Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Improve room temperature plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

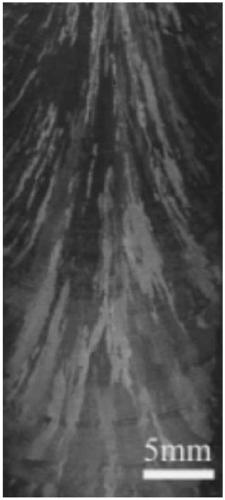

Method for preparing zirconium-base amorphous alloy with plasticity at room temperature

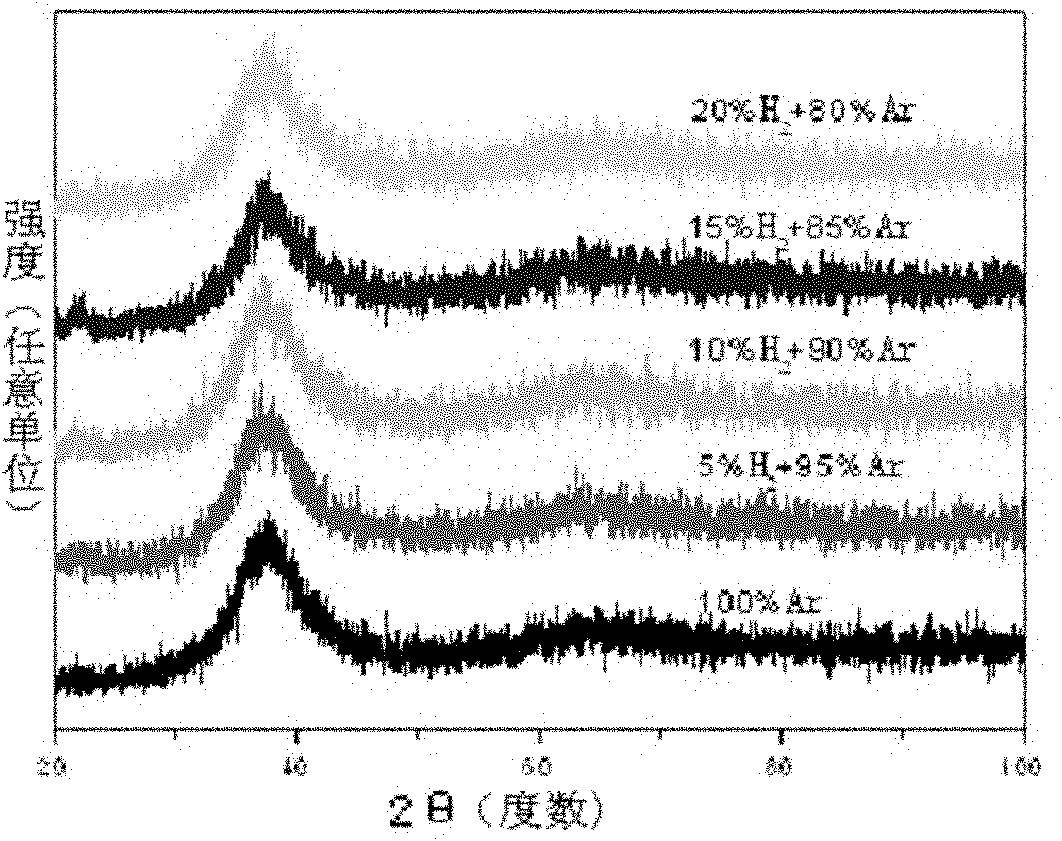

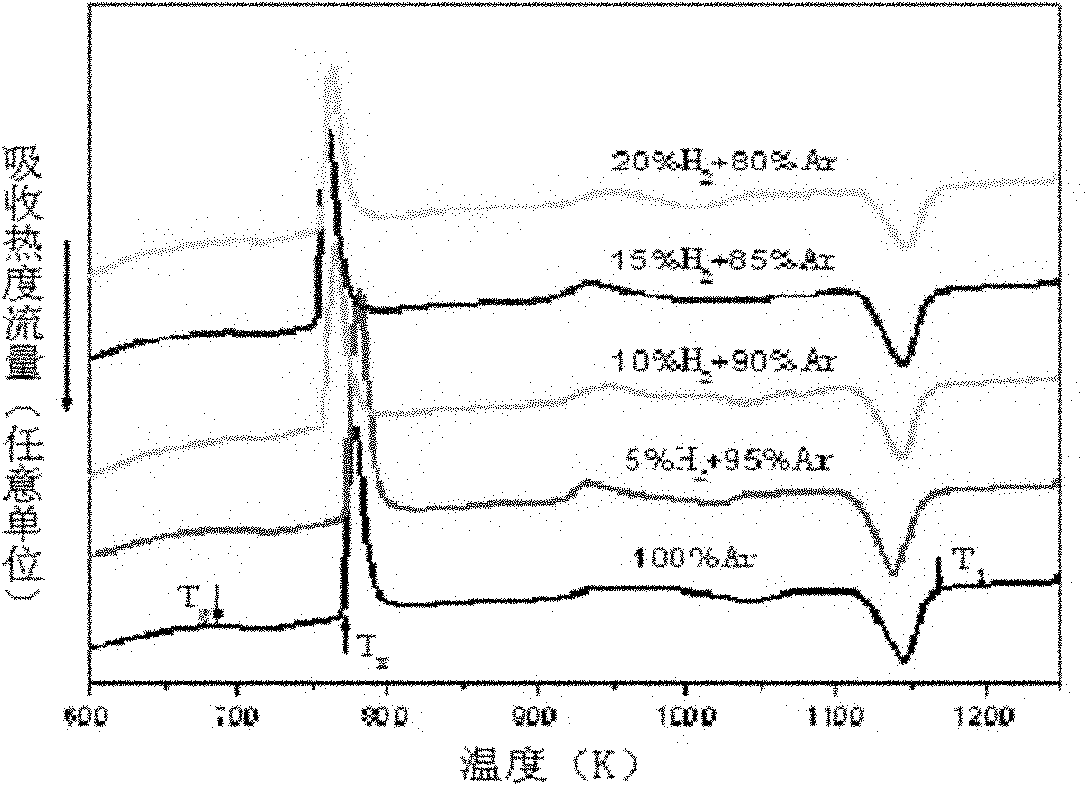

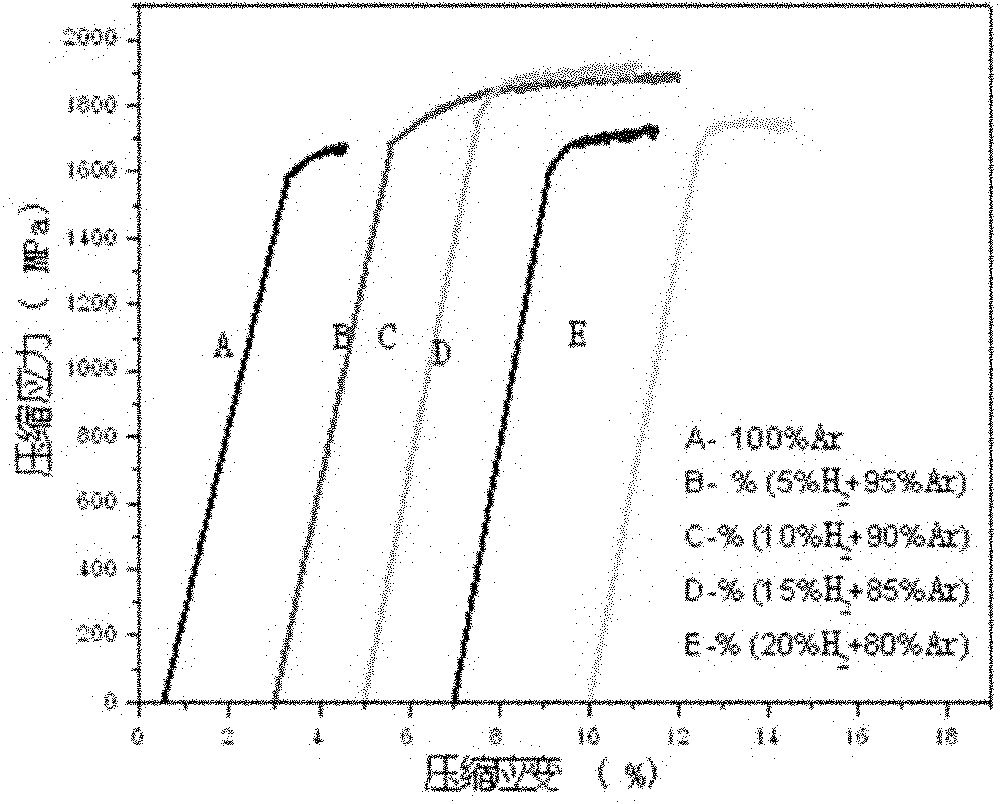

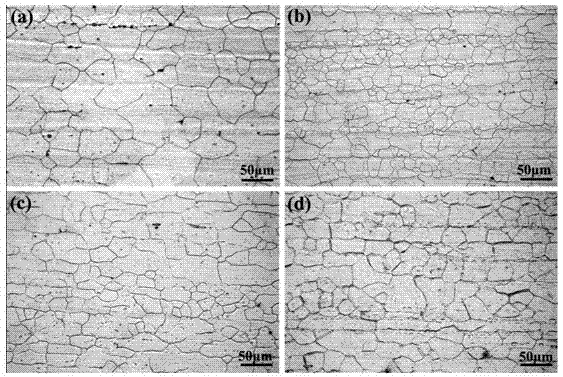

The invention relates to a method for preparing zirconium-base amorphous alloy with plasticity at room temperature, and relates to a method for preparing amorphous alloy, which solves the problem of poor plasticity at room temperature of the amorphous alloy in the prior art. The method comprises the following steps of: filling a zirconium-base amorphous alloy raw material into a water-cooling copper crucible of an arc furnace, vacuumizing a smelting chamber, introducing hydrogen and argon into the smelting chamber according to a certain ratio, smelting the raw material of the zirconium-base amorphous alloy in a mixed atmosphere, and preparing by a copper mold suction casting method to obtain the zirconium-base amorphous alloy with the plasticity at room temperature. The zirconium-base amorphous alloy has excellent plasticity at room temperature, and the plasticity is improved by 7 times. The method can be widely applied to the plastification of massive amorphous alloy, so that the amorphous alloy can be applied in fields of aerospace, weapon industry, precision machines, information technology and the like.

Owner:安徽哈特三维科技有限公司

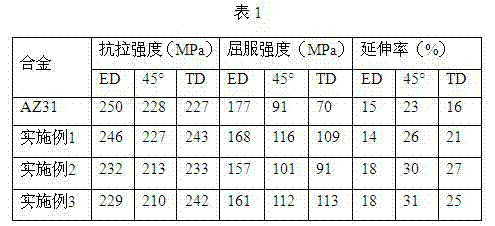

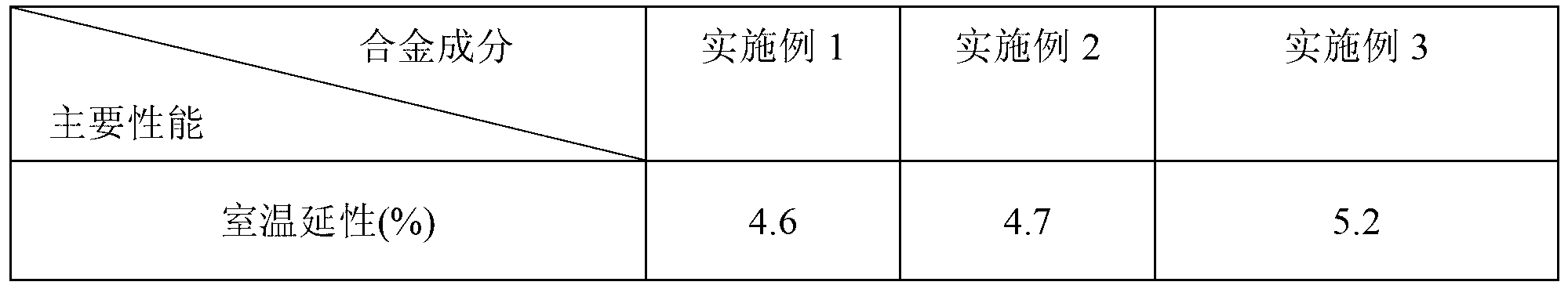

High-room-temperature ductility magnesium alloy material and preparation method thereof

The invention discloses a high-room-temperature ductility magnesium alloy material and a preparation method thereof. The magnesium alloy material comprises, by weight, 1.0%-5.0% of Li, 2.5%-3.5% of Al, 0.7%-1.3% of Zn, 0.2%-0.5% of Mn, no more than 0.3% of impurities, and the balance Mg. The preparation method comprises that under the condition of vacuumizing and inert gas leading-in, pure lithium and an AZ31 magnesium alloy, which are in a formula ratio are heated to 720 DEG C, when the alloy is melted completely, the alloy is subjected to heat preservation and storage at the temperature of 700 DEG C for 15min, and then the melted alloy liquid is poured into a mold. According to the method, Li elements are added into the AZ31 magnesium alloy, the obtained magnesium alloy material has high room-temperature ductility, and the anisotropy degree is low. Besides, the added alloy elements are low in cost relatively and simple in preparation process.

Owner:福建镁孚科技有限公司 +1

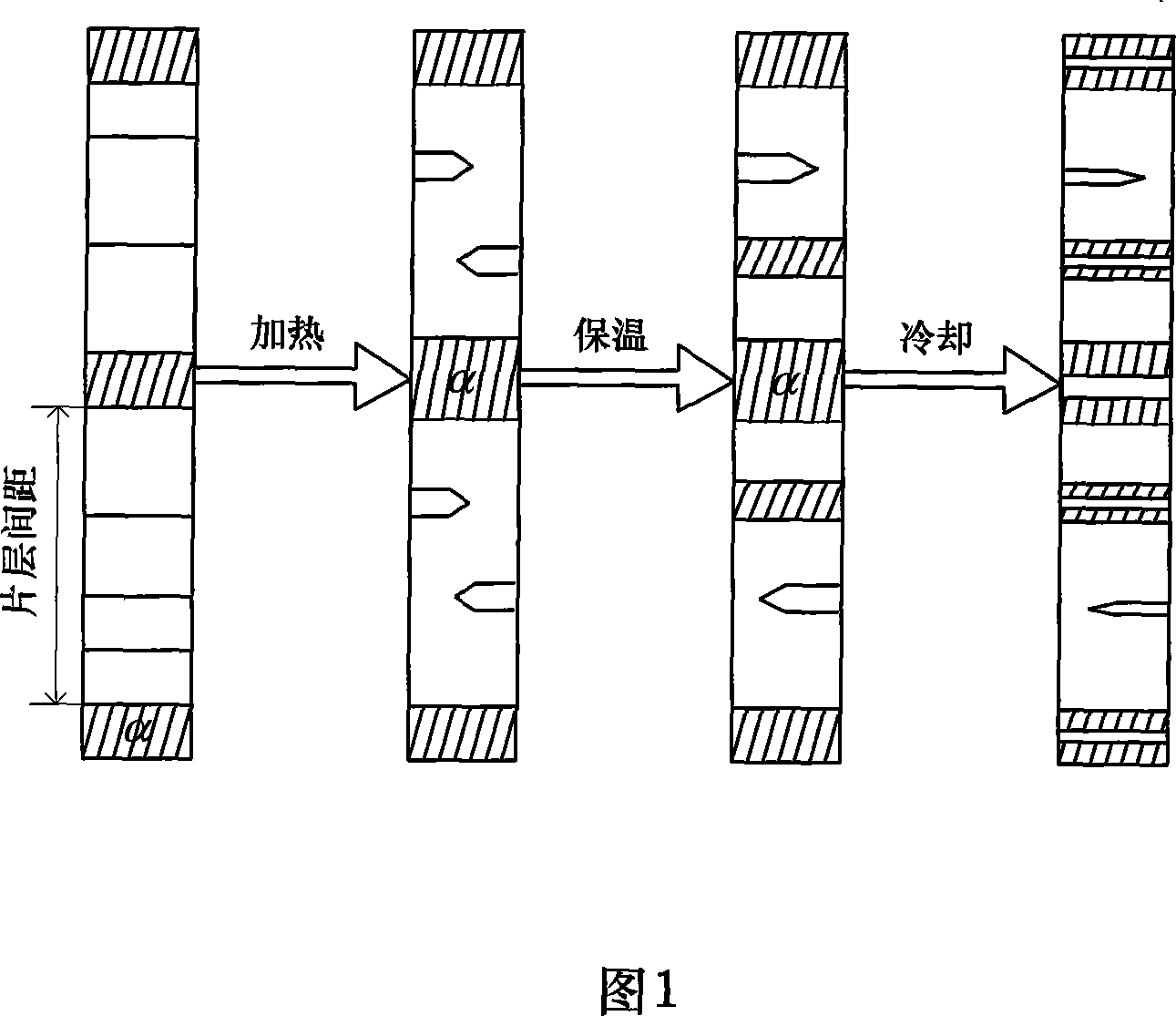

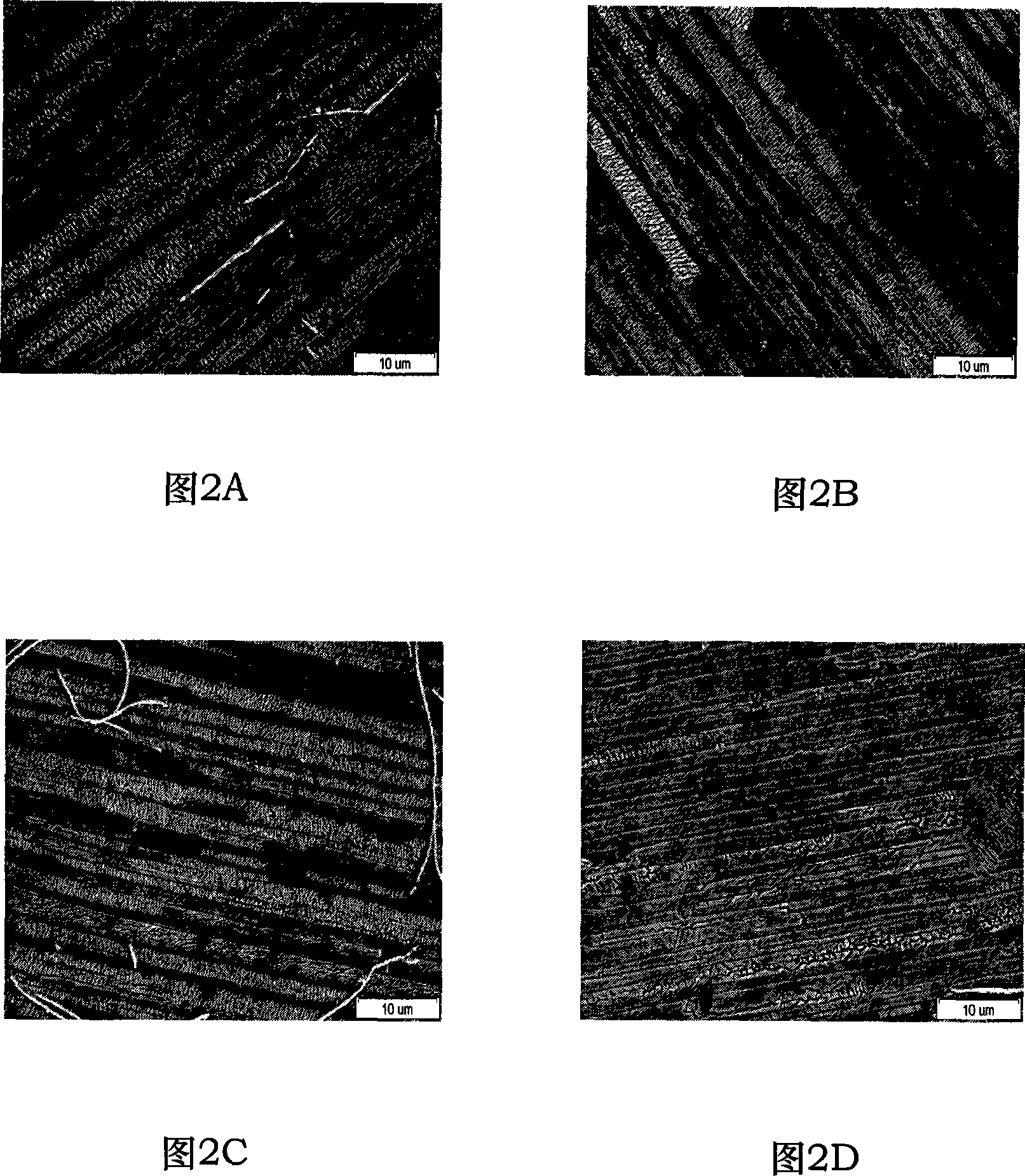

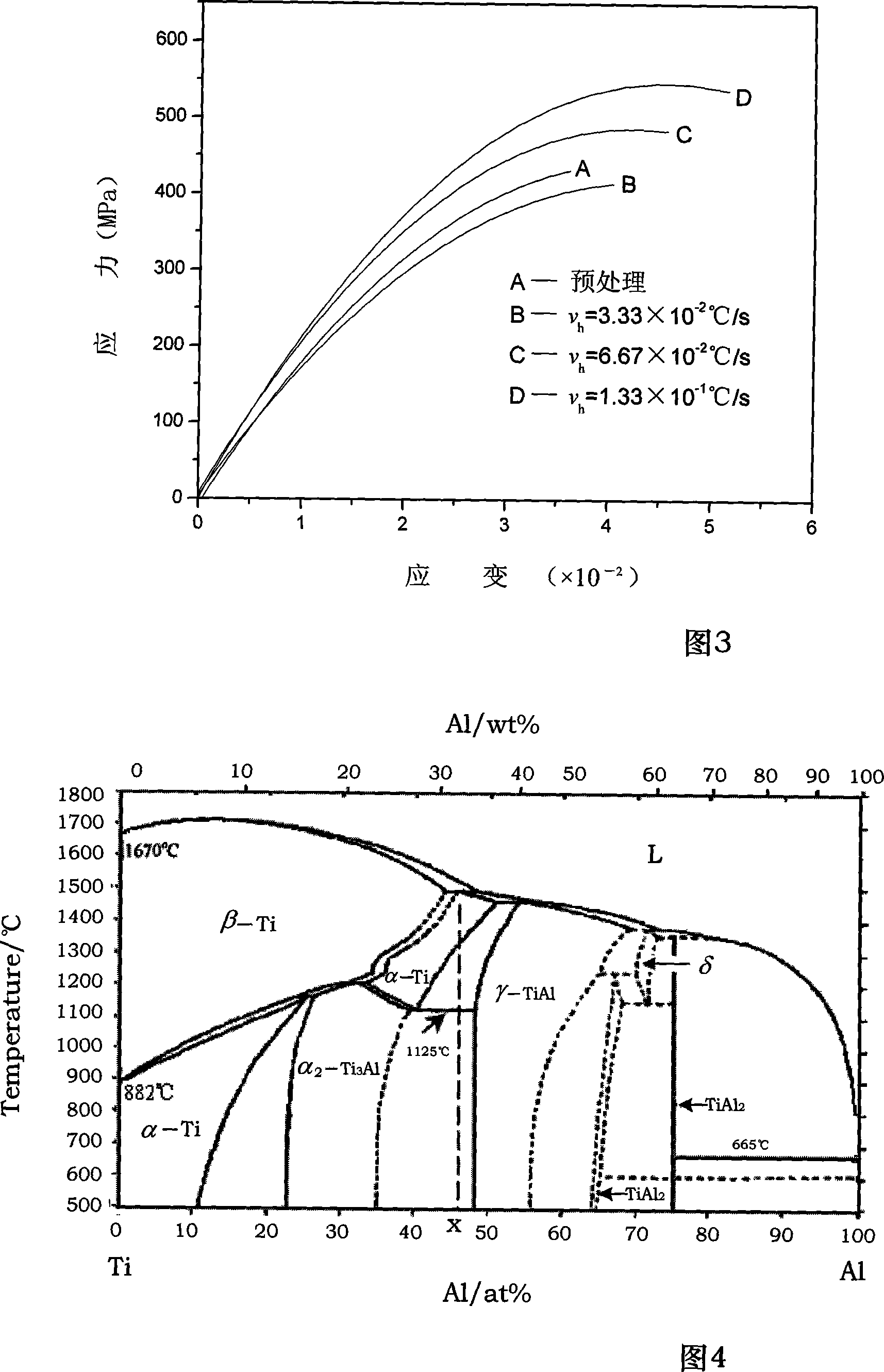

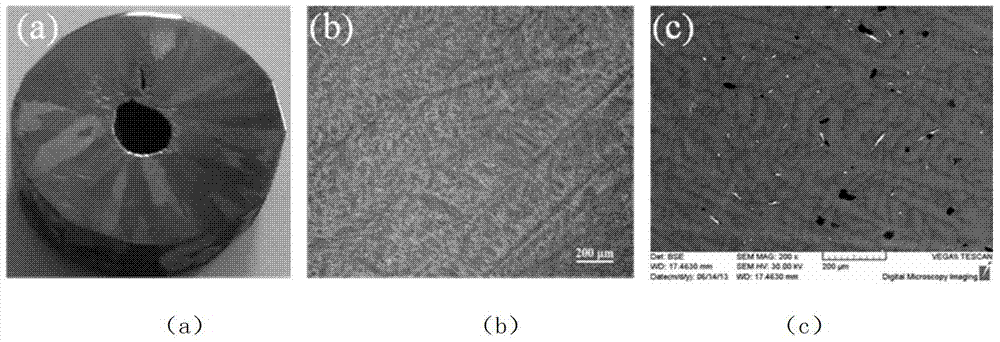

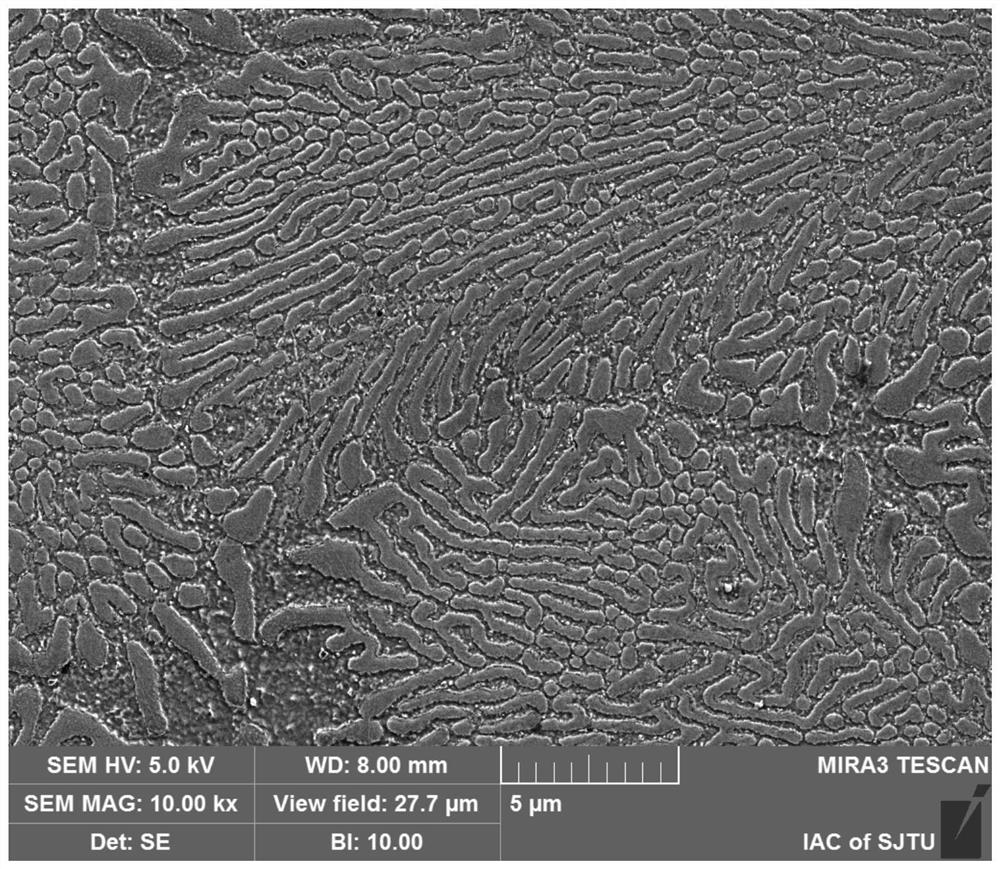

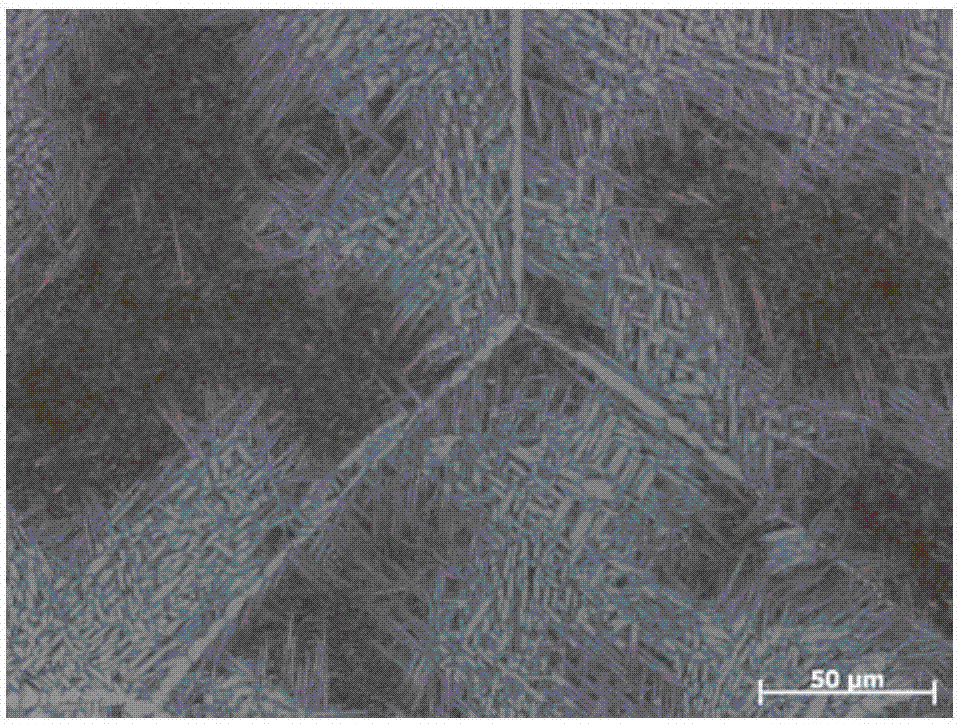

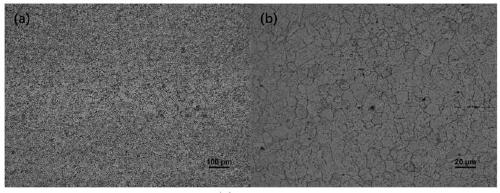

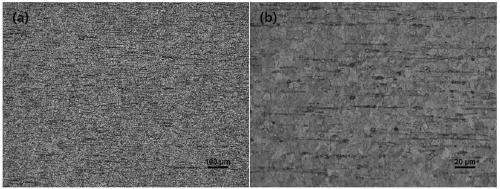

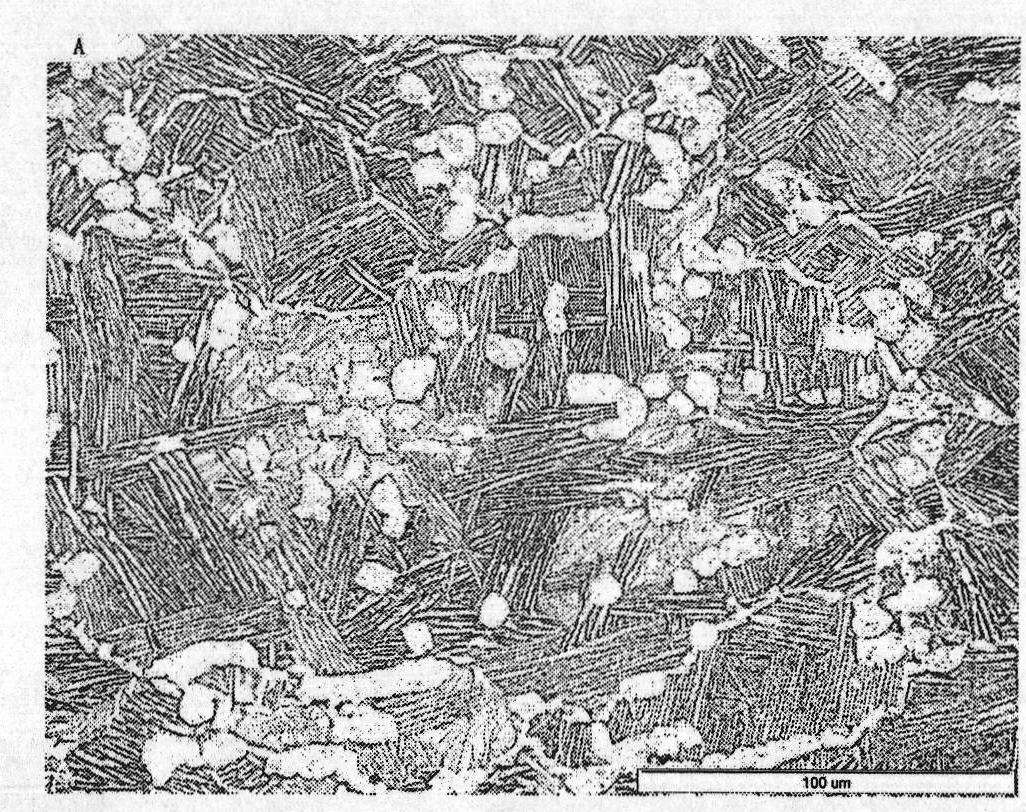

Heat processing technique for thinning TiAl-base alloy sheet interlayer spacing

A heat treatment of TiAl based alloy is used to fine lamellar distance, which is available for TiAl with 45-51at% Al content or TiAl with 42-46at% Al and 5-10at% Nb. Cast ingots are treated by homogenizing, heat isopressing, and aging at alpha and gamma zones cyclically. Parameters, e.g. heating and cooling rates, temperatures are all controlled to refine layer distance while keeping lamellar status.

Owner:BEIHANG UNIV

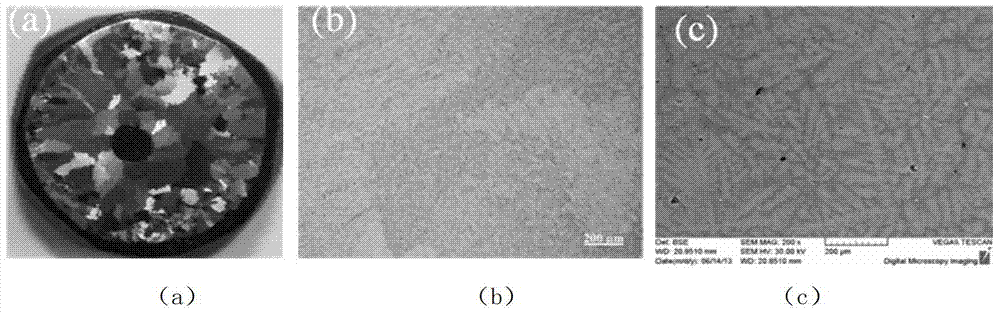

TiAl alloy crystal grain refinement method

The invention provides a TiAl alloy crystal grain refinement method. Through cyclic treatment in a solid-liquid two-phase region, a bulky columnar crystal undergoes remelting, a fused dendritic crystal can be used as a new nucleation particle which undergoes nucleation and growth, so a crystal grain is refined. According to the invention, treatment is carried out on a peritectic solidification path with a Ti48Al2Cr2Nb alloy as a representative, an alpha solidification path with a Ti50Al alloy as a representative and a beta solidification path with a Ti45Al8Nb0.2W0.2B alloy as a representative, and a substantial refinement effect is obtained; the method has the characteristics of a wide application scope and suitability for crystal grain refinement of a plurality of TiAl alloys.

Owner:重庆两航金属材料有限公司

Method for cladding TiC enhanced Ni3Al based composite coating on surface of aluminum alloy

InactiveCN103233223AThe preparation process is stableIncrease productivityMetallic material coating processesLaser beam welding apparatusExothermic reactionAlloy surface

The invention relates to a method for cladding TiC enhanced Ni3Al based composite coating on the surface of aluminum alloy. The method comprises the following steps of: (1) cleaning the surface of aluminum alloy matrix metal and removing greasy dirt and an oxidation layer; (2) uniformly mixing a Ni-based material with TiC powder to serve as a coating material, wherein the weight content of the Ni element of the Ni-based material is over 75 percent; (3) forming a molten bath on the surface of the aluminum alloy matrix metal by using laser beams in an argon protection device; and (4) conveying the coating material into the molten bath to form metallurgical bonding with the aluminum alloy matrix metal, and performing chemical exothermic reaction between Ni and Al to form the TiC enhanced Ni3Al based composite coating. The method has the characteristics of stable preparation process, basic avoidance of sputtering or burning loss, high production efficiency and the like. The prepared TiC enhanced Ni3Al based composite coating cladded on the surface of aluminum alloy has the advantages of good surface quality, uniform TiC distribution and diffusion, tiny crystal particles, metallurgical bonding with the matrix, high wear resistance and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Carbon-silicon-tungsten-yttrium lamellar structure high-niobium titanium-aluminum alloy and preparation method thereof

Owner:NANJING UNIV OF SCI & TECH

Heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties

The invention belongs to the technical field of new materials, and provides a heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties, which is mainly used in automobile engine exhaust system components of which the exhaust temperature exceeds 1000 DEG C, including exhaust manifolds, turbine casings and the like. The heat-resistant cast austenitic stainless steel comprises the following alloy components in percentage by mass: 0.1%-0.6% of C, 0.1%-0.5% of N, 0.4%-1.5% of Si, less than 1.5% of Mn, 17.5%-22.5% of Cr, 8.0%-13.0% of Ni, 1.0%-3.0% of Nb, less than 5.0% of W, less than 6.5% of Mo and the balance of matrix element Fe and impurity elements, including less than 0.04% of P, less than 0.03% of S, less than 0.04% of O and less than 0.05% of Al. The heat-resistant austenitic stainless steel is produced by a casting method without later-period heat treatment, and has the advantages of lower production cost, higher temperature resistance and higher durability as compared with like heat-resistant cast steel.

Owner:UNIV OF SCI & TECH BEIJING

Light refractory high-temperature-resistant eutectic high-entropy alloy and preparation method thereof

ActiveCN112981208AImprove high temperature performanceHigh phase contentChemical compositionHigh entropy alloys

The invention discloses a light refractory high-temperature-resistant eutectic high-entropy alloy and a preparation method thereof. The chemical component expression of the light refractory high-temperature-resistant eutectic high-entropy alloy is VaNbbMcSid, wherein M is one or more elements of Ti, Zr, Ta, Mo, Cr and Al, and a, b, c and d in the chemical expression respectively represent the molar percentages of the corresponding elements and meet the following relations: 0<a<= 45, 0<b<=35, 0<c<=35, 10<=d<=20, and a+b+c+d=100. The alloy is of a lamellar eutectic structure composed of a VNbM solid solution phase of a body-centered cubic structure and a (VNbM)5Si3 ordered compound phase of a tetragonal or hexagonal structure, has density far lower than that of a nickel-based and cobalt-based high-temperature alloy and an ultrahigh melting point, and has certain room-temperature plasticity, high high-temperature strength and excellent casting performance, thereby meeting the requirements for advanced high-temperature structural materials.

Owner:SHANGHAI JIAO TONG UNIV

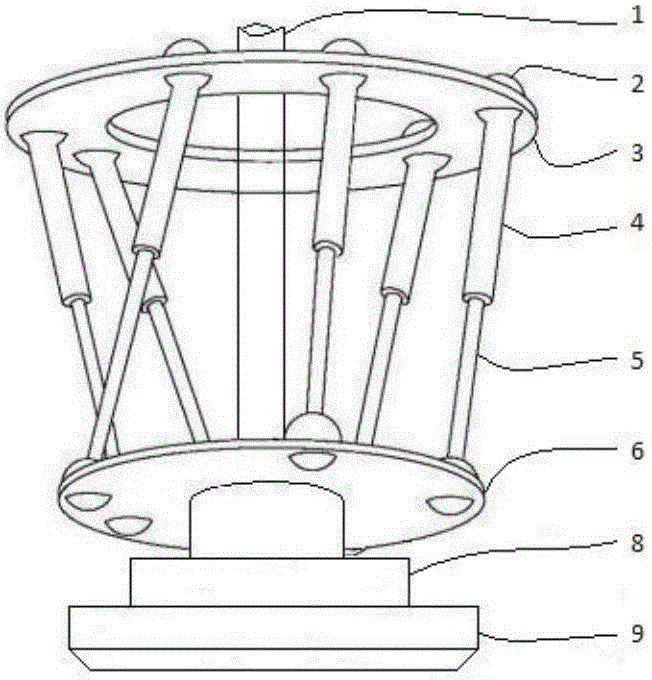

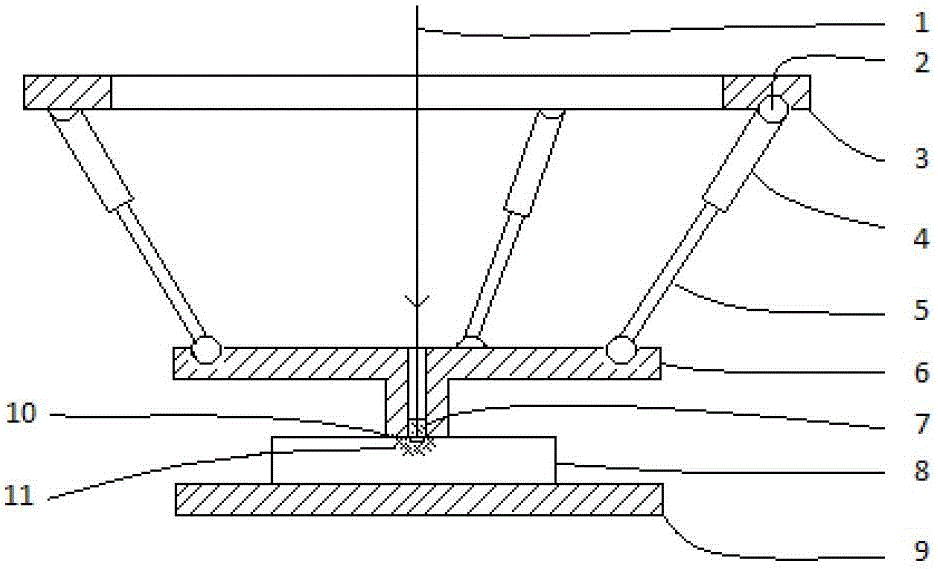

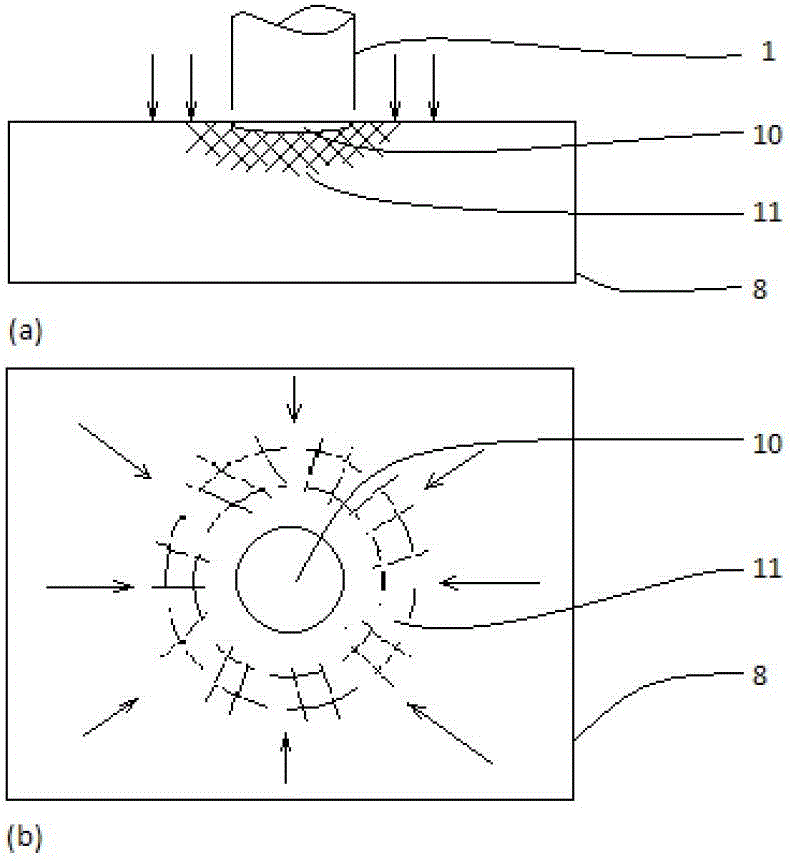

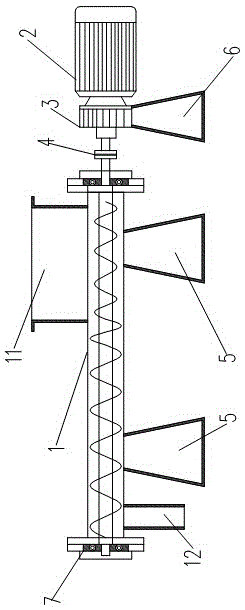

Method and device for improving room temperature plasticity of block amorphous alloy and structural member of block amorphous alloy

The invention relates to a method and a device for improving room temperature plasticity of block amorphous alloy and the structural member of the block amorphous alloy. The method comprises the following steps of: polishing and smoothening the surface of an amorphous alloy body and placing the polished amorphous alloy body on a rigid cushioning plate; introducing short-pulse laser beams to the surface of the polished amorphous alloy body through a boss with a center hole to generate explosion plasma impact waves which act on the amorphous alloy body so that an irradiated region generates trace high-strain-rate plastic deformation and compact shearing zone and residual compressive stress are formed. According to the invention, multiple mechanical and materialogical mechanisms for improving the room temperature plasticity of the amorphous alloy are compressively utilized, thus the plasticizing effect is obvious, and the method and the device are suitable for various amorphous alloy materials.

Owner:SHANDONG UNIV

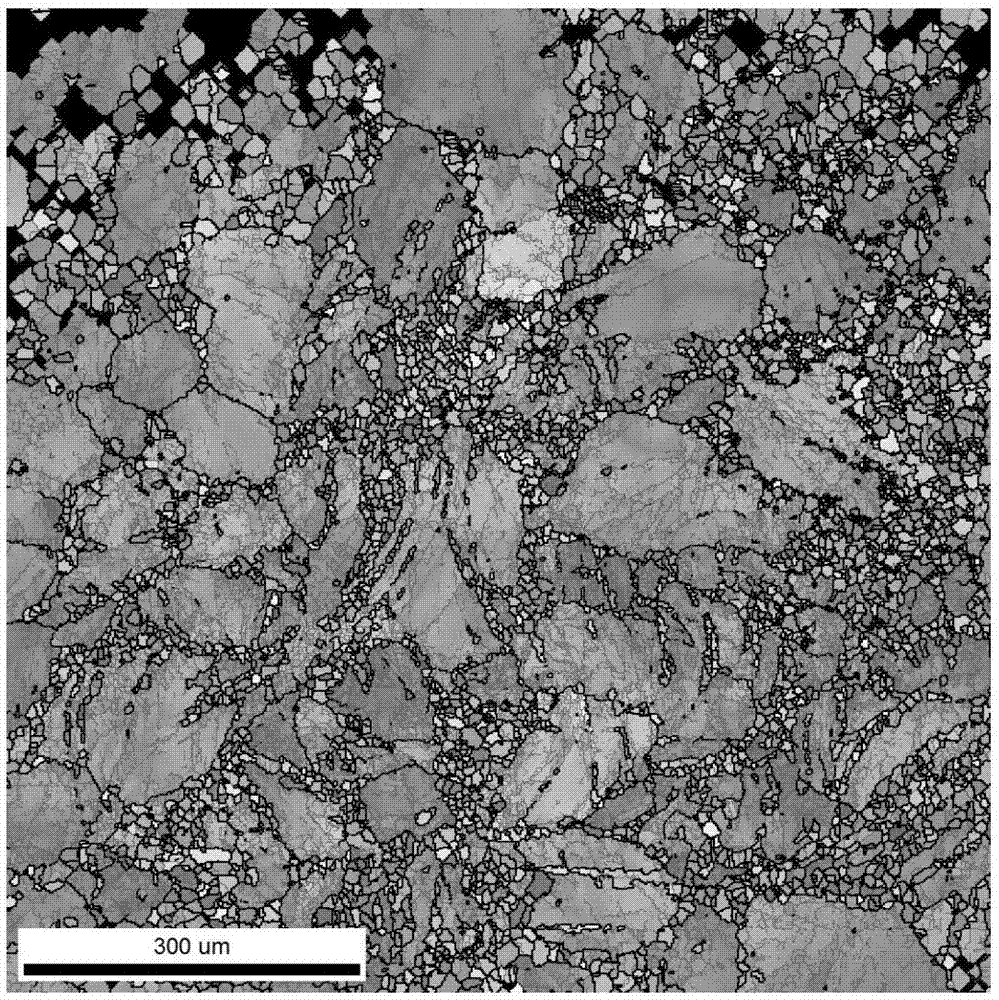

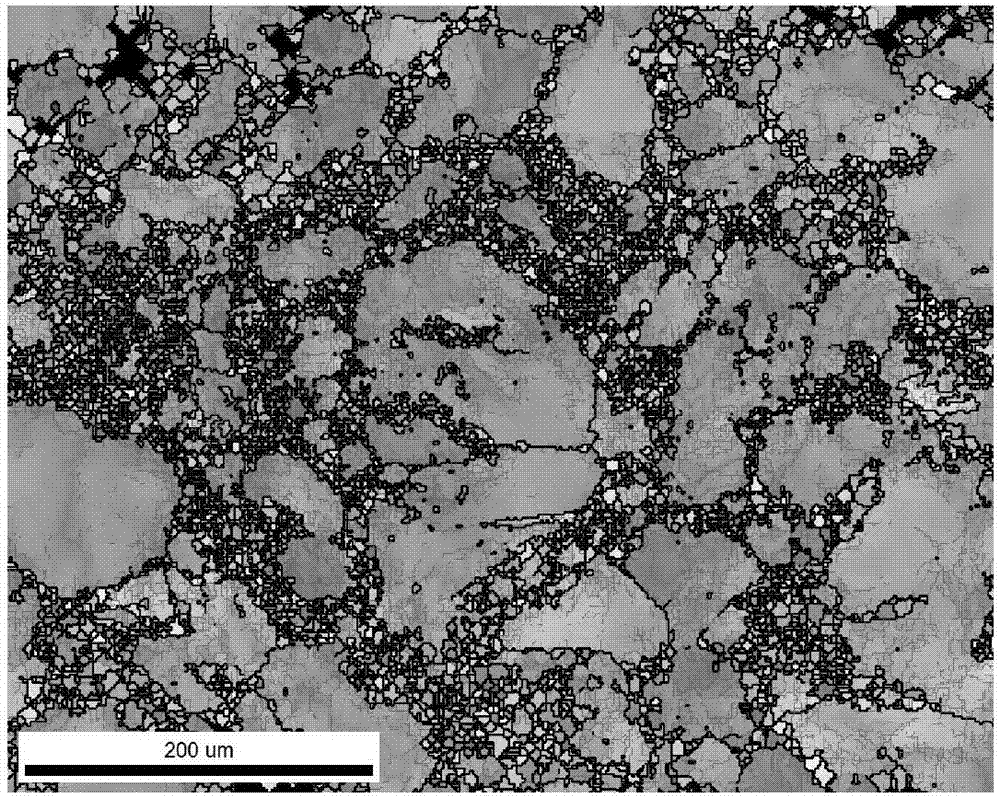

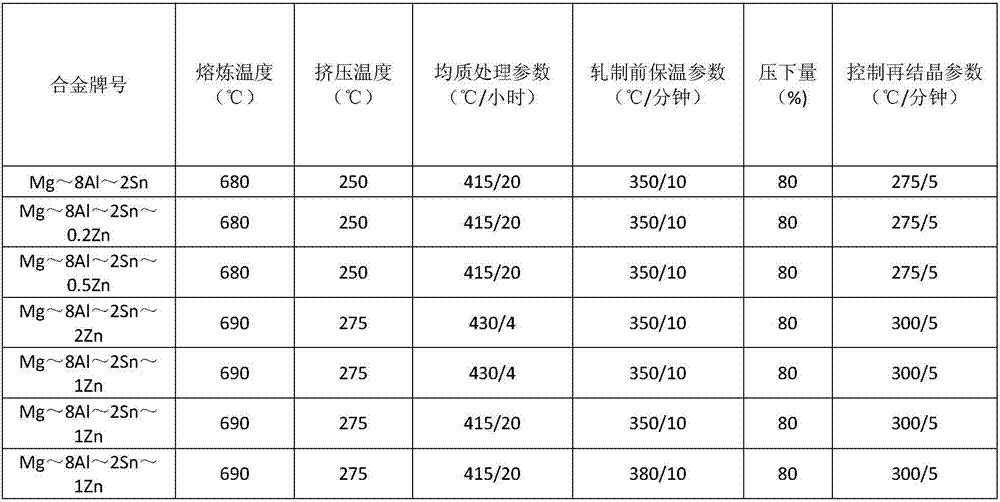

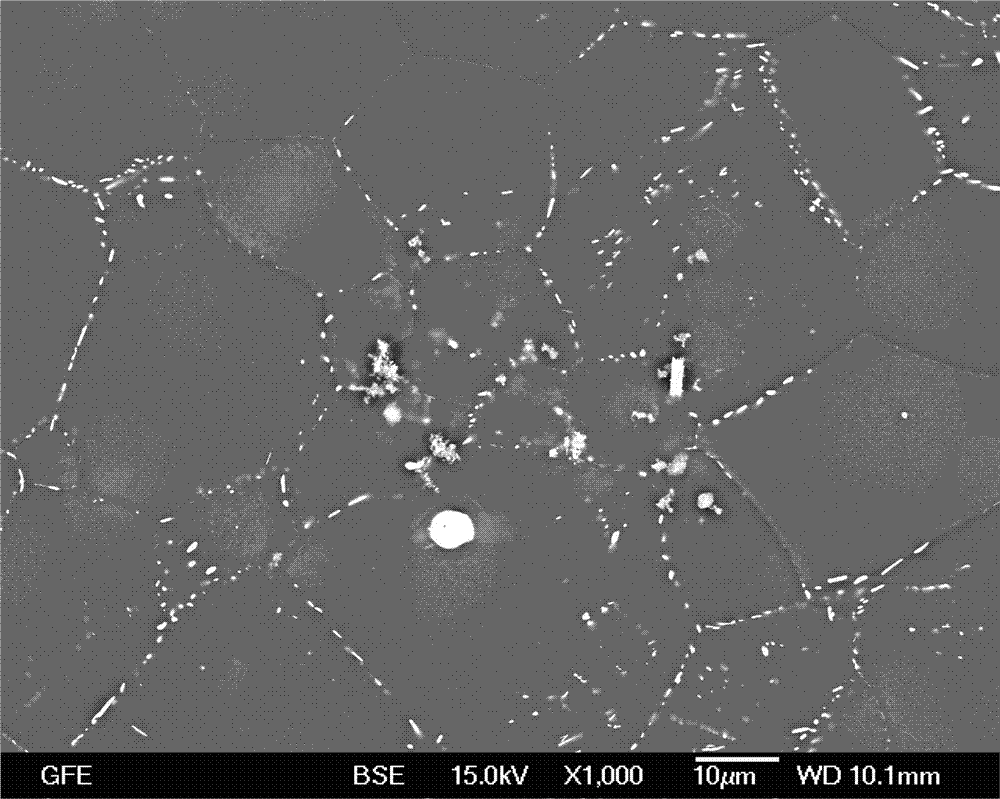

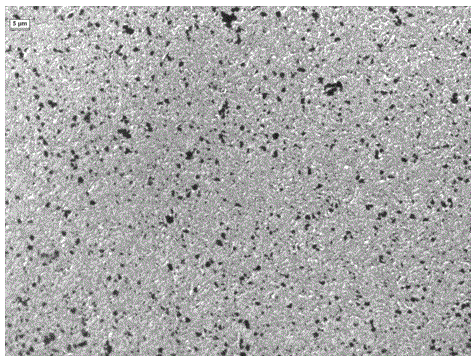

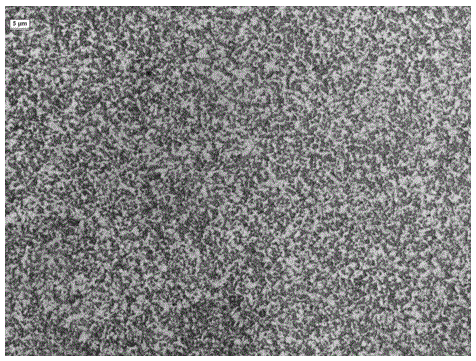

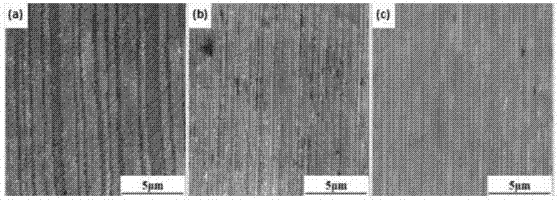

Controlled rolling preparation method for multicomponent and multi-scale-structure magnesium alloy with high aluminum content

The invention relates to a controlled rolling preparation method of a multi-element multi-scale structure high aluminum content magnesium alloy. The preparation method comprises four steps of smelting extrusion, homogenization treatment, controlled rolling and controlled recrystallization; the prepared magnesium alloy structure It has a multivariate and multi-scale grain distribution, consisting of ultra-fine grains with an average size of less than 1 micron, fine grains with a size of 1-10 microns, large grains with a size greater than 70 microns, and a uniformly dispersed second phase; prepared by this method The magnesium alloy room temperature plasticity is greater than 20%, and the strength is higher than 330MPa. The invention provides a controlled rolling preparation method of multi-element and multi-scale structure high-aluminum content magnesium alloy with simple and reliable process, which is easy to mass-produce and popularize and apply. ), fine grains (1-10 microns) and coarse grains (-70 microns) are uniformly mixed, and this organizational structure ensures that the magnesium alloy has good plasticity at room temperature while having high strength.

Owner:JILIN UNIV

Preparation method of rare earth magnesium alloy and sheet thereof

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is characterized by comprising the following components by mass percent: 0.5 to 4.0% of Zn, 0.1 to 2% of Gd, 0.3 to 0.9% of Zr, and the balance of Mg. The preparation method of the rare earth magnesium alloy sheet comprises the following steps of: treating a rare earth magnesium alloy ingot casting by uniform annealing; cooling with water; milling the surface; preheating a milled blank; rolling for four to eight times; melting down and heating once every two to three times after rolling; continuously rolling, wherein the total rolling reduction is 70 to 95%; annealing the sheet subjected to hot rolling; performing cold rolling for a moderate-thickness sheet subjected to hot rolling for two to four times; and then annealing the sheet subjected to cold rolling to obtain the rare earth magnesium alloy sheet. The invention also provides a preparation method of the rare earth magnesium alloy and the sheet thereof. The rare earth magnesium alloy sheet is high in plasticity and high in heat stability. Compared with hot rolling, cold rolling has the advantage that the magnesium alloy can be prevented from being oxidized into a film during heating; in addition, the prepared sheet is accurate in dimension and uniform in thickness; a thin belt which cannot be produced by hot rolling can be obtained; and mass production and application can be realized.

Owner:GUANGDONG INST OF NEW MATERIALS

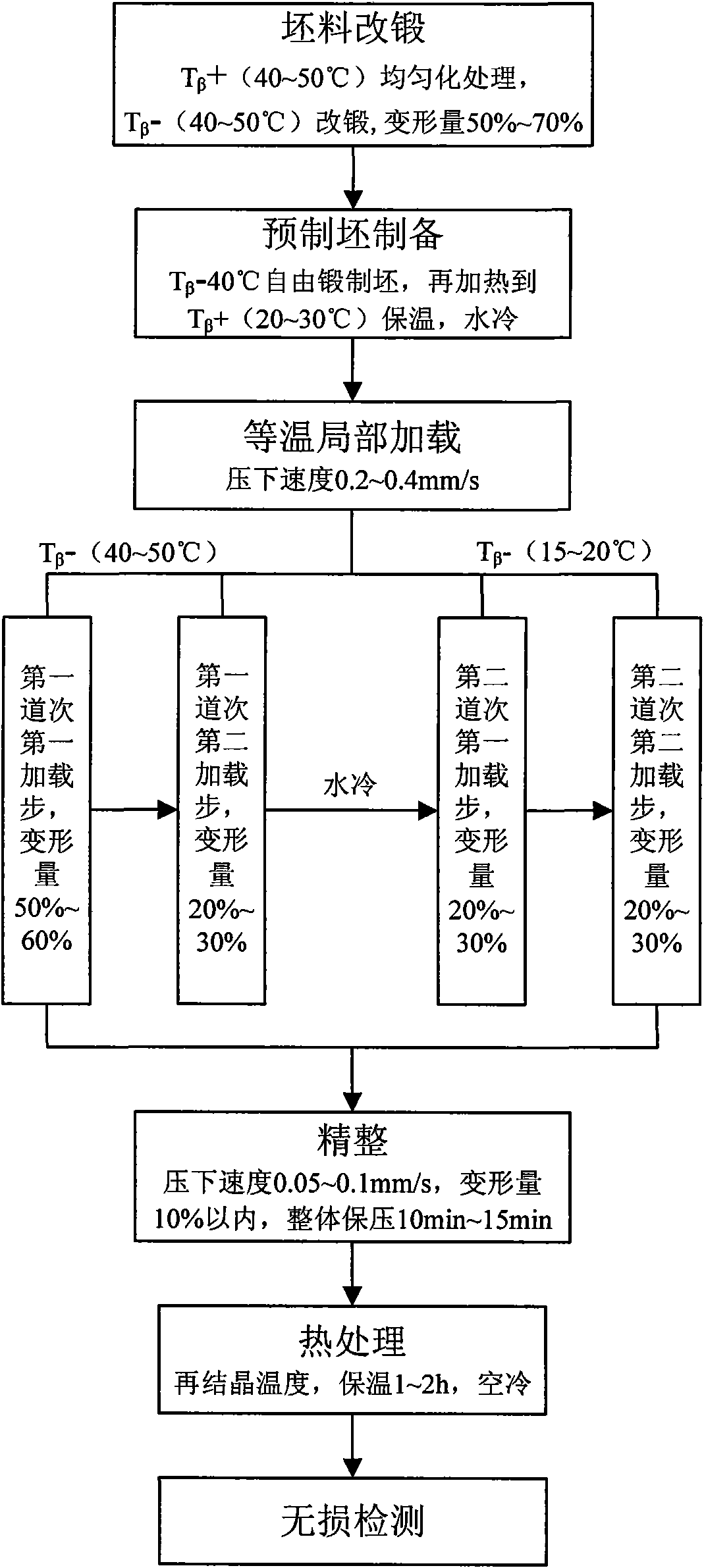

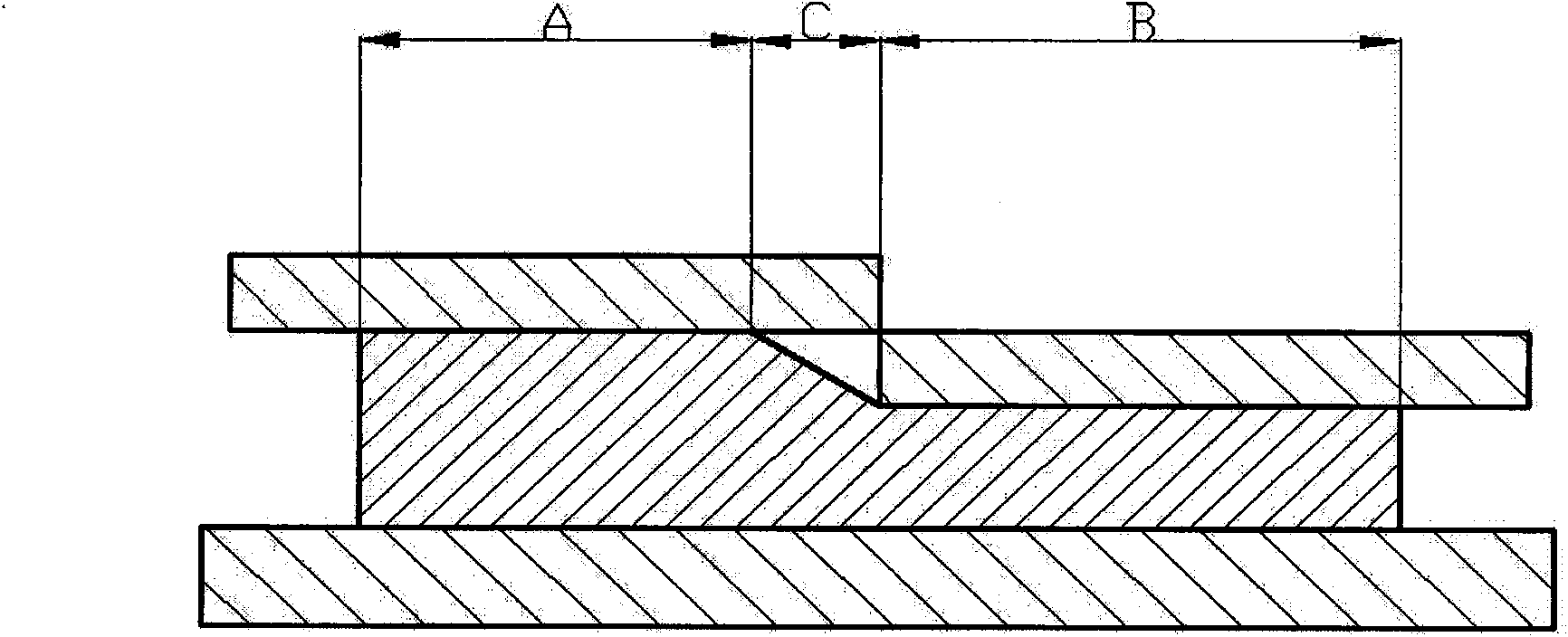

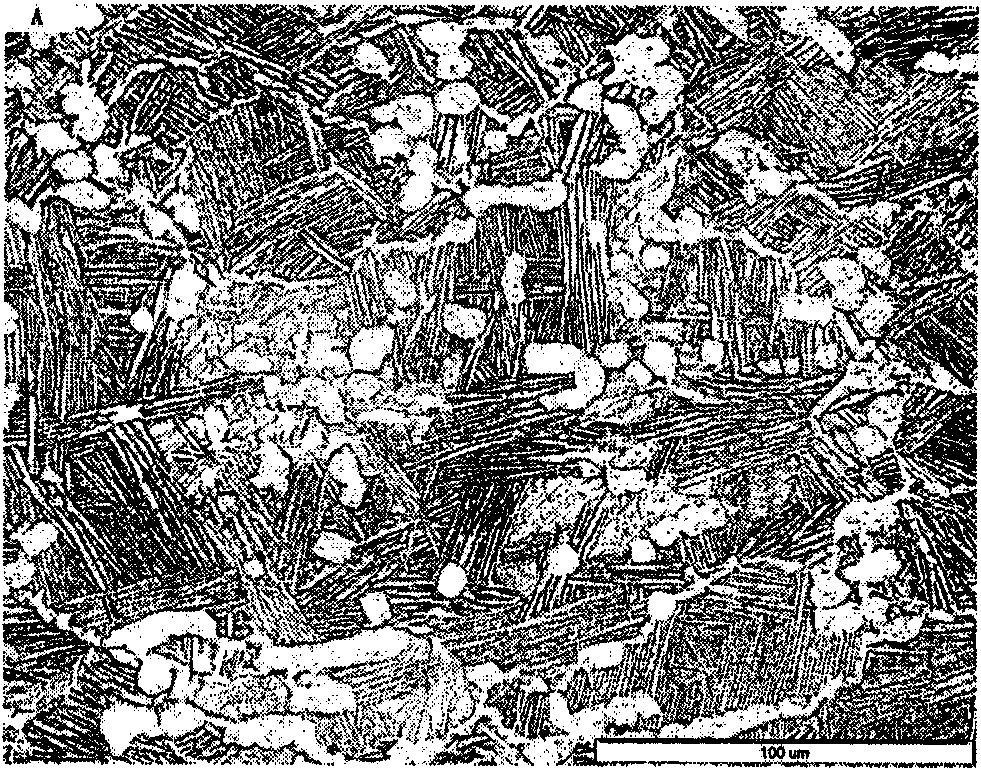

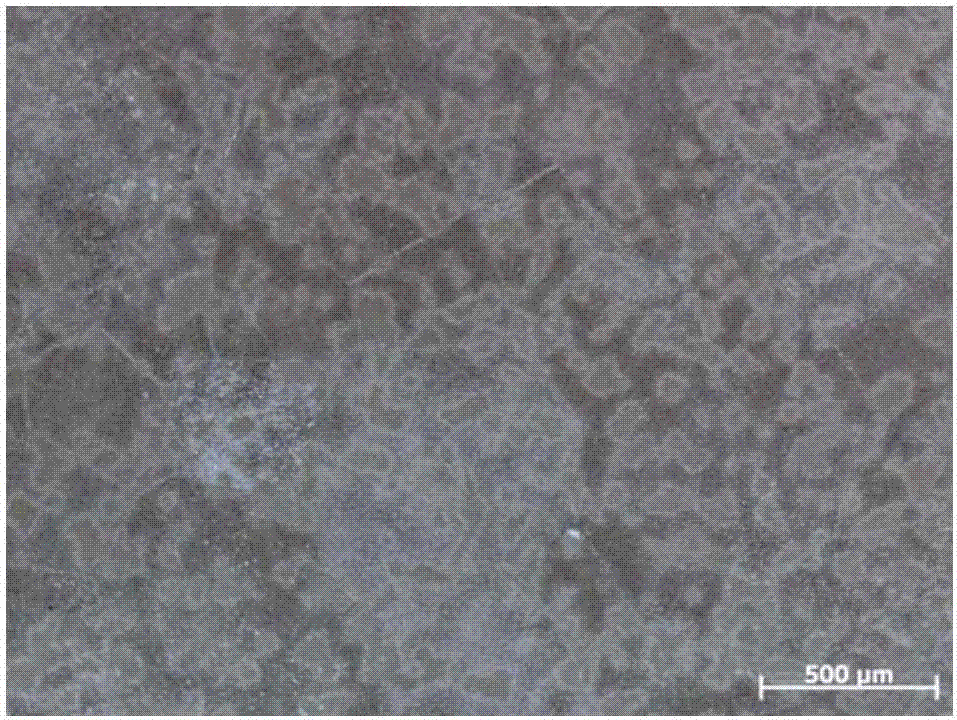

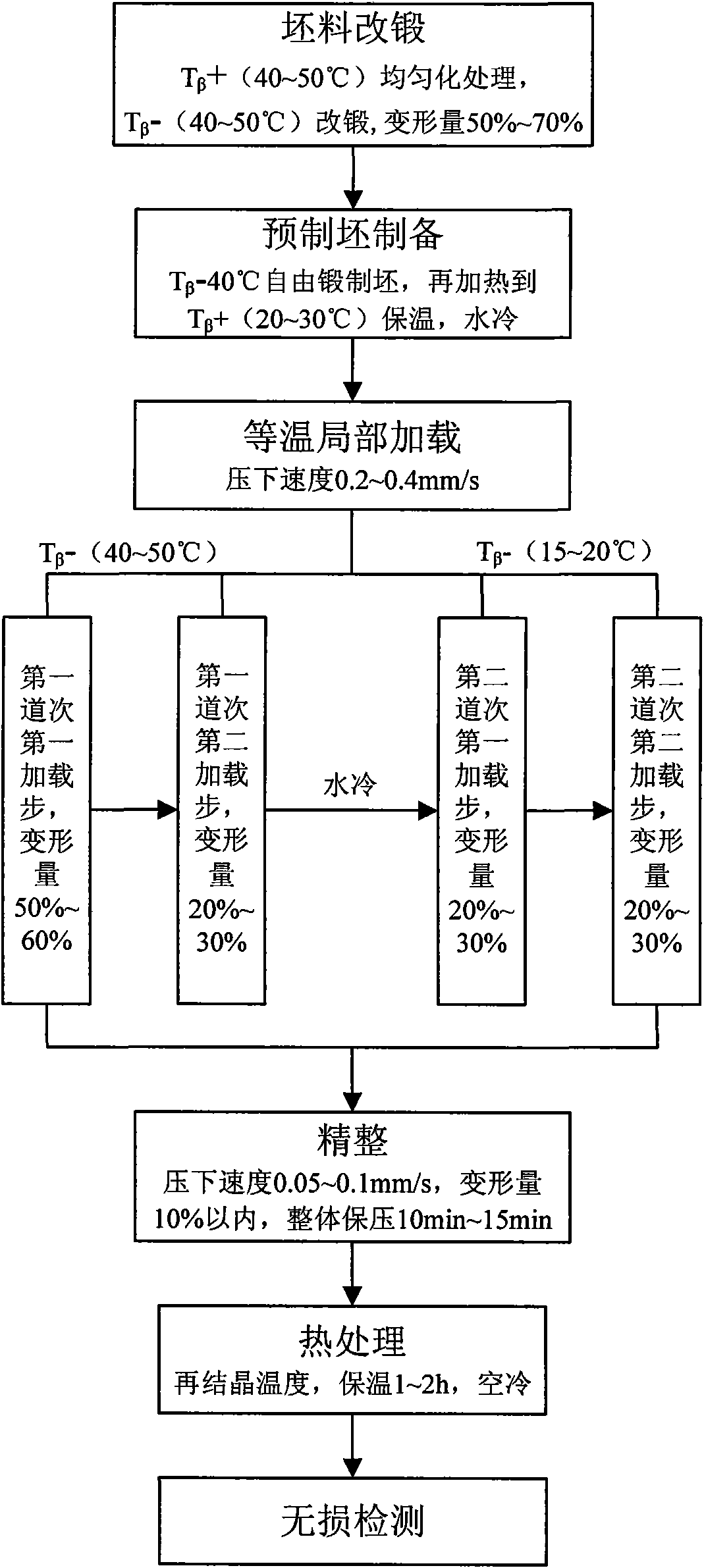

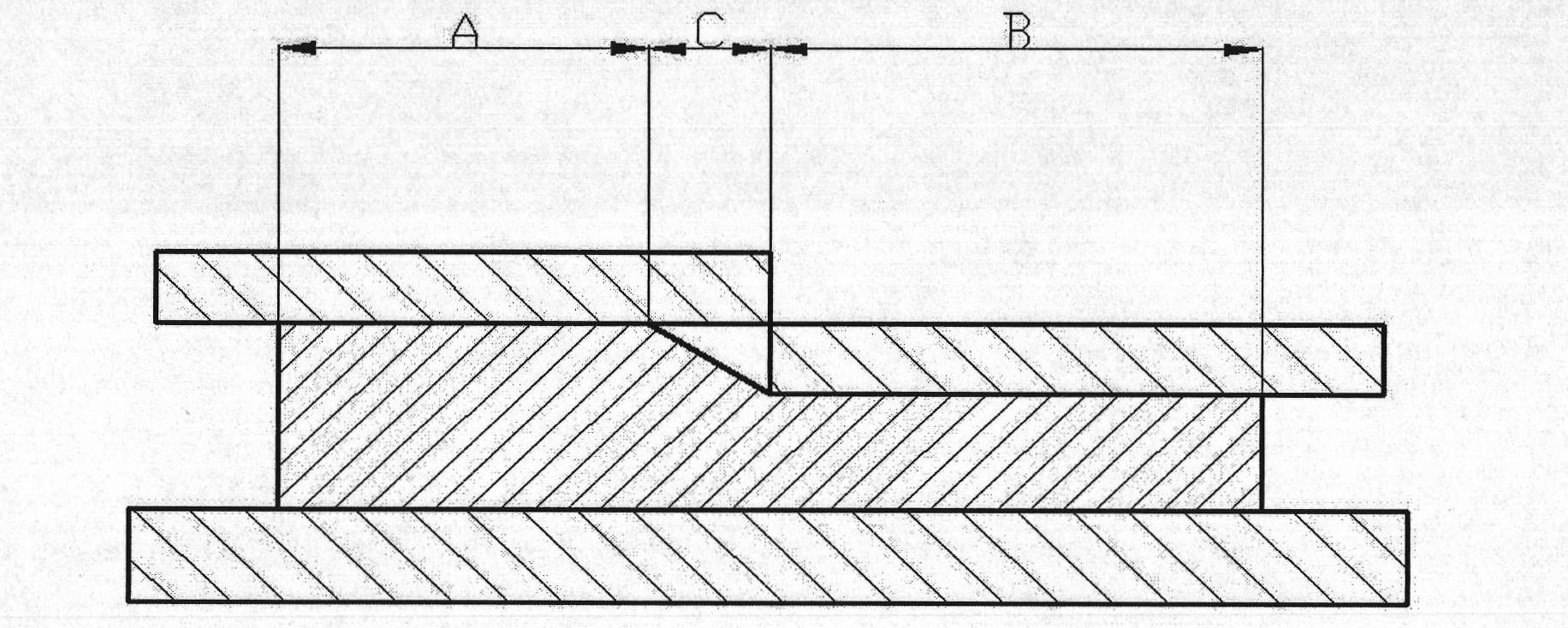

Method for realizing near alpha titanium alloy dual-property employing local loading process

The invention discloses a method for realizing near alpha titanium alloy dual-property employing local loading process, which divides a workpiece into an A loading zone and a B loading zone, and a C zone is the transition zone between the A loading zone and the B loading zone, wherein the A loading zone is a large deformation zone while the B loading zone is a small deformation zone, and the method is realized through the isothermal local loading with two passes and two loading steps in each pass. The specific shaping process comprises blank forging, preparation of preforming billet, isothermal local loading, finishing, thermal treatment and nondestructive testing. The shaped workpiece can obtain the tri-modal microstructure with high room temperature plasticity, high strength and long fatigue life and 20% equiaxial alpha phase content in the A loading zone, the lamellar microstructure with high tensile strength at high temperature, high fracture toughness and strong creep deformation resistance in the B loading zone, and the bimodal microstructure with higher equiaxial alpha phase content in the C transition zone than in the A loading zone so as to further realize the dual-property of the integral component; therefore, the method is a simple and efficient shaping method for the integral dual-property component.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

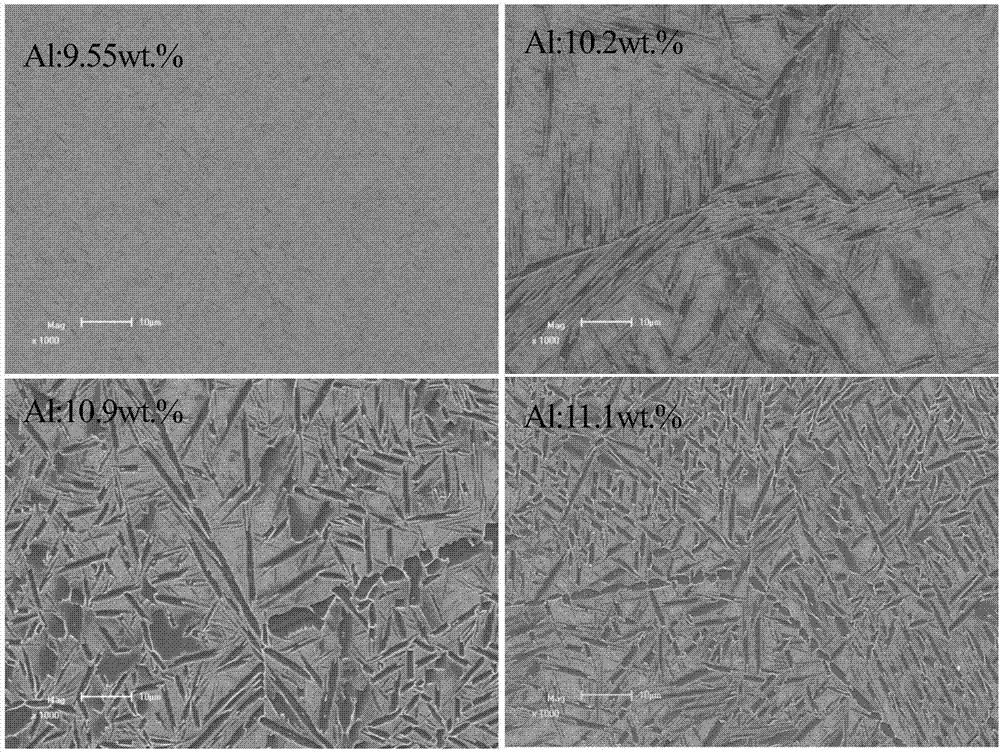

Cast toughened Ti3Al intermetallic compound as well as preparation method and application thereof

The invention belongs to the field of Ti-Al intermetallic compounds, and in particular relates to a cast toughened Ti3Al intermetallic compound as well as a preparation method and application thereof. The cast toughened Ti3Al intermetallic compound comprises constitution factors such as alloy components, smelting, precise casting and thermal treatment. The alloy components comprise 10.2-11.8 percent by weight of Al, 26.0-29.0 percent by weight of Nb, 1.0-3.0 percent by weight of Mo, and the balance of Ti and inevitable impurity elements, wherein the inevitable impurity elements comprise Fe, Si, O, N and H; Fe is less than or equal to 0.3%; Si is less than or equal to 0.3%, O is less than or equal to 0.15%; N is less than or equal to 0.04%; and H is less than or equal to 0.01%. Therefore, with the combination of the component optimization process and the thermal treatment processes, different matches between tensile strength and plasticity and between fatigue strength and thermal stability can be achieved, and the compound can be also used for manufacturing precise cast parts such as high-temperature parts of aero-engines, and can be used for a long time at 600-700 DEG C; and the alloy can be also used for manufacturing high-temperature resistant structural parts of aerospace crafts, and can be used for a short time at 650-750 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

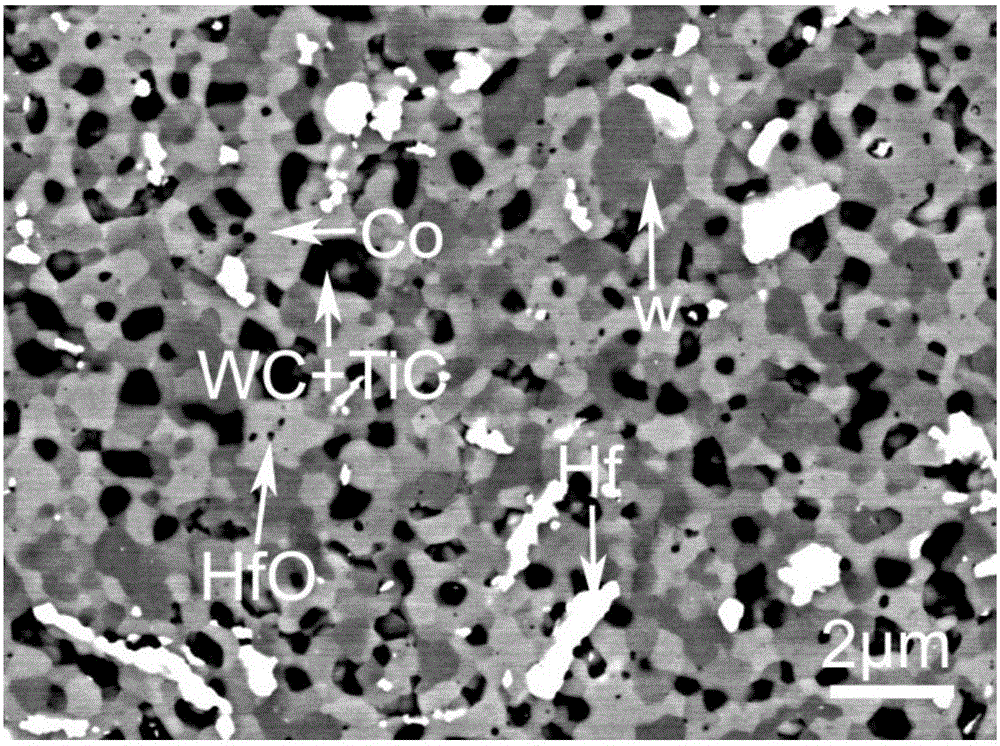

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

Room-temperature high-plasticity wrought magnesium alloy and preparation method thereof

ActiveCN103866169AMeet the needs of plastic processingIncrease productivitySmelting processGrain structure

The invention provides room-temperature high-plasticity wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components by weight percent: 5.5wt%-7.3wt% of Al, 0.40wt%-1.50wt% of Zn, 0.15wt%-0.50wt% of Mn, 0.05wt%-1.0wt% of P and the balance being Mg and inevitable impurities, wherein the inevitable impurities comprise the following components: not more than 0.05wt% of Si, not more than 0.004wt% of Fe, not more than 0.004wt% of Cu and not more than 0.002wt% of Ni. According to the magnesium alloy, a nonmetal element P is added in an existing magnesium alloy smelting process, a stable small grain structure is obtained under the action of the nonmetal element P, the room-temperature plasticity is improved, and the room-temperature processing and using requirements of finished products or semi-finished products can be met.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

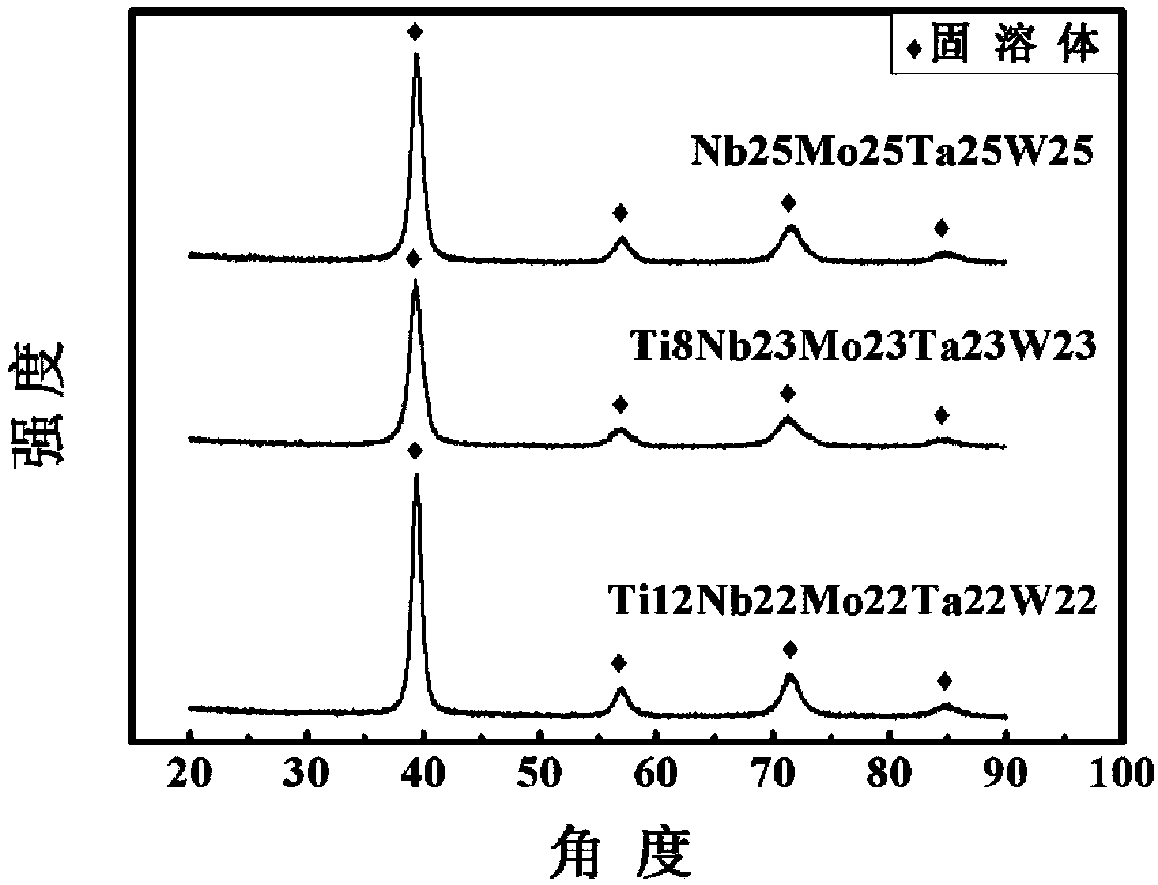

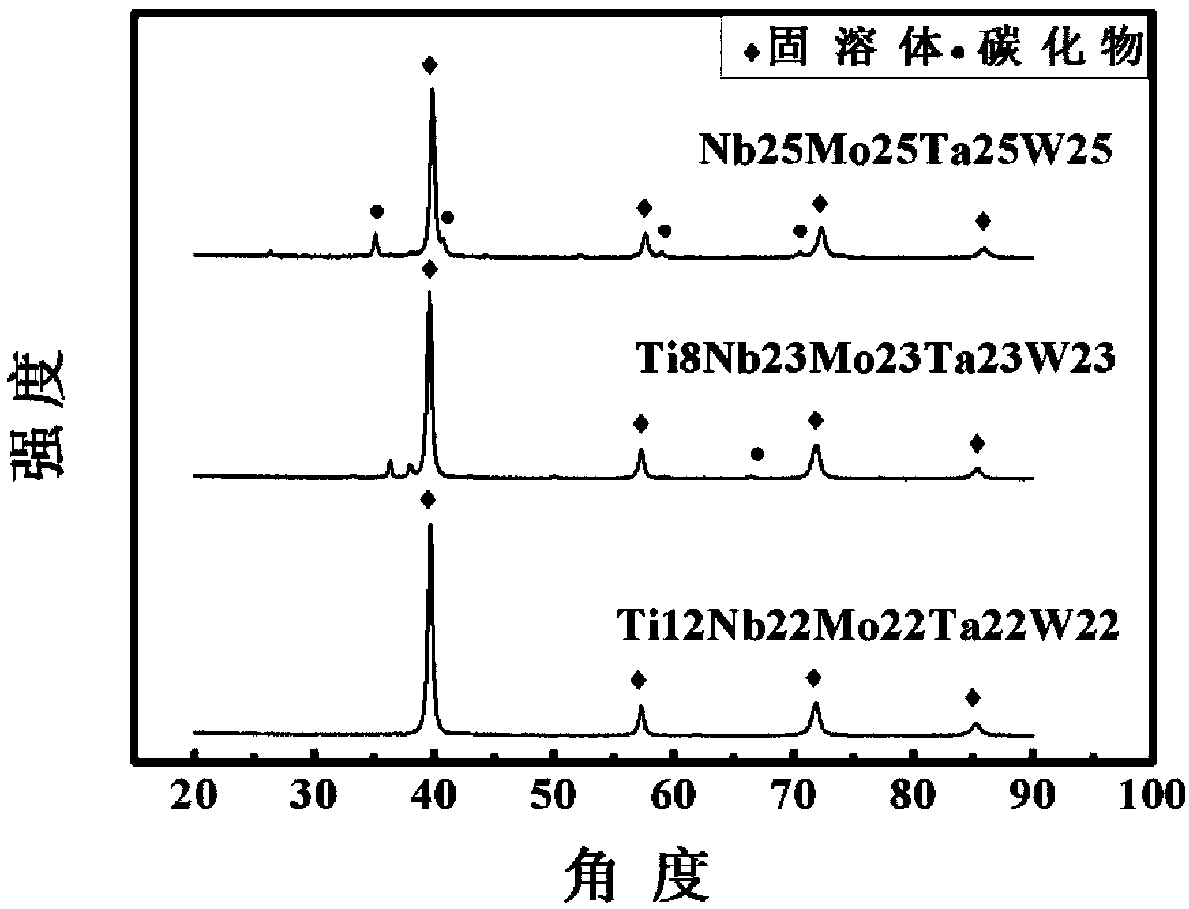

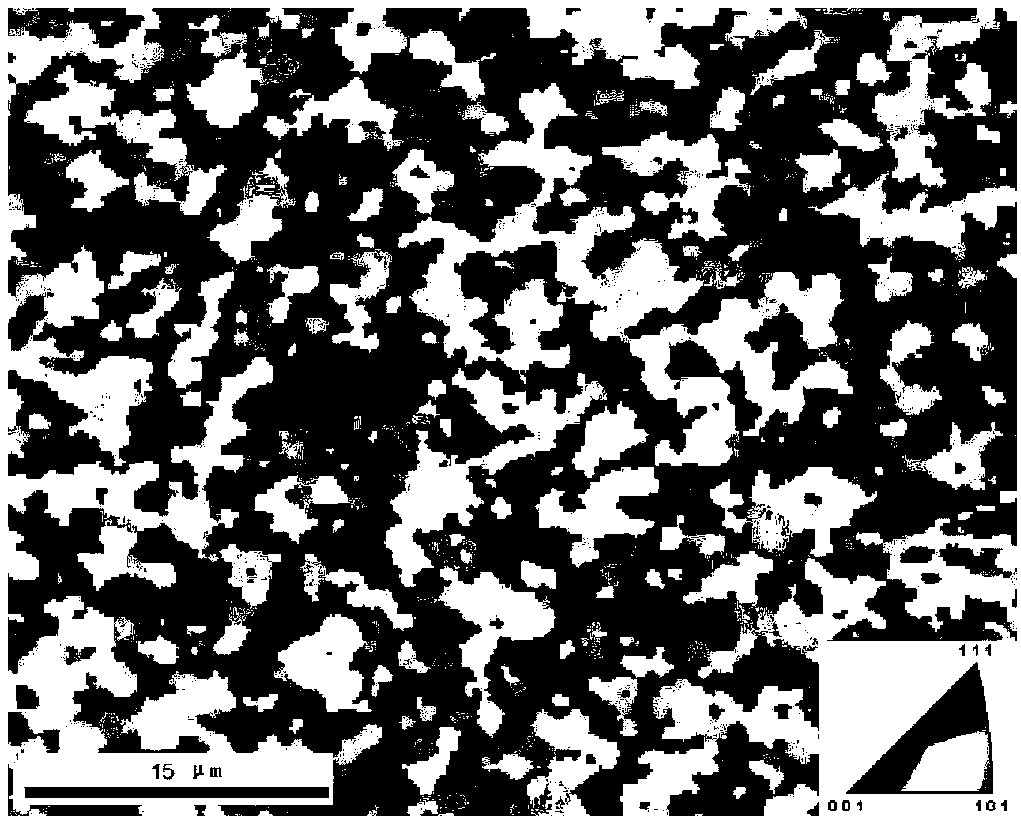

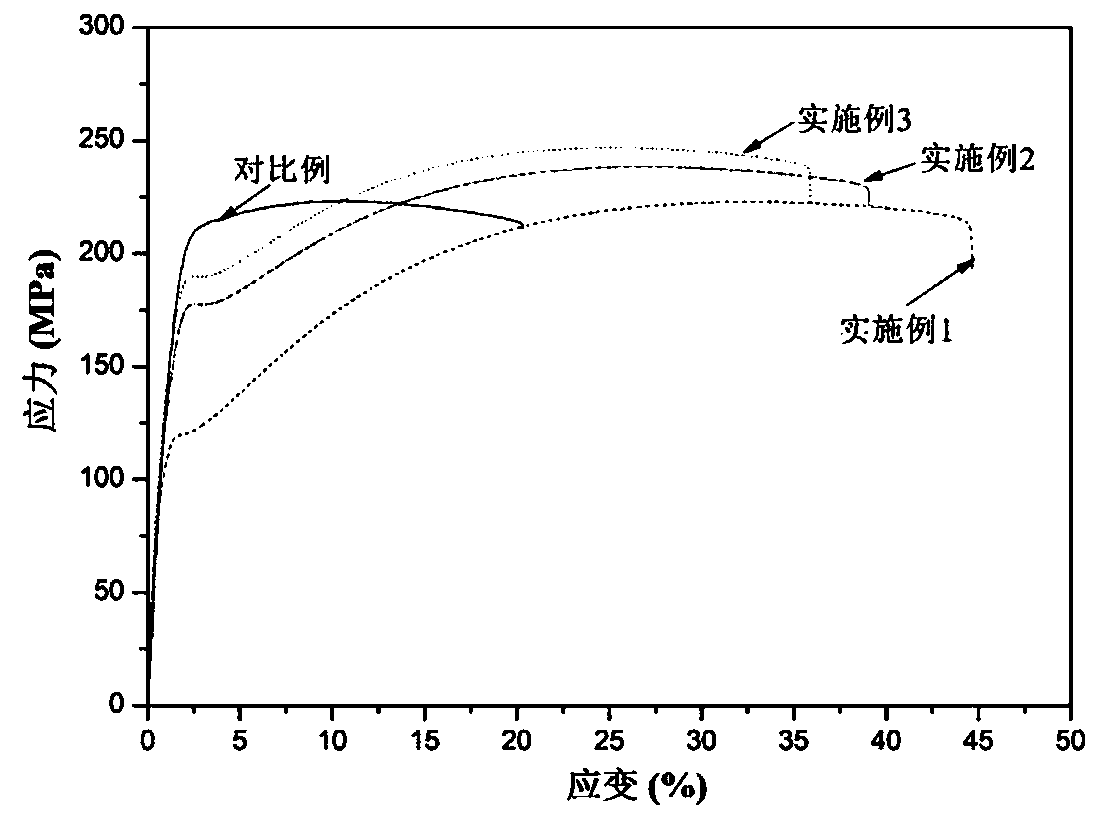

Multi-principal-component high-temperature alloy and preparation method thereof

The invention discloses a multi-principal-component high-temperature alloy and a preparation method thereof. The preparation method adopts a forming technique combining mechanical alloying with discharge plasma sintering, an element Ti is added on the basis of four elements of Nb, Mo, Ta and W with high melting points, alloying is achieved when the elements are in solid states, the melting and solidifying processes are not required, a blocky material with the high performance can be obtained through only one-time solid phase sintering, and the problem that a smelting method is high in smeltingtemperature is solved, so that the machining temperature is reduced substantially, and a technology is simplified; and the defect that a NbMoTaW multi-principal-component high-temperature alloy system is low in room-temperature plasticity is overcome. The preparation method has the advantages of low preparation temperature, high efficiency, less energy consumption and the like; a prepared alloy matrix is of a single-phase body-centered cubic structure, uniform in structure and small in crystal grain, has relatively high strength and plasticity, and is obvious in fine grain strengthening and carbide dispersion strengthening effects.

Owner:SOUTHEAST UNIV

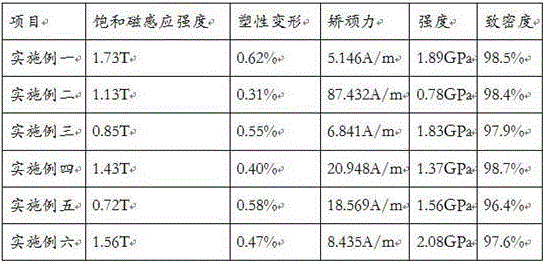

Fe-based amorphous alloy composite

ActiveCN106282848AImprove plasticityFacilitate forkingTransportation and packagingMetal-working apparatusRare-earth elementPowder metallurgy

The invention discloses a Fe-based amorphous alloy composite. The composition of the Fe-based amorphous alloy composite is FeaAlbGacY(3-d)VdInxCoyBzSir, wherein a, b, c, d, x, y, z, and r represent atomic percent, a is larger than or equal to 70 and smaller than or equal to 76, b is larger than or equal to 3 and smaller than or equal to 5, c is 0 or 2, d is larger than or equal to 0 and smaller than or equal to 3, x is larger than or equal to 0 and smaller than or equal to 1.86, Co is larger than or equal to 8 and smaller than or equal to 10, z is 4 or 8, and r is larger than or equal to 0 and smaller than or equal to 3. The Fe-based amorphous alloy composite has excellent high plasticity and soft magnetic properties and has the saturation induction density Bs up to 1.73T, the bulk amorphous alloy composite prepared with a powder metallurgy method has the compactness up to 98.7% and strength up to 2.08 GPa, has good mechanical properties and can meet the industrial requirement, meanwhile, the Fe-based amorphous alloy composite contains no expensive rare earth elements, the demand for the only more expensive indium is very low, so that the production cost is not high, the process is not complex, and commercial production is easy to implement.

Owner:南通巨升非晶科技股份有限公司

Plastic deformation magnesium alloy and preparation method thereof

InactiveCN109182861AImprove plastic deformation abilityPromote solid solutionRoom temperatureExcessive growth

The invention discloses a plastic deformation magnesium (Mg) alloy and a preparation method thereof. The plastic deformation Mg alloy is a Mg-Al-Bi-Sn-Ca-Y alloy, and consists of, by weight percent, 3.0-6.0% of Al, 1.0-3.0% of Bi, 0.5-2.0% of Sn, 0.02-0.05% of Ca, 0.02-0.05% of Y, and the balance Mg, wherein the total content of the element Ca and the element Y is greater than 0.05% and less than0.1%. The plastic deformation Mg alloy and the preparation method thereof adopt lower extrusion temperature and speed to form a large amount of Mg3Bi2 phases, Mg2Sn phases and Mg17Al12, and inhibit excessive growth of second phases by alloying a trace of the elements Ca and Y at the same time. In addition, the element Bi, the element Sn, a trace of the element Ca and a trace of the element Y are simultaneously dissolved into a matrix to improve the texture characteristics of the deformation alloy so as to develop the high-room-temperature-ductility deformation Mg alloy of which the room temperature elongation can reach upwards of 32%.

Owner:CITIC DICASTAL

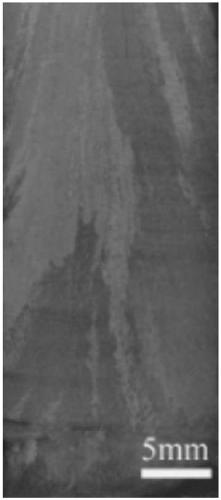

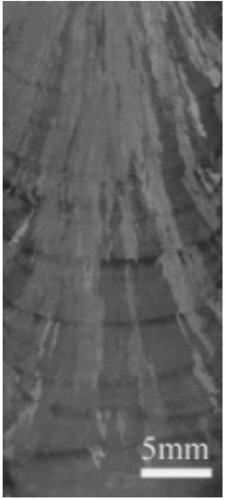

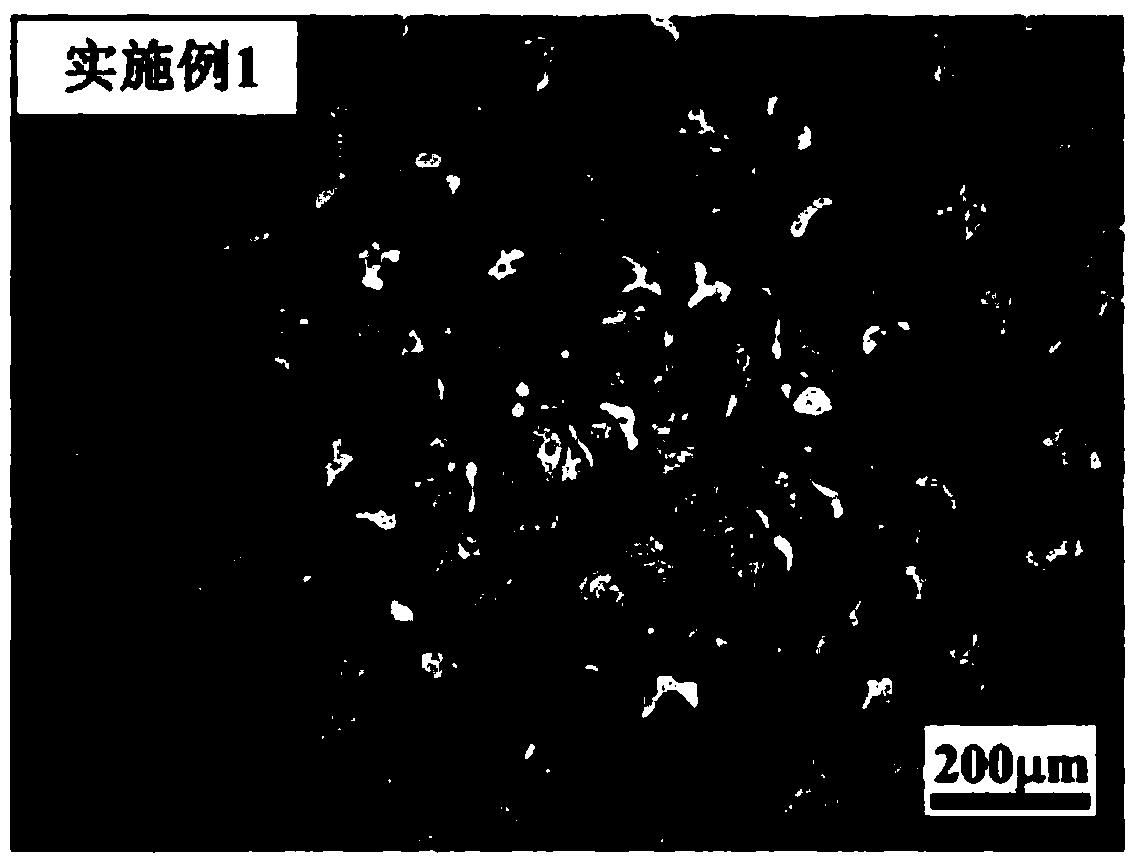

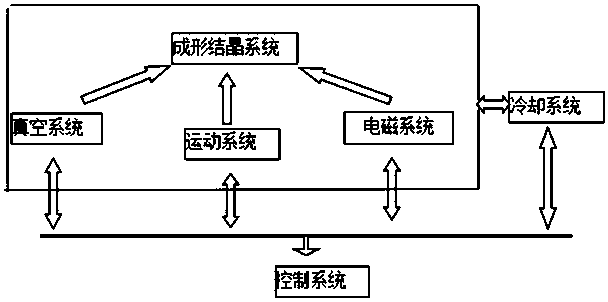

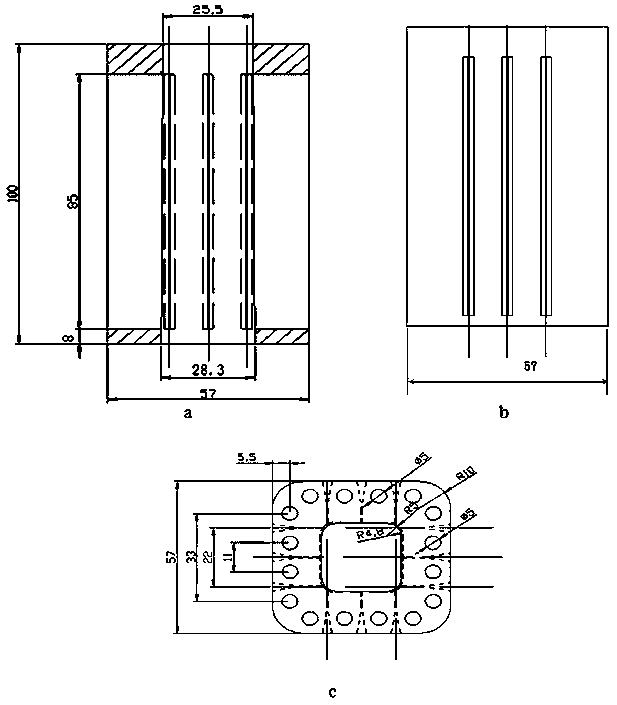

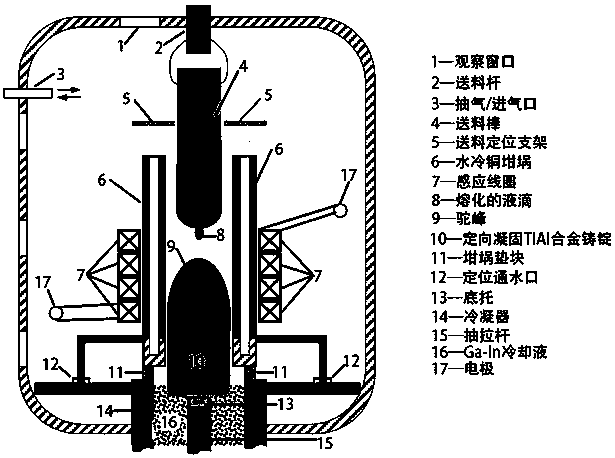

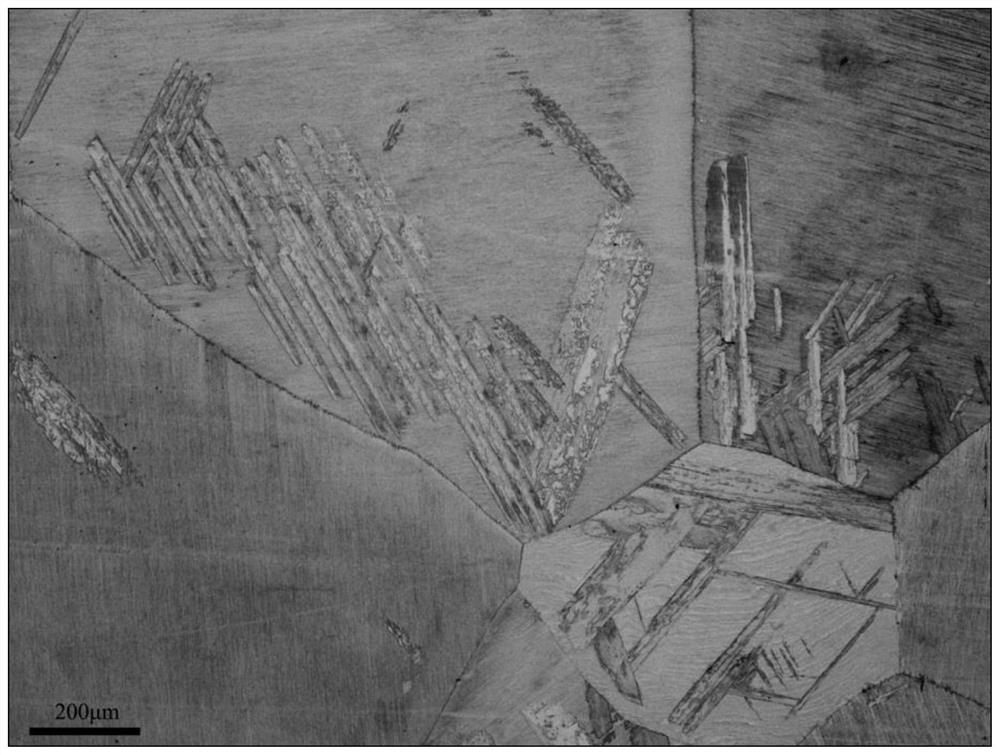

Cold crucible directional solidification method for refining lamellar structure of TiAl alloy

InactiveCN109280809AImprove room temperature plasticityIncrease cooling rateCrucibleRoom temperature

The invention provides a cold crucible directional solidification method for refining the lamellar structure of TiAl alloy, and belongs to the technical field of TiAl alloy treatment. The method comprises the following steps of: preparing an alloy ingot having a composition of Ti-47Al-2Nb-2Cr-0.2C; processing the alloy ingot into a round bar for cold crucible directional solidification experiment;processing the round bar into a TiAl intermetallic compound directional solidification sample in multifunctional cold crucible electromagnetic confinement precise forming directional solidification equipment; carrying out directional solidification experiment on the TiAl intermetallic compound directional solidification sample, and measuring the temperature gradient in a TiAl alloy solid phase inthe experimentation process to obtain a cooling rate; and changing the cooling rate of the directionally solidified TiAl alloy to prepare the directionally solidified TiAl alloy having different lamellar thicknesses. By increasing the drawing rate in the directional solidification process of the cold crucible, the cooling rate of the directionally solidified TiAl alloy is increased, and the lamellar structure of the directionally solidified TiAl alloy is refined without destroying the directional solidification effect of the directionally solidified TiAl alloy; and the cold crucible directional solidification method has very important significance for improving the room-temperature ductility of the TiAl alloy and realizing the engineering application of the TiAl alloy.

Owner:HARBIN INST OF TECH

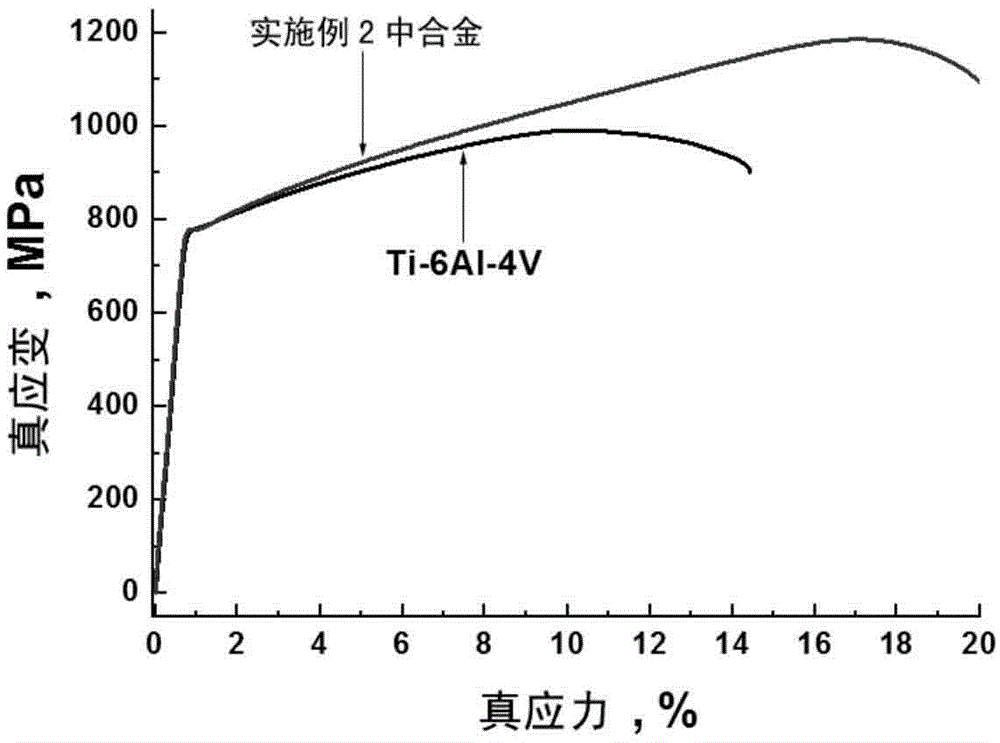

Novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy

The invention discloses a novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy, belonging to the technical field of a new titanium alloy. The novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy comprises the following elements by weight: 3.0-4.5% of Al, 2.0-3.0% of V, 0.5-1.5% of Fe, 0.5-2.0% of Cu and balance of Ti and impurity elements. Compared with Ti-6Al-4V alloy, the characteristics of the new alloy are as follows: (1) the raw materials are low in cost, hot workability plasticity is good, yield is high, and low is significantly reduced; (2) room temperature tensile strength of the new alloy after annealing is equal to that of the Ti-6Al-4V alloy, room temperature plasticity is higher, and the new titanium alloy is suitable for cold processing and warm processing forming of plates and pipes; and (3) corrosion resistance in seawater of the alloy is further improved. The titanium alloy is suitable for producing titanium alloy products such as rods, wires, plates, pipes,and the like, and can be widely used in the technical fields of aviation, spaceflight, ocean, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electromagnetic stirring auxiliary argon arc welding repairing method for cast magnesium alloy aviation component

InactiveCN107511569ALow melting pointReduce intensityWelding/soldering/cutting articlesWelding accessoriesElectromagnetic stirringArc welding

The invention relates to an electromagnetic stirring auxiliary argon arc welding repairing method for a cast magnesium alloy aviation component, and belongs to the technical field of argon arc welding. According to the method, for the cast magnesium alloy aviation component which is cracked and corroded and has other defects after servicing, a welding stick made of the same parent metal or similar components is selected, reasonable electromagnetic stirring and argon arc welding repairing technology parameters are adopted, and cracks and corrosive defects on the component are repaired, wherein the phi of the welding stick ranges from 1.0 mm to 1.6 mm. The repaired part deformation is in the tolerance range, the defects of cracks and incomplete fusion are avoided, and a repairing connector with few metallurgy defects and excellent performance is formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Nano TiC particle toughened Fe-Ni base cast high-temperature alloy for manufacturing vehicular turbosupercharger and preparation method thereof

ActiveCN108842082AGuaranteed StrengthImprove plastic toughnessMachines/enginesEngine componentsSuperalloyToughness

The invention discloses a nano TiC particle toughened Fe-Ni base cast superalloy for manufacturing a vehicular turbosupercharger. The nano TiC particle toughened Fe-Ni base cast superalloy comprises the following chemical components of, by mass percent, less than or equal to 0.10% of C, 11.00-16.00% of Cr, 34.00-45.00% of Ni, 4.00-8.00% of W, 1.80-2.40% of Al, 3.00-5.00% of Ti, 0.01-0.30% of TiC and the balance Fe. According to the nano TiC particle toughened Fe-Ni base cast superalloy for manufacturing the vehicular turbosupercharger, a nano TiC particle modificator is endogenously added to the nano TiC particle toughened Fe-Ni base cast superalloy for toughening a Fe-Ni base cast superalloy. The invention further provides a preparation method of the nano TiC particle toughened Fe-Ni basecast superalloy for manufacturing the vehicular turbosupercharger. A nano TiC iron base intermediate alloy is added to a Fe-Ni base superalloy melt, so that the endogenous nano TiC ceramic particle modificator toughened Fe-Ni base superalloy is obtained, and the plasticity and toughness of the Fe-Ni base cast superalloy are improved on the premise of ensuring the strength of the Fe-Ni base cast superalloy.

Owner:JILIN UNIV

Preparing method of TiAl inter-metallic compound containing rare earth element Er

ActiveCN109022906AImprove room temperature plasticityDoes not destroy the directional solidification effectRare-earth elementChemical compound

The invention discloses a preparing method of a TiAl inter-metallic compound containing the rare earth element Er. The method comprises the following steps: step 1, preparing a Ti-47Al-2Nb-2Cr-0.2Er alloy ingot of which the rear earth element Er content is 0.2at.%; step 2, processing the Ti-47Al-2Nb-2Cr-0.2Er alloy ingot into a round bar for directional solidification experiments; and step 3, preparing the round bar for the directional solidification experiments into a TiAl inter-metallic compound directional solidification sample containing the Er. The rare earth element Er is added into directional solidification TiAl-based alloy, oxygen atoms dissolved in the TiAl-based alloy are cleared by utilizing the rare earth element Er, the directional solidification structure is purified, and the lamellar structure of the directional solidification TiAl alloy is refined. At the same time, the directional solidification effect is not destroyed, and a great role is played on improving the room-temperature ductility of the TiAl alloy and realizing the engineering application of the TiAl alloy.

Owner:HARBIN INST OF TECH

High-temperature molybdenum alloy and preparation method thereof

The invention discloses a high-temperature molybdenum alloy and a preparation method thereof. The molybdenum alloy comprises molybdenum, potassium, silicon and unavoidable impurities, wherein the content of potassium is 500-555 ppm times of that of molybdenum, the content of silicon is 8.58-10.8 ppm times of that of molybdenum. The preparation method comprises the following steps: adding molybdenum dioxide powder into a mixed solution of potassium metasilicate, potassium oxalate and potassium hydroxide to prepare molybdenum-doped powder; reducing the molybdenum-doped powder by heating the molybdenum-doped powder in a hydrogen atmosphere to obtain molybdenum-doped powder; performing isostatic pressing operation on the molybdenum-doped powder to obtain a high-temperature molybdenum pressed product; performing sintering, hot-swage and hot drawing on the high-temperature molybdenum pressed product to obtain the high-temperature molybdenum alloy. The high-temperature molybdenum alloy provided by the invention has the benefits that the doping amount of potassium and silicon in the high-temperature molybdenum alloy is much lower than that in a conventional product; raw materials are easy to obtain, and thus the production cost is reduced.

Owner:SHANGHAI XIPU HANXIN ELECTRONICS TECH

Method for realizing gamma-TiAl alloy refinement by accurately controlling metastable structure stabilization

ActiveCN114214532ARealize continuous controlImprove room temperature plasticityIncreasing energy efficiencyIngotHeat conservation

The invention discloses a method for refining gamma-TiAl alloy by accurately controlling metastable structure stabilization, the gamma-TiAl alloy comprises the following components in atomic percent: 47.0%-48.5% of Al, 1.0%-2.5% of Nb, 0.0%-2.0% of Cr, 1.0%-3.0% of Ta, 0.01%-0.1% of B and the balance of Ti, and the method comprises the following steps: 1, preparing a gamma-TiAl alloy ingot; 2, carrying out hot isostatic pressing and homogenization treatment; thirdly, heating and heat preservation are conducted in an alpha single-phase region and an alpha + gamma two-phase region in sequence, and the heat treatment process is circulated multiple times; and fourthly, heating and heat preservation are conducted in the alpha single-phase region, and the gamma-TiAl alloy of the fine-grain fully lamellar structure is obtained. According to the method, alloy element adding is combined with circulating heat treatment, the metastable structure is continuously regulated and controlled, grain refinement in the gamma-TiAl alloy is achieved, and the room-temperature plasticity, strength and other performance of the gamma-TiAl alloy are improved.

Owner:XI'AN PETROLEUM UNIVERSITY

High plasticity magnesium alloy and preparation method thereof

InactiveCN101392341AImprove coordination and deformation abilitySignificant increase in plasticityStress concentrationUltimate tensile strength

The invention discloses a magnesium alloy with high plasticity, which contains the following components by mass percent: 0.5 percent to 4 percent of Sn, 0.1 percent to 6 percent of Pb, 0.05 percent to 6 percent of Zr, and Mg as the rest. The preparation steps thereof are as follows: materials are proportioned according to the proportion of alloy components, metals proportioned are heated and melted in protective atmosphere of SF6, the mass percent of Zr in Mg-Zr hardener is 30 percent, and the magnesium alloy of high plasticity is obtained after the temperature reaches 700 DEG C to 730 DEG C and is maintained for 5 minutes to 10 minutes. Magnesium can form a compound with both tin and lead, coordinating with deformation and alleviating stress concentration, thus greatly improving the plastic deformation capacity of magnesium alloy, not only effectively enhancing the strength of the magnesium alloy but also increasing the plasticity of the alloy. Under the function of a certain amount of Zr, tin and lead can impose a more obvious effect on the increasing of the plasticity of magnesium. The magnesium alloy of high plasticity only uses general elements of common tin and lead, thereby avoiding the use of a large amount of rare and precious elements, and has simple production and preparation technique, quite low cost and high normal-temperature plasticity.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

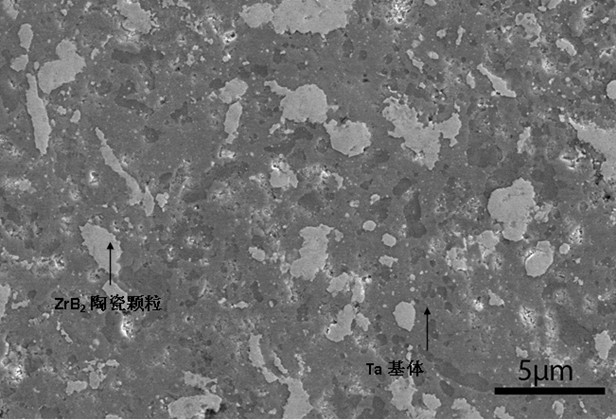

Ta-Hf-Zr-ZrB2 alloy bar and preparation method thereof

ActiveCN112281039AApplications with tubingImprove mechanical propertiesOxidation resistantUltimate tensile strength

The invention provides a Ta-Hf-Zr-ZrB2 alloy bar. The Ta-Hf-Zr-ZrB2 alloy bar is prepared from the following raw materials in percentage by mass: 3-9% of Hf, 4-8% of Zr, 3-7% of ZrB2, and the balanceTa and inevitable impurities. The invention further provides a method for preparing the alloy bar. The method comprises the following steps that: (1) all the raw materials are weighed according to themass percentages, and are ball-milled and uniformly mixed under argon protection to obtain mixed powder; (2) the mixed powder is pressed to obtain a blank; (3) the blank is put in a shell; and the shell is sealed after vacuumizing; (4) the hot isostatic pressing sintering is performed to obtain a Ta-Hf-Zr-ZrB2 alloy sintered body; and (5) the hot extrusion is performed to obtain the Ta-Hf-Zr-ZrB2alloy bar. The alloy bar is excellent in high-temperature oxidation resistance, room-temperature plasticity and tensile strength and excellent in fatigue strength, high-temperature strength and superplasticity, and can be applied to high-temperature structural parts.

Owner:西安鑫昌机电设备有限责任公司

Ti2AlNb particle plasticized TiAl-based composite material and preparation method thereof

ActiveCN112981156AImprove stabilityImprove room temperature plasticityAdditive manufacturing apparatusNew materialsAdditive layer manufacturing

The invention belongs to the technical field of new material design and additive manufacturing. The invention provides a Ti2AlNb particle plasticized TiAl-based composite material and a preparation method thereof. The composite material is composed of, by volume, 1.0%-10.0% of Ti2AlNb and 90.0%-99.0% of TiAl alloy, wherein the TiAl alloy is composed of, by atomic percent, 45%-48.5% of Ti, 45%-48.5% of Al and 3%-5% of other alloy elements, the alloy elements are the combination of 2-4 elements of Cr, Nb, V, Mn, Mo and C, and the atomic percent of C in the TiAl alloy is smaller than or equal to 0.15%. The preparation method comprises the following steps of carrying out high-temperature heating treatment on a substrate before forming; and preparing by adopting a synchronous high-temperature heating and electromagnetic stirring assisted laser direct deposition method; According to the TiAl-based composite material and the preparation method, grain refinement of the material is achieved, the room-temperature plasticity is greatly improved, and the TiAl-based composite material and the preparation method have important significance in promoting development and application of the TiAl-based material in engine parts.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

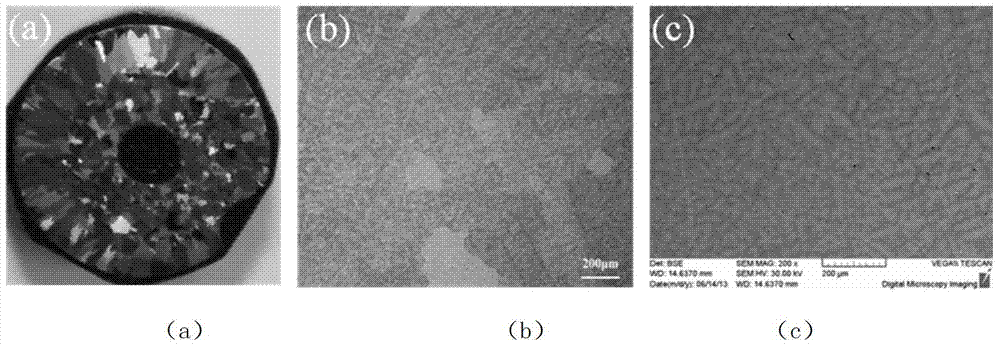

Orientation-enhanced tungsten-containing high-niobium-titanium-aluminium alloy and preparation method thereof

The invention discloses an orientation-enhanced tungsten-containing high-niobium-titanium-aluminium alloy and a preparation method thereof. The alloy comprises the following components: 45.0-48.0% of Al, 5.0-8.0% of Nb, 0.2-0.8% of W, and the balance of Ti. The preparation method disclosed by the invention comprises the following steps of preparing a button ingot by utilizing electric arc melting; performing suspension smelting and suction casting to obtain a cylindrical test bar; and performing orientated solidification on the test bar by a Bridgeman method to obtain the orientation-enhanced tungsten-containing high-niobium-titanium-aluminium alloy. The alloy has the advantages that the alloy has a fine and uniform fully lamellar structure, and the included angle of the final lamellar structure direction and the preferentially growing direction of orientated solidification is 0 degree or close to 0 degree.

Owner:NANJING UNIV OF SCI & TECH

Method for realizing near alpha titanium alloy dual-property employing local loading process

The invention discloses a method for realizing near alpha titanium alloy dual-property employing local loading process, which divides a workpiece into an A loading zone and a B loading zone, and a C zone is the transition zone between the A loading zone and the B loading zone, wherein the A loading zone is a large deformation zone while the B loading zone is a small deformation zone, and the method is realized through the isothermal local loading with two passes and two loading steps in each pass. The specific shaping process comprises blank forging, preparation of preforming billet, isothermal local loading, finishing, thermal treatment and nondestructive testing. The shaped workpiece can obtain the tri-modal microstructure with high room temperature plasticity, high strength and long fatigue life and 20% equiaxial alpha phase content in the A loading zone, the lamellar microstructure with high tensile strength at high temperature, high fracture toughness and strong creep deformationresistance in the B loading zone, and the bimodal microstructure with higher equiaxial alpha phase content in the C transition zone than in the A loading zone so as to further realize the dual-property of the integral component; therefore, the method is a simple and efficient shaping method for the integral dual-property component.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com