Preparation method of spherical titanium-alloy powder for 3D printing

A 3D printing, alloy powder technology, applied in the field of additive manufacturing, can solve the problems of uneven particle size of Ti-6Al-4V alloy powder, unable to meet the requirements of 3D printing, irregular shape, etc. Control, high sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] The specific embodiment one, the preparation method of the 3D printing spherical titanium alloy powder of the present embodiment is carried out according to the following steps:

[0014] 1. According to the composition of the titanium alloy, add Ti powder and the alloy powder of the elements contained in the ball mill, the ball-to-material ratio is (5-20): 1, fill the ball mill tank with high-purity argon, and the ball mill speed is 200 Under the condition of ~280 rpm, ball mill for 30-80 hours to obtain titanium alloy powder;

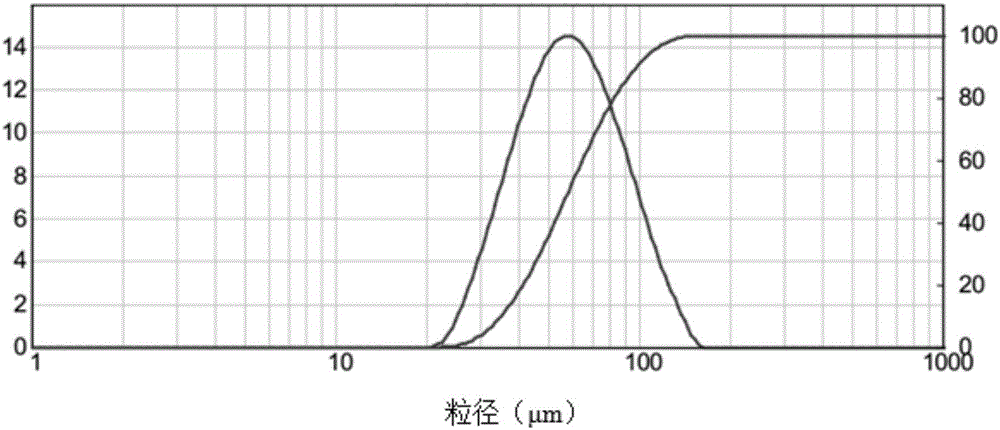

[0015] 2. Screen the titanium alloy powder obtained in step 1, and sieve out the titanium alloy powder of 10 to 70 microns;

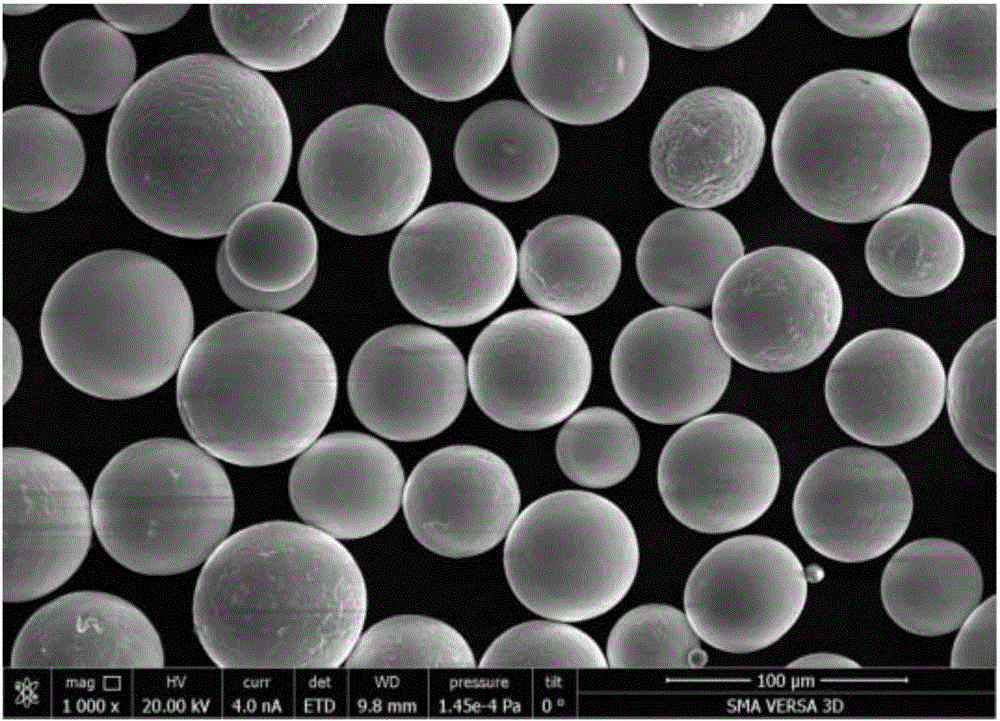

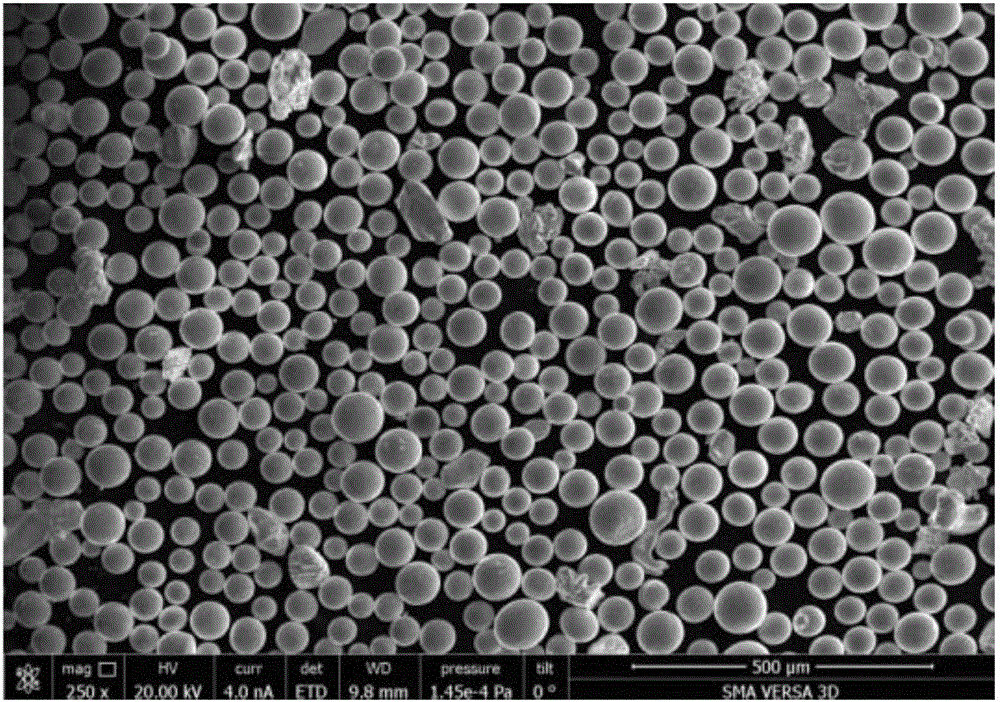

[0016] 3. Transport the titanium alloy powder obtained in step 2 to thermal plasma spheroidization equipment for spheroidization treatment to obtain spherical titanium alloy powder for 3D printing; wherein the powder delivery amount is 5-20g / min, and the plasma input power is 10 ~50kW, system negative pressure is -2000~-...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment is different from Embodiment 1 in that the titanium alloy described in step 1 is TC4 (Ti-6Al-4V), TC21, TB8, TA18 or Ti45Nb. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass percent concentration of high-purity argon in step 1 is greater than 99.999%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com