Beta type Ti Nb Zr alloy with low modulus of elasticity, preparation method and application

A low elastic modulus, ti-nb-zr technology, applied in the field of medical materials, can solve the problems of increased alloy cost, increased difficulty of smelting, and alloys that are not easy to organize uniformly, and achieve the effect of controlling alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

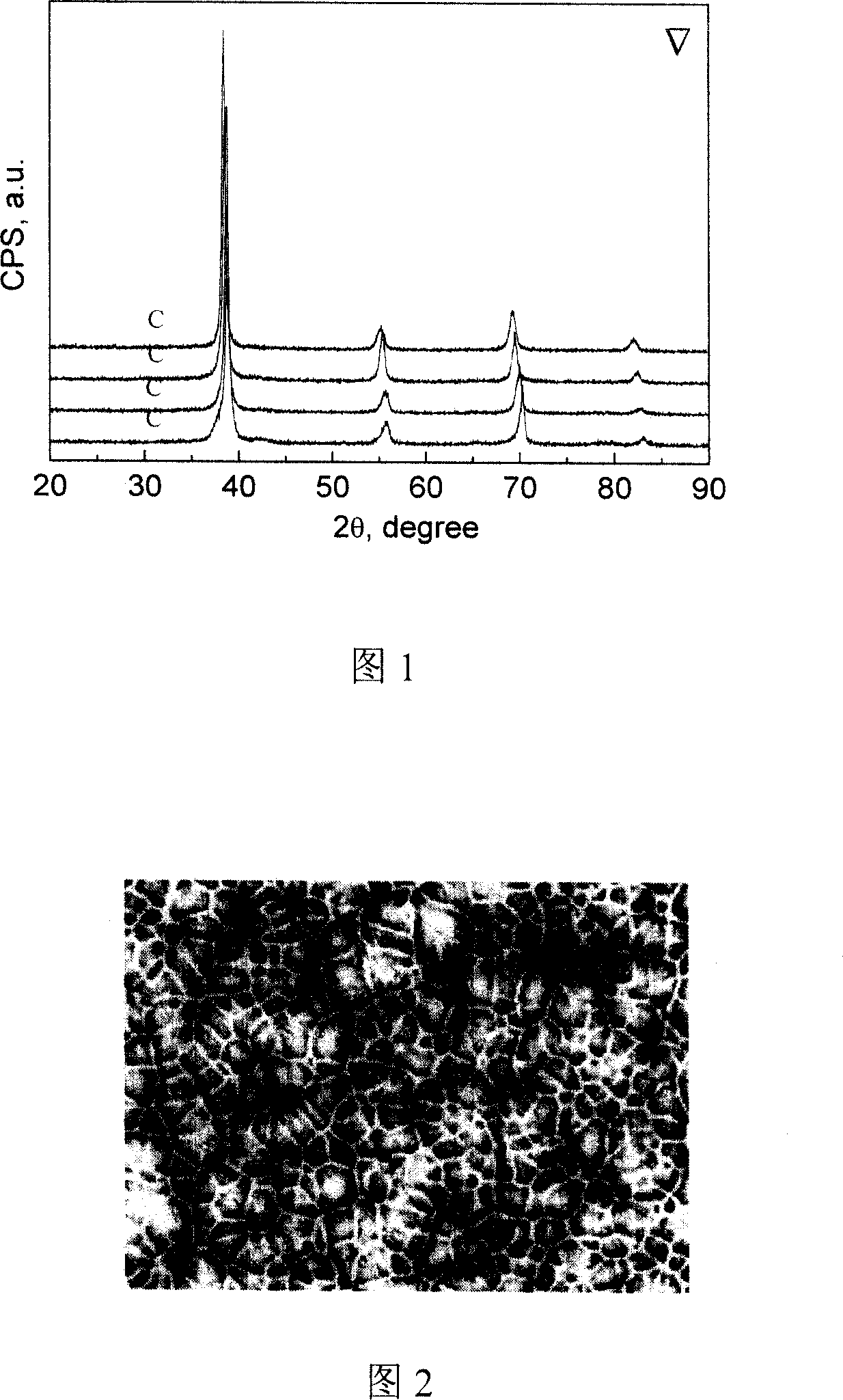

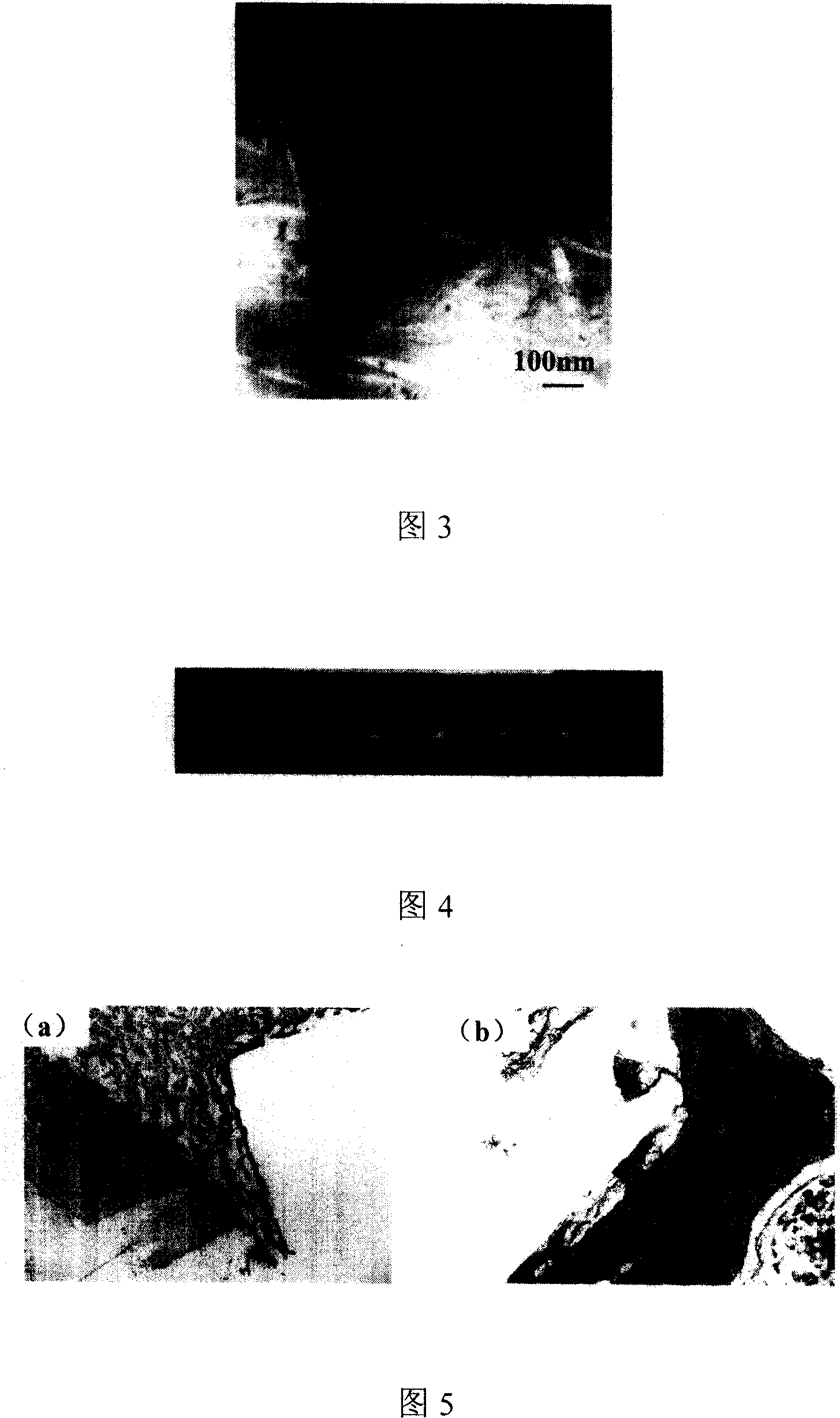

[0021] Sponge titanium, sponge zirconium, and niobium-titanium master alloy are used as raw materials, and the weight percentage of each component is Nb35%, Ti65%. After being mixed and pressed to form an electrode, it is smelted into an ingot twice in a vacuum consumable electric arc furnace with a smelting voltage of 30 volts and a smelting current of 1500 amperes. Then directly aged at 500° C. for 6 hours, and water-cooled to prepare the alloy of the present invention. The measured tensile properties at room temperature are:

[0022] σ b =847MPa, σ 0.2 =751MPa, E=60GPa, δ=5.4%

Embodiment 2

[0024] The composition of the alloy is Nb35% and Zr5% by weight of each component. The balance is titanium. Aging treatment at 500° C. for 4 hours, water cooling, and other conditions are the same as in Example 1 to prepare the alloy of the present invention. The measured tensile properties at room temperature are:

[0025] σ b=875MPa,σ 0.2 =760MPa, E=59GPa, δ=8.1%

Embodiment 3

[0027] The alloy composition is that the weight percentage of each component is Nb35%, Zr10%. The balance is titanium. Aging treatment at 500° C. for 4 hours, water cooling, and other conditions are the same as those in Example 1, to prepare the alloy of the present invention. The measured room temperature tensile properties are:

[0028] σ b =706MPa,σ 0.2 =639MPa, E=51GPa, δ=20.1%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Σ0.2 | aaaaa | aaaaa |

| Σ0.2 | aaaaa | aaaaa |

| Σ0.2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com