Low-cost alpha and beta-type titanium alloy

A titanium alloy, low-cost technology, applied in the alloy field, can solve the problems of high price, high processing cost, high production cost, etc., and achieve the effect of reducing production cost, broad engineering application prospects, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The alloy material is prepared according to the nominal composition Ti-3.5Al-2.5Mo-2Zr-2.3Cr (weight percent, %), and the raw materials are Al-55% Mo master alloy, 0-grade sponge titanium, firearm sponge zirconium, pure Al and pure Cr. After mixing the materials, press them into electrodes, and smelt them three times in a vacuum consumable electric arc furnace to obtain alloy ingots. After peeling the ingot, cutting off the riser and tail end, the billet is forged at 1150°C, and the β Under -30℃~80℃, multi-fire pier drawing is carried out to refine the structure, and finally forged into a Ф55mm bar. The typical values of the mechanical properties of the bar after heat treatment at 650°C / 1h / AC are: yield strength ≥ 870MPa, breaking strength ≥ 950Mpa, elongation ≥ 10%.

Embodiment 2

[0011] The alloy material is prepared according to the nominal composition Ti-3Al-2.5Mo-2Zr-2.8Cr (weight percent, %), and the raw materials are Ti-32% Mo master alloy, 0-grade sponge titanium, firearm sponge zirconium, pure Al and Ti-Fe intermediate alloy. After mixing the materials, press them into electrodes, and smelt them three times in a vacuum consumable electric arc furnace to obtain alloy ingots. After peeling the ingot, cutting off the riser and tail end, the billet is forged at 1150°C, and the β -30 ℃ ~ 80 ℃ for multiple times of piercing to refine the structure, and finally rolled into a Ф22mm bar. The typical values of the mechanical properties of the bar after heat treatment at 860°C / 1h / WQ+650°C / 2h / AC are: yield strength ≥ 910MPa, breaking strength ≥ 980Mpa, elongation ≥ 13%.

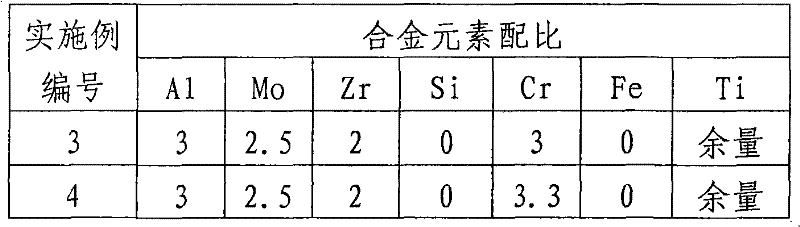

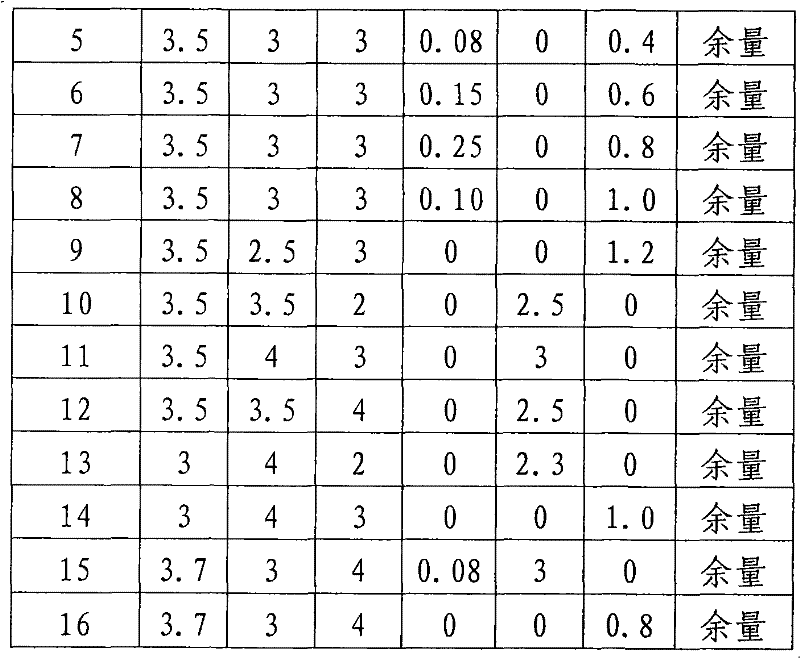

[0012] See Table 1 for the nominal composition of the alloys of Examples 3 to 16.

[0013] Table 1 Alloy Nominal Composition of Embodiment 3~Example 16

[0014] Al: 3%~3.7%; Mo: 2.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com