Preparation method of TiBw/Ti-6Al-4V composite bar adopting quasi-continuous reticular structure

A technology of ti-6al-4v and composite materials, which is applied in the field of material preparation, can solve problems such as incapable of large-scale production, low production efficiency, and complicated preparation process, and achieve good tissue uniformity, short production cycle, and simplified preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

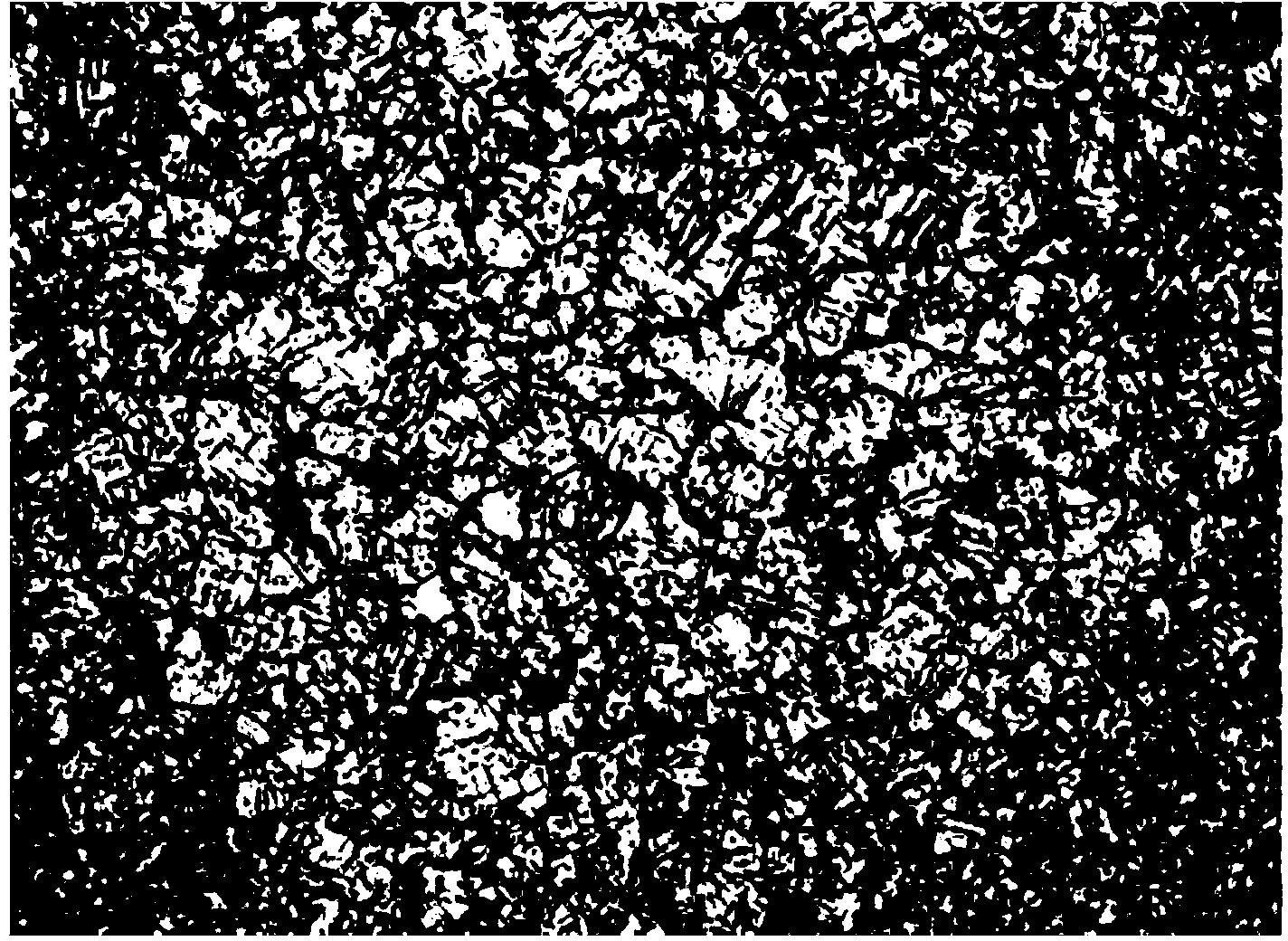

[0023] (1) Low-energy ball mill mixed powder: spherically atomized Ti-6Al-4V powder with a particle size of 130 μm and TiB with a particle size of 2 μm 2 The powder is mixed by ball milling to make the fine TiB 2 The powder is uniformly coated on the surface of the large particle Ti-6Al-4V, thus obtaining TiB 2 / Ti-6Al-4V mixed powder, the process conditions are as follows: the ball milling speed is 120r / min, the ball milling time is 8h, and the mass ratio of ball to material is 5:1.

[0024] (2) Cold press forming: TiB 2 / Ti-6Al-4V mixed powder is placed in a metal sheath, and is formed by cold pressing at a pressure of 900MPa, then vacuum degassed, sealed and welded to obtain an extrusion billet, and the vacuum degree is 10 -3 Pa.

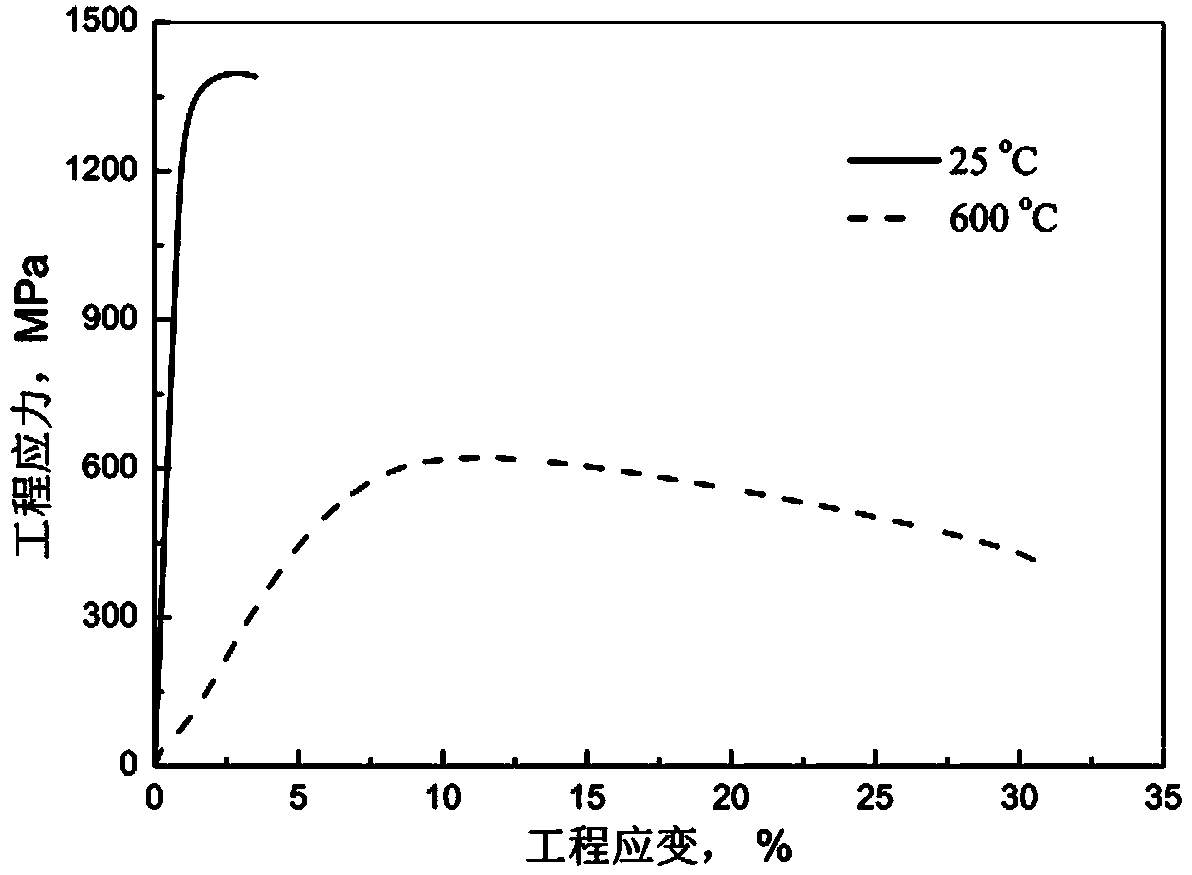

[0025] (3) Pre-sintering and hot extrusion: pre-sinter the extruded billet obtained in step (2) at 1050°C for 1 hour, and in situ react self-generated TiB whiskers (TiBw) to obtain a pre-sintered extruded billet . Then, the pre-sintered extr...

Embodiment 2

[0028] (1) Low-energy ball mill mixed powder: spherically atomized Ti-6Al-4V powder with a particle size of 75 μm and TiB with a particle size of 3 μm 2 The powder is mixed by ball milling to make the fine TiB 2 The powder is uniformly coated on the surface of the large particle Ti-6Al-4V, thus obtaining TiB 2 / Ti-6Al-4V mixed powder, the process conditions are as follows: the ball milling speed is 90r / min, the ball milling time is 10h, and the mass ratio of ball to material is 5:1.

[0029] (2) Cold press forming: TiB 2 / Ti-6Al-4V mixed powder is placed in a metal sheath, and is formed by cold pressing at a pressure of 800MPa, then vacuum degassed, sealed and welded to obtain an extrusion billet, and the vacuum degree is 10 -3 Pa.

[0030] (3) Pre-sintering and hot extrusion: Pre-sinter the extruded billet obtained in step (2) at 1000°C for 2 hours, and in situ react self-generated TiB whiskers (TiBw) to obtain a pre-sintered extruded billet . Then, the pre-sintered extr...

Embodiment 3

[0033] (1) Low-energy ball mill mixed powder: spherically atomized Ti-6Al-4V powder with a particle size of 175 μm and TiB with a particle size of 1 μm 2 The powder is mixed by ball milling to make the fine TiB 2 The powder is uniformly coated on the surface of the large particle Ti-6Al-4V, thus obtaining TiB 2 / Ti-6Al-4V mixed powder, the process conditions are as follows: the ball milling speed is 150r / min, the ball milling time is 6h, and the mass ratio of ball to material is 5:1.

[0034] (2) Cold pressing forming: TiB 2 / Ti-6Al-4V mixed powder is placed in a metal sheath, and it is formed by cold pressing at a pressure of 1000MPa, then vacuum degassed, sealed and welded to obtain an extrusion billet, and the vacuum degree is 10 -3 Pa.

[0035] (3) Pre-sintering and hot extrusion: Pre-sinter the extrusion billet obtained in step (2) at 1200°C for 0.5h, and in situ react self-generated TiB whiskers (TiBw) to obtain pre-sintered extrusion billet. Then, the pre-sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com