the most commonly used titanium alloys and is applied in a wide range of applications where low density and excellent corrosion resistance are necessary...

Alpha-beta type titanium alloy

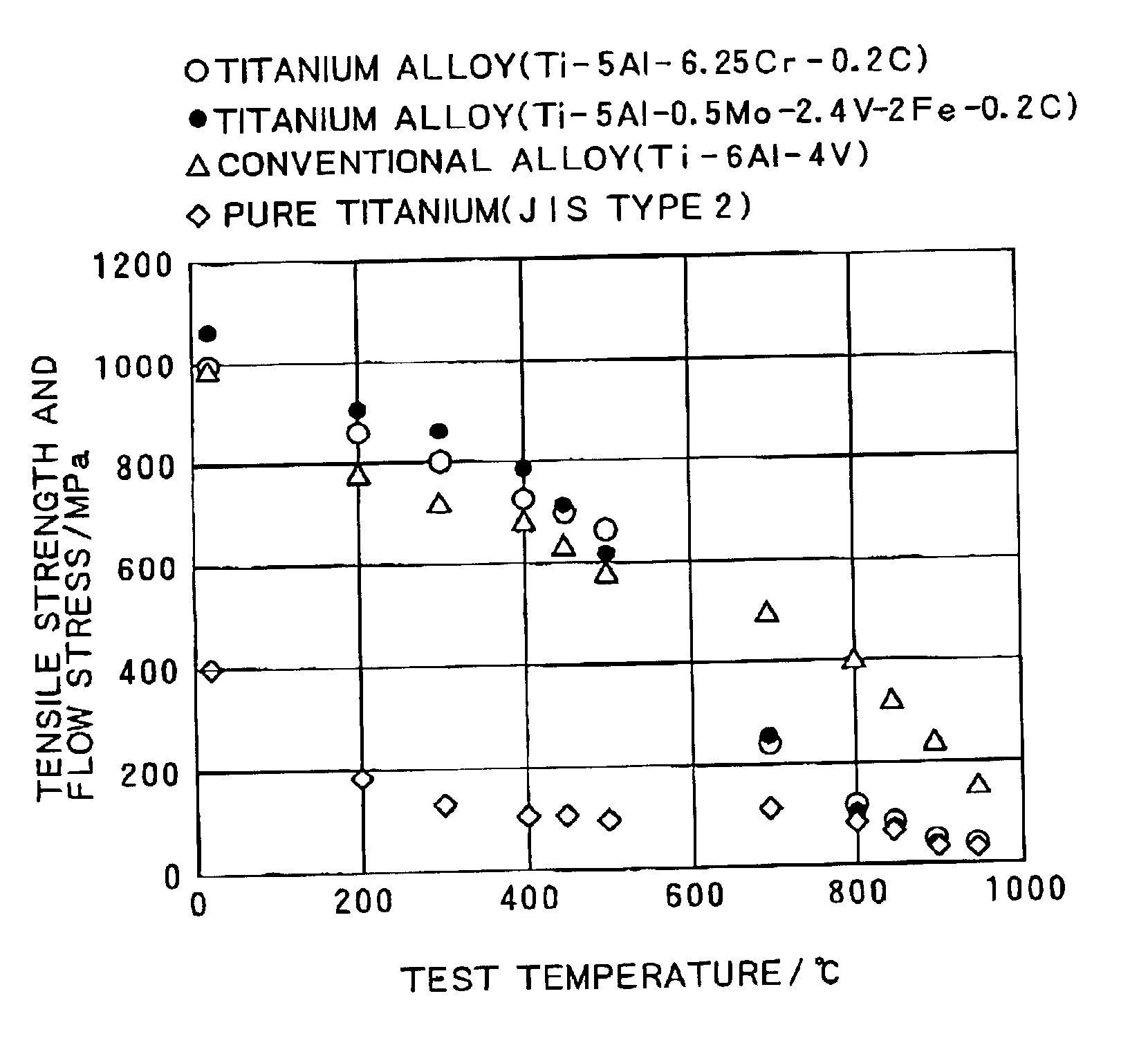

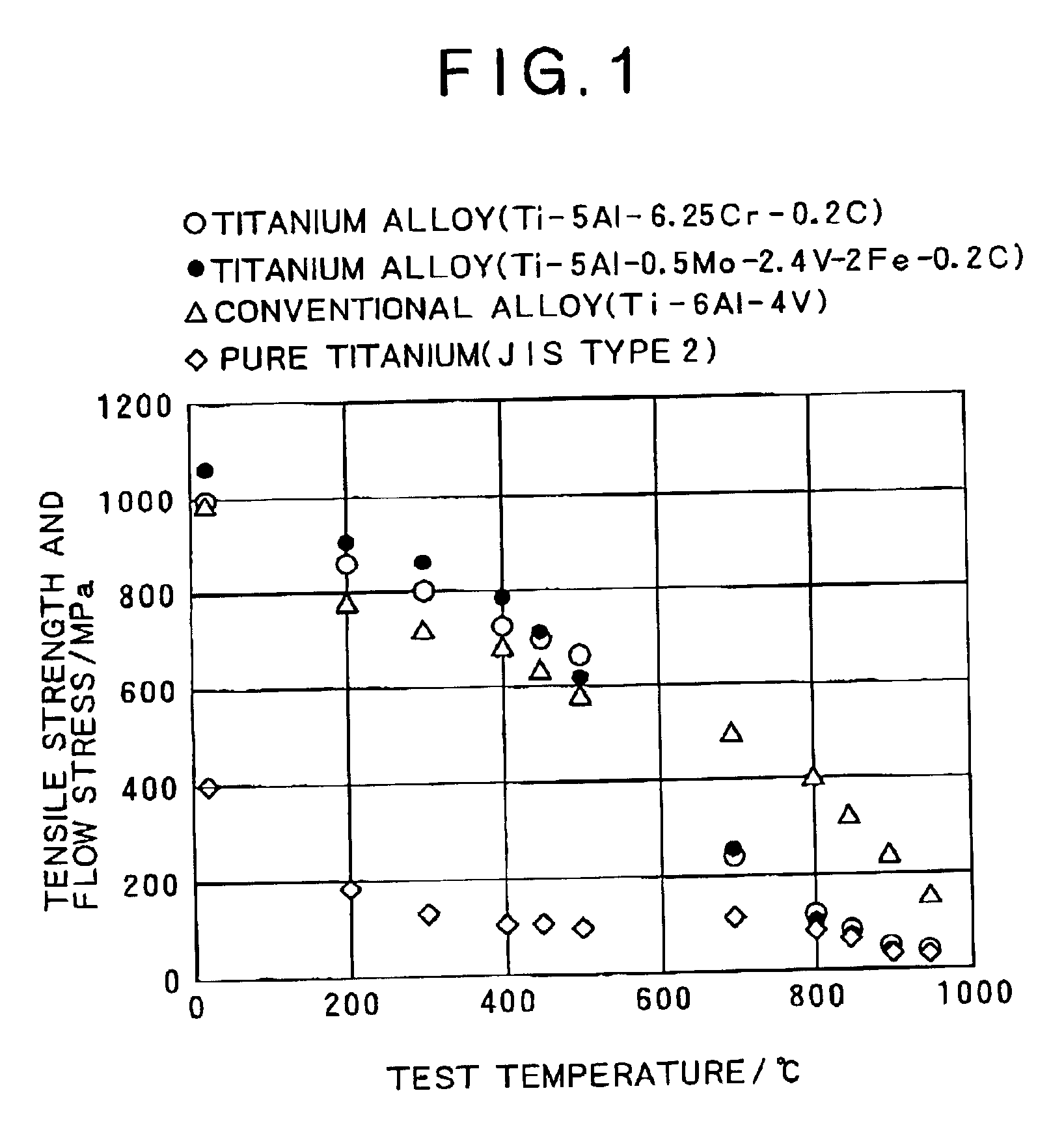

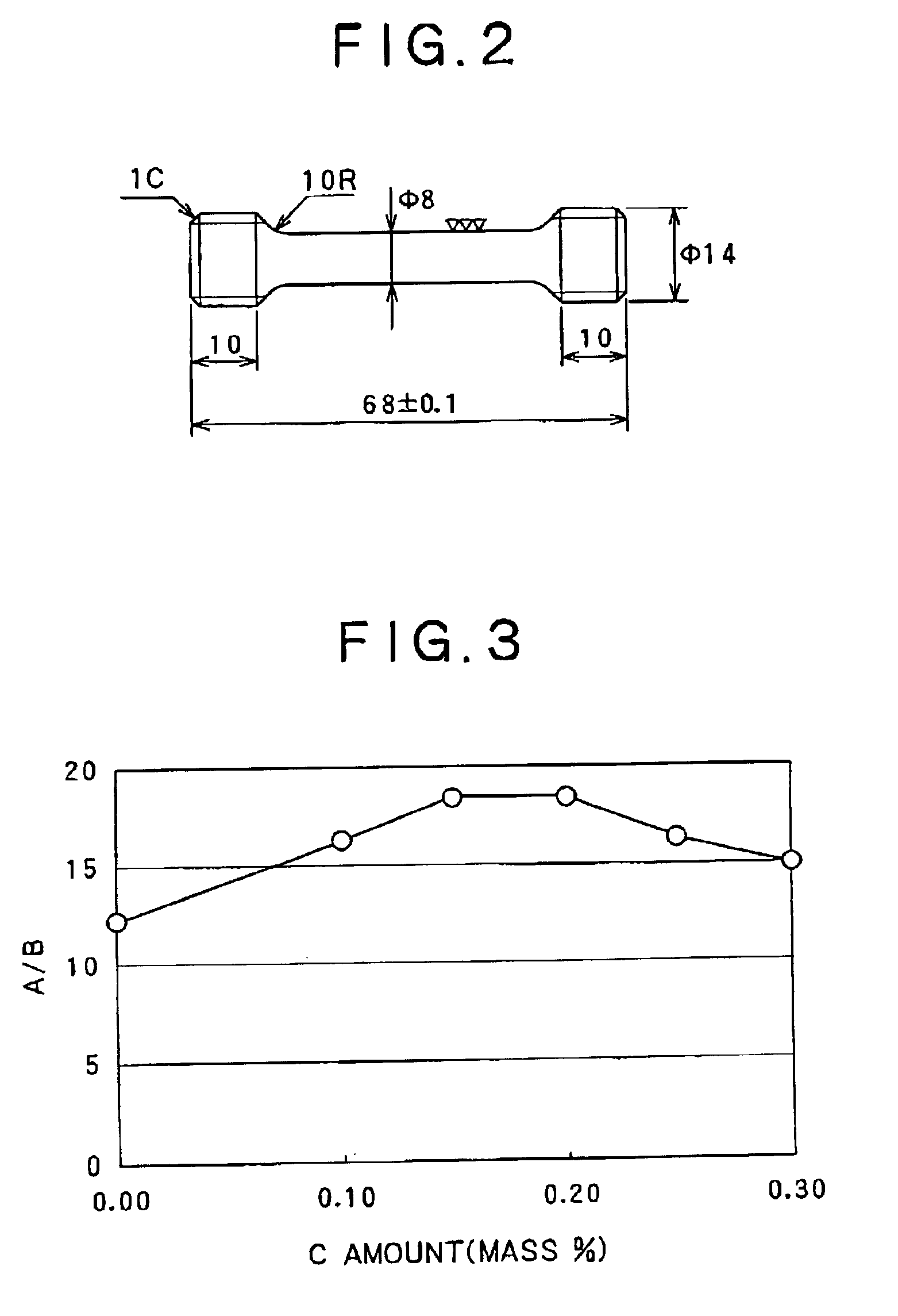

There is provided an α-β type titanium alloy having a normal-temperature strength equivalent to, or exceeding that of a Ti-6Al-4V alloy generally used as a high-strength titanium alloy, and excellent in hot workability including hot forgeability and subsequent secondary workability, and capable of being hot-worked into a desired shape at a low cost efficiently. There is disclosed an α-β type titanium alloy having high strength and excellent hot workability wherein 0.08-0.25% C is contained, the tensile strength at room temperature (25° C.) after annealing at 700° C. is 895 MPa or more, the flow stress upon greeble test at 850° C. is 200 MPa or less, and the tensile strength / flow stress ratio is 9 or more. A particularly preferred α-β type titanium alloy comprises 3-7% Al and 0.08-025% C as α-stabilizers, and 2.0-6.0% Cr and 0.3-1.0% Fe as β-stabilizers.

Owner:KOBE STEEL LTD

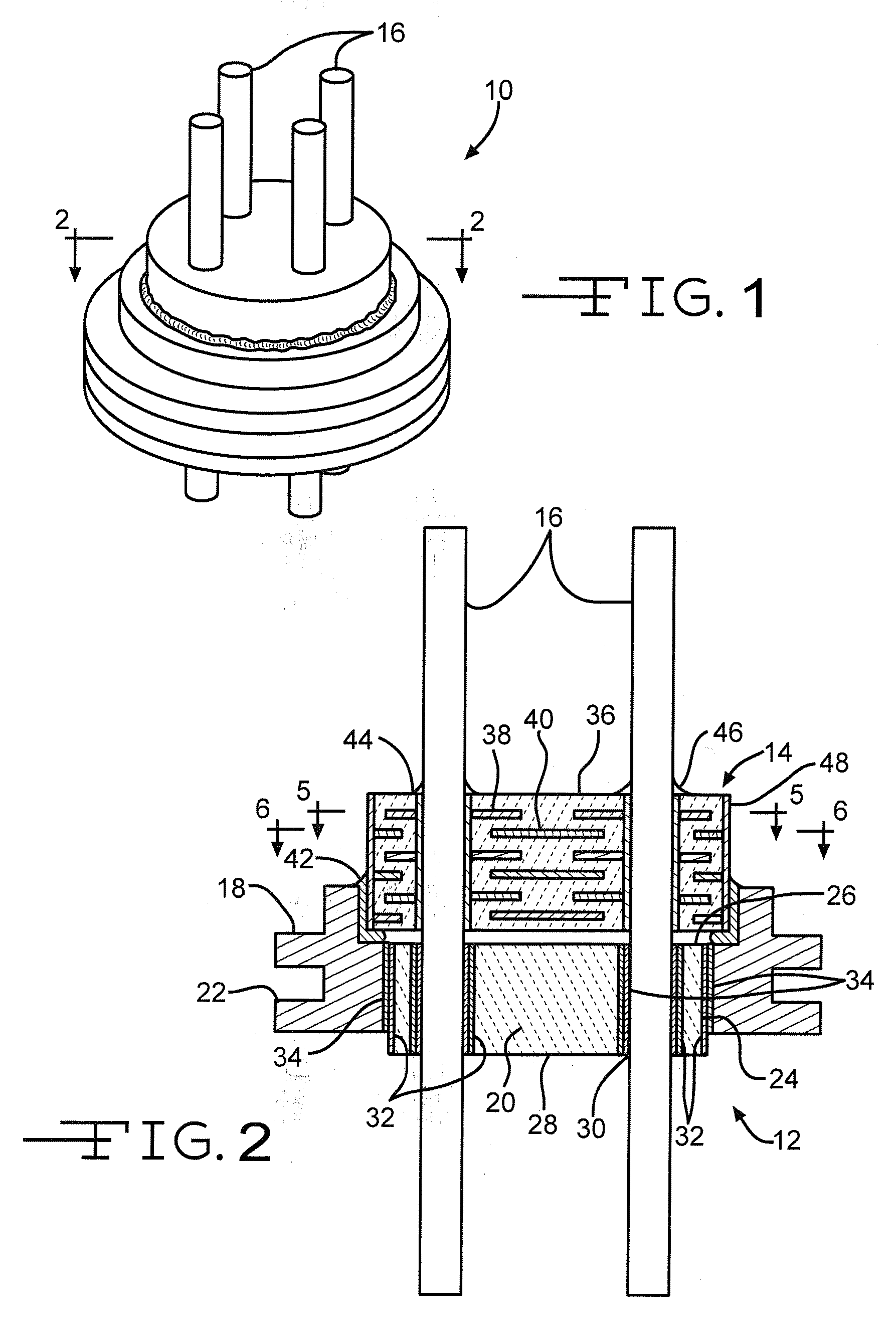

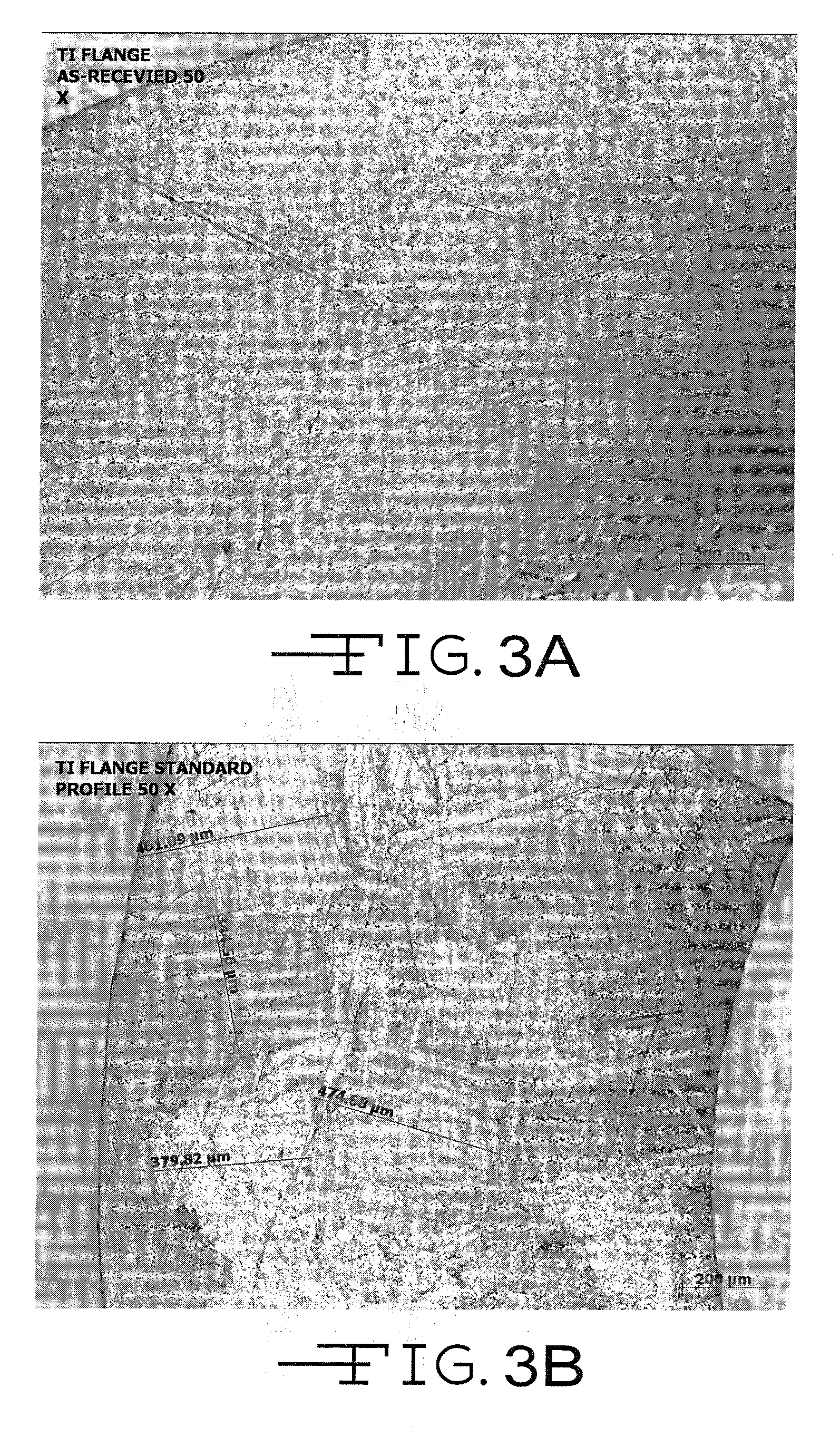

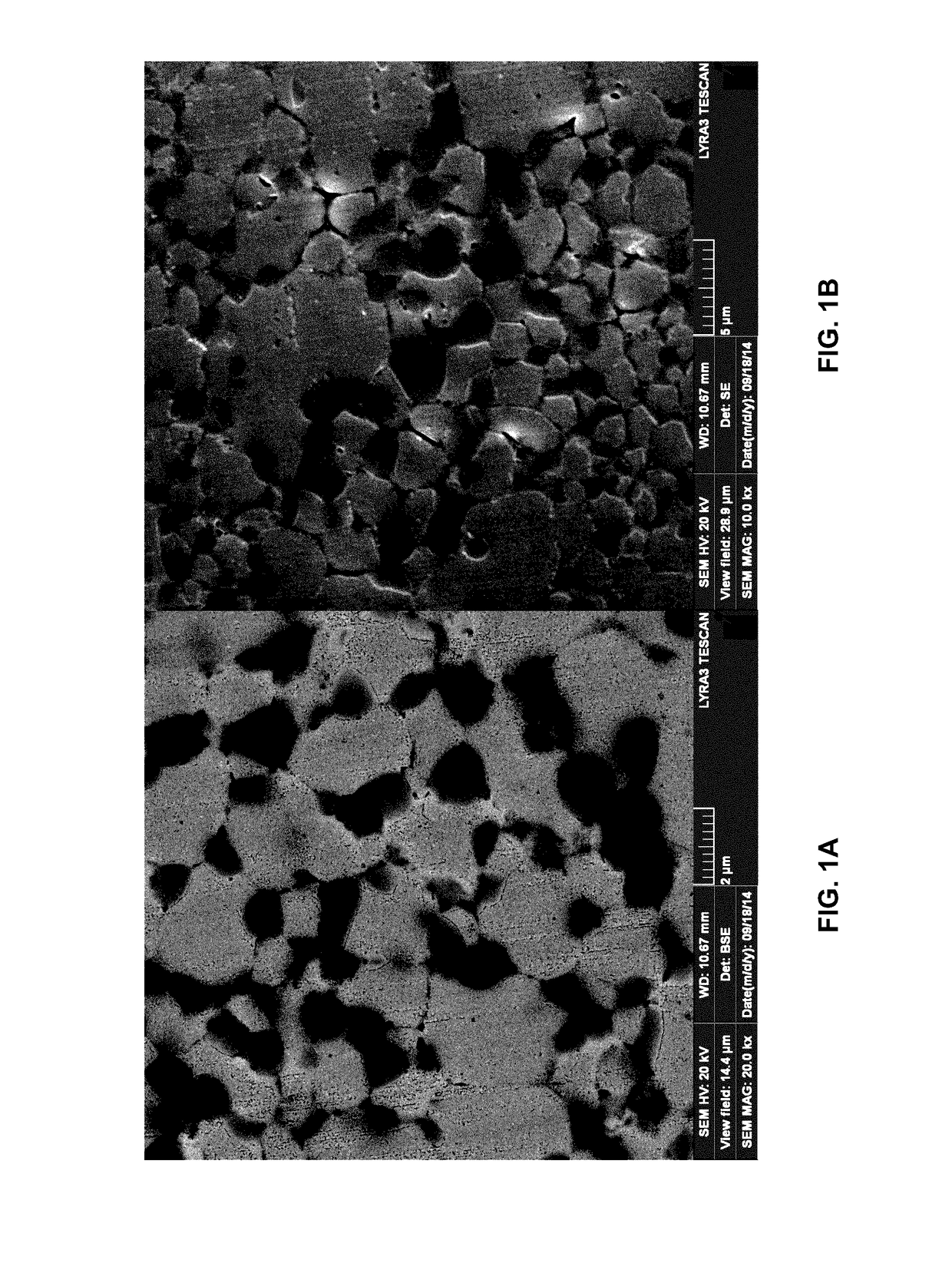

Nano-Titanium For Making Medical Implantable Hermetic Feedthrough Assemblies

InactiveUS20070183118A1Prevent leakagePrevent travelAnti-noise capacitorsFeed-through capacitorsCardiac pacemakerTi 6al 4v

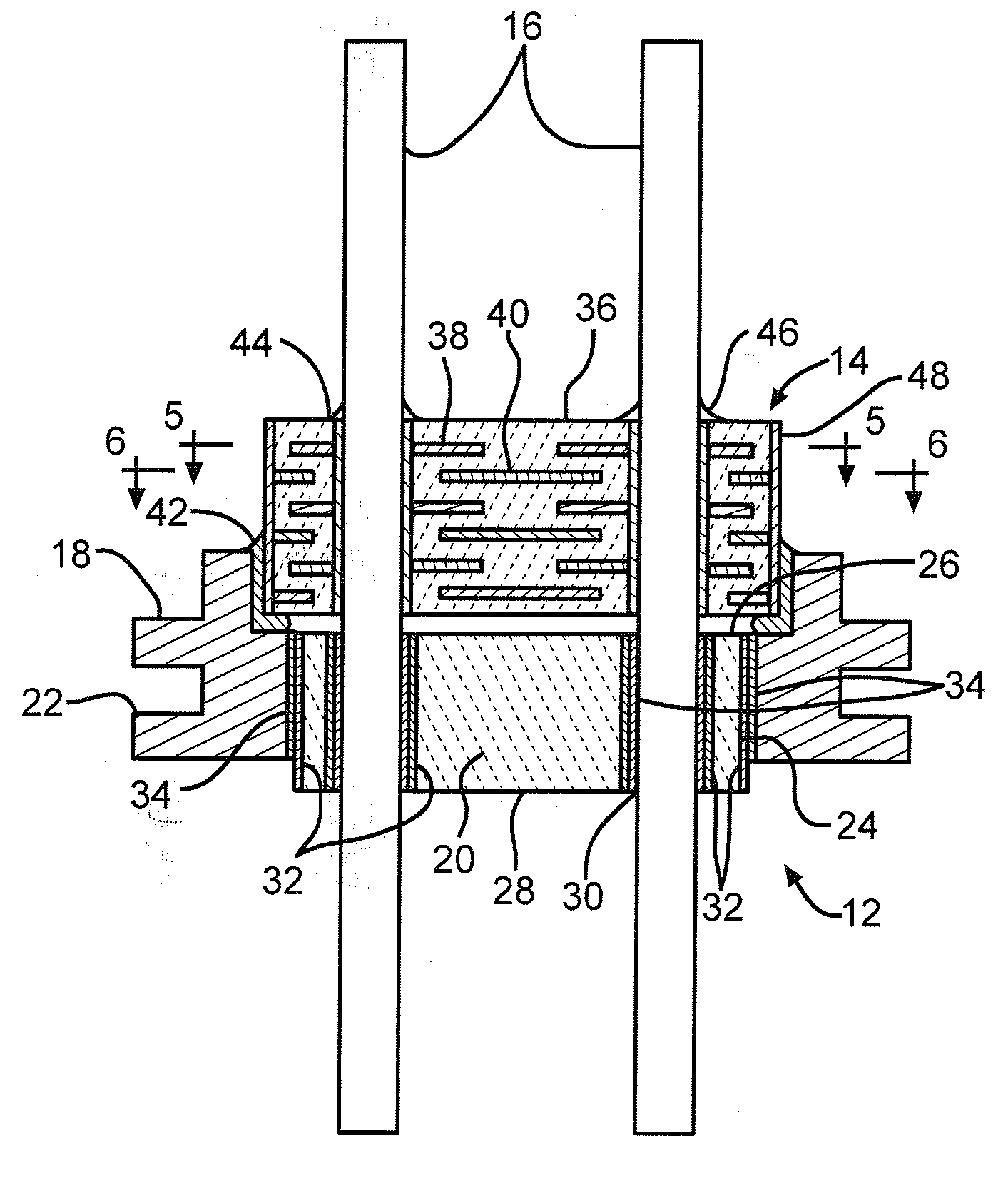

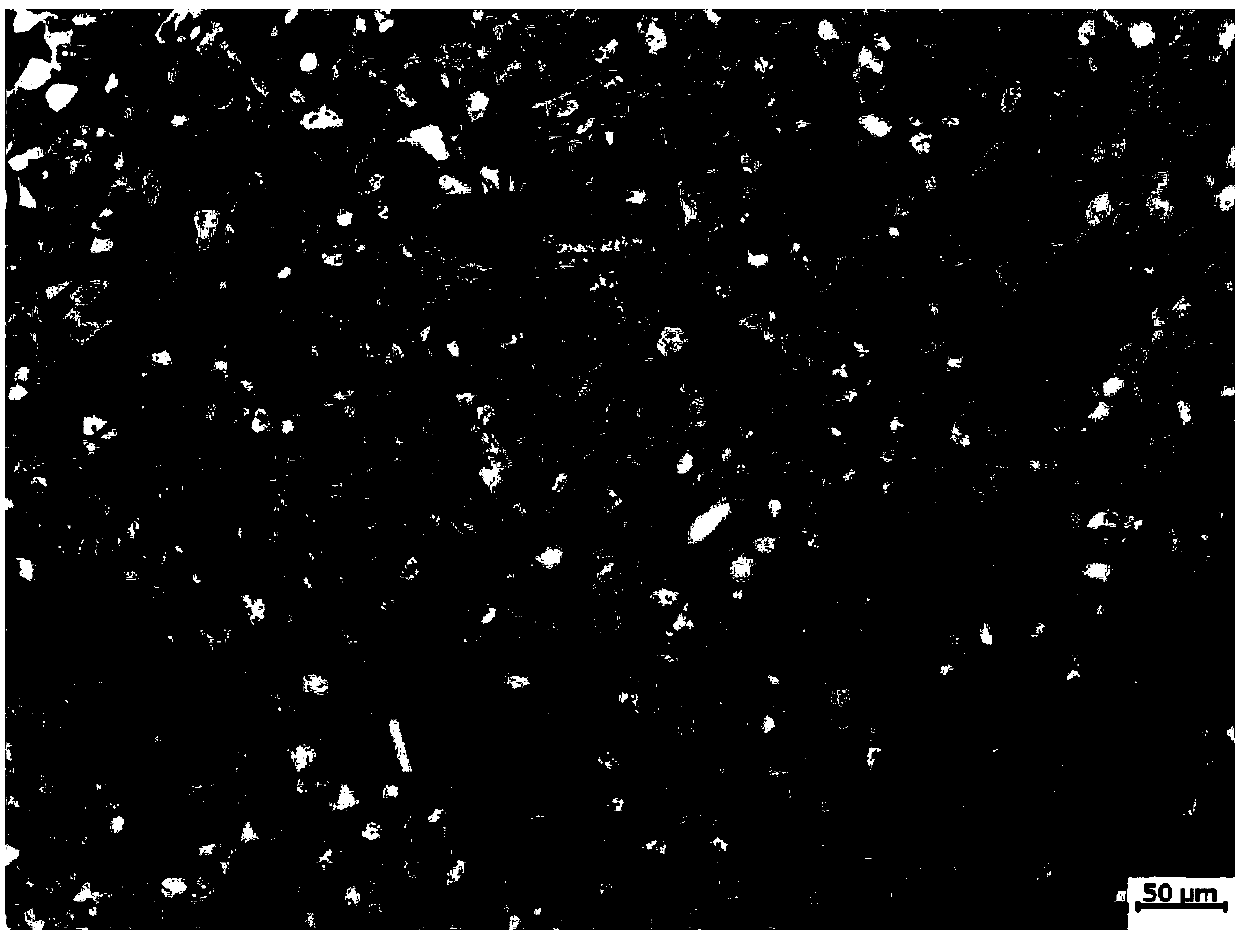

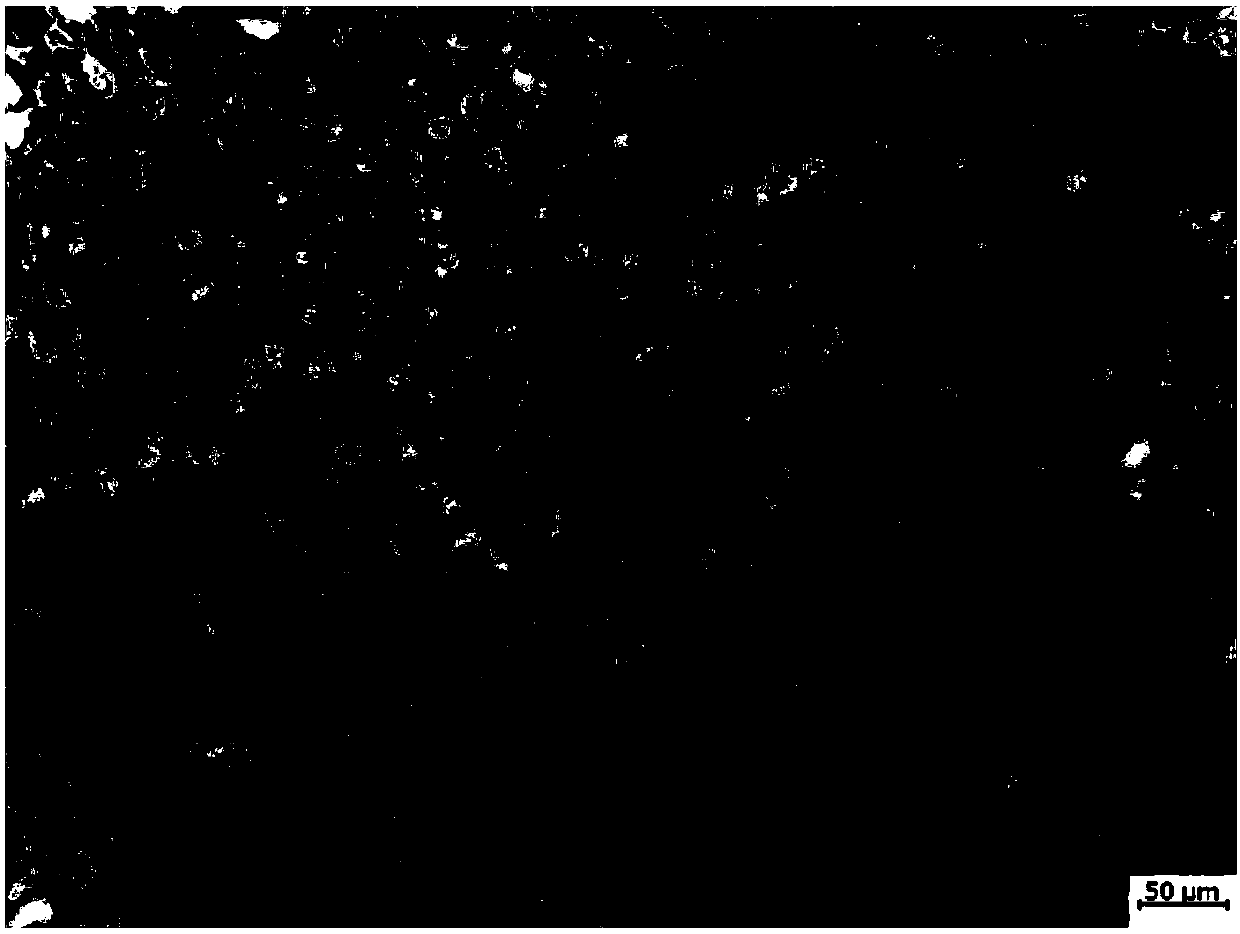

Ferrules made of nano-titanium for incorporation into feedthrough filter capacitor assemblies are described. The feedthrough filter capacitor assemblies are particularly useful for incorporation into implantable medical devices such as cardiac pacemakers, cardioverter defibrillators, and the like, to decouple and shield internal electronic components of the medical device from undesirable electromagnetic interference (EMI) signals. Nano-titanium experiences significantly less grain growth after high temperature brazing in comparison to commercially pure (CP) titanium and the titanium alloy Ti-6Al-4V. For that reason, nano-titanium is an ideal material for use in implantable medical applications where high strength, structural integrity even after heating and corrosion resistance are desired.

Owner:WILSON GREATBATCH LTD

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

Method for manufacturing fully dense metal sheets and layered composites from reactive alloy powders

InactiveUS20040096350A1Improve mechanical propertiesReduce residual porosityIncreasing energy efficiencyWelding/cutting media/materialsTi 6al 4vVolumetric Mass Density

The method is suitable for the manufacture of flat or shaped titanium aluminide articles and layered metal matrix composites such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and blades, composite electrodes, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as for sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The method includes the following steps: (a) forming a porous preform of the reactive powder alloy or a porous multi-layer composite preform consisting of reactive powder metals and alloys by consolidation using at least one method selected from low-temperature loose sintering in vacuum, high-temperature loose sintering in vacuum, low-pressure sintering in an inert gas, cold pressing, direct powder rolling, isostatic or die pressing, and other means of room temperature and warm temperature consolidation, and / or combination thereof, to provide the density not less than 25% from the theoretical density of said reactive alloy; (b) hot consolidating by hot pressing said preform, hot rolling, hot isostatic pressing, or hot extrusion to obtain the density of 98-100% from the theoretical density of said reactive alloy; (c) additional sintering and / or annealing at the temperature being at least 900° C. to decrease the residual porosity, control the microstructure, and improve the mechanical properties, especially ductility and / or plasticity of the resulting metal sheets or layered composites. The hot pressing is carried out at the temperature ranging 950-1700° C., preferably at 1250-1450° C., and at pressure ranging 50-350 kg / cm<2>. The HIP is carried out at the temperature ranging 1250-1350° C. and at pressure ranging 15000-40000 psi. The layered composite preform is manufactured by individual loose sintering, one layer of the composite at a time, and assembling them in the desired order. The composite consists of layers of titanium and / or titanium hydride, Ti-6Al-4V alloy, alpha-titanium aluminide alloy, beta-titanium aluminide alloy, and gamma-titanium aluminide alloy in any combinations.

Owner:ADVANCED MATERIALS PRODS

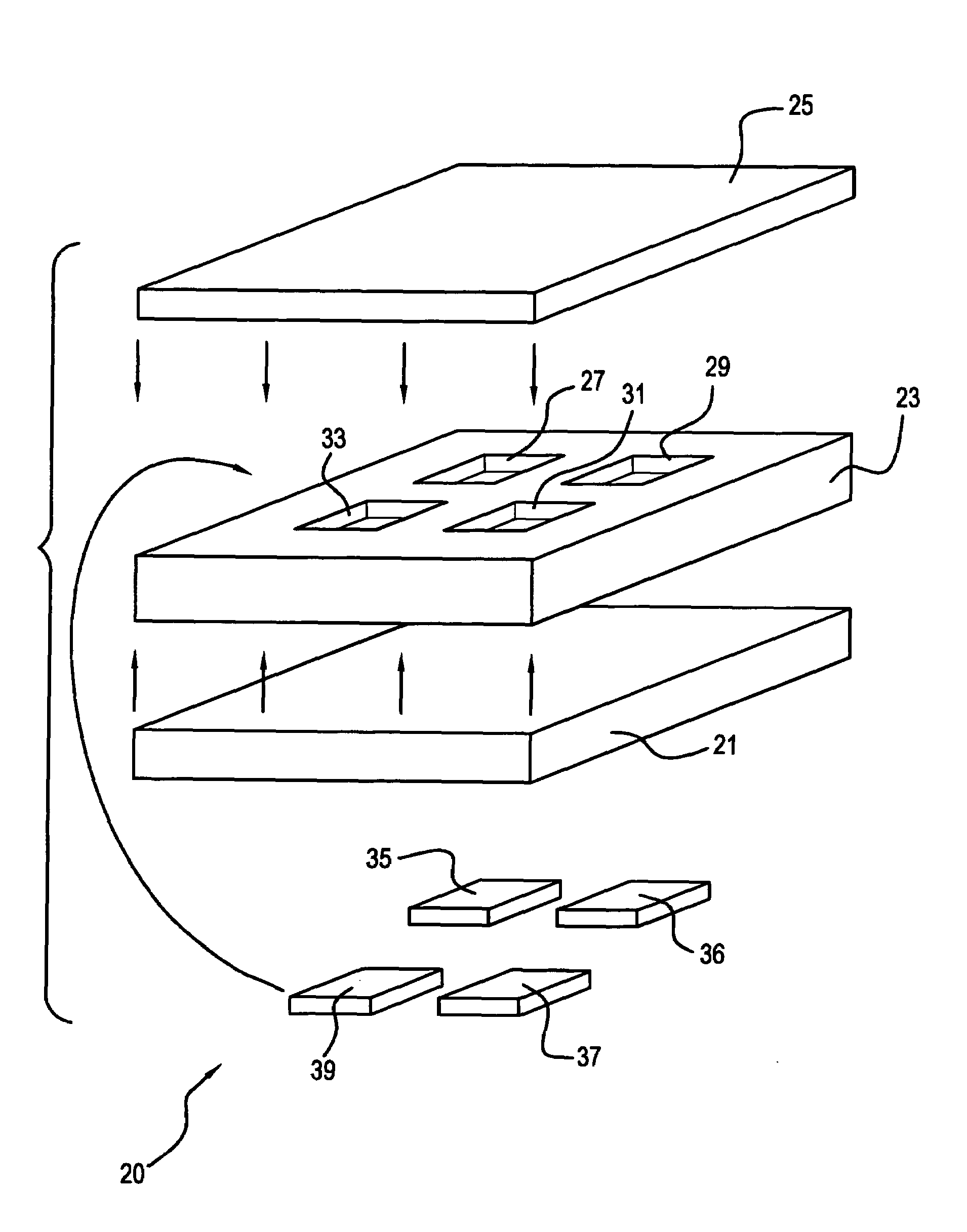

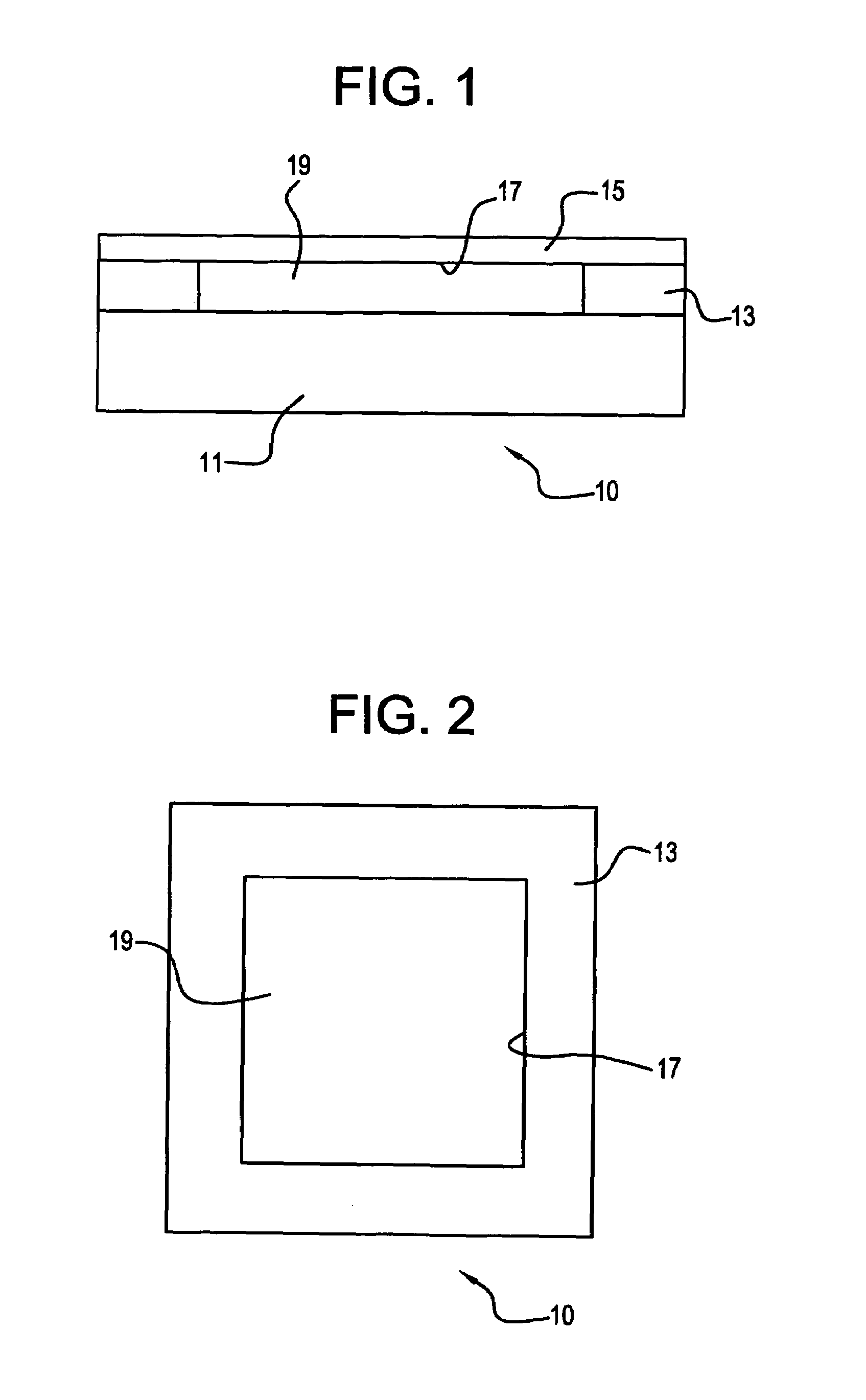

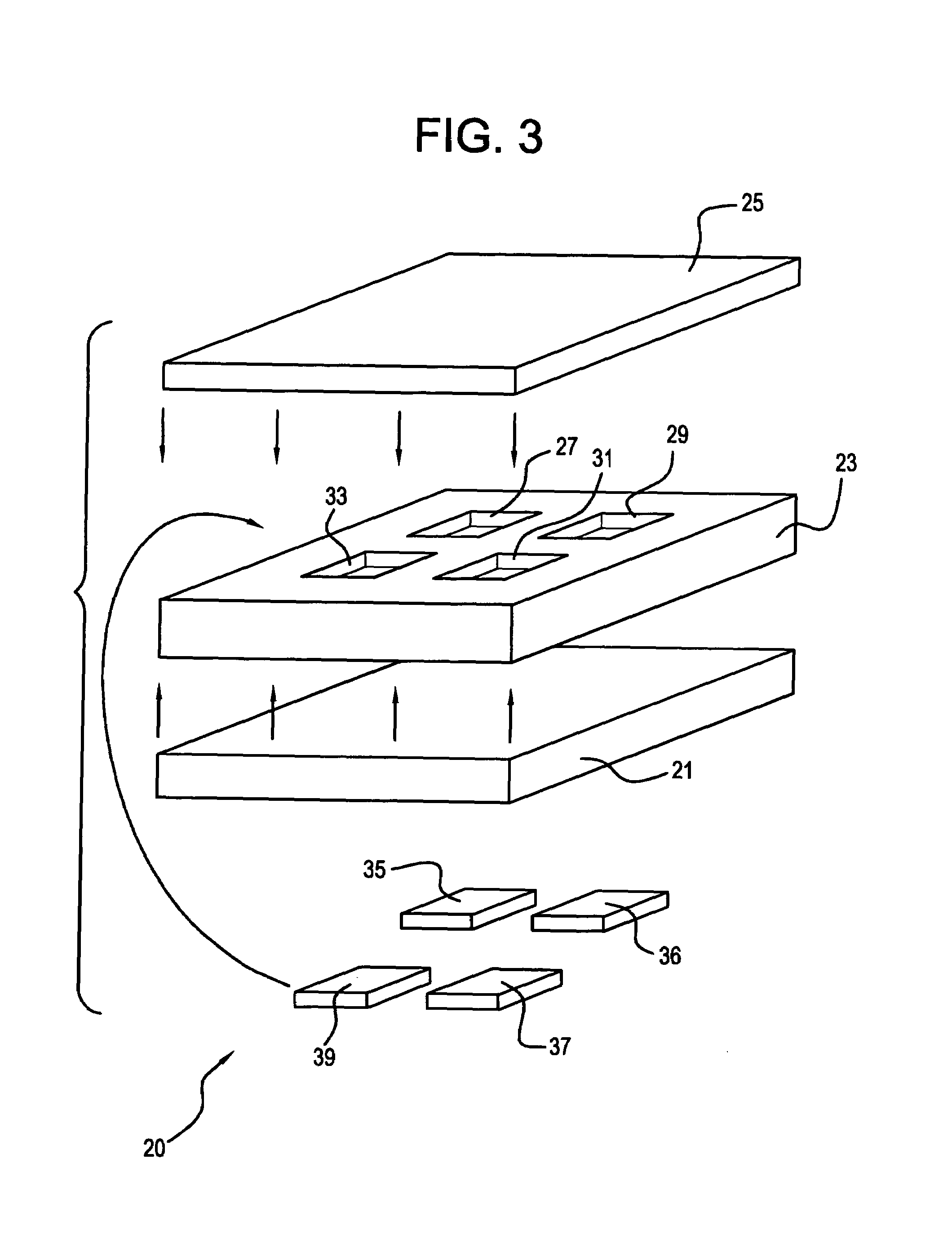

Ceramic armor and method of making by encapsulation including use of a stiffening plate

InactiveUS7069836B1Improve simplicityDoor/window protective devicesArmoured vehiclesCeramic compositeBoron carbide

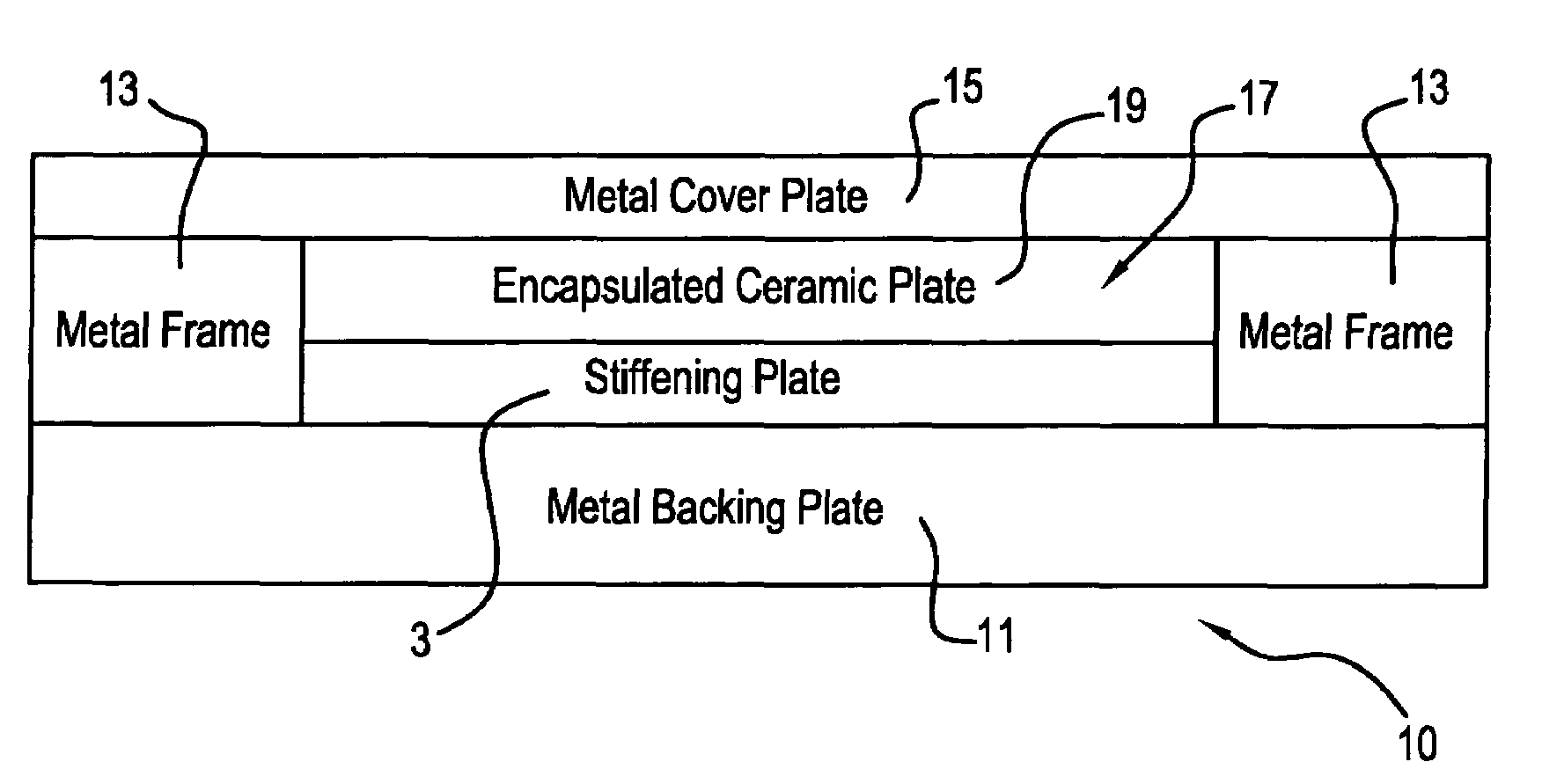

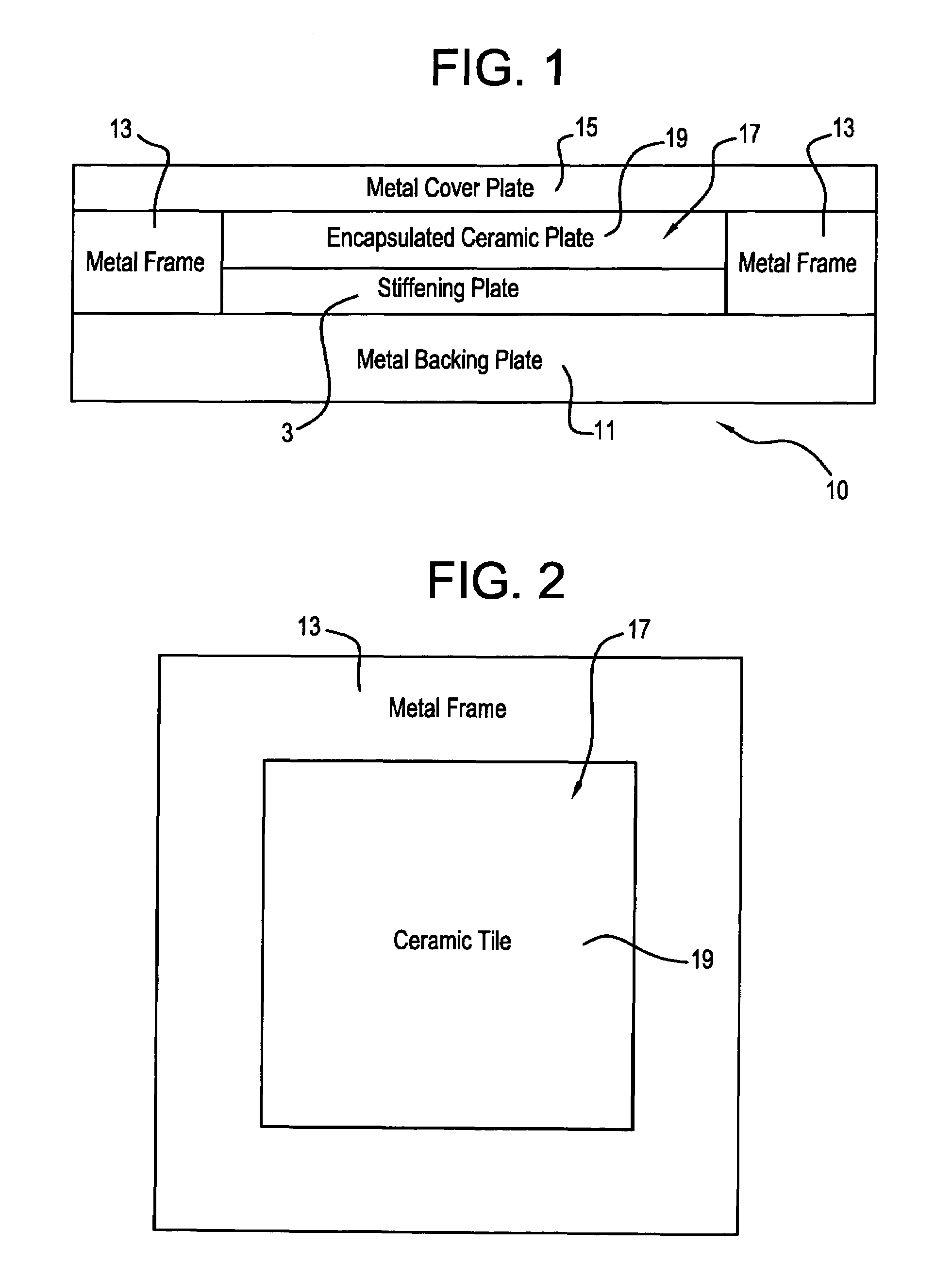

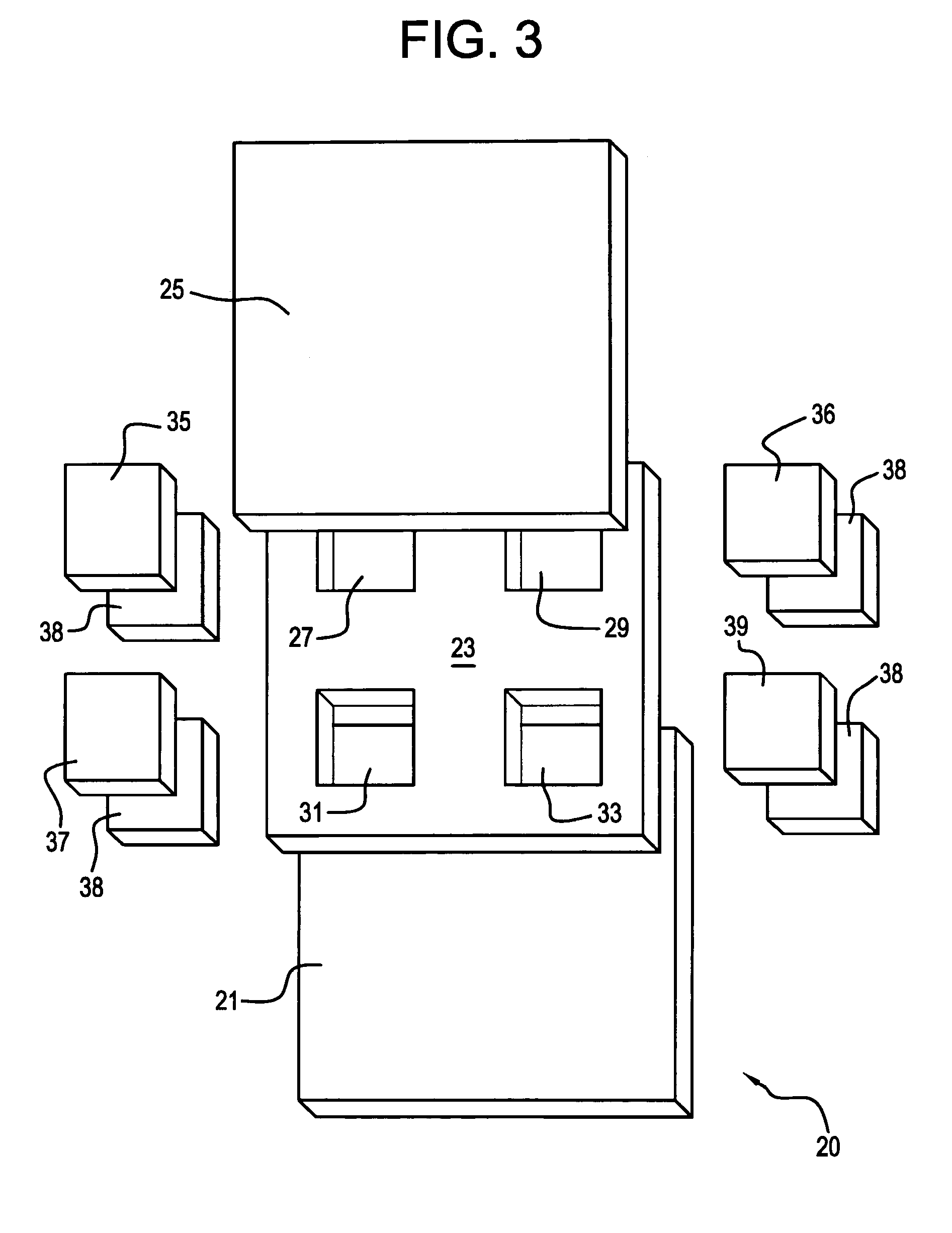

A ceramic armor is disclosed in several embodiments. In a first embodiment, a metal base plate has a metal frame assembled on it having a central opening into which the ceramic material and stiffening plate are placed. A cover plate is placed over the frame to enclose the ceramic material on all sides. In a second embodiment, the frame has an open central area that has two crossing walls that define four sub-chambers. Four sets of ceramic material and stiffening plate are placed in the respective sub-chambers and a covering plate is placed over them. In a further embodiment, the frame has a plurality of cavities mechanically formed in it. A stiffening plate and a ceramic tile or plate are placed in each cavity and a cover plate is placed over the frame. The metal used to encapsulate the ceramic material may, if desired, comprise a Titanium alloy such as Ti-6Al-4V, and the ceramic material may comprise Silicon Carbide, Boron Carbide, Tungsten Carbide, Titanium Diboride, Aluminum Oxide or Aluminum Nitride. The stiffening plate is preferably made of a Ti—TiB cermet composite but may also be comprised of an armor ceramic such as WC, TiB2, Al2O3 or B4C. A hot pressing procedure is carried out on the armor to cause the metal to plastically deform about the encapsulated ceramic material.

Owner:BAE SYST ADVANCED CERAMICS

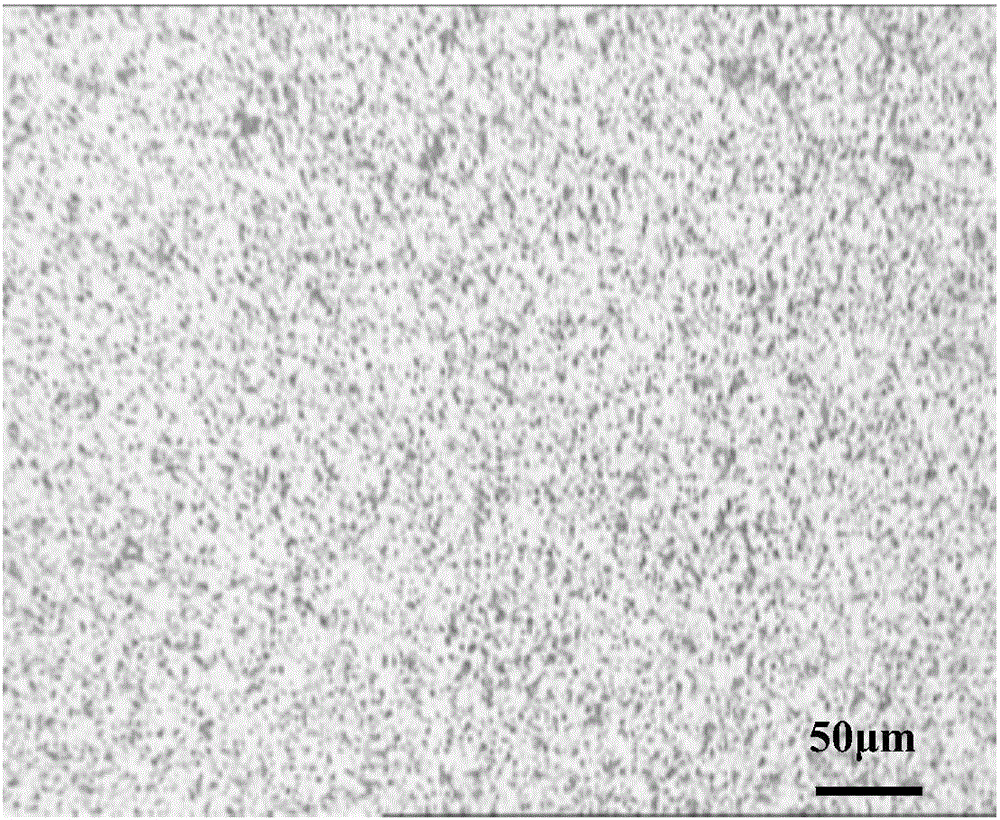

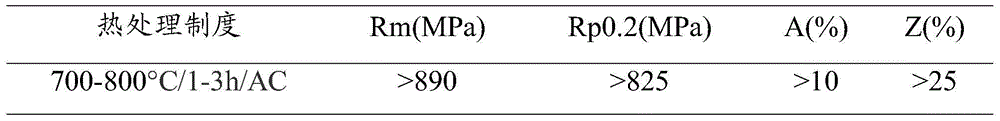

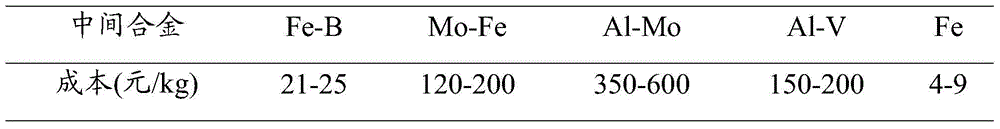

Low cost high strength titanium alloy

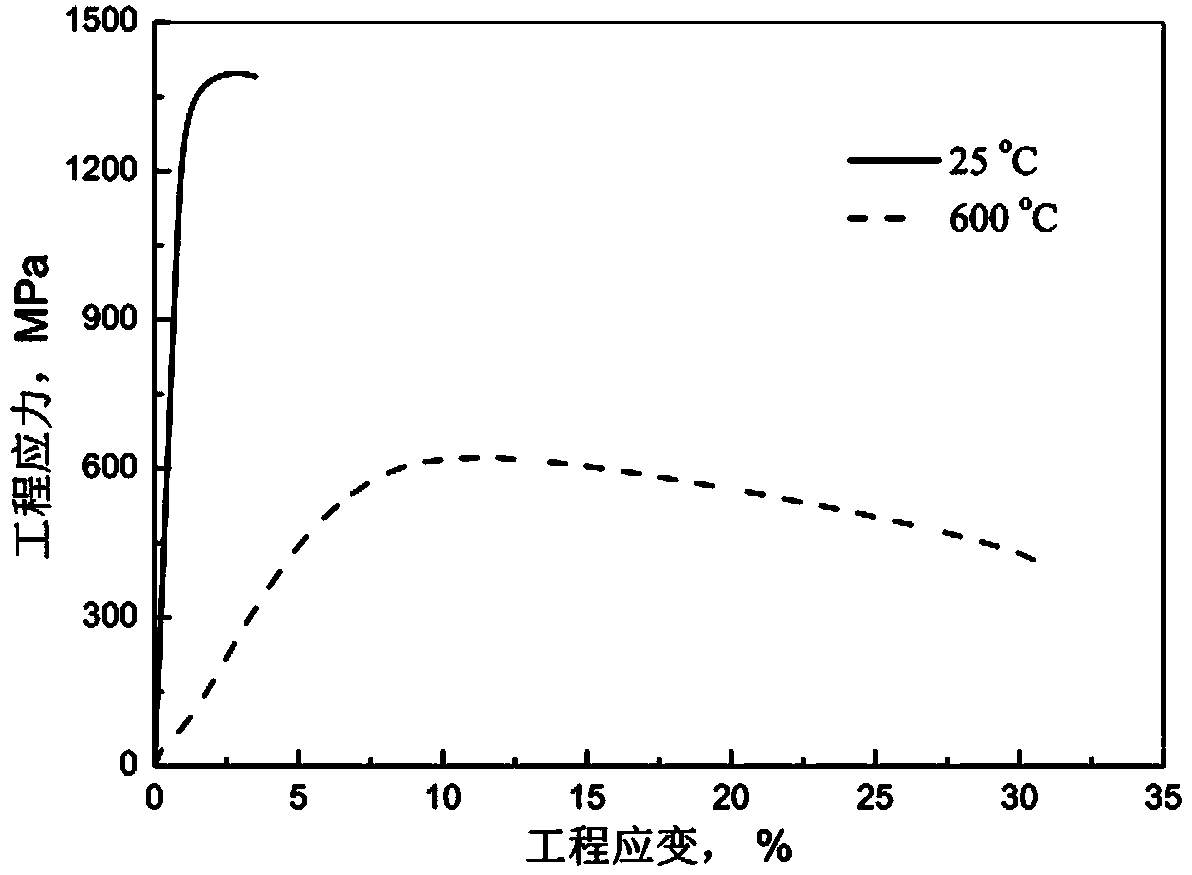

The invention discloses a low-cost and high-strength titanium alloy. The alloy is to mix a Al-V or Fe-V intermediate alloy, electrolytic chromium, pure titanium or titanium alloy decoration shavings, industrial iron and titanium sponge to press electrodes according to the designed compositions and to be cast into an alloy pig through secondary smelting by a general vacuum consumable electrode arc furnace. The compositions by weight percent of the alloy are 4 to 6 percent of aluminum, 1.9 to 2.9 percent of vanadium, 1 to 3 percent of chromium, 1 to 3 percent of iron, and the balance being titanium and unavoidable impurities. Compared with a Ti-6Al-4V alloy and the prior high strength titanium alloy, the low-cost and high-strength titanium alloy has the advantages that the alloy has high plasticity under the condition that high strength is guaranteed; the cost of the alloy is lower than that of the Ti-6Al-4V; the hot workability of the alloy is good; and the alloy is easy to produce and is suitable for the requirements of various application fields on the low-cost and high-strength titanium alloy.

Owner:WESTERN METAL MATERIAL

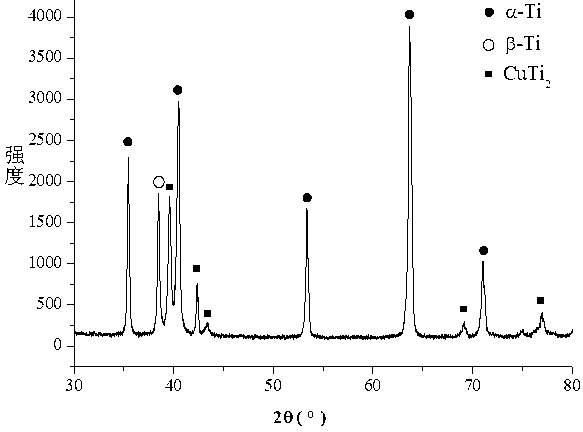

Anti-infective medical titanium alloy

The invention aims to provide an anti-infective medical titanium alloy. Based on the chemical components of existing medical titanium alloy Ti-6Al-4V, a proper amount of element copper is added. After a special antibacterial heat treatment, a titanium copper phase is precipitated in the substrate of the medical titanium alloy, thus endowing the medical titanium alloy an anti-bacterial infection function. The titanium alloy can be widely applied to various titanium alloy medical equipment used in departments of orthopedics, stomatology and other medical clinical fields, thus solving the problems of bacterial infection and the like caused by implantation of medical titanium alloy medical equipment in current clinical practice.

Owner:SUZHOU SILVAN MEDICAL DEVICE CO LTD

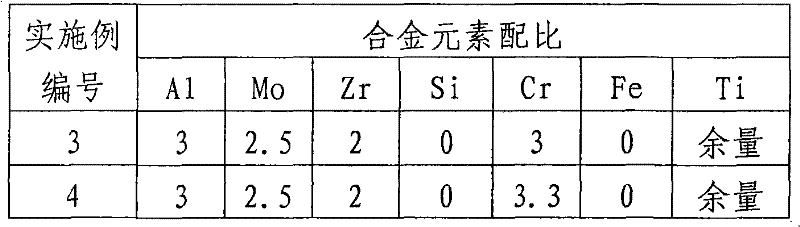

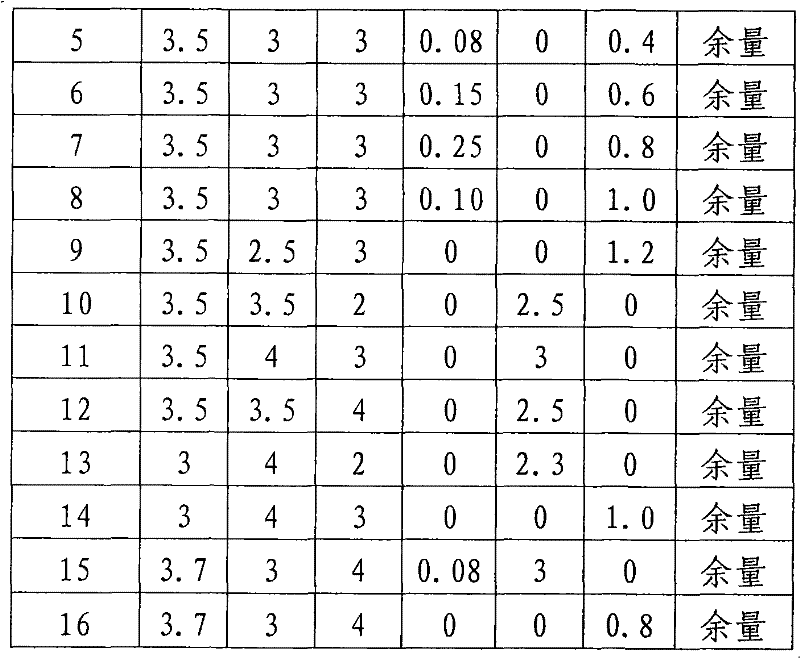

Low-cost alpha and beta-type titanium alloy

The invention belongs to the technical field of alloys, and relates to a low-cost alpha and beta-type titanium alloy. The alloy is characterized by comprising the following components in percentage by weight: 3 to 3.7 percent of Al, 2.5 to 4 percent of Mo, 2 to 4 percent of Zr, 0 to 0.35 percent of Si, 2.3 to 3.3 percent of Cr or 0.4 to 1.2 percent of Fe, and the balance of Ti; the total amount of the impurity elements in the alloy is less than or equal to 0.4 percent, and the interstitial impurity element C is less than or equal to 0.04 percent; and the alloy comprises the following impurityelements: less than or equal to 0.04 percent of C, less than or equal to 0.15 percent of O, less than or equal to 0.04 percent of N, and less than or equal to 0.015 percent of H. Expensive vanadium element is substituted by using other metals with low prices in the alpha and beta-type titanium alloy, so the production cost of the alloy is reduced. Because the comprehensive mechanical property of the alpha and beta-type titanium alloy is equivalent to that of Ti-6Al-4V, the alpha and beta-type titanium alloy has higher cost performance and broad engineering application prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

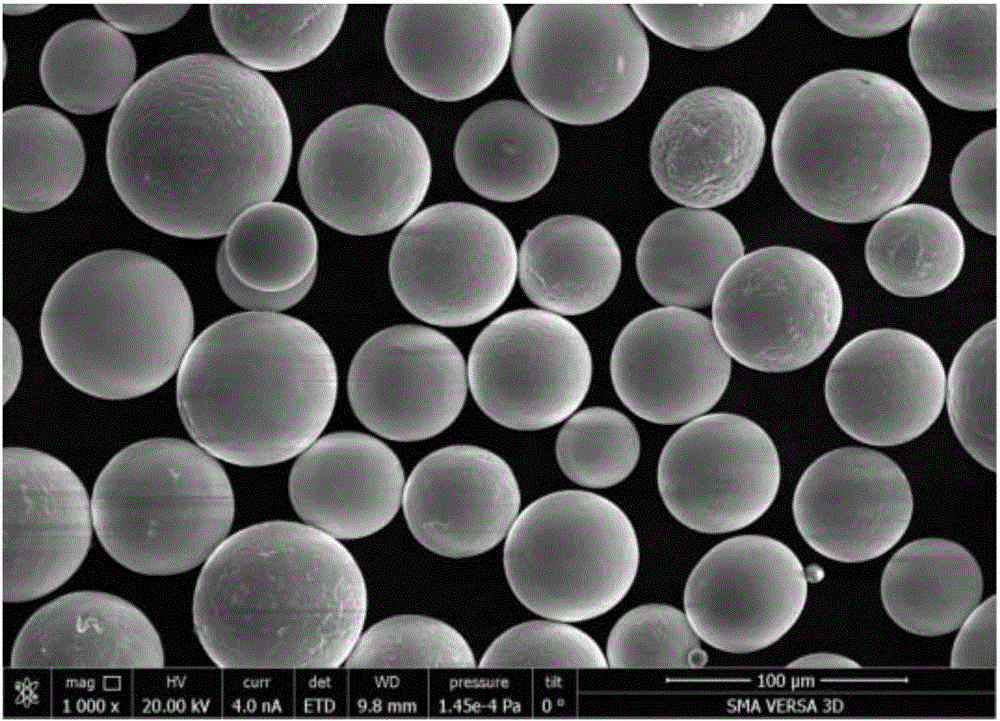

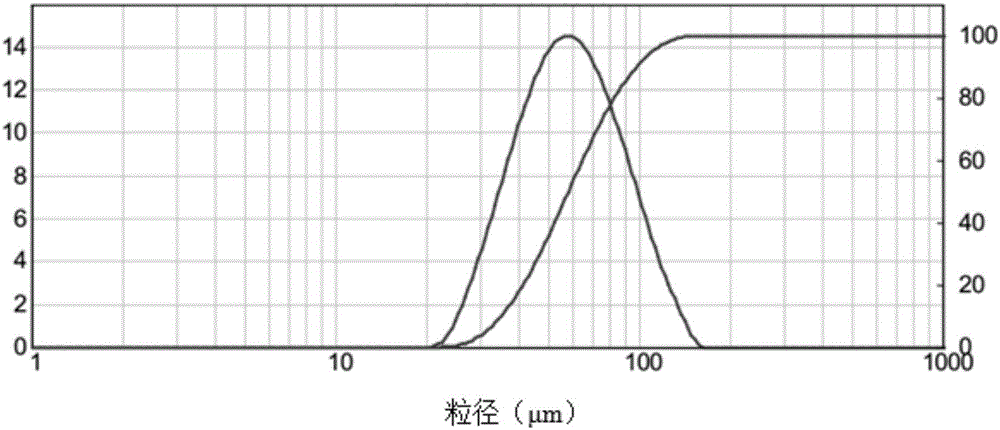

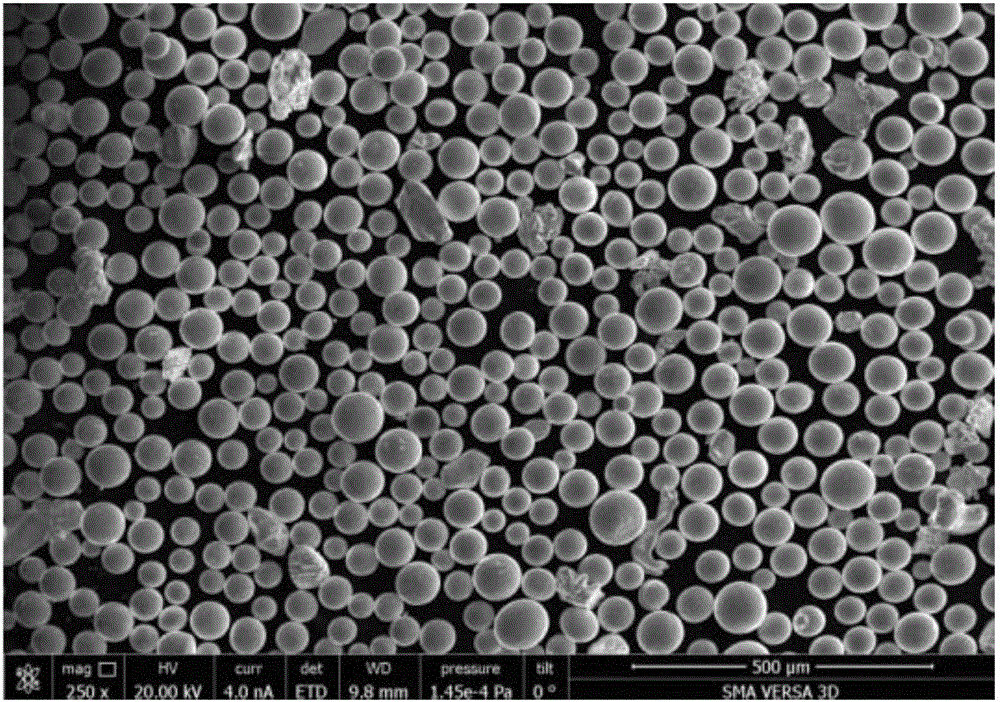

Preparation method of spherical titanium-alloy powder for 3D printing

InactiveCN106493350AUniform particle sizeImprove liquidityAdditive manufacturing apparatusTransportation and packagingHydrogenMicrometer

The invention provides a preparation method of spherical titanium-alloy powder for 3D printing, relates to a method for manufacturing 3D printing consumables, and aims at solving the technical problems that existing Ti-6Al-4V alloy powder is nonuniform in particle size and irregular in shape, and cannot meet the usage requirement of 3D printing. The method comprises the steps that Ti powder and alloy powder of contained elements are added into a ball mill for ball milling according to components of titanium alloy, and titanium-alloy powder is obtained; and the titanium-alloy powder is screened and conveyed to thermal plasma spheroidizing equipment for plasma spheroidizing in hydrogen-containing gas, and the spherical titanium-alloy powder for 3D printing is obtained. According to the spherical titanium-alloy powder, the particle size is smaller than or equal to 100 micrometers, the spheroidization degree is larger than 95%, and the spherical titanium-alloy powder can be applied to the field of 3D printing manufacturing.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Ceramic armor and method of making by encapsulation in a hot pressed three layer metal assembly

Owner:BAE SYST ADVANCED CERAMICS

Beta type Ti Nb Zr alloy with low modulus of elasticity, preparation method and application

This invention discloses a beta-type Ti alloy with low elastic modulus for mrdical application. The Ti alloy comprises: Nb 30-37%, Zr 0-20%, and Ti. The cast structure of the Ti alloy is beta phase. The Ti alloy has moderate strength, and can satisfy the strength requirement for clinical bearing material. The elastic modulus of the Ti alloy is only 45-55% that of Ti-6Al-4V alloy. The alloy is a casting alloy, and has no noble metals added such as Ta, thus effectively lowering the cost. Besides, all the added elements have biocompatibility, and toxic elements are avoided. The Ti alloy has high biocompatibility and mechanical compatibility, and can be used to produce bone plates with reduced stress shielding effect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

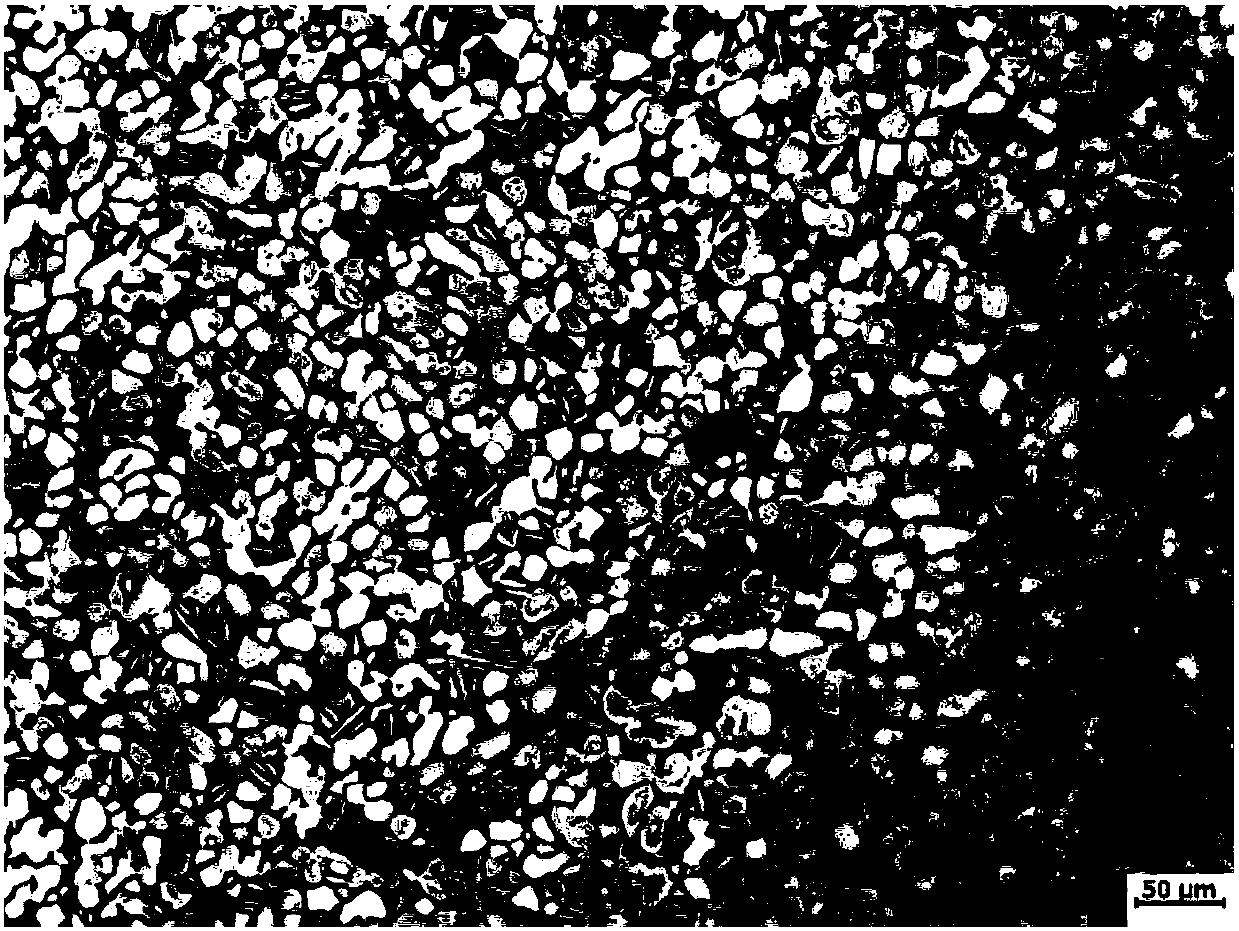

Preparation method of TiBw/Ti-6Al-4V composite bar adopting quasi-continuous reticular structure

The invention relates to a preparation method of a TiBw / Ti-6Al-4V composite bar adopting a quasi-continuous reticular structure and solves problems that existing Ti-6Al-4V composites are harsh in technological condition, high in equipment requirement, low in production efficiency, difficult to produce on a large scale and the like. The method comprises steps as follows: low-energy ball milling and mixing are performed on spherical Ti-6Al-4V powder and TiB2 powder firstly; then TiB2 / Ti-6Al-4V mixed powder is placed in a metal sheath for cold press molding, and vacuum degassing and sheath sealing welding are performed to obtain an extrusion billet; finally, short-time pre-sintering is performed on the obtained extrusion billet, and hot extrusion deformation is performed on the pre-sintered extrusion billet to obtain a required material. The method can be applied to preparation of a TiBw / Ti-6Al-4V composite adopting the quasi-continuous reticular structure.

Owner:HARBIN INST OF TECH AT WEIHAI

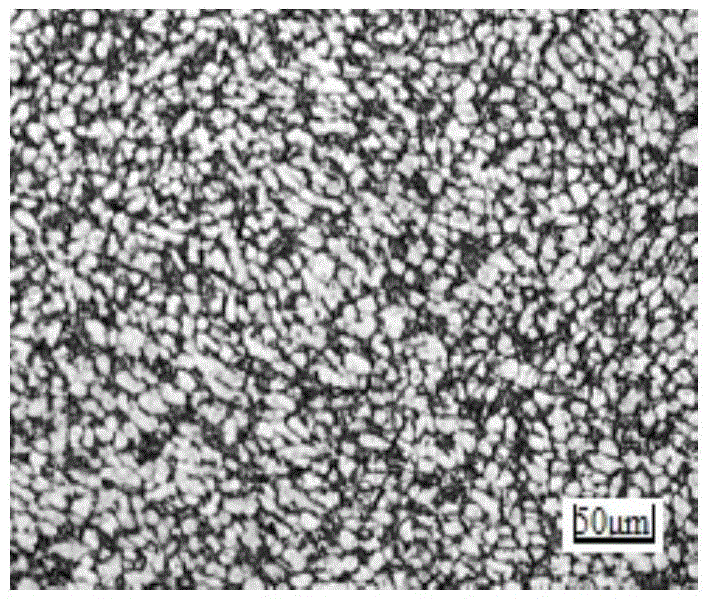

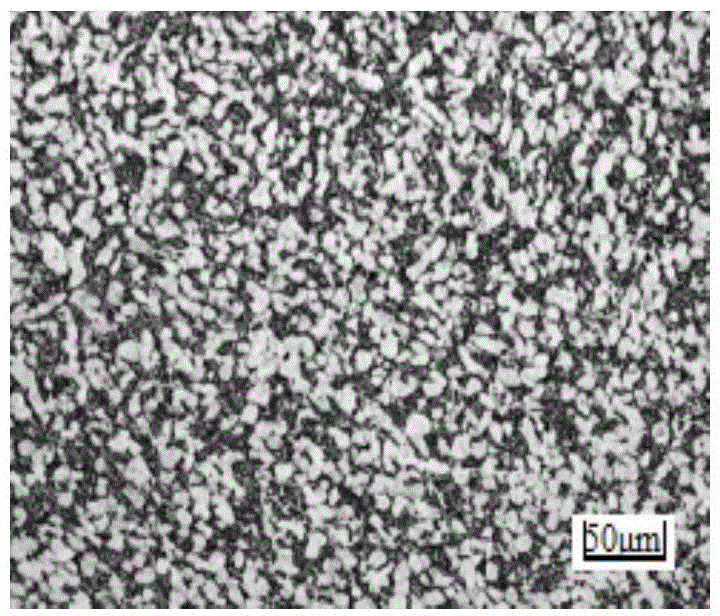

Method for processing Ti-6Al-4V titanium alloy large size bar material

The invention relates to a large-scale processing method of Ti-6Al-4V titanium alloy rod bars with the phi of 200-400mm and the length of over 3000mm. The technique is characterized by adopting Ti-6Al-4V titanium alloy casting ingots with the phi of 700-950 mm, a gas furnace for heating and heat preserving at 1150 DEG C, a hydraulic press for hammer cogging, and adopting multi-heating number smithing over the beta transition temperature with the whole smithing ratio not smaller than 3; heating and smithing below the beta transition temperature by 20-30 DEG C with a smithing ratio of 1.5-1.8; preserving the heat for 0.5-3 hours over the beta transition temperature by 20 DEG C, water cooling, performing homogenization treatment; finally heating below the beta transition temperature by 30-50 DEG C, performing multi-heating number smithing in the alpha+beta phase section to the finished product format and the total forging ratio of the alpha+beta phase section being not less than 6. The weight of a single rod bar is greatly improved through integral smithing of casting ingots / large-scale smithing stocks, the length of the rod bar can reach more than 3 m and the rod bars have favorable tissue and performance.

Owner:BAOJI TITANIUM IND CO LTD

Process of direct powder rolling of blended titanium alloys, titanium matrix composites, and titanium aluminides

The present invention relates to the manufacture of fully dense strips, plates, sheets, and foils of titanium alloys, titanium metal matrix composites, titanium aluminides, and flat multilayer composites of said materials manufactured by direct rolling and sintering of blended powders. The resulting titanium alloy flat products are suitable in the aerospace, automotive, sporting goods, and other industries. The process includes the following steps: (a) providing a C.P. titanium matrix powder and at least one powder of alloying components such as elemental alloying powder, pre-alloyed master alloy powders, and / or hard reinforcing particles, (b) mechanical activation by attrition of all alloying components, whereby the particle size of attrited alloying powders is at least ten times smaller than the particle size of the matrix titanium powder, (c) blending titanium powder as a ductile matrix material with attrited alloying powders obtained in step (b), (d) cold direct powder rolling of the blend in a mill with horizontally-positioned rolls to achieve density of the rolled strip of 60±20% of the theoretical value, whereby diameters of rolls are different, so that the green strip is bent for the subsequent densification by a second horizontal re-rolling mill staying in line with the first powder rolling mill, and rotations of edging pair of rolls of at least one of the said mills differ in the rate by 5-15% to promote densification of the green strip by shear deformation, the diameter of the rolls of the direct powder rolling mill is 40-250 times larger than thickness of the rolled strip, (e) densification by cold re-rolling of the green strip in a horizontal rolling mill, whereby diameter of the rolls of the densification mill is 1.1-5 times larger than the diameter of rolls of the direct powder rolling mill to provide compressive action and avoid shearing action of the green strip and achieve density of the rolled strip in the range of 90±10%, (f) multiple cold re-rolling of the strip in vertically-positioned rolls at equal rotation rate of the edging rolls to achieve density of the green rolled strip about 100% of the theoretical value, and (g) sintering of near fully-dense green rolled strip in vacuum, or in protective atmosphere batch furnace, or in continuous belt furnace in protective atmosphere. Typical mechanical properties of fully-dense Ti-6Al-4V alloy strips manufactured by the process of the present invention are: tensile strength is 130-140 ksi (897-966 MPa), yield strength is 120-130 ksi (828-897 MPa), and elongation is over 10%.

Owner:ADMA PRODS

Biomedical high-strength and toughness Ti-6Al-4V titanium alloy bar and preparation method thereof

The invention discloses a biomedical high-strength and toughness Ti-6Al-4V titanium alloy bar which is prepared from the following elements in percentage by mass: 6.0%-6.3% of Al, 4.0%-4.3% of V, 0.16%-0.18% of O, 0.18%-0.25% of Fe and 88.97%-89.66% of Ti, wherein the sum of the content of the elements is 100%. The prepared bar has the characteristics of high hardness, high toughness and high strength, can be widely applied to a medical spinal jackscrew fixing system. The invention further discloses a preparation method of the bar. The method comprises the following steps: preparing a cast ingot, forging, drawing into a square billet, and rolling into the bar; and carrying out heat treatment and finish machining. Massive production of the titanium alloy bar which is high in strength and toughness and relatively good in mechanical property consistency can be realized; and the production efficiency of the high-toughness titanium alloy bar is effectively improved.

Owner:西安赛特思迈钛业有限公司

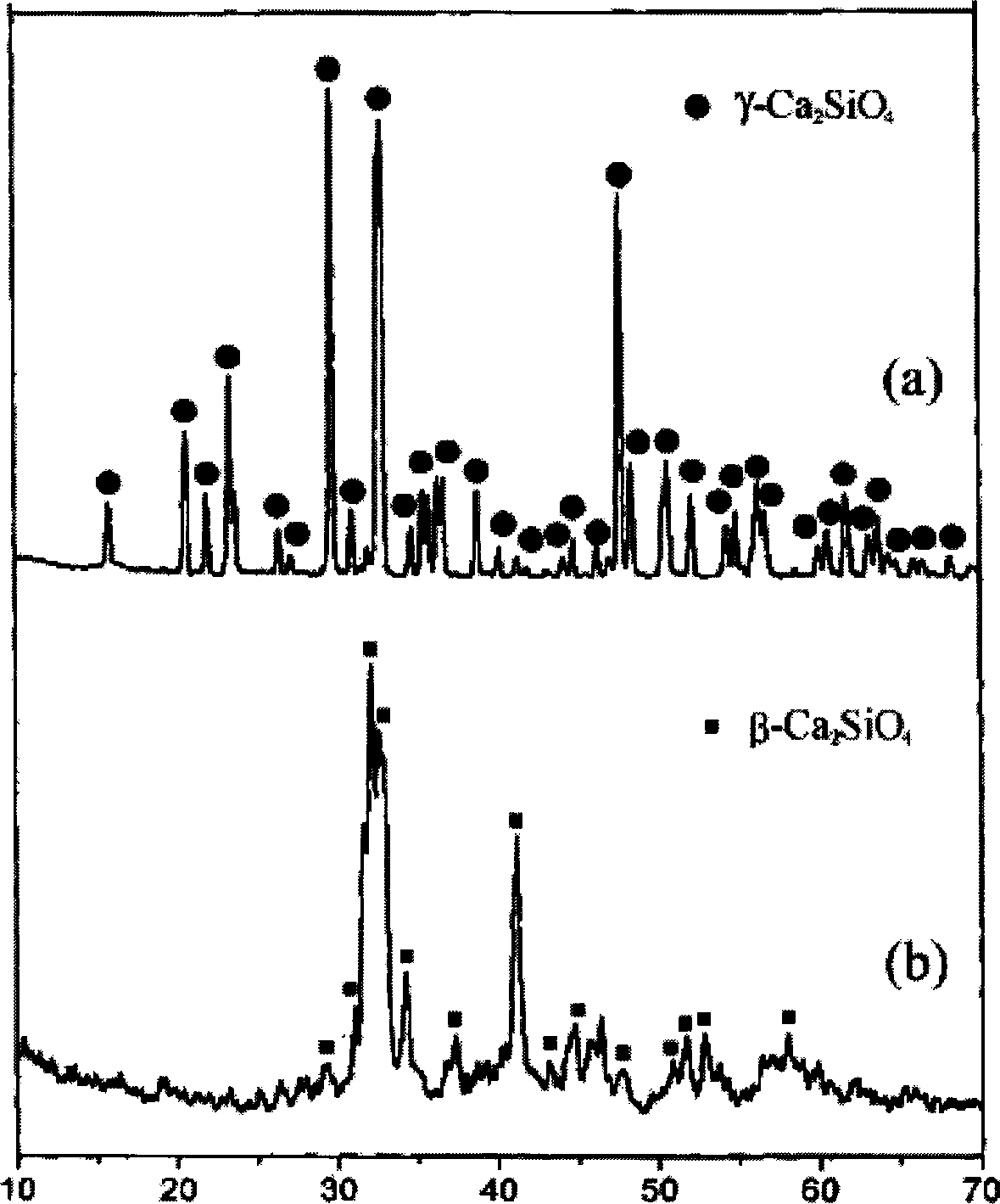

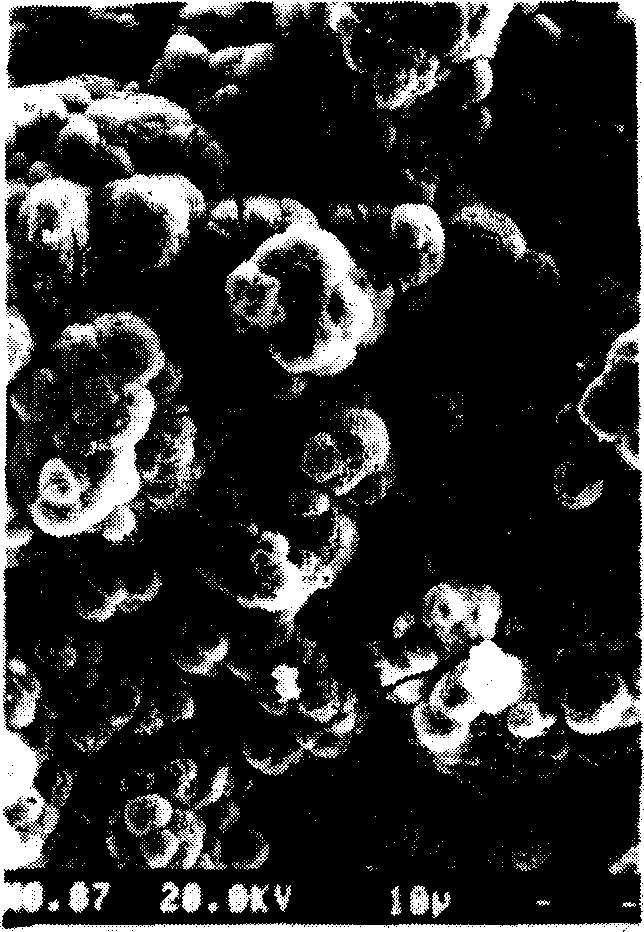

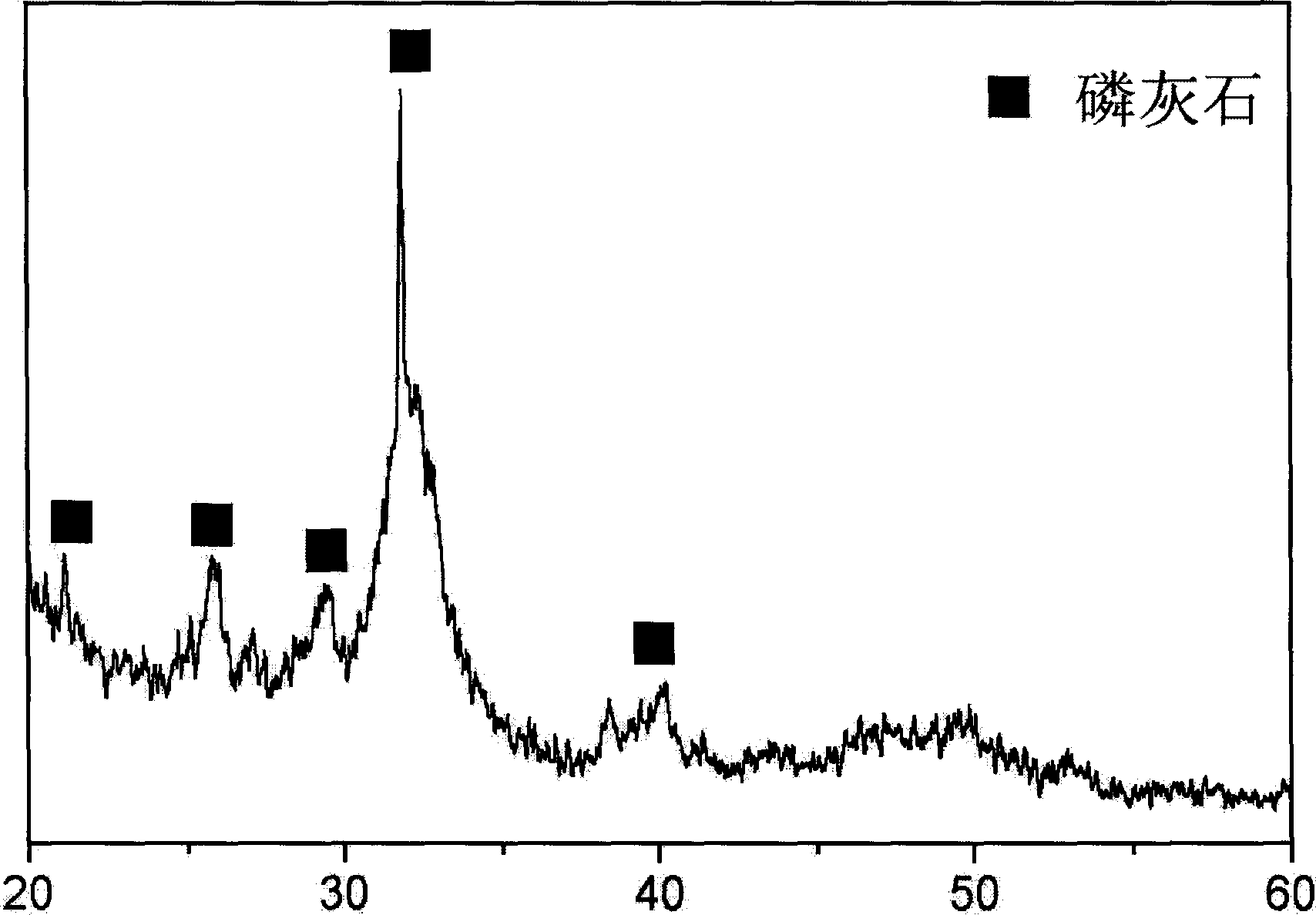

Dicalcium silicate coating layer-titanium alloy loading bone replacement material and its preparation method

The present invention relates to a bone substituted material. Said bone substitute material is dicalcium silicate coating layer deposited on the surface of titanium alloy of Ti-6Al-4V, said coating layer is formed from beta-Ca2SiO4 and glass phase, and its thickness if 50-400 micrometers. Its preparation method incldues the following steps: firstly, synthesizing gamma-Ca2SiO4, then using atmospheric plasma spraying process to deposit the dicalcium silicate coating layer on the titanium alloy base body, and the combination strength of said coating layer and base body is greater than 34-40 MPa.The tests show that the bone apatite can be formed on the surface of dicalcium silicate, and cell can quickly grow and proliferate on the beta-Ca2SiO4 coating layer surface, so that said substitute material possesses good biological activity and compatibility.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Low cost alpha and beta type titan alloy

The invention discloses a low-cost alpha plus beta type titanium alloy, which consists of 4.5-8 percent of aluminum, 0.3-3 percent of chromium, 0.3-2 percent of iron, and the rest of titanium and inevitable impurities by weight percent, wherein 0-3 percent of molybdenum, 0-3 percent of tin or 0-3 percent of zirconium can also be included. The alpha plus beta type titanium alloy of the invention has low cost of constituent elements and high comprehensive mechanical performance equivalent to Ti-6Al-4V, thus not only reducing the production cost of the titanium alloy, but also improving the cost performance. Therefore, the low-cost alpha plus beta type titanium alloy has wide market prospect.

Owner:北京正安广泰新材料科技有限公司

Boron-containing titanium alloy powder for additive manufacturing and preparation method thereof

ActiveCN107841654AGuaranteed uniformityImprove performanceAdditive manufacturing apparatusTi 6al 4vImpurity

The invention discloses boron-containing titanium alloy powder for additive manufacturing and a preparation method thereof and belongs to the technical field of titanium alloy materials. The boron-containing titanium alloy powder comprises the chemical components of, by weight, 4.5%-5.5% of Al, 3.5%-4.5% of V, 0.05%-1% of B and the balance Ti and inevitable impurity elements. Compounding is conducted according to the required alloy components, raw materials such as titanium boride and titanium sponge are mixed evenly and then pressed into an electrode; the electrode is subjected to vacuum consumable smelting into an ingot; and the ingot is forged into a bar, and then the bar is prepared into the titanium alloy powder through a non-crucible induction melting gas atomizing method. The detection result of the structural performance of a member manufactured by adopting the boron-containing titanium alloy powder shows that compared with existing Ti-6Al-4V powder, the boron element is addedso that cylindrical crystals caused by the temperature gradient in the additive manufacturing process can be weakened significantly, meanwhile crystal grains can be refined, and the mechanical performance of a material is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing high-strength modified Ti-6Al-4V titanium alloy large-size rod

ActiveCN107760925AIncrease the content of α-phase stable elementsHigh strengthMetal-working apparatusTi 6al 4vIngot

The invention discloses a method for preparing a high-strength modified Ti-6Al-4V titanium alloy large-size rod. The method comprises the following steps: heating Ti-6Al-4V titanium alloy ingots obtained by vacuum arc re-melting under a condition of Tbeta+100 DEG C-Tbeta+160 DEG C, keeping the temperature, performing blooming fogging, sequentially heating under conditions of Tbeta-20 DEG C-Tbeta-50 DEG C and Tbeta+20 DEG C-Tbeta+100 DEG C, keeping the temperature, performing ramming fogging, rapidly cooling with water, performing ramming fogging under a condition of Tbeta-20 DEG C-Tbeta-60 DEGC, keeping the temperature, performing air cooling so as to obtain a blank, performing chamfering, rolling rounding and throwing rounding on the blank, performing thermal treatment, and performing air cooling, thereby obtaining the high-strength modified Ti-6Al-4V titanium alloy large-size rod, wherein the diameter of the titanium alloy rod is 180-220mm, the length of the titanium alloy rod is greater than 2000mm, the tensile strength Rm of the titanium alloy rod is greater than 960Mpa, and the yield strength RP0.2 of the titanium alloy rod is greater than 860Mpa. By slightly adjusting the contents of components of main elements in the titanium alloy, and with the combination of phase cross heating, large-deformation fogging and rapid water cooling processes, the strength of the titaniumalloy is improved, and the good matching of strength and plasticity is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

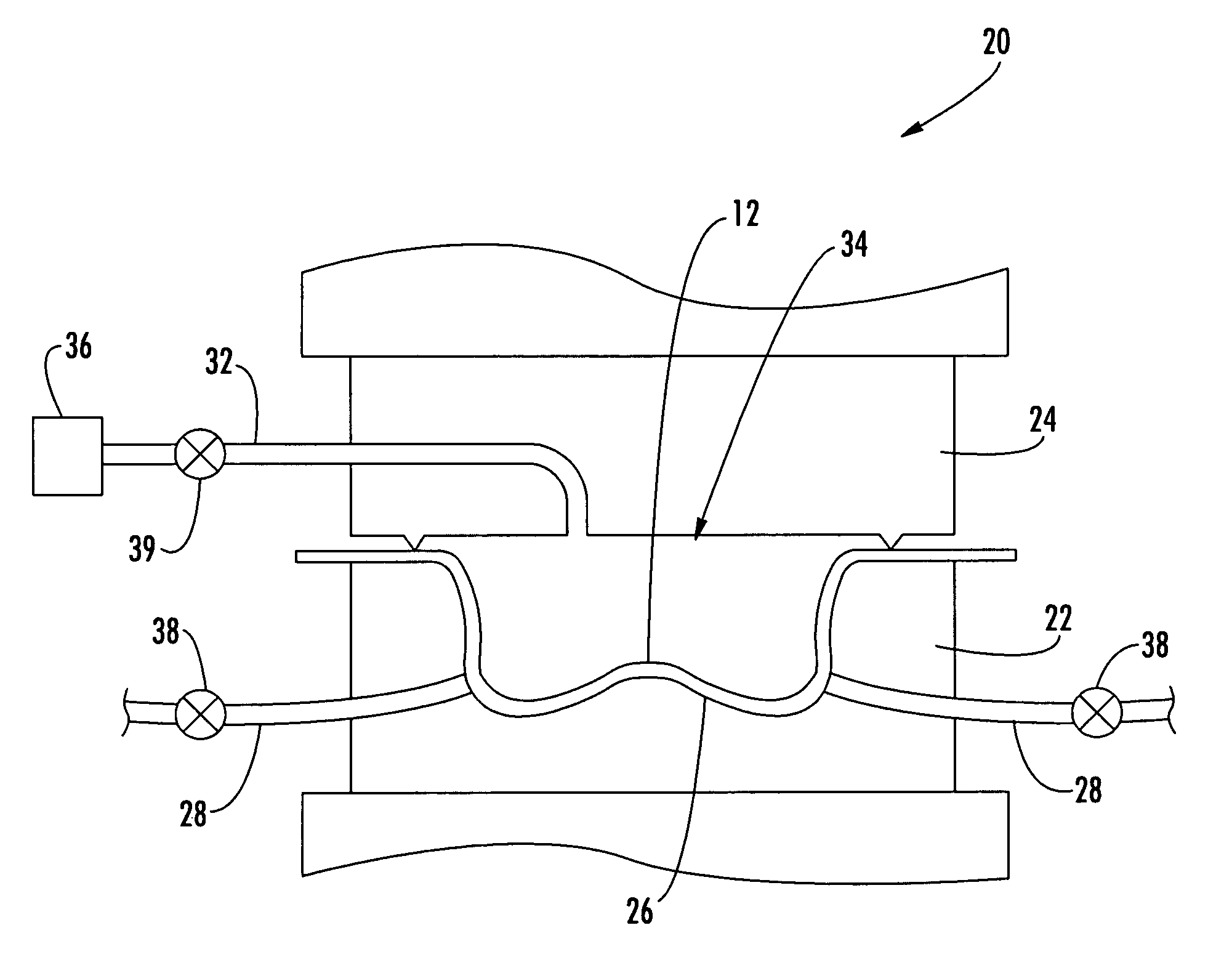

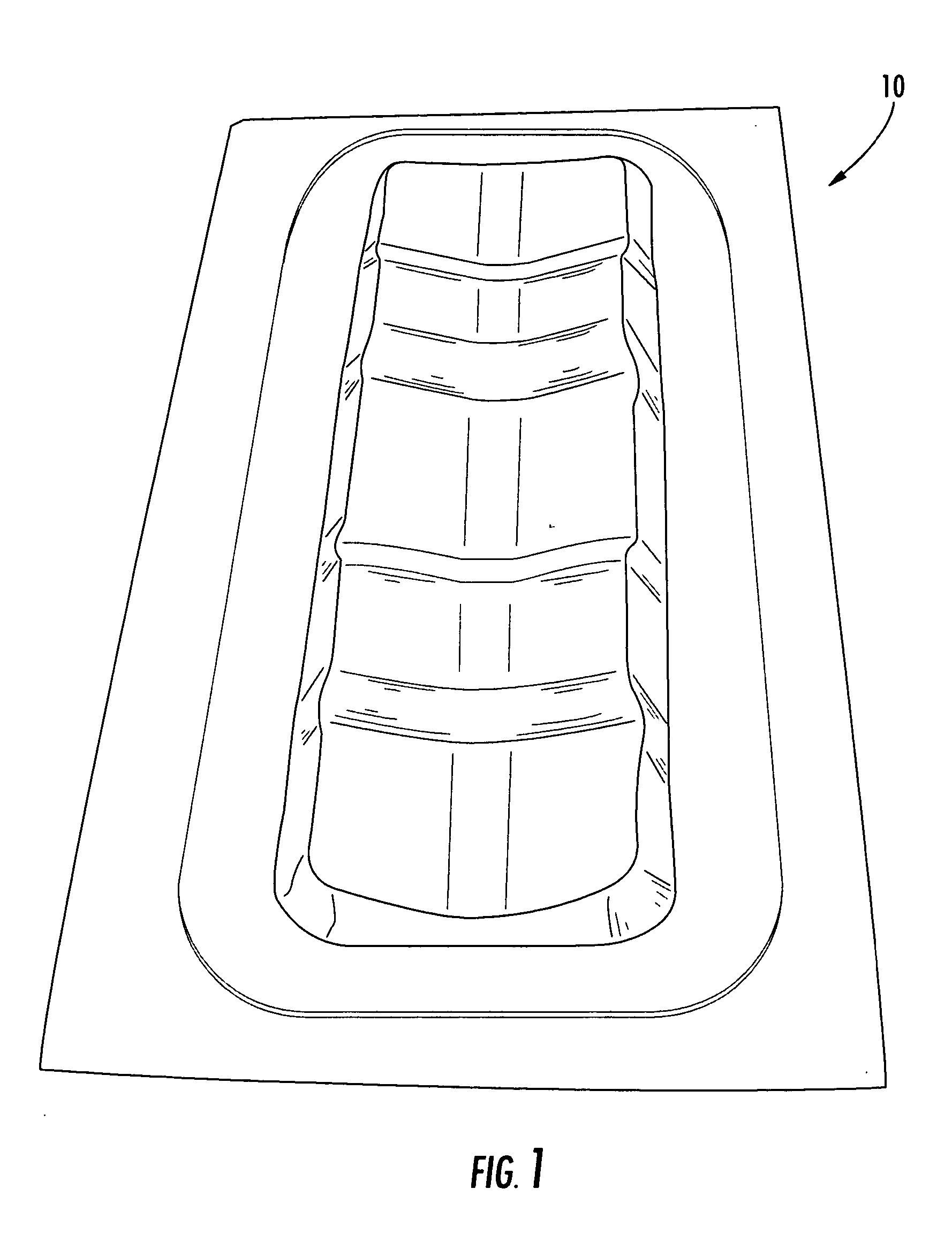

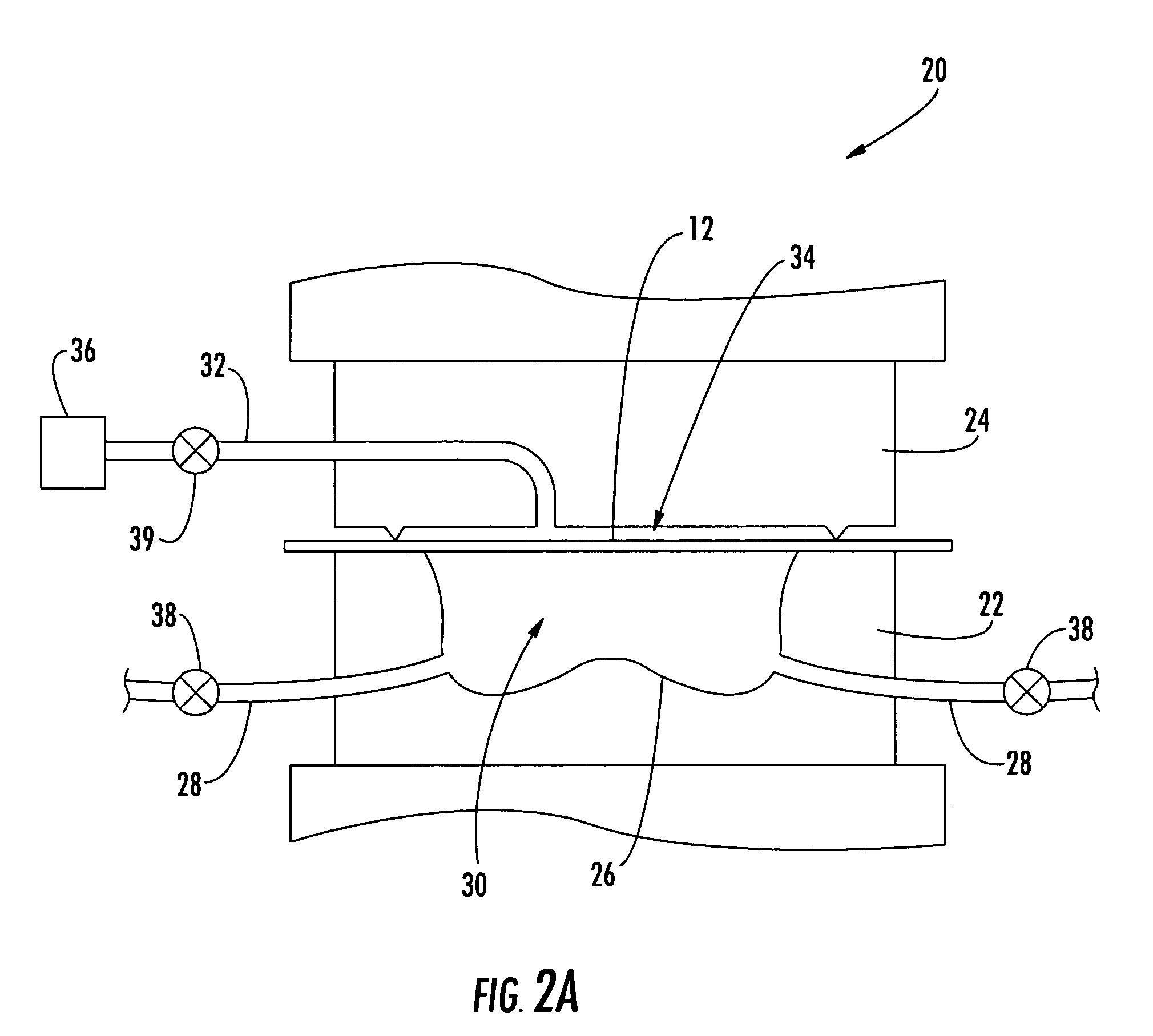

Superplastic forming and diffusion bonding of fine grain titanium

ActiveUS20050218193A1Less heatReduce the impactWelding/soldering/cutting articlesNon-electric welding apparatusThermal energyTitanium

A method for superplastically forming and / or diffusion bonding a structural member and an associated structural member are provided. The structural member is formed at least partially of titanium, e.g., Ti-6Al-4V, and has a fine grain structure. For example, the grain size of the material of the structural member can be less than 2 micron. The member can be superplastically formed and / or diffusion bonded at a reduced temperature, thereby potentially reducing the thermal energy required for forming and bonding, and also reducing the effects of heating on the structural member and the forming apparatus. In addition, the structural member can be formed at an increased strain rate.

Owner:THE BOEING CO

Low cost alpha and beta type titan alloy

The invention discloses a low-cost Alpha+Beta type titanium alloy, the titanium alloy contains, in weight percent: aluminum 4.5 to 8 percent, chromium 0.3 to 2 percent, iron 0.3 to 2 percent, molybdenum 0 to 1 percent, balance titanium and unavoidable impurities. The Alpha+Beta type titanium alloy of the invention contains no noble metal of vanadium, and has equivalent comprehensive mechanical properties compared with Ti-6Al-4V, thereby increasing the price performance ratio while reducing the titanium alloy manufacturing cost, and having the broad market prospect.

Owner:北京正安广泰新材料科技有限公司

Medical high-strength Ti-6Al-4V alloy wire and preparation technique and application thereof

ActiveCN105970019AMeet performance requirementsEasy to operateFurnace typesHeat treatment furnacesStress reliefTi 6al 4v

The invention relates to a medical high-strength Ti-6Al-4V alloy wire and a preparation technique and application thereof and belongs to the technical field of metal material preparation. The medical high-strength Ti-6Al-4V alloy wire comprises, by mass, 5.9%-6.3% of Al, 4.0%-4.3% of V, 0.10%-0.16% of O, 0.14%-0.22% of Fe and the balance Ti. The preparation technique comprises the steps of smelting, forging, two times of large-deformation rolling, cold drawing, intermediate annealing, temperature-control hot drawing, stress relief annealing of a semi-finished product, one-pass cold drawing, straightening and cutting-off, stress relief annealing, polishing and obtaining of a finished product. The medical high-strength Ti-6Al-4V alloy wire and the preparation technique and application thereof have the beneficial effects that the Ti-6Al-4V alloy wire is prepared through the technical process that heat machining, cold drawing and temperature-control hot drawing are combined, and the Ti-6Al-4V alloy wire has the advantages that the mechanical performance is high, the dimensional precision is high, the surface smoothness is high, and the structure property uniformity is good.

Owner:DALIAN SUNNY TITANIUM IND

Preparation method for Ti-6Al-4V alloy part

InactiveCN108326283AHigh strengthImprove compactnessTransportation and packagingMetal-working apparatusTi 6al 4vAlloy

The invention provides a preparation method for a Ti-6Al-4V alloy part. A mixture of spherical Ti-6Al-4V alloy powder, nonspherical Ti-6Al-4V alloy powder and a catalytic degreasing binder is subjected to banburying at the protective atmosphere, the material obtained through banburying are pelletized, and then alloy feed is obtained; the alloy feed is sequentially subjected to injection molding and pressure maintaining, and an alloy part forming blank is obtained; at the protective atmosphere, the alloy part forming blank is subjected to degreasing, and a presintering body is obtained; and under the vacuum condition, the presintering body is subjected to sintering, and after cooling, the Ti-6Al-4V alloy part is obtained. According to the alloy part obtained through the method, the tensilestrength can reach 765 MPa, and the bending strength can reach 1,145 MPA. Alloy parts in complex shapes can be prepared.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Low-cost and high-performance titanium alloy and preparation method thereof

The invention relates to a low-cost and high-performance titanium alloy and a preparation method thereof. The alloy is a quaternary titanium alloy which is formed by taking titanium as a main body element and additionally adding three elements. The alloy comprises the following components in percentage by mass: 1-5% of Fe, 0.1-0.4% of O, 0.1-0.3% of B and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: adding the raw materials into a suspended smelting furnace of a cold crucible where argon is introduced in a designed alloy component proportion; repeatedly smelting for several times to obtain cast ingots; cogging and forging the cast ingots above the phase transformation point to form sheared billets; then rolling the sheared billet to form rods; thermally treating the sampled rods; and finally representing structure and performance of the rods. The preparation process is simple in method, and the prepared alloy is uniform in component. The tensile strength reaches over 950MPa, the ductility is not less than 15%, and the percentage reduction of area is not less than 25%. The basic mechanical property of the alloy is equivalent to that of Ti-6Al-4V but the cost has the advantage of over 15% compared with that of the Ti-6Al-4V. The alloy can replace part of titanium alloys which are relatively high in price in some fields.

Owner:NANJING UNIV OF TECH

Preparation method of double-scale crystalline grain Ti-6Al-4V material

InactiveCN102703756AProportional precision controlOvercome the defect that the ratio is difficult to control preciselyHigh energyTi 6al 4v

The invention discloses a preparation method of a double-scale crystalline grain Ti-6Al-4V material. The preparation method adopts a forming way combining a high energy ball milling process with a spark plasma sintering process, and comprises the following steps of: firstly, taking powder in a segmentation manner in the whole high energy ball milling process to obtain powder with different refining degrees, wherein the grain size distribution range of the ultrafine crystal powder is controlled to be between 100nm and 1 mu m, and the grain size distribution range of the nanocrystalline powder is controlled to be between 10nm and 100nm; then, compounding and uniformly mixing one of the powder serving as the raw material and the ultrafine crystal powder with the nanocrystalline powder according to any mass ratio; and finally, optimizing the spark plasma sintering process. By controlling the mixing proportion of the two powder, the proportion of a rough crystal zone and a fine crystal area in a double-scale crystalline grain Ti-6Al-4V material tissue can be accurately controlled, and the defect that the proportion of rough and fine crystals are difficult to be accurately controlled is overcome; and meanwhile, by optimizing the sintering parameters of the spark plasma sintering process, the material has an excellent comprehensive mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

Biological living being in medical use for Embeded to human body, and preparation method

A medical biologicl body to be transplanted in human body is prepared from a 4-element (Ca-Si-P-Mg) glass paint and a Ti alloy (Ti-6Al-4V) substrate through depositing said glass paint on the surface of Ti alloy substrate. Said glass paint contains micro crystals of calcium phosphate and calcium silicate, and has high bioactivity and biocompatibility.

Owner:安吉县阳光医药用品有限责任公司

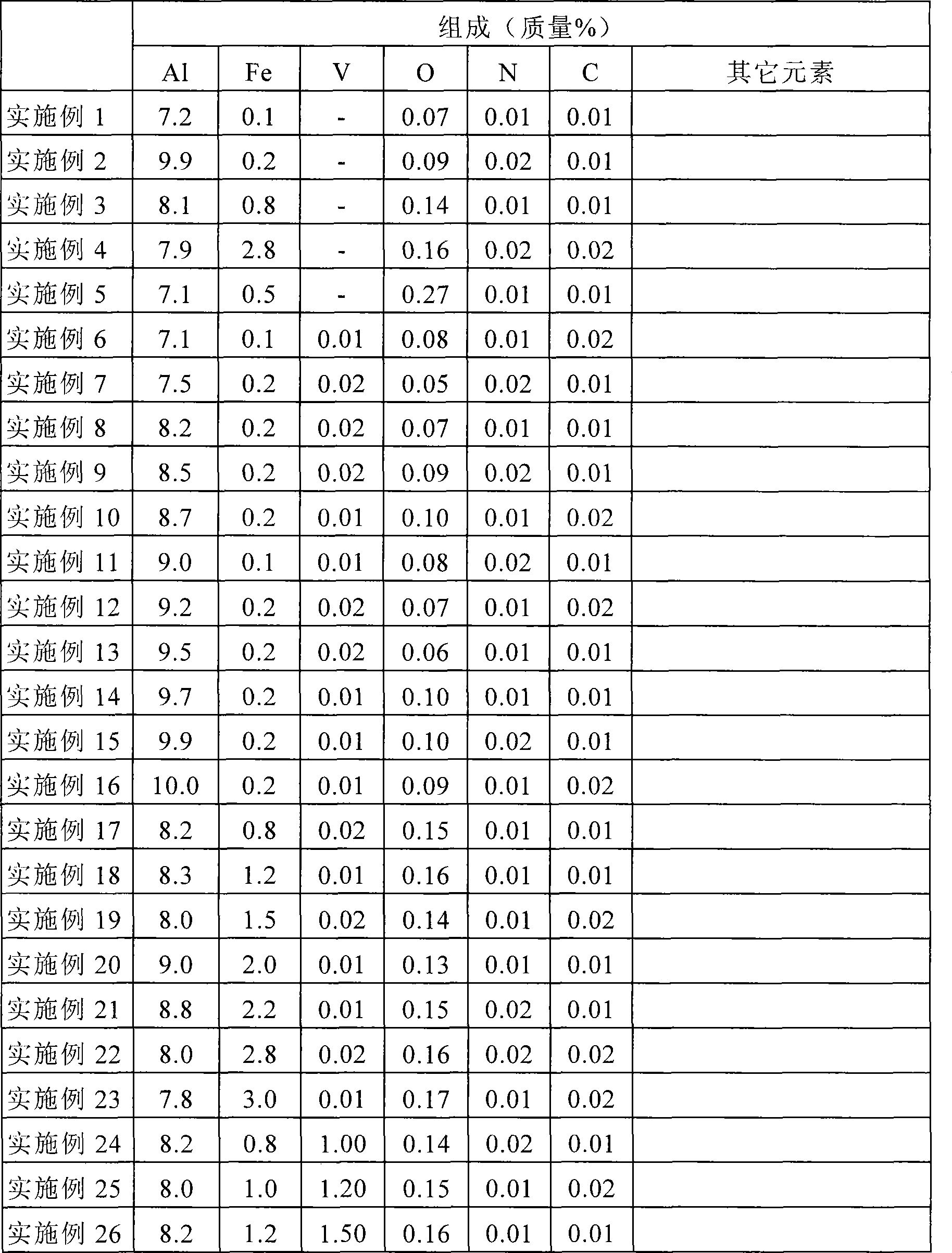

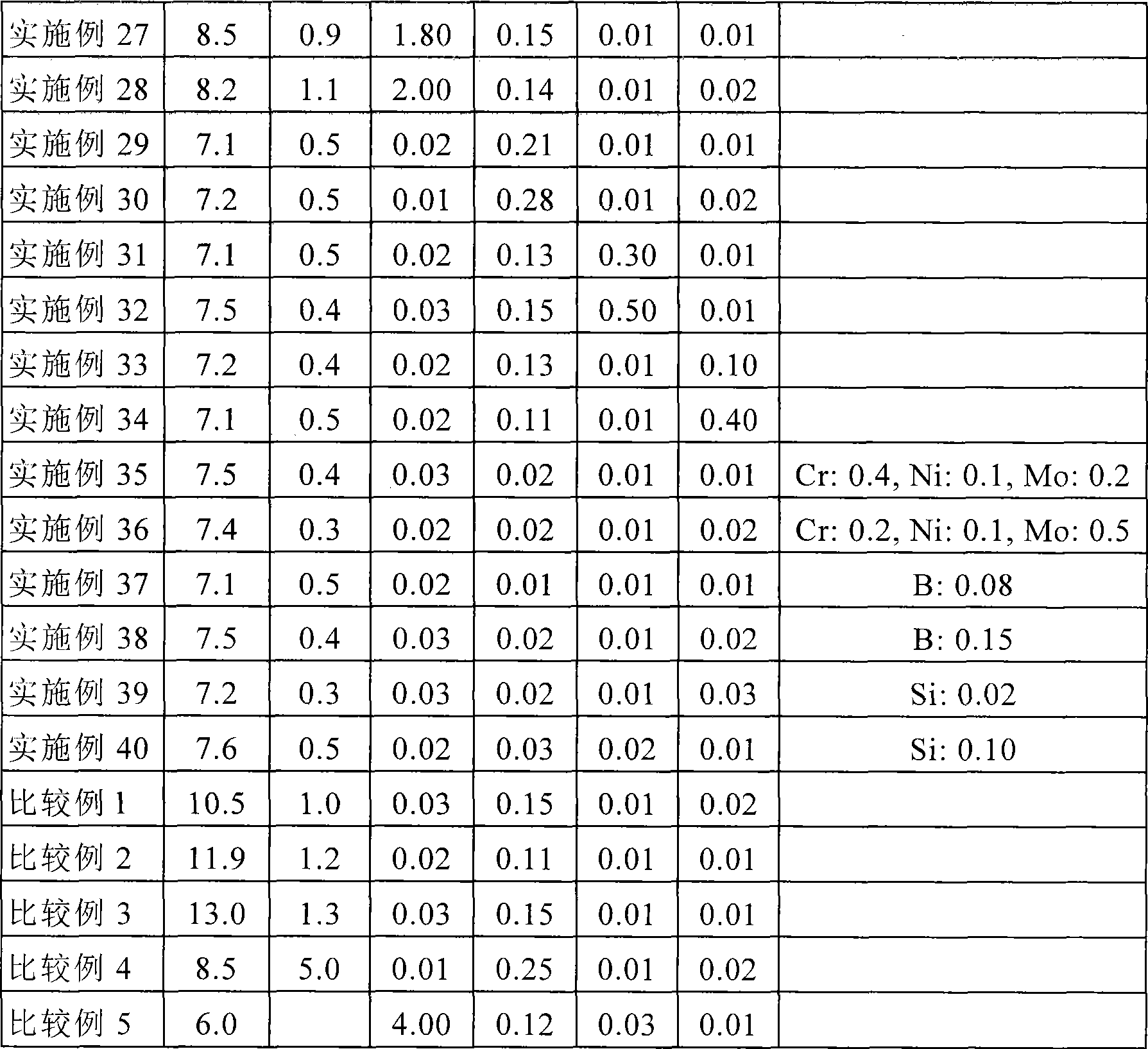

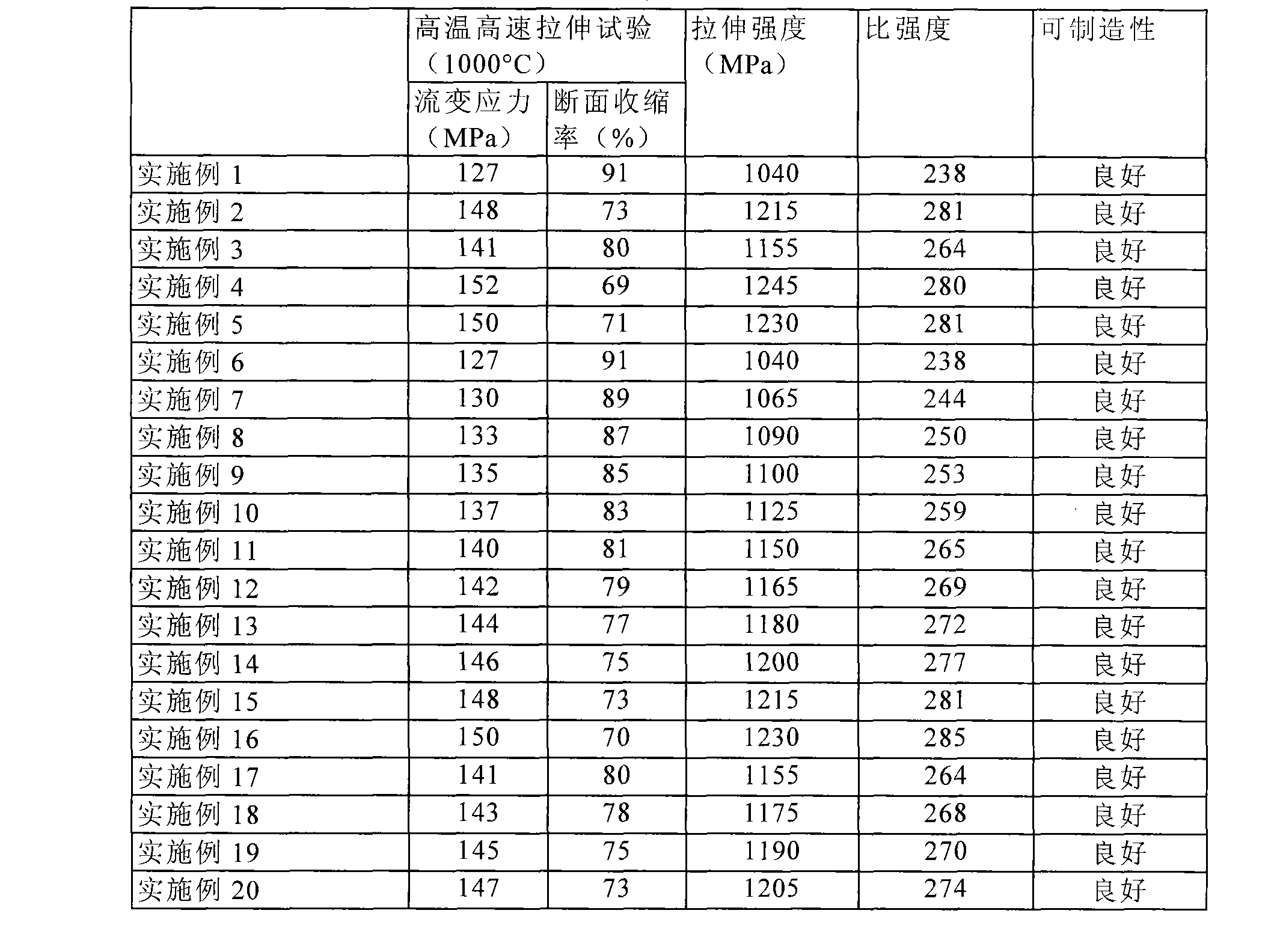

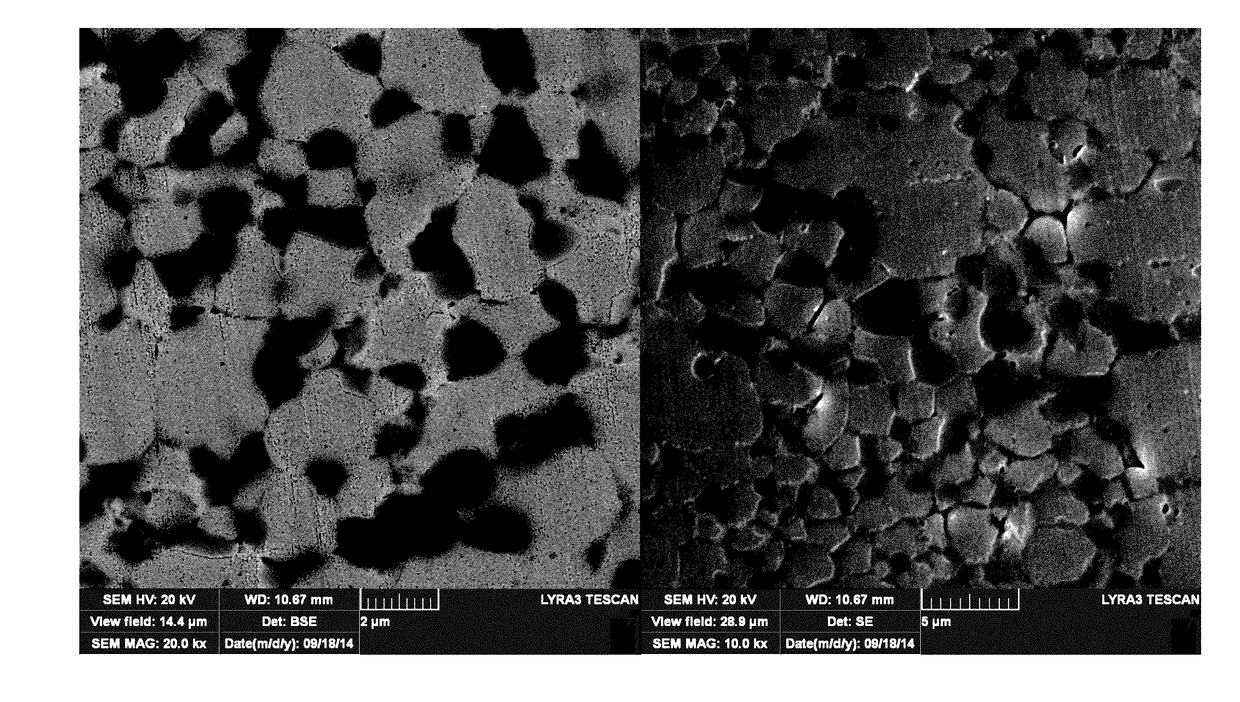

Low density titanium alloy, golf club head, and process for prouducing low density titanium alloy part

The present invention relates to a low density titanium alloy, containing: 7.1 to 10.0 mass % of Al; 0.1 to 3.0 mass % of Fe; 0.01 to 0.3 mass % of O; 0.5 mass % or less of N; 0.5 mass % or less of C; and a remainder being Ti and inevitable impurities; a golf club head using the alloy; and a production method for a low density titanium alloy part using the alloy. The alloy of the invention may further contain 0.01 to 2.0 mass % of V. The alloy of the invention has higher specific strength as compared to the Ti-6Al-4V alloy, is excellent in hot workability, and is reduced in cost.

Owner:DAIDO STEEL CO LTD

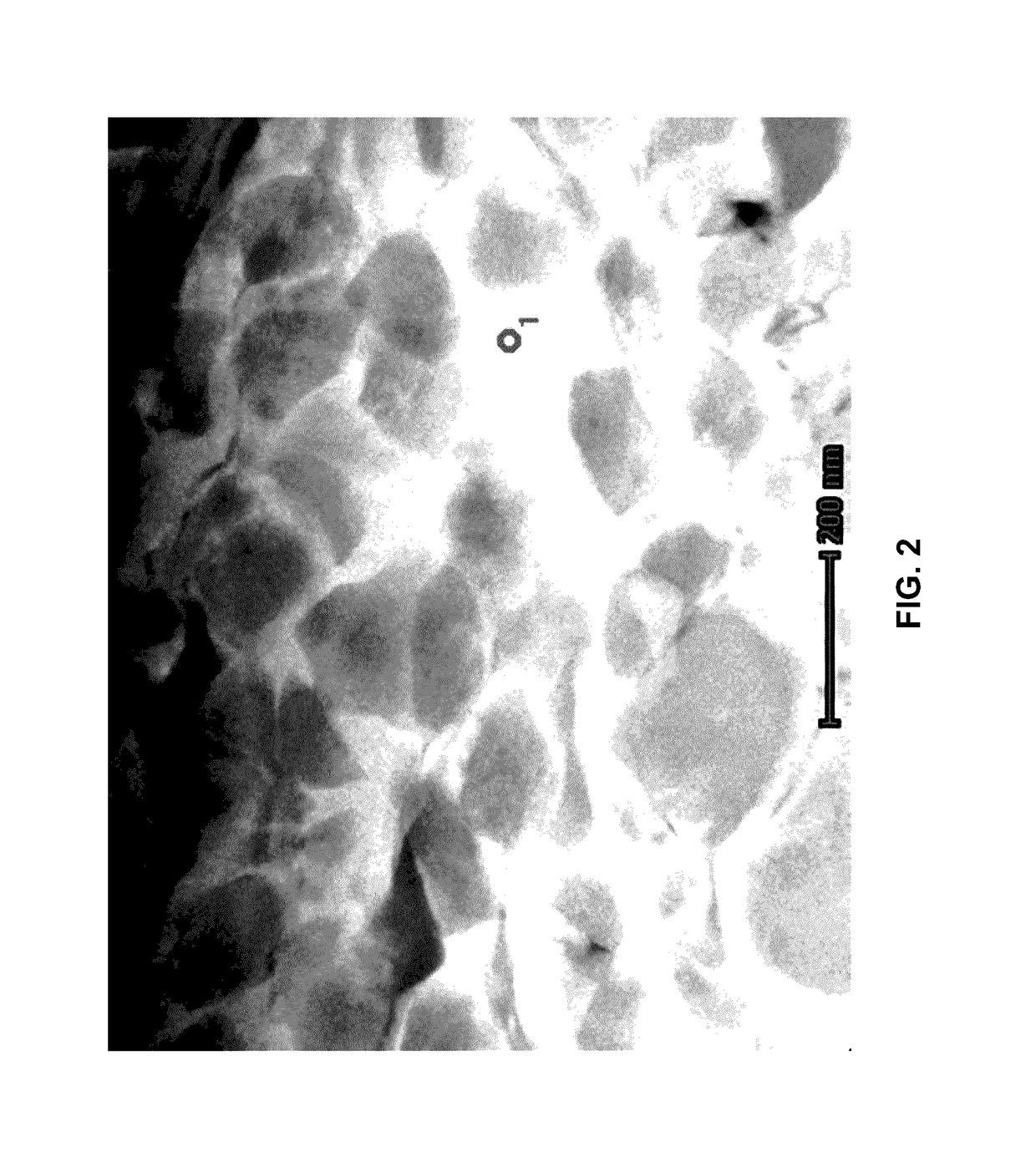

Titanium alloys for biomedical applications and fabrication methods thereof

Alloys of titanium with 20-22 at. % niobium and 12-13 at. % zirconium. The alloys are prepared by mechanical alloying of elemental powders and densification by spark plasma sintering. The alloys have a nano-scaled, equiaxed granular structure, a microhardness of at least 650 HV and a modulus of 90-140 GPa. The inventive alloy is corrosion resistant, biocompatible, and is of a higher wear resistance and durability compared to the Ti-6Al-4V alloy. The bioactive surface of the inventive nanostructured alloy promotes a higher protein adsorption that stimulates new bone formation than other titanium-based alloys. These alloys are suitable for various biomedical and dental applications.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

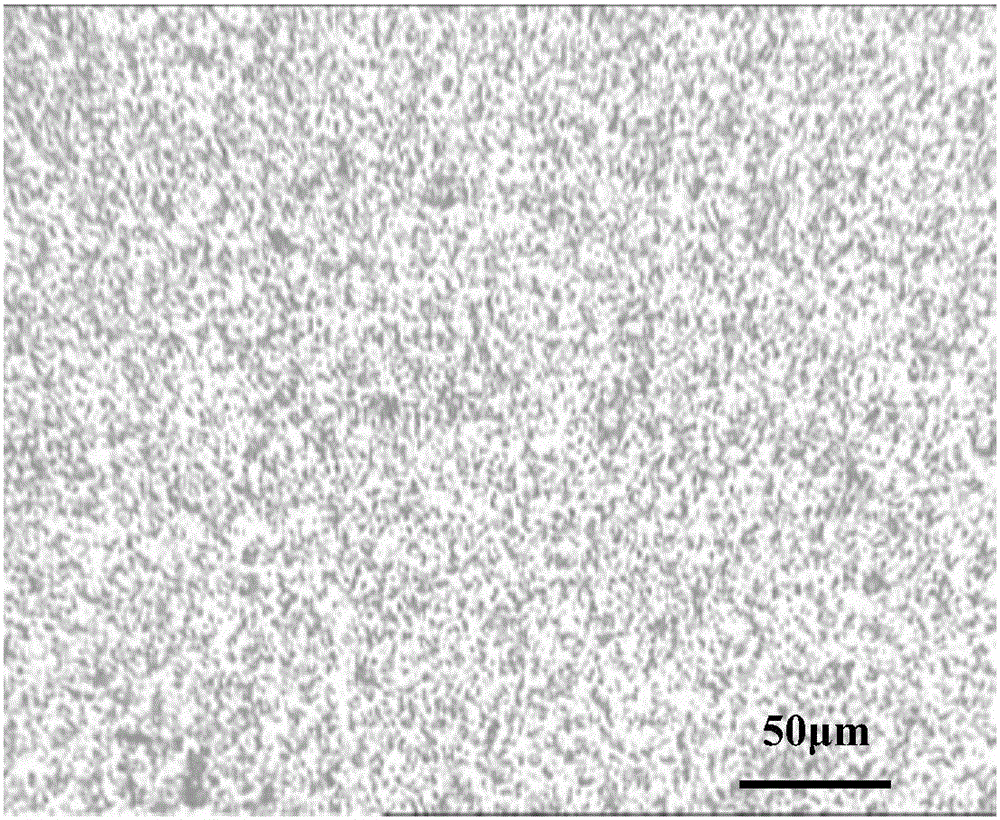

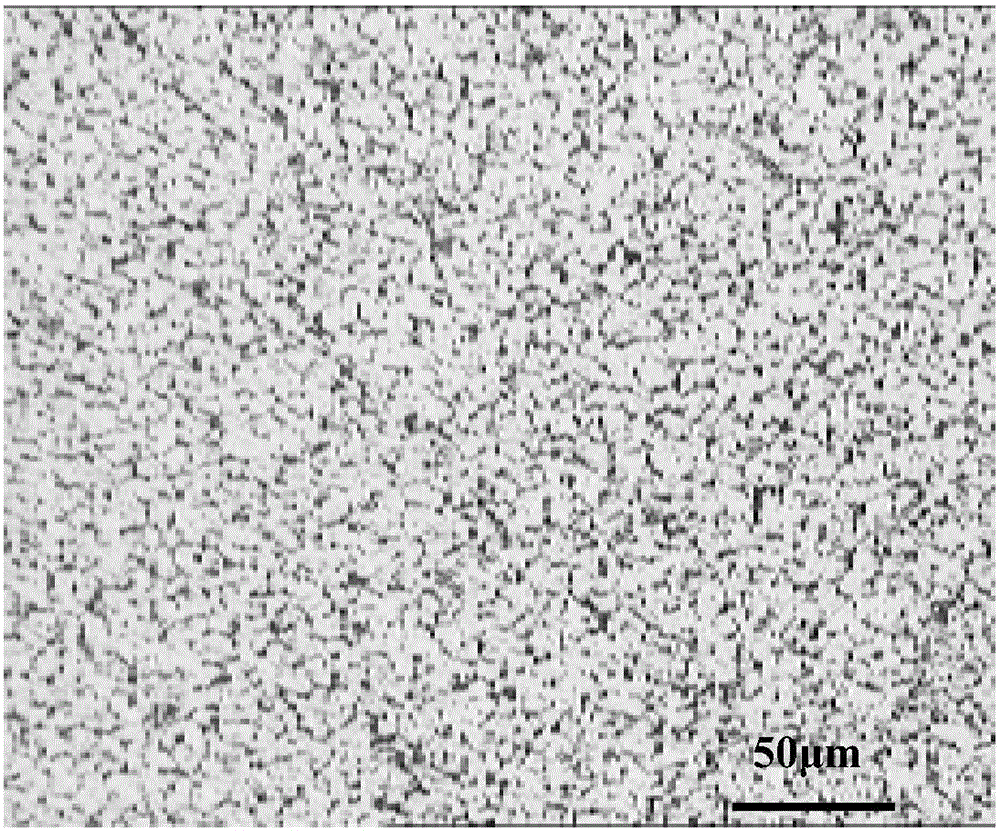

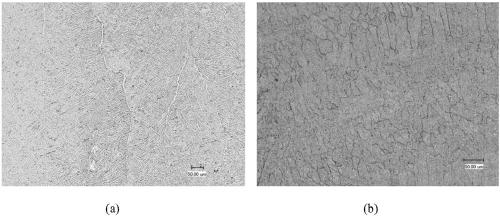

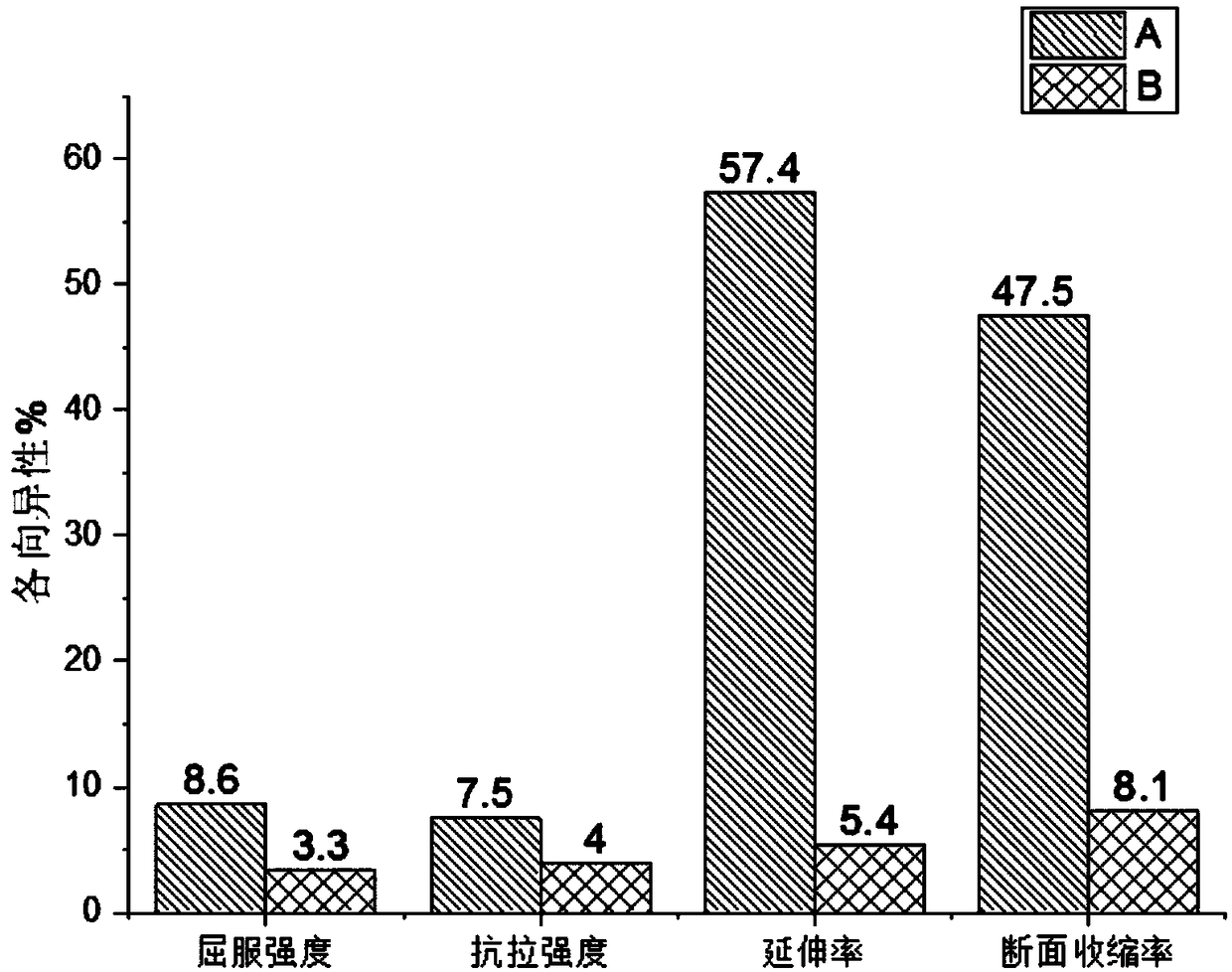

Method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing

InactiveCN109226743AGrain equiaxation and refinementReduce anisotropyAdditive manufacturing apparatusIncreasing energy efficiencyTi 6al 4vSedimentation

The invention discloses a method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing. The method includes the following steps of S1, drying Ti-6Al-4V-0.05B alloy powder under a vacuum environment at 120 DEG C for 8 hours; S2, using a laser additive manufacturing device for conducting laser melting, covering and forming on the alloy powder dried in step S1 under a protective atmosphere of inert gas to obtain a formed sample component; S3, conducting thermal dissolution and aging treatment on the formed component under argon protection of the inert gas. By using a new material obtained by alloying boron and TC4 in the method for laser melting, covering and sedimentation, boron effectively inhibits generation of thick preliminary cylindrical crystals in a TC4 titanium alloy during forming and facilitates isometry and refining of TC4 titanium alloy grains, the structure is more uniform, and the anisotropy of conventional mechanical performance is controlled within 10%. A new approach is provided for laser additive manufacturing of the TC4 titanium alloy.

Owner:XI AN JIAOTONG UNIV

Method for manufacturing titanium alloy thick-wall pipe

The invention discloses a method for manufacturing a titanium alloy thick-wall pipe, which is suitable for thermal stretching manufacture of a Ti-6Al-4V titanium alloy thick-wall pipe. The method is characterized by comprising the following steps: (1) preparing a blank; (2) heating the pipe blank; (3) thermally stretching the pipe blank; (4) thermally scalping the pipe blank; (5) thermally straightening the pipe blank; (6) polishing a surface oxidation film; (7) fixing the size and blanking the pipe blank; and (8) polishing the pipe blank to obtain a qualified product. The method for producing the Ti-6Al-4V titanium alloy thick-wall pipe by adopting a new thermal stretching process overcomes the defect of the traditional drilling method, and has the characteristics of quick efficiency, good material, high yield and the like.

Owner:沈阳德兴钛业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com