Preparation method of three dimensional nanometer porous titanium and alloy thereof

A three-dimensional nano- and nano-porous technology, applied in the field of nano-metal materials, can solve the problems of explosion, high safety requirements, complex process, etc., and achieve the effects of high safety, simple and easy process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

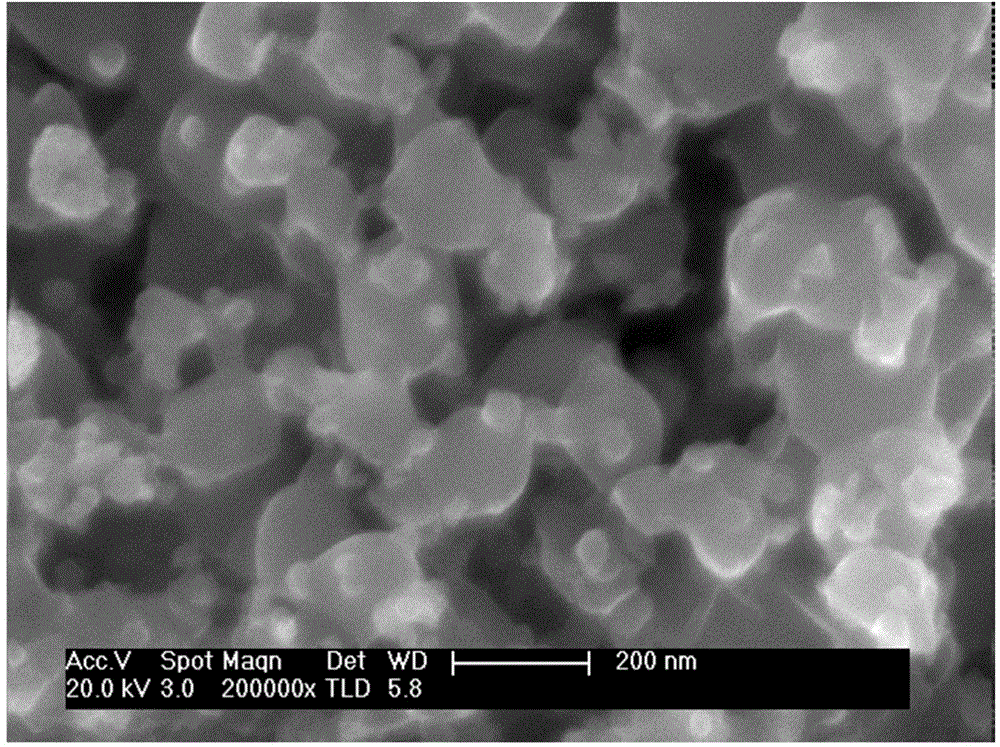

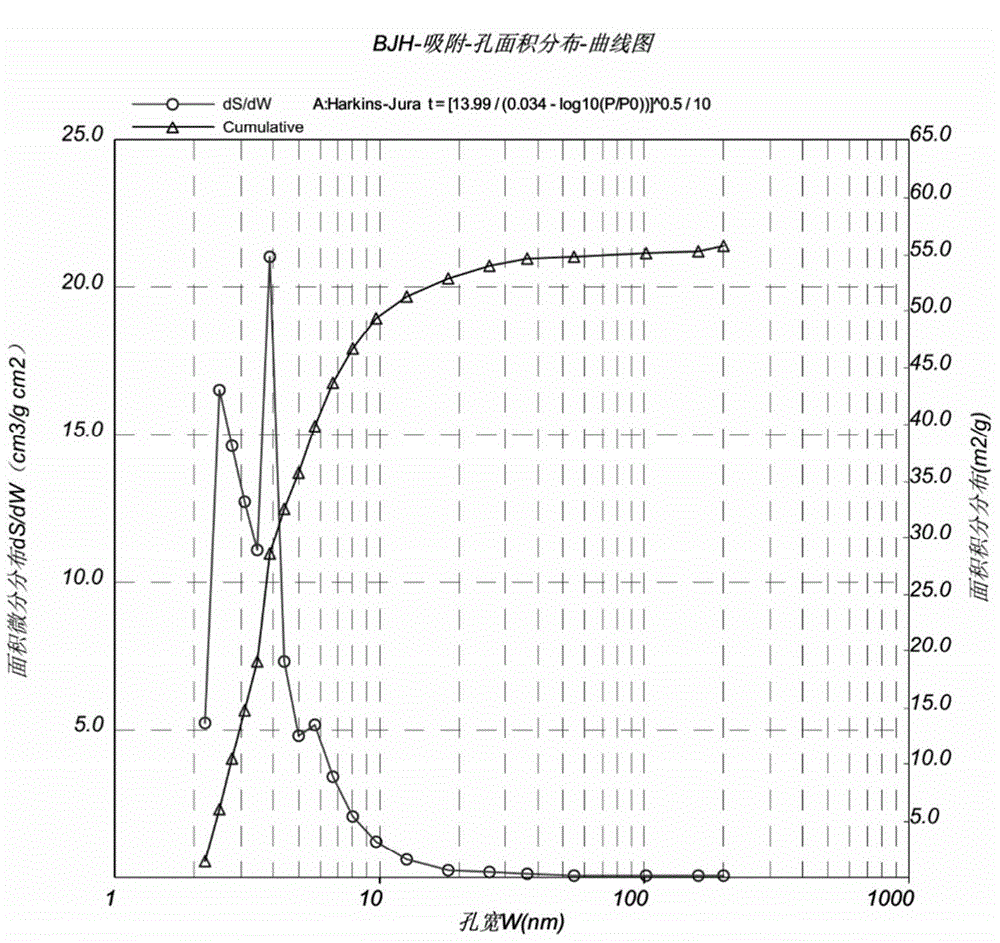

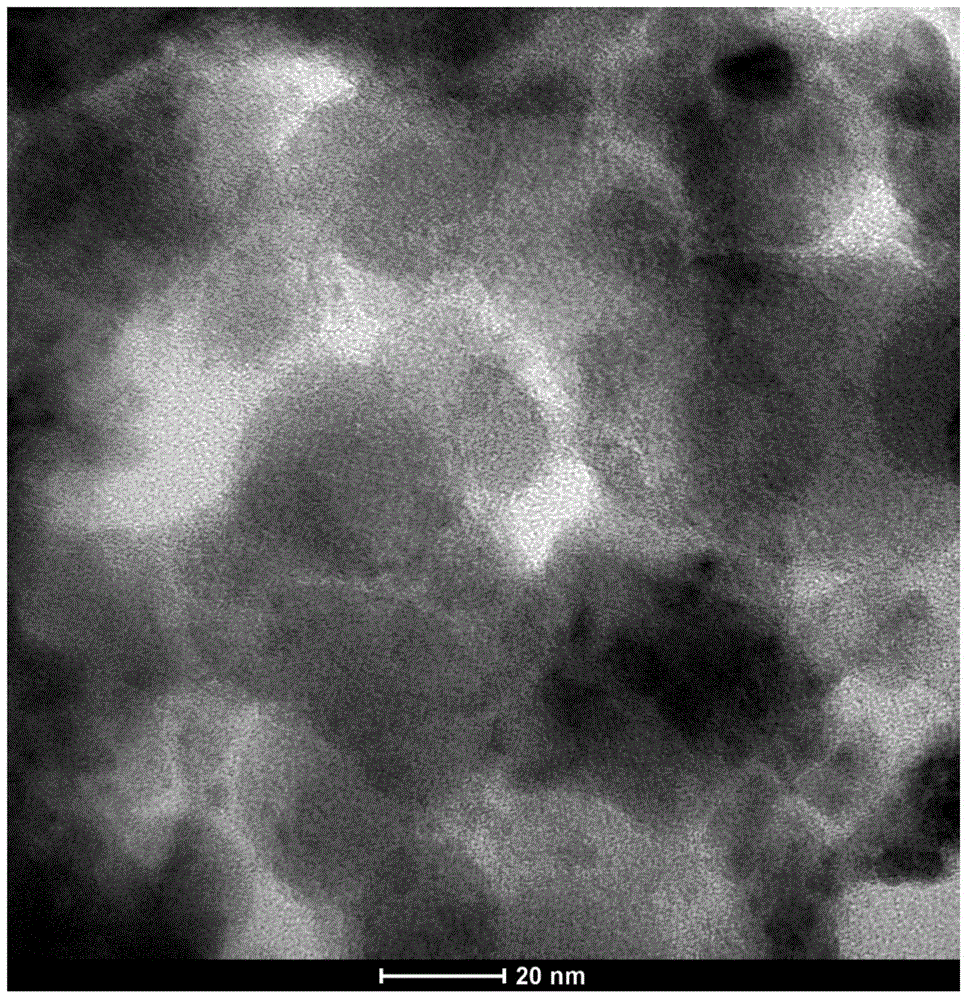

[0025] The preparation of nanoporous α-titanium porous metal material, the specific process is as follows:

[0026] ①According to the atomic number ratio of titanium to copper is 30:70, weigh the titanium powder and copper powder, put them into a ball mill tank for ball milling, the ball material ratio is 8:1, the ball milling medium is n-hexane, the ball milling time is 20 hours, fully ball milling, Make it evenly mixed, and the powder becomes finer; take the titanium-copper powder that has been ball-milled, and sinter it with spark plasma sintering technology to prepare the titanium-copper master alloy. The heating rate is 50°C / min, and the pressure is 80MPa. Dense master alloy block, the sintering temperature is 750°C, and the holding time is 20min;

[0027] ② Wire cut the prepared titanium-copper master alloy block into small slices with a thickness of 0.2mm, clean the oil stains on the surface with deionized water and alcohol, and then dry them in a vacuum drying oven for...

Embodiment 2

[0033] The preparation of nanoporous α-titanium porous metal material, the specific process is as follows:

[0034] ① According to the atomic number ratio of titanium 40% nickel 60%, weigh titanium and nickel raw materials. The raw materials are put into a special melting furnace for titanium alloy and smelted at 1700°C for 5 hours to make the structure homogeneous and fully solid-soluted, and the temperature is lowered to obtain a titanium-nickel master alloy.

[0035] ② Cut the prepared titanium-nickel master alloy block into small slices with a thickness of 0.02mm, wash off the oil stains on the surface with deionized water and alcohol, and then dry them in a vacuum drying oven for 4 hours at a drying temperature of 50°C. spare;

[0036] ③ Coat the above-mentioned small flakes with magnesium-calcium powder with a particle size of 1.0 microns, and dealloy them in argon-protected hot-press sintering at a sintering temperature of 600°C; holding time for 10 minutes;

[0037] ...

Embodiment 3

[0039] The preparation of nanoporous α-titanium porous metal material, the specific process is as follows:

[0040] ① According to the atomic number ratio of 20% titanium to 80% silicon, weigh titanium and silicon raw materials. The raw materials are put into a special melting furnace for titanium alloy and smelted at 1720°C for 6 hours to homogenize the structure and fully solidify. The temperature is lowered and cooled to obtain a titanium-silicon master alloy.

[0041] ② Wire-cut the prepared titanium-silicon master alloy block into small slices with a thickness of 0.1mm, wash off the oil stains on the surface with deionized water and alcohol, and then dry them in a vacuum drying oven for 6 hours at a drying temperature of 80°C ,spare;

[0042] ③ Coat the above-mentioned small flakes with magnesium-lithium powder with a particle size of 10 nanometers, and dealloy them in vacuum-protected discharge plasma sintering. The sintering temperature is 500 ° C; the holding time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com