Method for preparing high-strength modified Ti-6Al-4V titanium alloy large-size rod

A ti-6al-4v, titanium alloy technology, applied in the field of titanium alloys, can solve the problems of low level of ultrasonic flaw detection, poor consistency of structure and performance, etc., and achieve the effect of improving uneven structure, good consistency and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

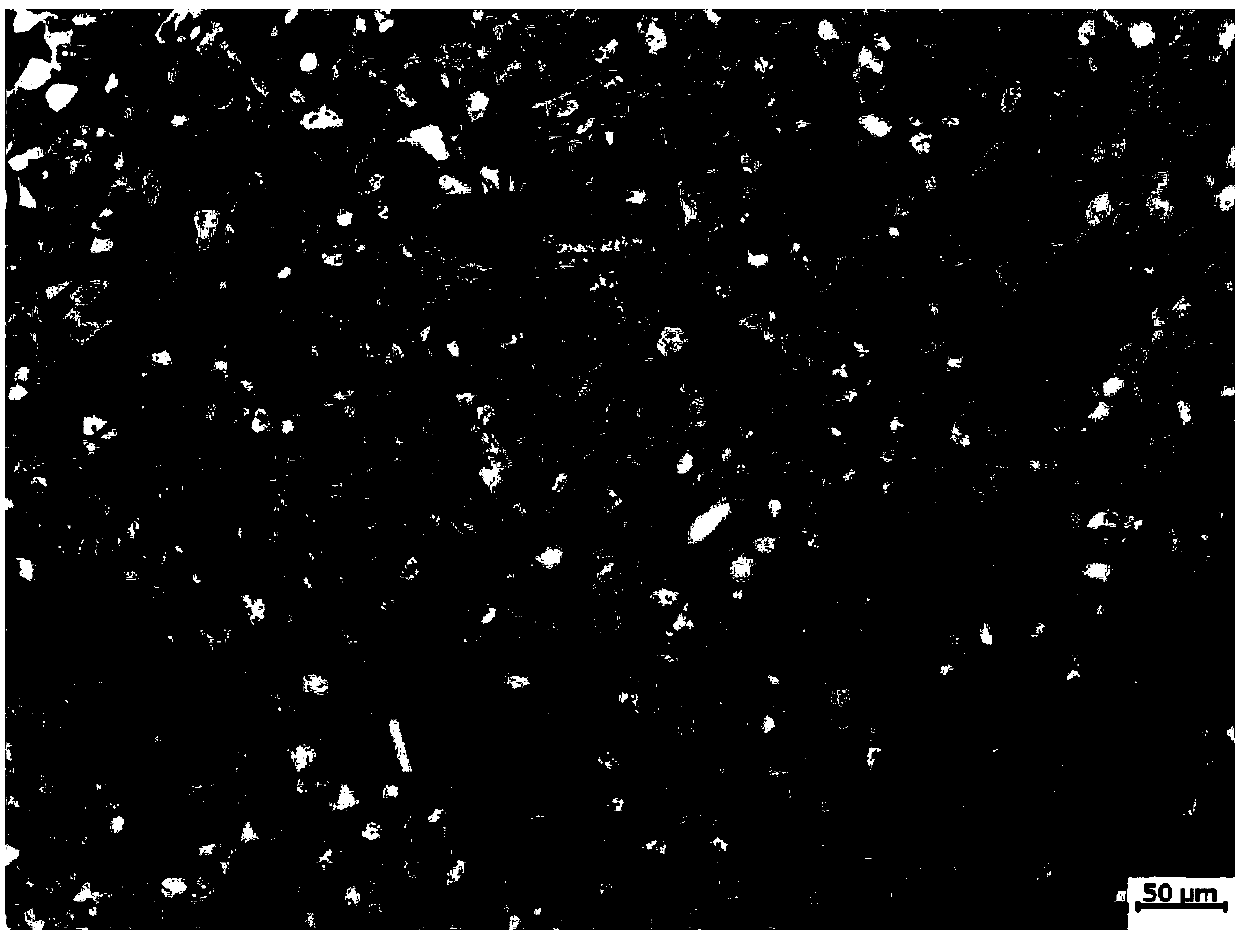

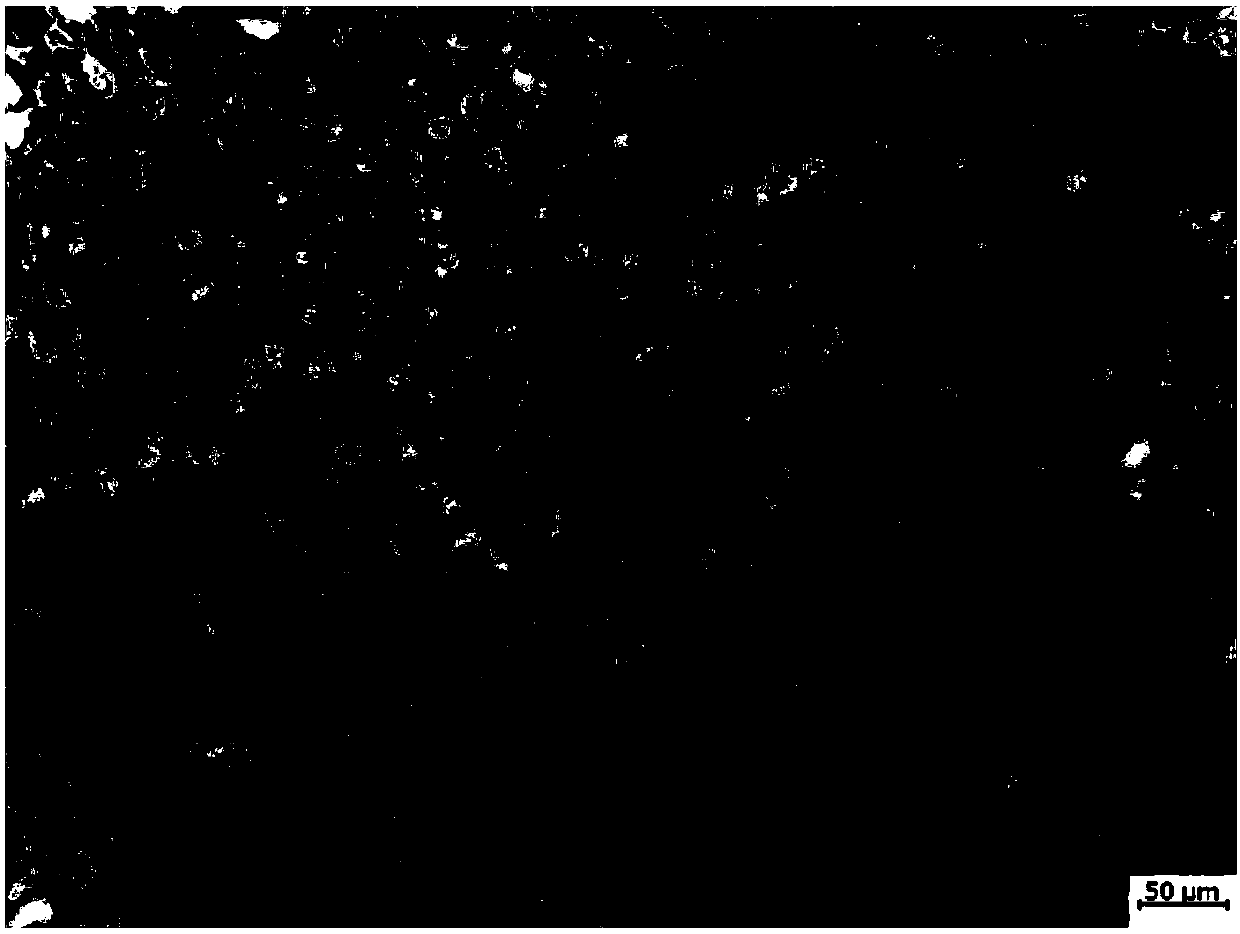

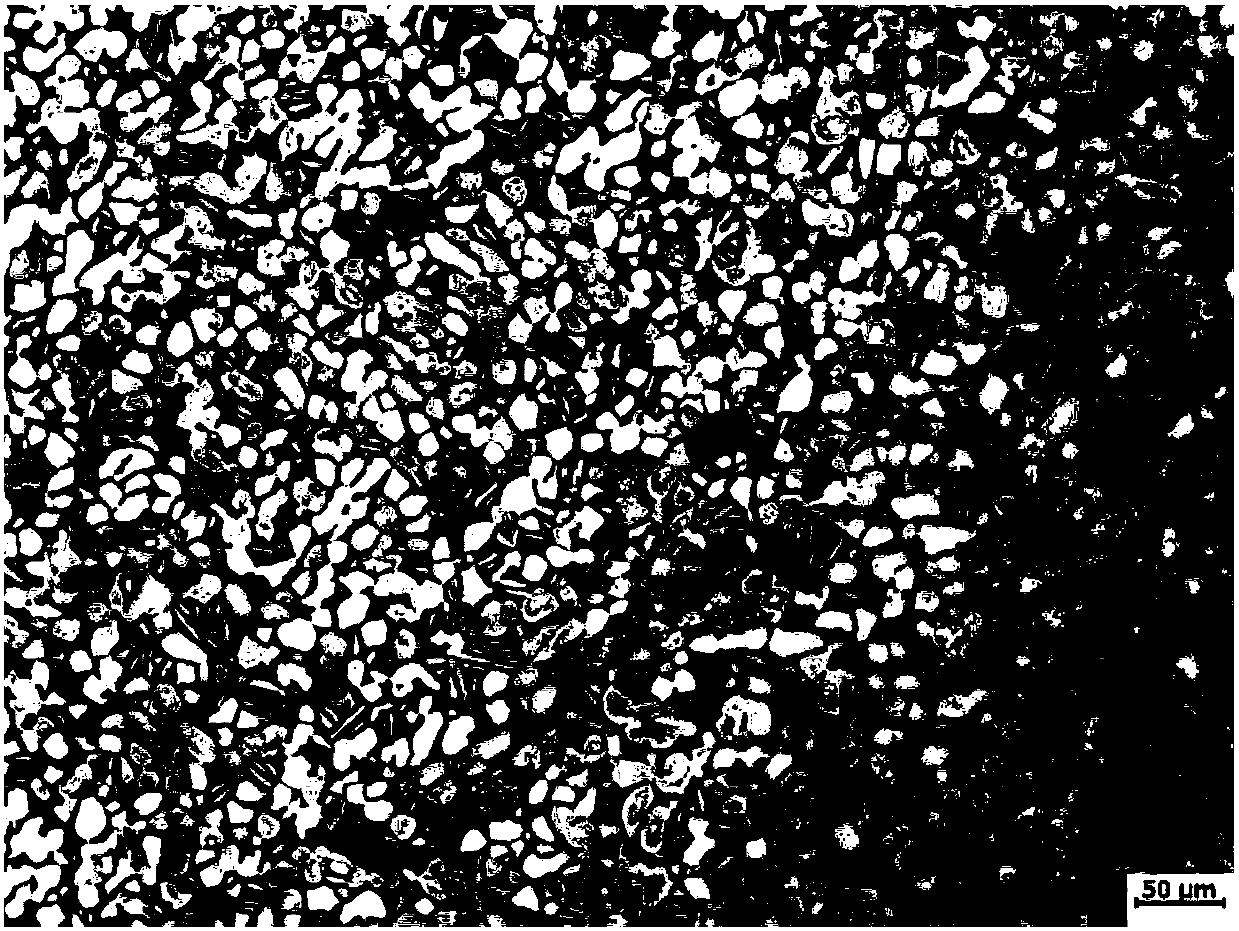

Image

Examples

Embodiment 1

[0032] The preparation method of the present embodiment comprises the following steps:

[0033] Step 1, the 0-grade sponge titanium, Al-V master alloy, Al-V-Fe master alloy, aluminum beans and TiO 2 The powders were mixed and pressed into electrodes, and then subjected to three times of vacuum consumable arc melting to obtain a Ti-6Al-4V titanium alloy ingot with a diameter of 500mm; the Ti-6Al-4V titanium alloy ingot was composed of the following mass percentages: Al 6.6%, V 4.2%, Fe 0.26%, O0.2%, C≤0.02%, N≤0.01%, H≤0.003%, and the rest is Ti; the parameters of the three vacuum consumable arc melting are: The current of the first vacuum consumable arc melting is 5kA, the voltage is 30V, and the vacuum degree is 5Pa; the current of the second vacuum consumable arc melting is 8kA, the voltage is 32V, and the vacuum degree is 0.06Pa; The current of consumable arc melting is 15kA, the voltage is 35V, and the vacuum degree is 0.05Pa;

[0034] Step 2, heat the Ti-6Al-4V titanium...

Embodiment 2

[0050] The preparation method of the present embodiment comprises the following steps:

[0051] Step 1, the 0-grade sponge titanium, Al-V master alloy, Al-V-Fe master alloy, aluminum beans and TiO 2 The powders were mixed and pressed into electrodes, and then subjected to three times of vacuum consumable arc melting to obtain a Ti-6Al-4V titanium alloy ingot with a diameter of 490 mm; the Ti-6Al-4V titanium alloy ingot was composed of the following mass percentages: Al 6.4%, V 4.3%, Fe 0.24%, O0.22%, C≤0.02%, N≤0.01%, H≤0.003%, and the rest is Ti; the parameters of the three vacuum consumable arc melting are: The current of the first vacuum consumable arc melting is 6kA, the voltage is 20V, and the vacuum degree is 3Pa; the current of the second vacuum consumable arc melting is 15kA, the voltage is 25V, and the vacuum degree is 0.03Pa; the third vacuum consumable arc melting The current of consumable arc melting is 20kA, the voltage is 25V, and the vacuum degree is 0.02Pa;

...

Embodiment 3

[0069] The preparation method of the present embodiment comprises the following steps:

[0070] Step 1, the 0-grade sponge titanium, Al-V master alloy, Al-V-Fe master alloy, aluminum beans and TiO2 The powders were mixed and pressed into electrodes, and then subjected to three times of vacuum consumable arc melting to obtain a Ti-6Al-4V titanium alloy ingot with a diameter of 520 mm; the Ti-6Al-4V titanium alloy ingot was composed of the following mass percentages: Al 6.3%, V 4.4%, Fe 0.3%, O0.25%, C≤0.02%, N≤0.01%, H≤0.003%, and the rest is Ti; the parameters of the three vacuum consumable arc melting are: The current of the first vacuum consumable arc melting is 8kA, the voltage is 25V, and the vacuum degree is 3Pa; the current of the second vacuum consumable arc melting is 10kA, the voltage is 30V, and the vacuum degree is 0.05Pa; the third vacuum consumable arc melting The current of consumable arc melting is 18kA, the voltage is 31V, and the vacuum degree is 0.04Pa;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com