Cast toughened Ti3Al intermetallic compound as well as preparation method and application thereof

A technology of intermetallic compounds and manufacturing methods, which is applied in the field of manufacturing new cast tough Ti3Al intermetallic compounds, can solve the problems of not meeting the weight reduction requirements of high thrust-to-weight ratio engines, high density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

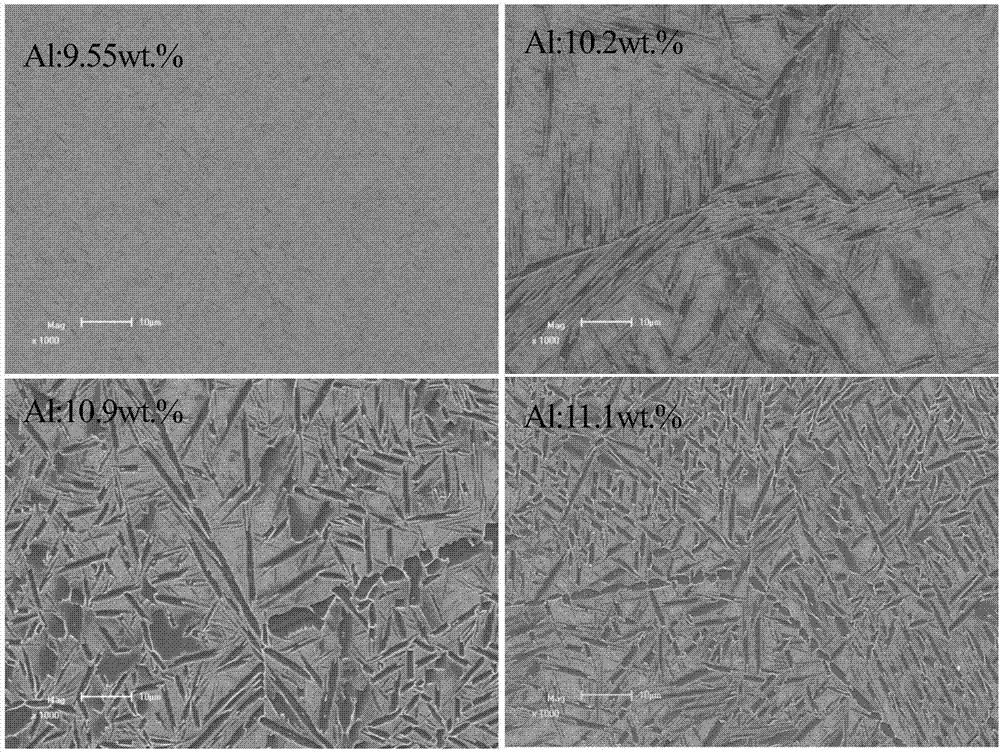

[0045] Example 1 # ~4 #

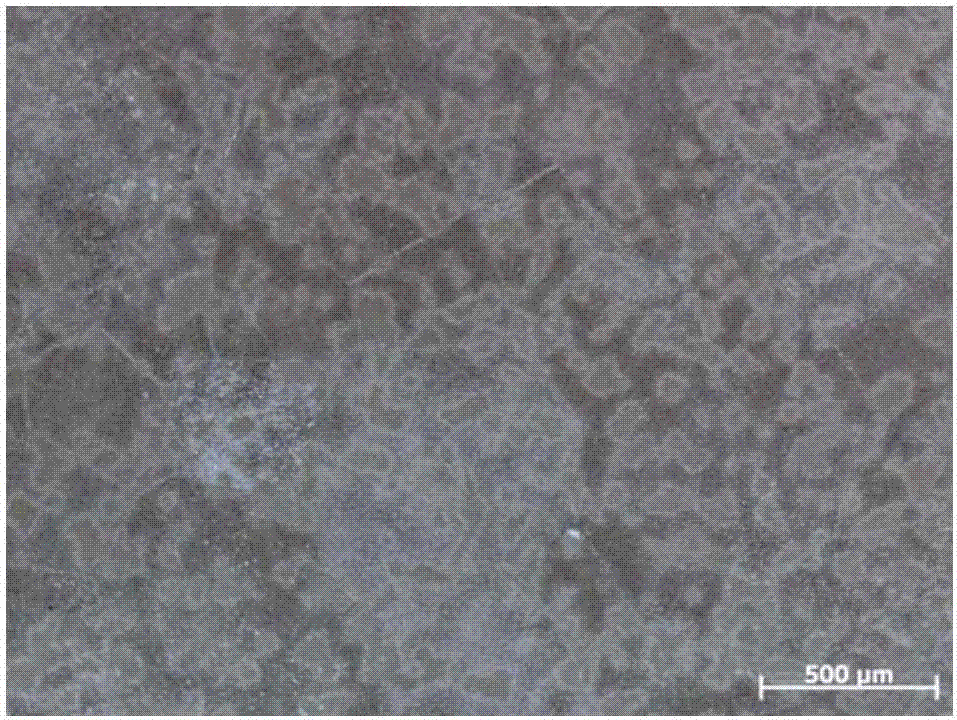

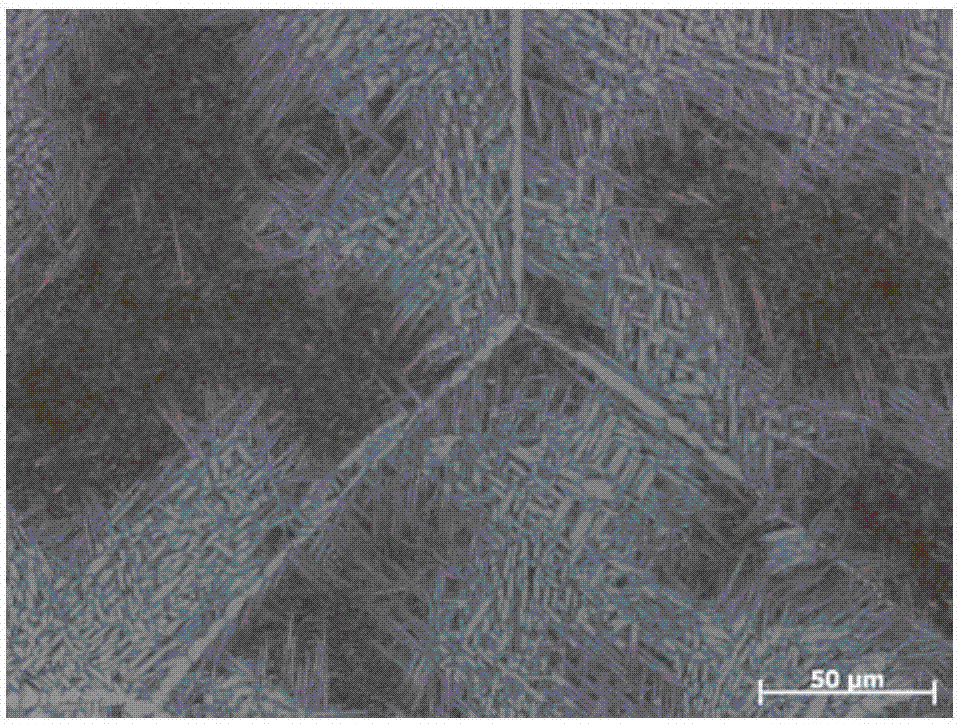

[0046] Example 1 # ~4 # The ingredients are listed in Table 2. The smelting process of the ingot is a vacuum consumable smelting, a vacuum shell smelting, a vacuum suspension smelting, and then casting into a φ70mm casting rod in a steel mold. After the cast rod is solution heat treated, the sample is processed and the mechanical properties are tested. The heat treatment system adopted is: solid solution temperature 1020°C, solid solution time 1h, cooling rate 0.5°C / s. The microstructure of the sample under the scanning electron microscope can be seen image 3 , and the tensile results at room temperature are shown in Table 3.

[0047] Table 2: Example 1 # ~4 # alloy composition

[0048] Example

Alloy Nominal Composition (at.%)

Measured Al content (wt.%)

Measured O content (wt.%)

1 #

Ti-18.5Al-15Nb-1Mo

9.55

0.068

2 #

Ti-19.5Al-15Nb-1Mo

10.2

0.069

3 #

Ti-20.5Al-15Nb-1Mo

10....

Embodiment 5

[0053] Example 5 # ~6 #

[0054] Example 5 # The nominal composition is Ti-22Al-15Nb-0.5Mo (at.%), Example 6 # The nominal composition of Ti-22Al-15Nb-1Mo (at.%). The smelting process of the ingot is two vacuum consumable smelting, one vacuum suspension smelting, and then casting into a φ70mm casting rod in a steel mold. The cast rod is first processed by hot isostatic pressing (HIP): the hot isostatic pressing pressure is 130MPa, the temperature is 1020±20°C, the time is 3 hours, and it is cooled to below 300°C with the furnace. After hot isostatic pressing, the samples were subjected to different solution heat treatments and the mechanical properties were tested. The tests are shown in Tables 4 and 5.

[0055] Table 4: Example 5 # ~6 # Room temperature tensile properties

[0056]

[0057] Table 5: Example 5 # ~6 # Tensile properties at 600°C

[0058]

[0059] From the tensile properties in Tables 4 and 5, it can be seen that when the Mo content changes from ...

Embodiment 7

[0060] Example 7 # ~10 #

[0061] Example 7 # ~10 # The measured components are listed in Table 6. In the alloy ingredients, the gradient increasing O element is based on TiO 2 The preparation process of other alloys remains unchanged. The smelting process of the ingot is a vacuum consumable smelting, a vacuum shell smelting, a vacuum suspension smelting, and then casting into a φ70mm casting rod in a steel mold. After the cast rod is solution heat treated, the sample is processed and the mechanical properties are tested. The heat treatment system adopted is: solid solution temperature 1020°C, solid solution time 1h, cooling rate 0.5°C / s. The tensile results at room temperature are shown in Table 7.

[0062] Table 6: Example 7 # ~10 # alloy composition

[0063] Example

[0064] Table 7: Example 7 # ~10 # Room temperature tensile properties

[0065] Example

[0066] It can be seen from Table 7 that when the O content is between 0.068 and 0.15wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com