Alpha+beta type titanium alloy wire for 960MPa intensity level electron beam fused deposition rapid-forming members

A technology of fuse accumulation and forming components, applied in the field of titanium-based alloys, can solve the problems of coarse microstructure and large plasticity restrictions of material strengthening materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1, the alloy composition is (wt%): Al: 7.2%; V: 4.0%; Fe: 0.50%; O: 0.12%; Si: 0.05%; C: 0.08%; impurity elements.

Embodiment 2

[0043] Example 2, the alloy composition is (wt%): Al: 6.2%; V: 5.5%; Fe: 0.20%; O: 0.22%; Si: 0.10%; C: 0.03%; impurity elements.

Embodiment 3

[0044] Example 3, the alloy composition is (wt%): Al: 6.8%; V: 5.0%; Fe: 0.10%; O: 0.17%; Si: 0.12%; C: 0.04%; impurity elements.

[0045] After the present invention has verified that the overall performance of the above-mentioned alloy reaches the expected goal, a large number of alloy composition optimization tests have been carried out, and its preferred composition will be further described in detail through the following examples, but the present invention is not limited to the following Several preferred embodiments.

[0046] The alloy composition of table 1 preferred embodiment

[0047]

[0048] Table 2 Test material stacking process

[0049] Accelerating voltage

focus current

Beam

Movement speed

Wire feeding method

60KV

820mA

135mA

15mm / s

double wire

35mm / s

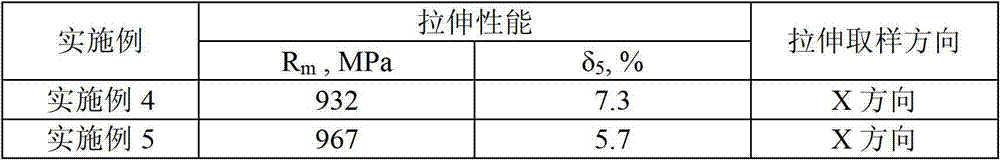

[0050] Table 3 is the performance data of the electron beam rapid prototyping material corresponding to the embodiment in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com