Method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing

An anisotropic, additive manufacturing technology, applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of difficult part processing technology, large temperature gradient, poor thermal conductivity, etc., to suppress coarse primary columnar crystals. Growth, increased plasticity and toughness, reduced anisotropy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

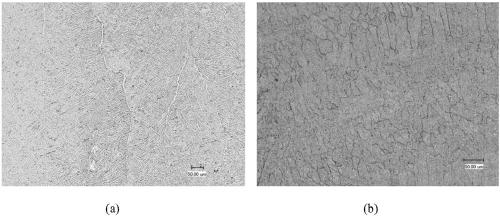

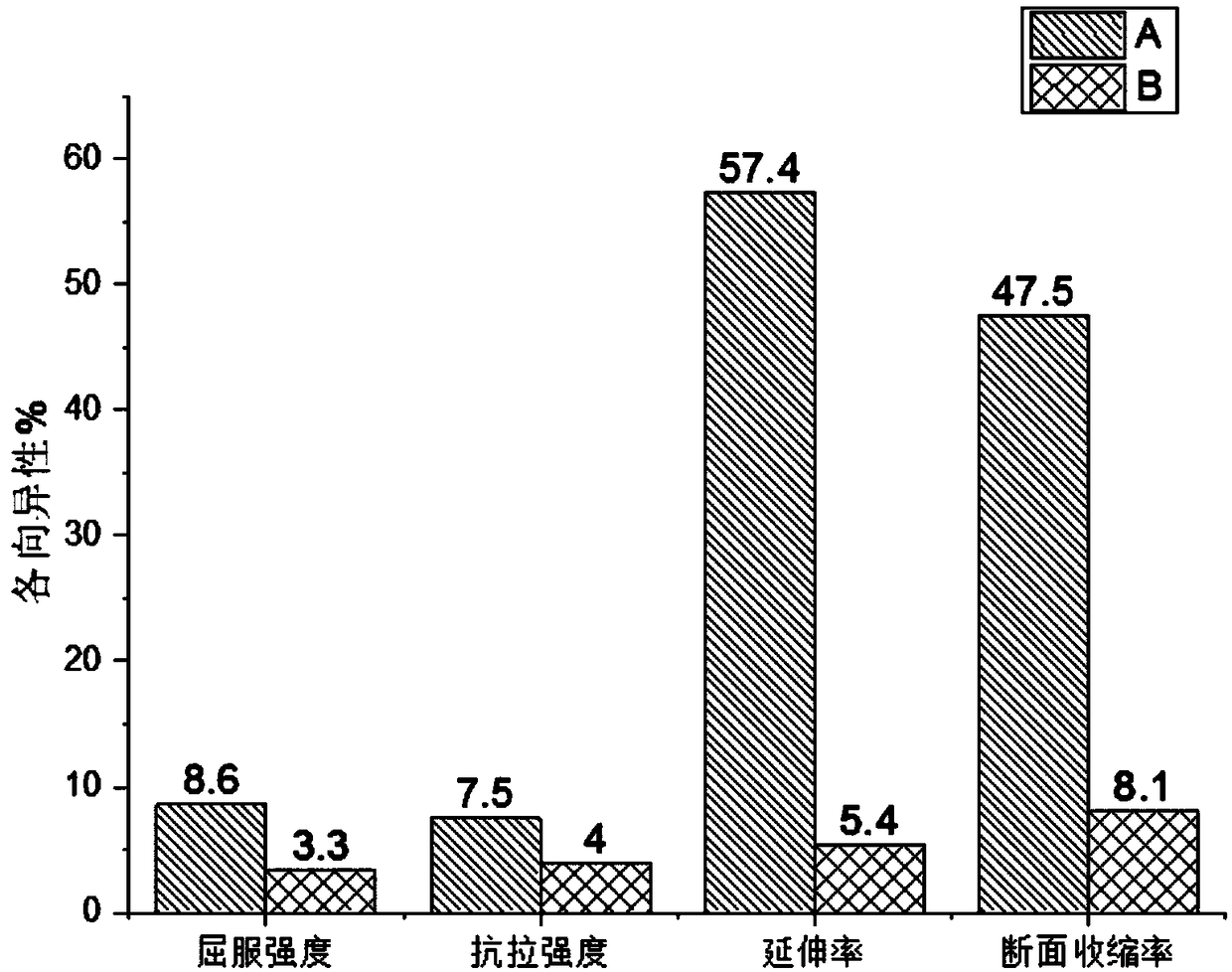

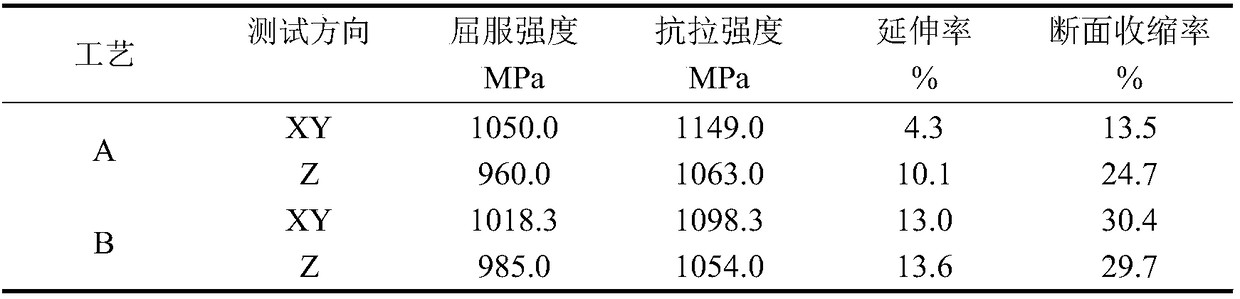

[0024] In process A, take TC4 titanium alloy powder with a particle size of 50-150 μm, and dry it in a vacuum at 120°C for 8 hours; then use a laser additive manufacturing device to perform laser cladding forming under an argon protective atmosphere. The laser power is 180W, the laser spot diameter is 0.5mm, the scanning speed is 10mm / s, the powder feeding amount is 2.5g / min, the Z-axis lifting amount △Z=0.10mm, and the scanning distance is 0.2mm. Then, the formed parts are subjected to solution aging heat treatment under the protection of inert gas argon, the solution temperature is 950°C, heat preservation for 1h, and air cooling; the aging temperature is 550°C, heat preservation for 4h, and then air cooling. The horizontal and vertical tensile properties of the room temperature of the formed alloy are shown in Table 1, and the metallographic diagram of the obtained sample is shown in Table 1. figure 1 As shown in -a, the structure is dominated by short rod-shaped columnar c...

Embodiment 2

[0026] B process, take the alloyed Ti-6Al-4V-0.05B powder, wherein the mass fraction of boron element is 0.05%, the particle size of the alloy powder is 50-150 μm, and dry at 120 ℃ for 8 hours in vacuum; then use The laser additive manufacturing device performs laser cladding forming under an argon protective atmosphere. The laser power is 180W, the laser spot diameter is 0.5mm, the filling speed is 10mm / s, the powder feeding amount is 2.5g / min, the Z-axis lifting amount △Z=0.10mm, and the scanning distance is 0.2mm. Then, the formed parts are subjected to solution aging heat treatment under the protection of inert gas argon, the solution temperature is 950°C, heat preservation for 1h, and air cooling; the aging temperature is 550°C, heat preservation for 4h, and then air cooling. The horizontal and vertical tensile properties of the room temperature of the formed alloy are shown in Table 1, and the metallographic diagram of the obtained sample is shown in Table 1. figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com