Metastable beta titanium alloy with low elastic modulus and preparing method thereof

A low elastic modulus, β titanium alloy technology, applied in the field of low elastic modulus metastable β titanium alloy and its preparation, titanium alloy materials and preparation, can solve the problems of simplification of use, containing toxic elements, etc., to achieve optimal performance, Effect of strength and elastic modulus optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Ingredients: According to the composition of Ti-19wt%Nb-1wt%Mo-4wt%Zr-7wt%Sn-0.2wt%O alloy, prepare zero-grade sponge Ti and TiO respectively 2 , Ti-52Nb master alloy, Ti-32Mo master alloy, and Ti-80Sn master alloy are mixed evenly; the purity of the sponge Zr is ≥99.9%.

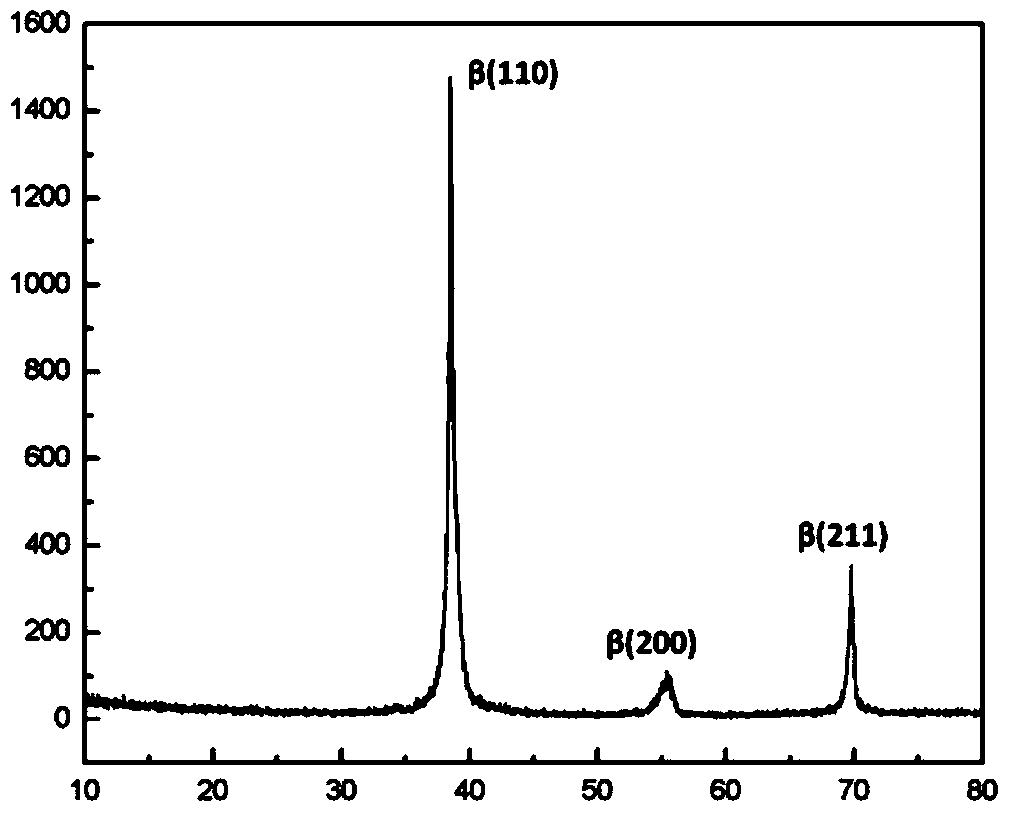

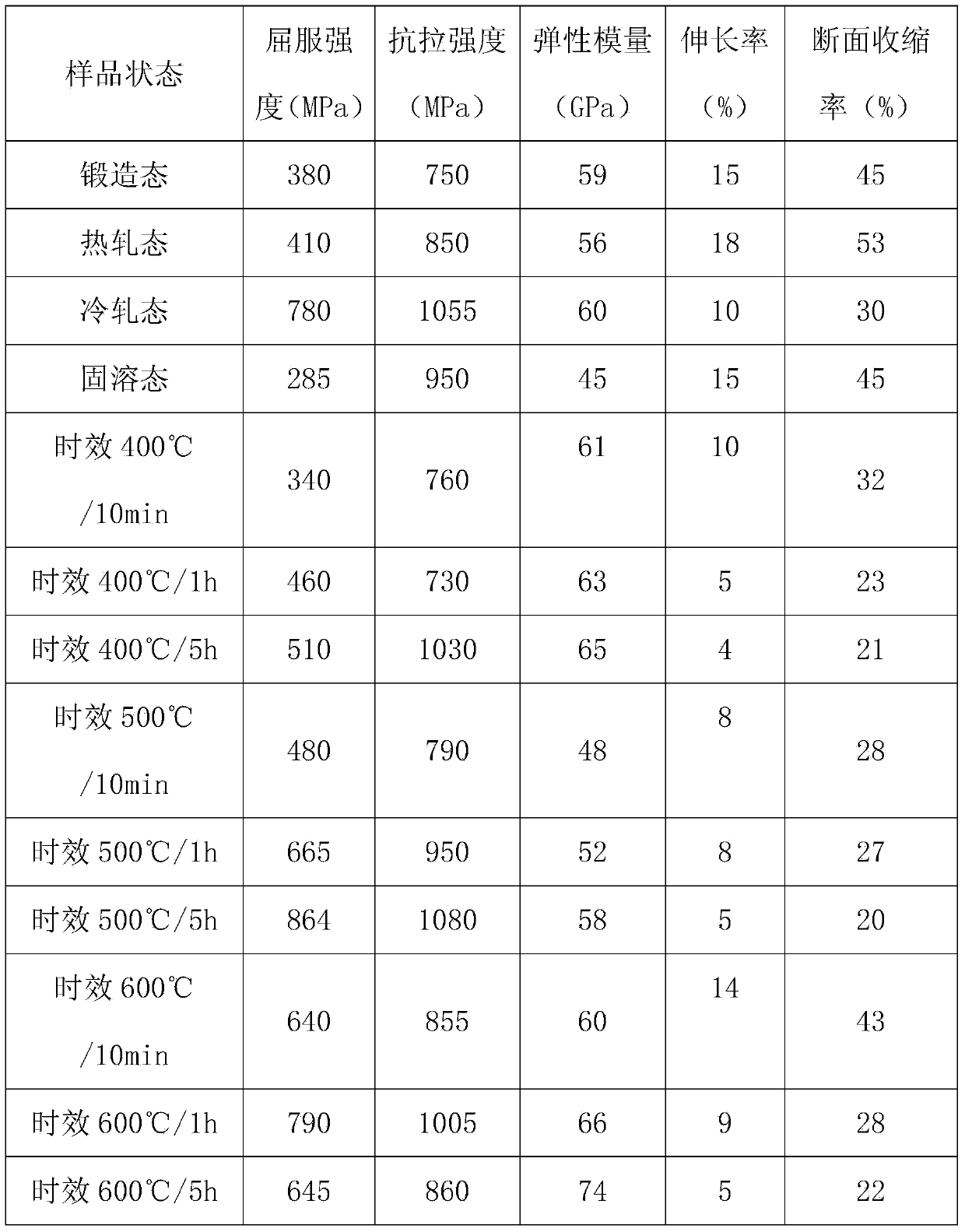

[0039] 2. Smelting: Press the prepared raw materials into electrodes on a hydraulic press, and smelt three times in a vacuum consumable electric arc furnace. During smelting, control the vacuum in the furnace to ≤10-2Pa, and the furnace temperature is 1600°C. The smelting time is 30 minutes; the alloy ingot is obtained. After sufficient cooling, samples were taken for differential thermal analysis and metallographic analysis, and the β→α phase transition temperature of the alloy was measured, and chemical methods were used to analyze whether there was composition segregation in the ingot. Then perform homogenization annealing (with Ar gas protection) in a vacuum furnace, the homogenization tempera...

Embodiment 2

[0049] 1. Ingredients: According to the composition of Ti-19wt%Nb-1.5wt%Mo-4wt%Zr-8wt%Sn-0.3wt%O alloy, prepare zero-grade sponge Ti and TiO respectively 2 , Ti-52Nb master alloy, Ti-32Mo master alloy, and Ti-80Sn master alloy are mixed evenly; the purity of the sponge Zr is ≥99.9%.

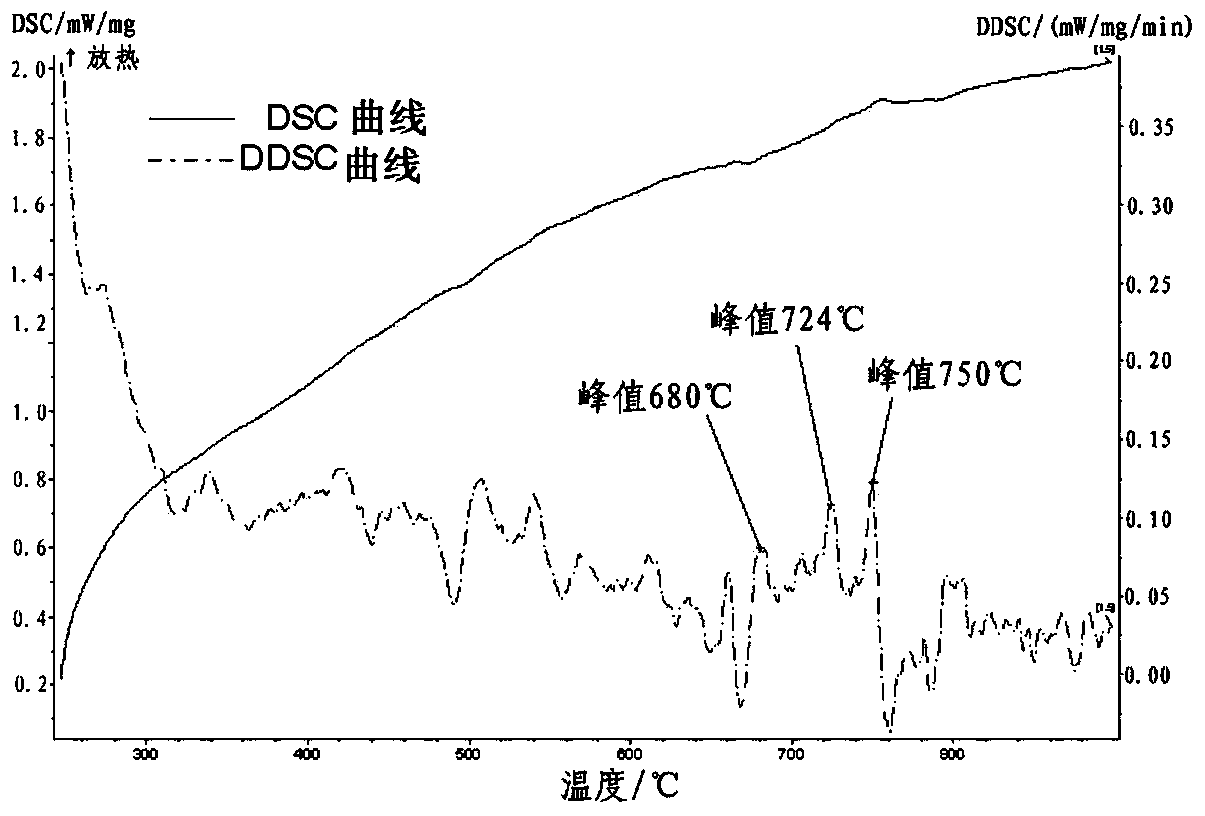

[0050] 2. Smelting: Press the prepared raw materials into electrodes on a hydraulic press, and carry out 3 times of smelting in a vacuum consumable electric arc furnace. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the temperature in the furnace is 1700°C, and the melting time is 45 minutes each time; an alloy ingot is obtained. After sufficient cooling, samples were taken for differential thermal analysis (see figure 2 ) and metallographic analysis, from figure 2 It can be seen that the β→α phase transition temperature of the alloy is about 750 °C, and the chemical method is used to analyze whether there is composition segregation in the ingot. Then perform homoge...

Embodiment 3

[0060] 1. Ingredients: According to the composition of Ti-18wt%Nb-1.5wt%Mo-4wt%Zr-7wt%Sn-0.2wt%O alloy, prepare zero-grade sponge Ti and TiO respectively 2 , Ti-52Nb master alloy, Ti-32Mo master alloy, and Ti-80Sn master alloy are mixed evenly; the purity of the sponge Zr is ≥99.9%.

[0061] 2. Smelting: Press the prepared raw materials into electrodes on a hydraulic press, and carry out smelting twice in a vacuum consumable electric arc furnace. During smelting, control the vacuum degree in the furnace to ≤10 -2 Pa, the temperature in the furnace is 1650°C, and the melting time is 60 minutes each time; an alloy ingot is obtained. After sufficient cooling, samples were taken for differential thermal analysis and metallographic analysis, and the β→α phase transition temperature of the alloy was measured, and chemical methods were used to analyze whether there was composition segregation in the ingot. Then perform homogenization annealing (with Ar gas protection) in a vacuum fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com