Low density titanium alloy, golf club head, and process for prouducing low density titanium alloy part

A low-density, titanium alloy technology, applied in the field of low-density titanium alloy to manufacture low-density titanium alloy parts, can solve the problems of high price and high cost, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 40 and comparative example 1 to 5

[0136] 1. Sample Preparation

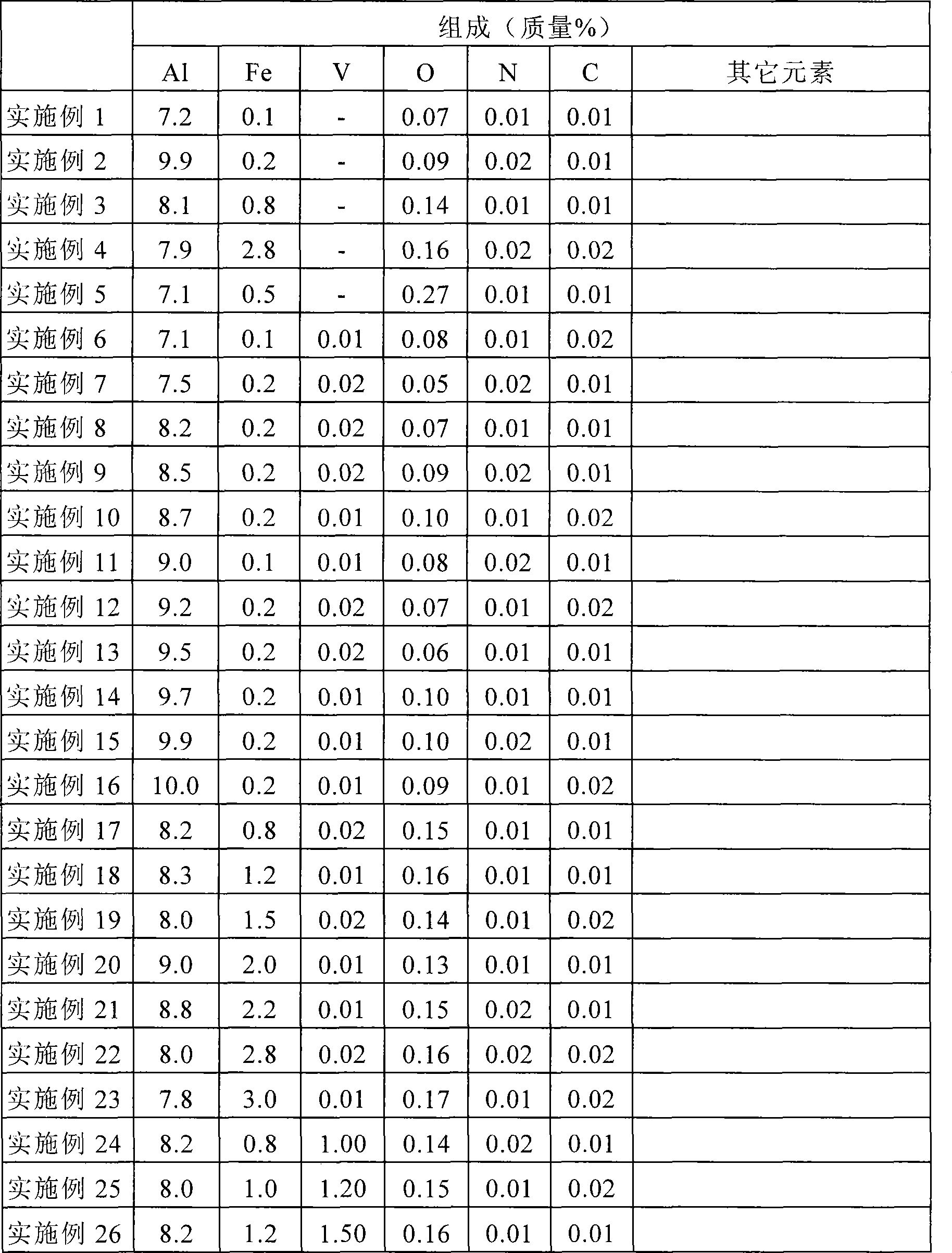

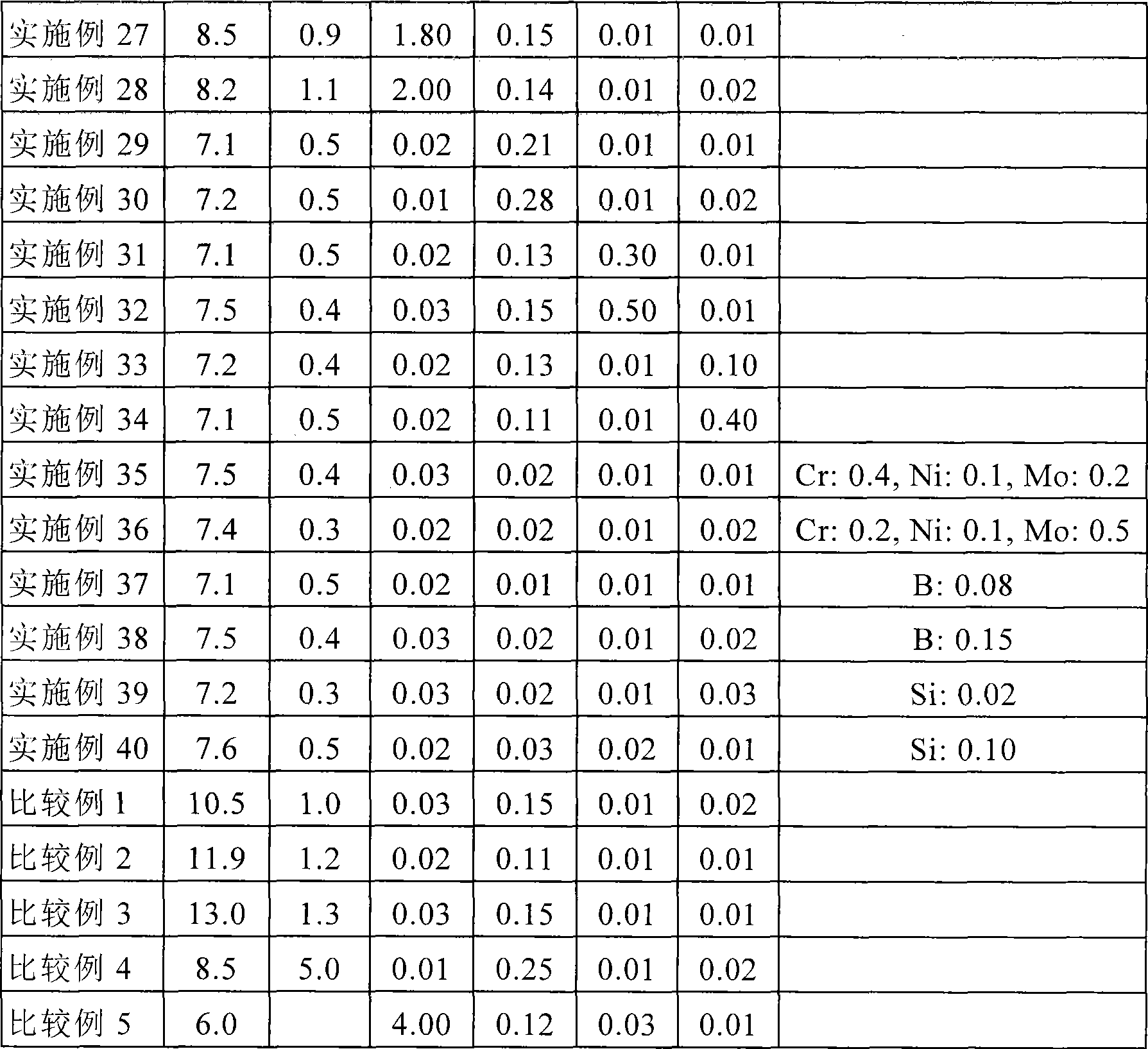

[0137] The raw materials were weighed to obtain a predetermined composition, and melted in a plasma coagulation furnace to obtain a titanium alloy ingot with a mass of 6 kg and a diameter of 100 mm. Shown in Table 1 are the chemical compositions of the ingots obtained above.

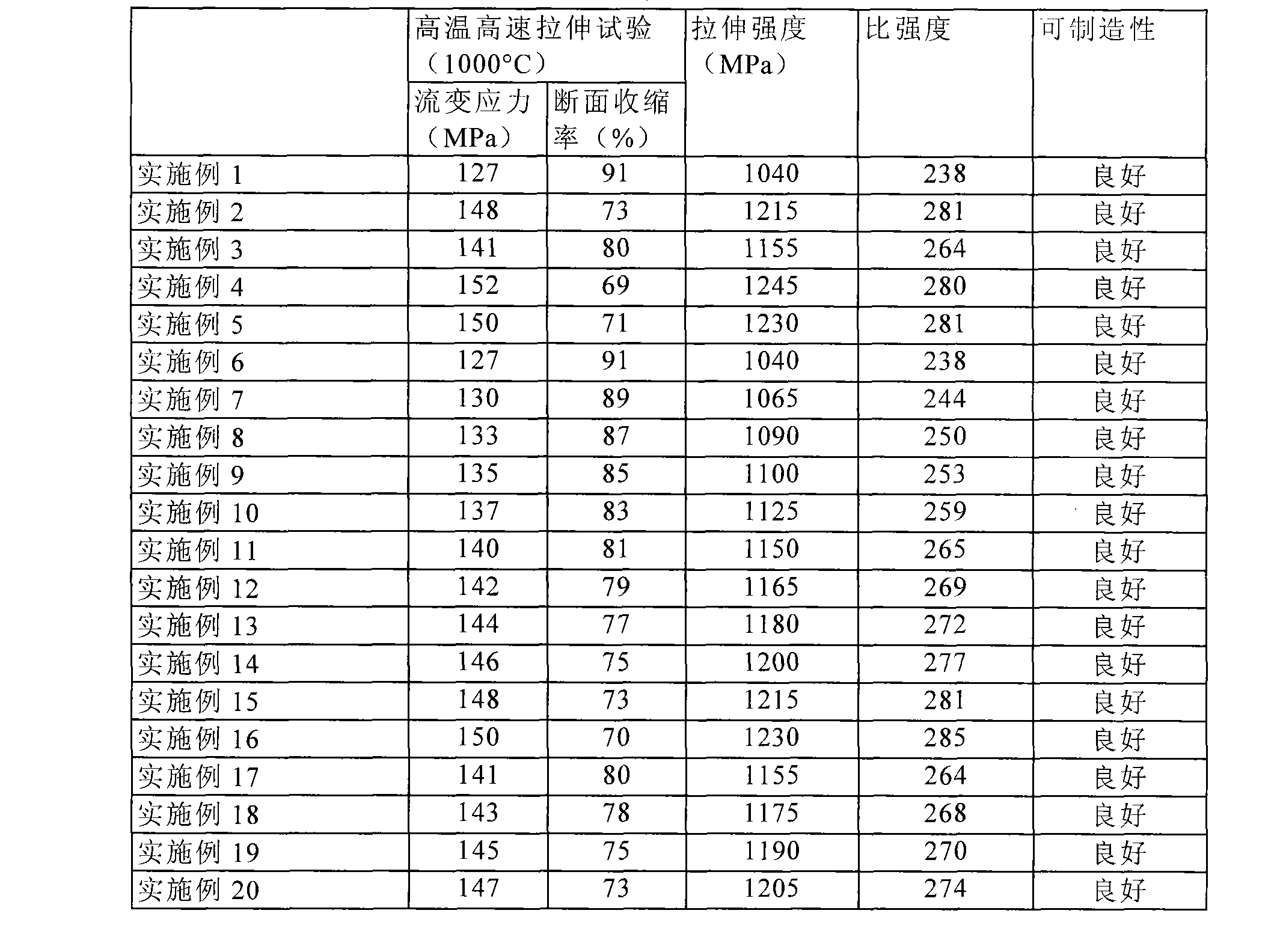

[0138] Test pieces for high-temperature high-speed tensile tests were cut from each ingot.

[0139] In addition, each ingot was heated to 1000° C., and a round bar having a diameter of 20 mm was obtained by hot forging. In addition, heat treatment was performed at 750° C. for 2 hours under air cooling (AC). A No. 3 tensile test piece (diameter: 6.35 mm, evaluation distance: 25 mm) defined in ASTM E8 was prepared from the heat-treated round bar.

[0140] Table 1

[0141]

[0142]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com