Biological living being in medical use for Embeded to human body, and preparation method

An implant and biological technology, used in prostheses, medical science, coatings, etc., can solve the problems of poor bonding strength between the coating and the titanium alloy substrate, large internal stress in the coating, and peeling off of the coating, and achieve no toxic side effects. , low cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 According to chemical composition: (Wt%)

[0029] SiO2 40.9

[0030] CaO 39.2

[0031] P2O5 13.0

[0032] MgO6.4

[0033] F 0.2

[0034] After the prepared powder is stirred evenly, it is melted at a high temperature of 1410°C, then quickly poured into water to quench, and dried to make a spray powder. Using the plasma jet spraying technology, the bioglass powder was deposited on the cleaned and sandblasted medical titanium alloy-based (Ti-6Al-4V) artificial tooth root implant (the implant diameter was 4 mm), and the spraying process parameters were: :

[0035] Plasma spray primary gas (N2) flow rate of 40 Nl / min

[0036] Plasma spray gas (H2) flow rate of 6 Nl / min

[0037] Spray distance 100mm

[0038] Powder carrier gas (N2) flow at 3 Nl / min

[0039] Powder feeding rate 20g

[0040] Spraying current 430A

[0041] Spray voltage 85V

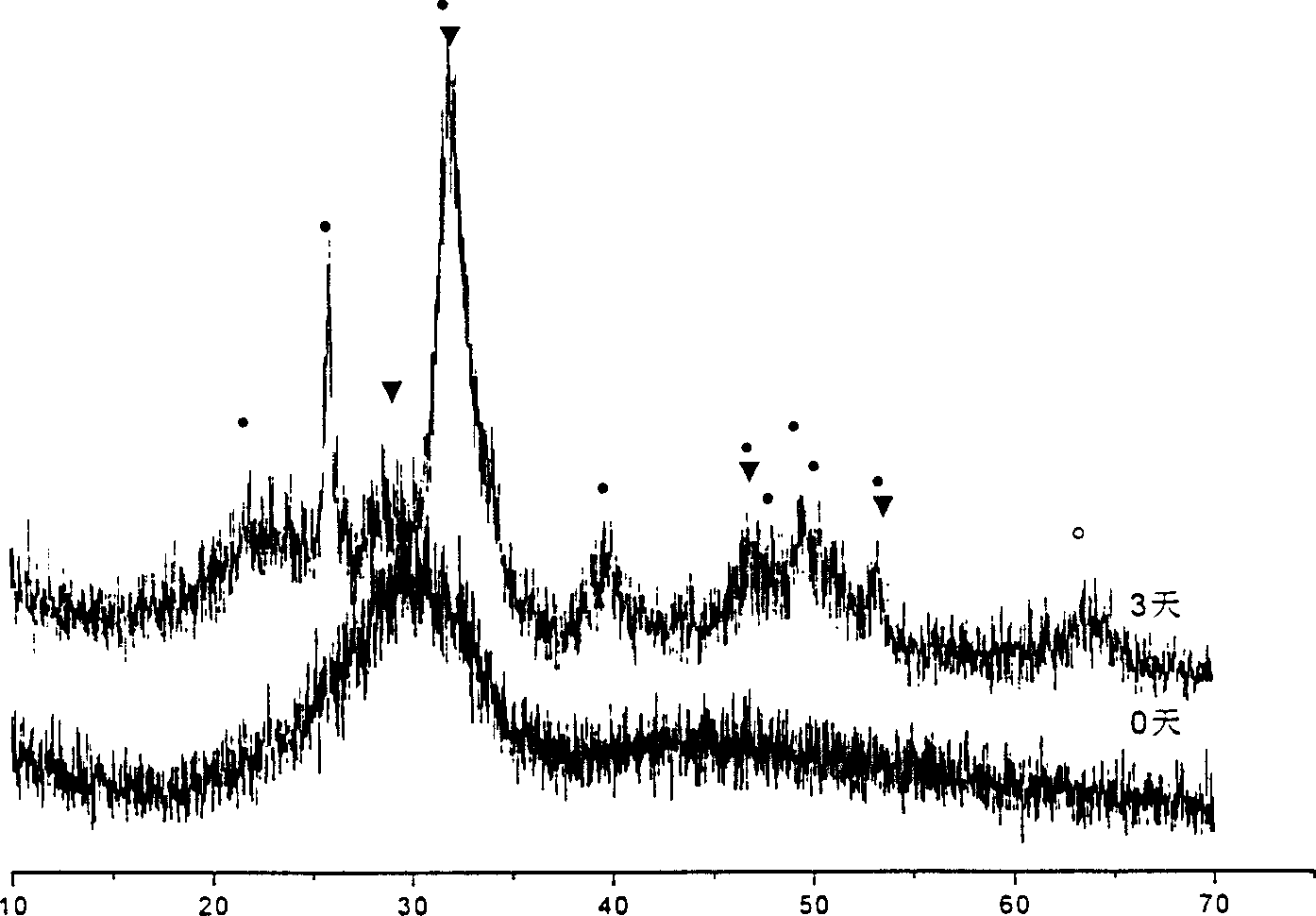

[0042] The glass-coated artificial tooth root implant is composed of a glass phase, w...

Embodiment 2

[0043] Embodiment 2 According to chemical composition: (Wt%)

[0044] SiO2 41.0

[0045] CaO 40.0

[0046] P2O5 13.0

[0047] MgO 6.0

[0048] After the prepared powder is stirred evenly, it is melted at a high temperature of 1410°C, then quickly poured into water to quench, and dried to make a spray powder. Using plasma jet spraying technology, the biological glass powder was deposited on the cleaned and sandblasted medical titanium alloy-based (Ti-6Al-4V) artificial joint implant. The spraying process parameters are:

[0049] Plasma spray primary gas (N2) flow rate of 45 Nl / min

[0050] Plasma spray gas (H2) flow rate of 6 Nl / min

[0051]Spray distance 110mm

[0052] Powder carrier gas (N2) flow at 3 Nl / min

[0053] Powder feeding rate 20g

[0054] Spraying current 450A

[0055] Spray voltage 85V

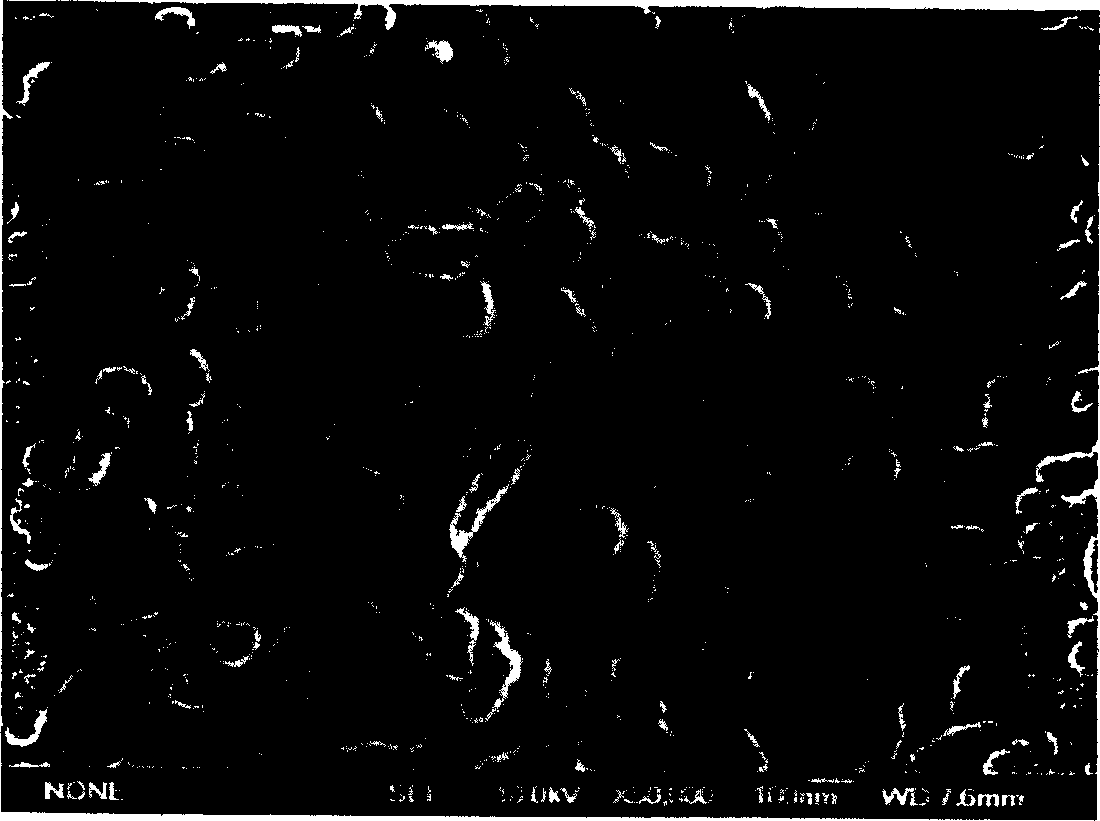

[0056] The glass-coated artificial joint implant has a coating thickness of 500 μm, is well bonded to the titanium alloy base, has a shear stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com