Ta-Hf-Zr-ZrB2 alloy bar and preparation method thereof

An alloy bar and raw material technology, which is applied in the field of Ta-Hf-Zr-ZrB2 alloy bar and its preparation, can solve the problem of not being able to greatly improve mechanical properties, achieve good high-temperature oxidation resistance, improve room temperature plasticity, and inhibit crystallinity. The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

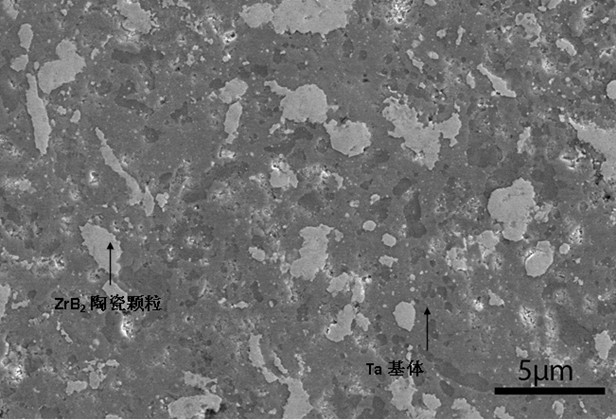

Image

Examples

Embodiment 1

[0024] In this embodiment Ta-Hf-Zr-ZrB 2 Alloy rods are made of raw materials with the following mass percentages: Hf 6%, Zr 6%, ZrB 2 5%, the balance is Ta and unavoidable impurities; the raw materials are all powdery raw materials, that is: Hf is Hf powder with a particle size not greater than 20 μm, Zr is Zr powder with a particle size not greater than 20 μm, ZrB 2 ZrB with a particle size not greater than 10 μm 2 Powder, Ta is Ta powder with a particle size not greater than 10 μm, of which Hf powder, Zr powder and ZrB powder 2 The mass purity of Ta powder is not less than 99.0%, and the mass purity of Ta powder is not less than 99.9%.

[0025] In this embodiment Ta-Hf-Zr-ZrB 2 The preparation method of alloy bar comprises the following steps:

[0026] Step 1, weighing each raw material according to the mass percentage, and then ball milling and mixing the weighed raw materials evenly under the protection of argon to obtain a mixed powder;

[0027] Step 2, using a hydr...

Embodiment 2

[0034] In this embodiment Ta-Hf-Zr-ZrB 2 Alloy rods are made of raw materials with the following mass percentages: Hf 6%, Zr 6%, ZrB 2 5%, the balance is Ta and unavoidable impurities; the raw materials are all powdery raw materials, that is: Hf is Hf powder with a particle size not greater than 20 μm, Zr is Zr powder with a particle size not greater than 20 μm, ZrB 2 ZrB with a particle size not greater than 10 μm 2 Powder, Ta is Ta powder with a particle size not greater than 10 μm, of which Hf powder, Zr powder and ZrB powder 2 The mass purity of Ta powder is not less than 99.0%, and the mass purity of Ta powder is not less than 99.9%.

[0035] In this embodiment Ta-Hf-Zr-ZrB 2 The preparation method of alloy bar comprises the following steps:

[0036] Step 1, weighing each raw material according to the mass percentage, and then ball milling and mixing the weighed raw materials evenly under the protection of argon to obtain a mixed powder;

[0037] Step 2, using a hydr...

Embodiment 3

[0043] In this embodiment Ta-Hf-Zr-ZrB 2 Alloy rods are made of raw materials with the following mass percentages: Hf 6%, Zr 6%, ZrB 2 5%, the balance is Ta and unavoidable impurities; the raw materials are all powdery raw materials, that is: Hf is Hf powder with a particle size not greater than 20 μm, Zr is Zr powder with a particle size not greater than 20 μm, ZrB 2 ZrB with a particle size not greater than 10 μm 2 Powder, Ta is Ta powder with a particle size not greater than 10 μm, of which Hf powder, Zr powder and ZrB powder 2 The mass purity of Ta powder is not less than 99.0%, and the mass purity of Ta powder is not less than 99.9%.

[0044] In this embodiment Ta-Hf-Zr-ZrB 2 The preparation method of alloy bar comprises the following steps:

[0045] Step 1, weighing each raw material according to the mass percentage, and then ball milling and mixing the weighed raw materials evenly under the protection of argon to obtain a mixed powder;

[0046] Step 2, using a hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com