Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "High temperature capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

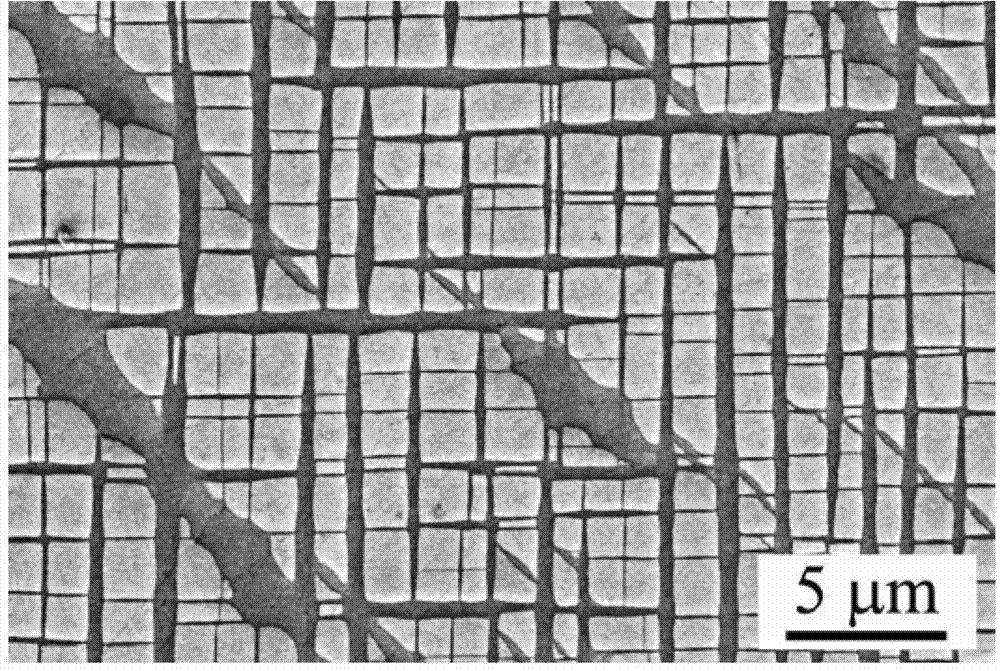

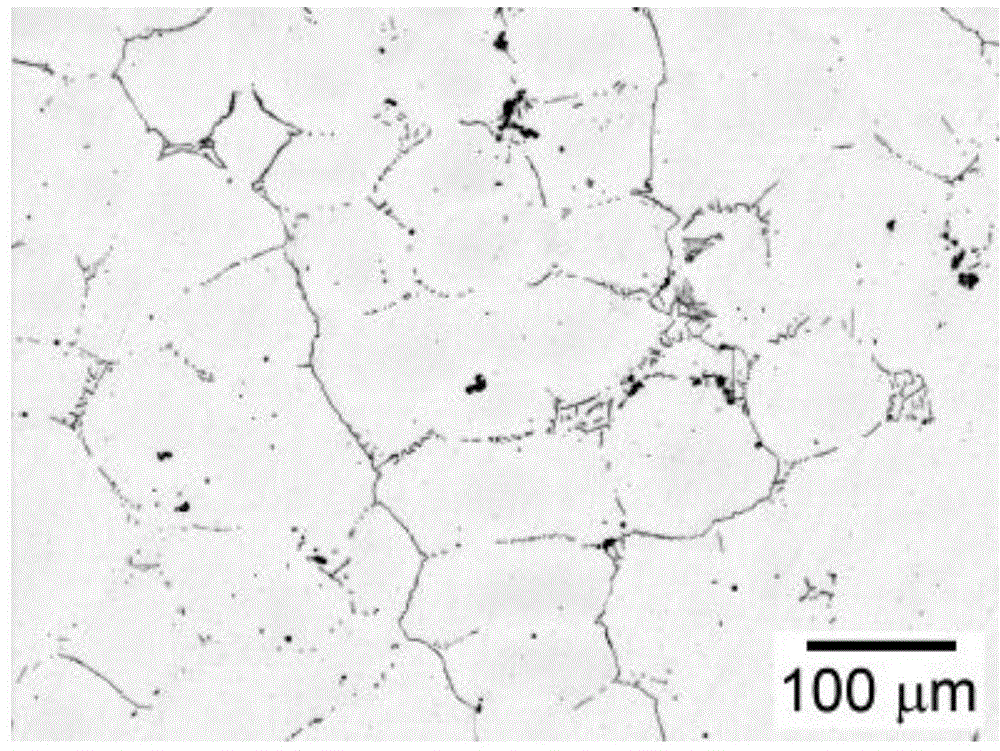

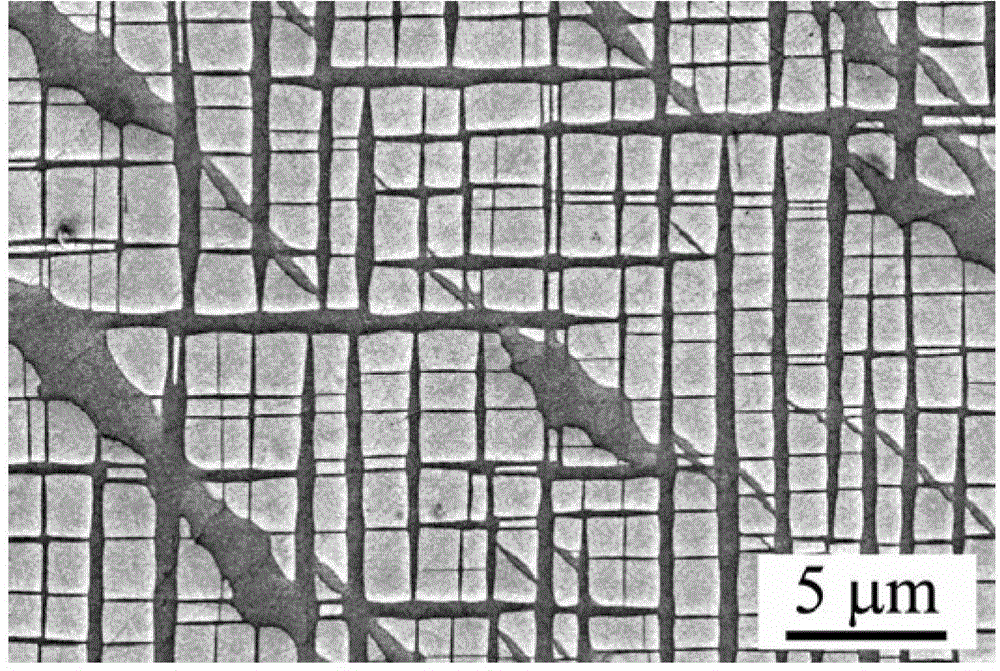

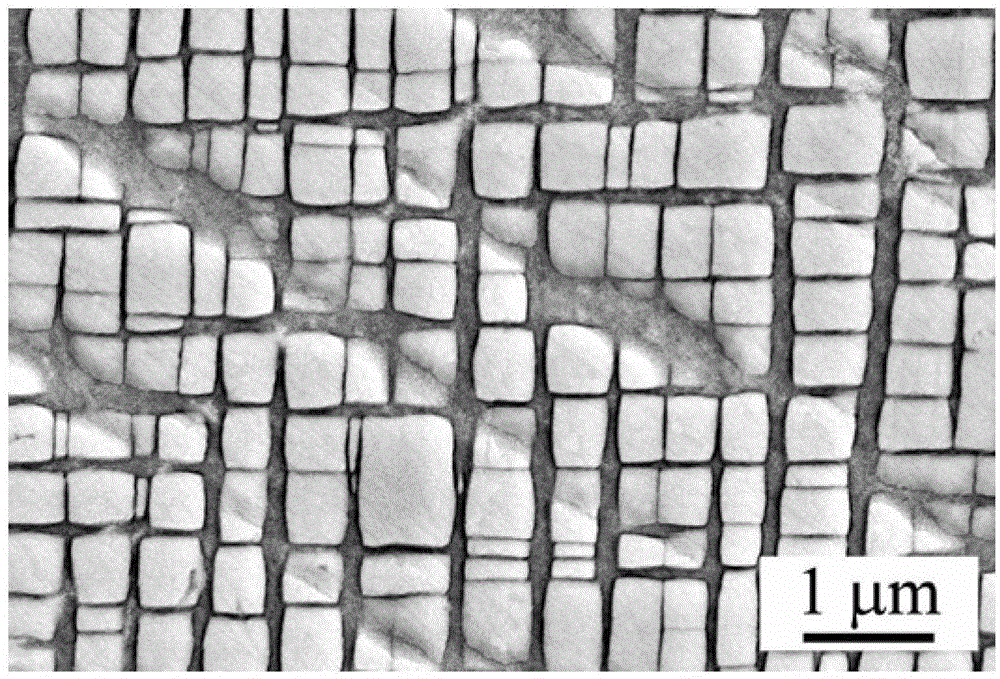

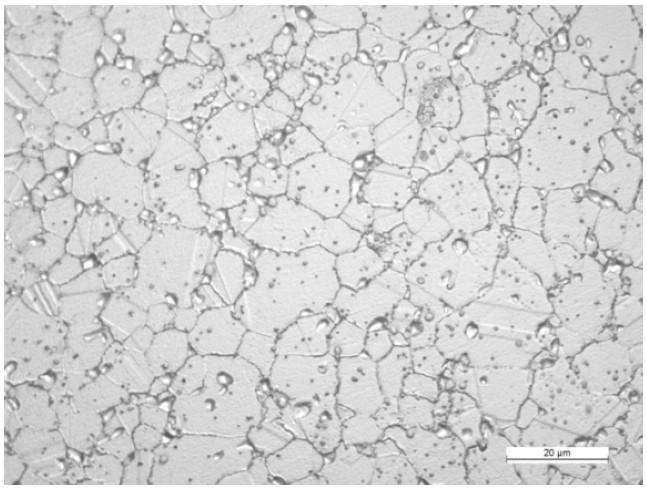

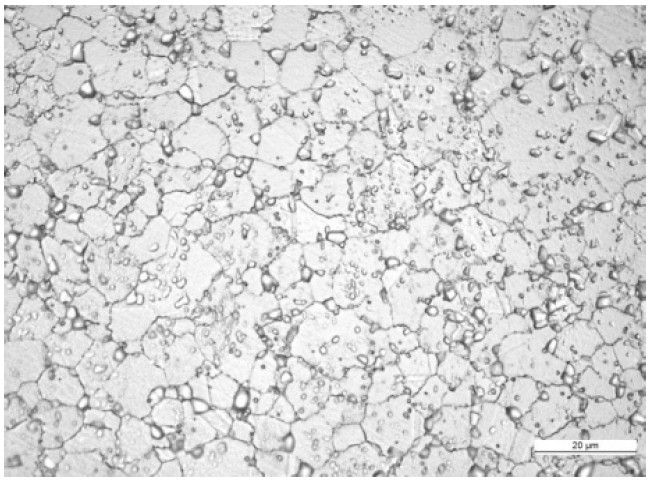

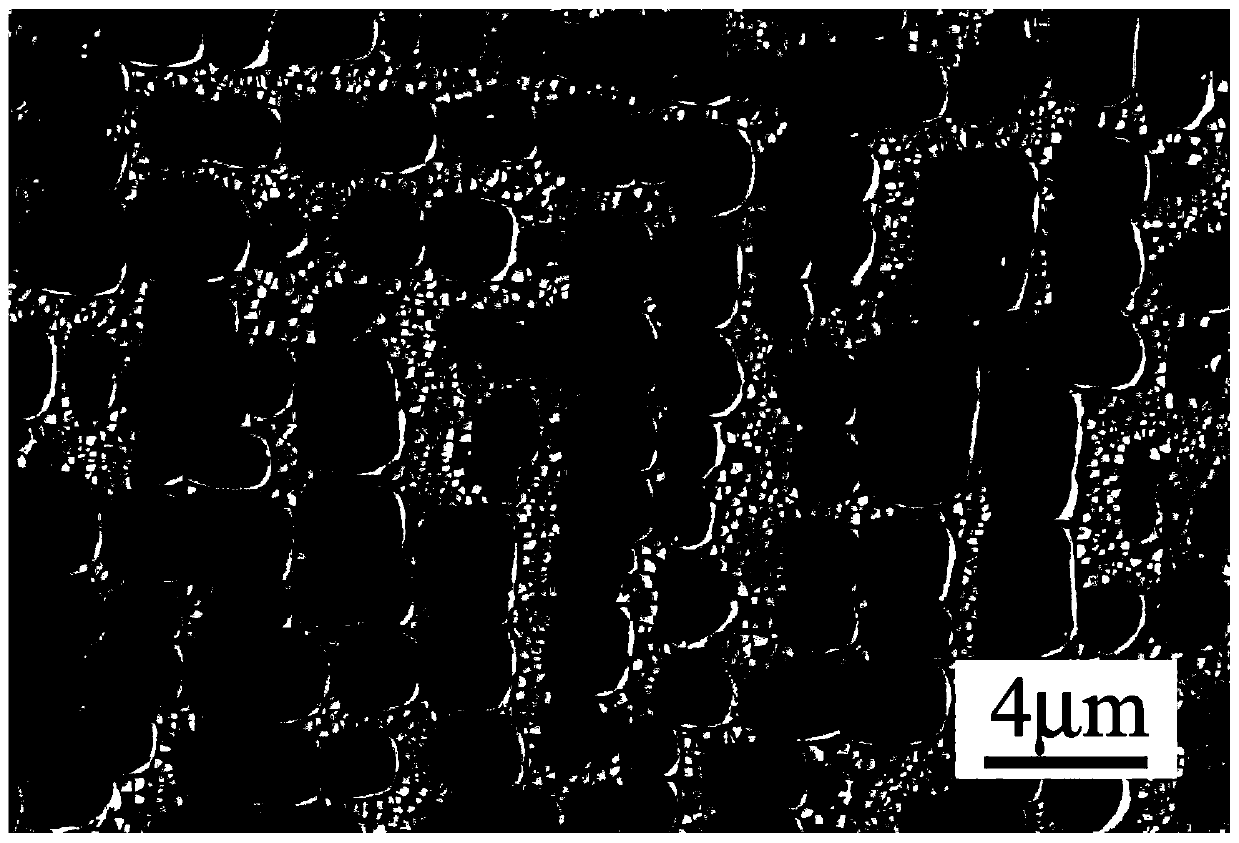

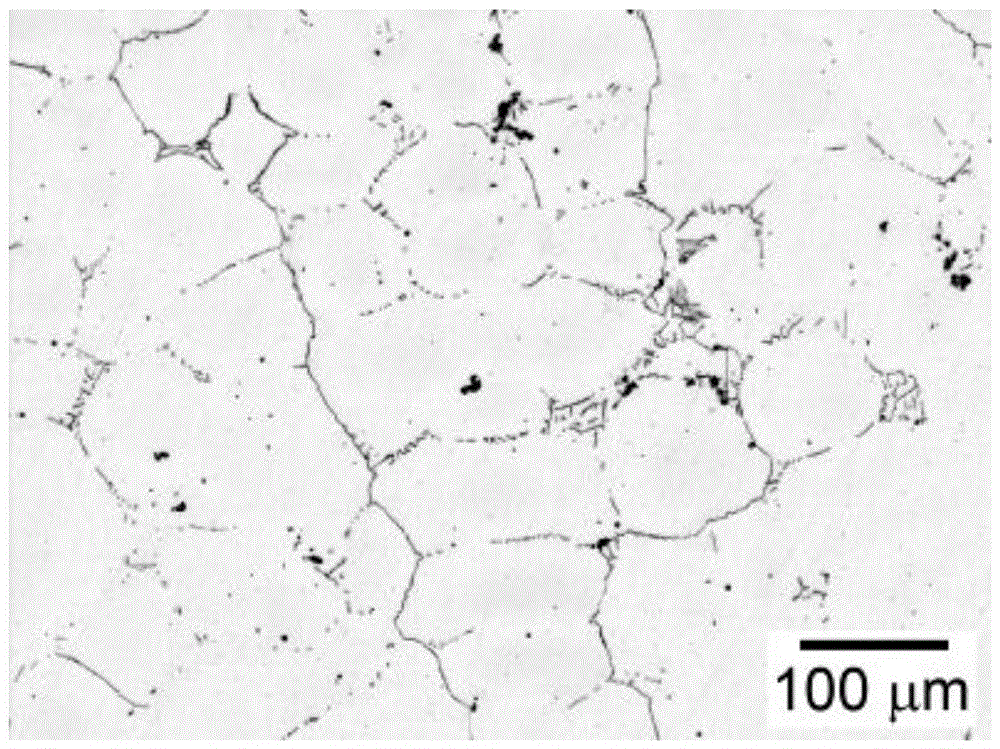

The invention belongs to the technical field of new materials, and relates to a gamma'-phase high-temperature-stability cobalt-base high-temperature alloy with gamma / gamma' two-phase structure, which is a candidate material for high-temperature hot end components of gas turbines for aviation, spaceflight, vessels, power generation and the like. The alloy comprises the following components in atomic percentage: 4-12% of Al, 4-12% of W, 1-4% of Ta, 1-6% of Ti, 0-10% of Cr, 0-3% of Mo, 0-2% of Hf, 0-1% of C, 0-1% of B and the balance of Co. The preparation method comprises the following steps: smelting in a vacuum induction furnace, carrying out solid solution heat treatment at 1250-1300 DEG C, and carrying out aging heat treatment at 1000-1100 DEG C. After carrying out L12-type gamma'-phase high-temperature reinforcement, the gamma' shape is cubic, the volume percent is higher than 60%, and the gamma'-phase is uniformly distributed in the gamma-phase. Compared with the traditional cobalt-base high-temperature alloy, the alloy provided by the invention has higher application temperature; and compared with the recently developed similar cobalt-base alloys, the alloy provided by the invention has higher gamma'-phase solution temperature and gamma / gamma' two-phase structure stable existence temperature.

Owner:UNIV OF SCI & TECH BEIJING

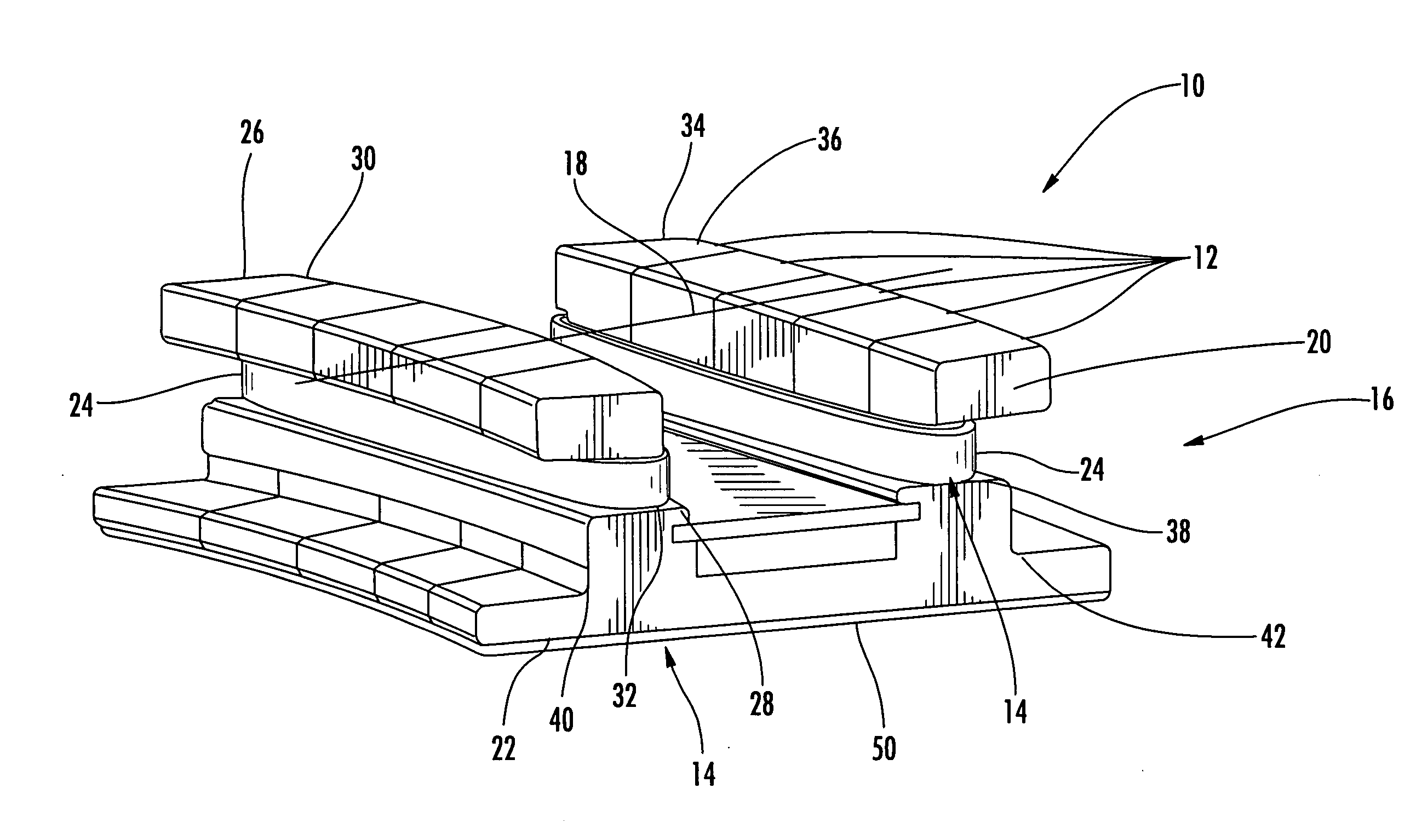

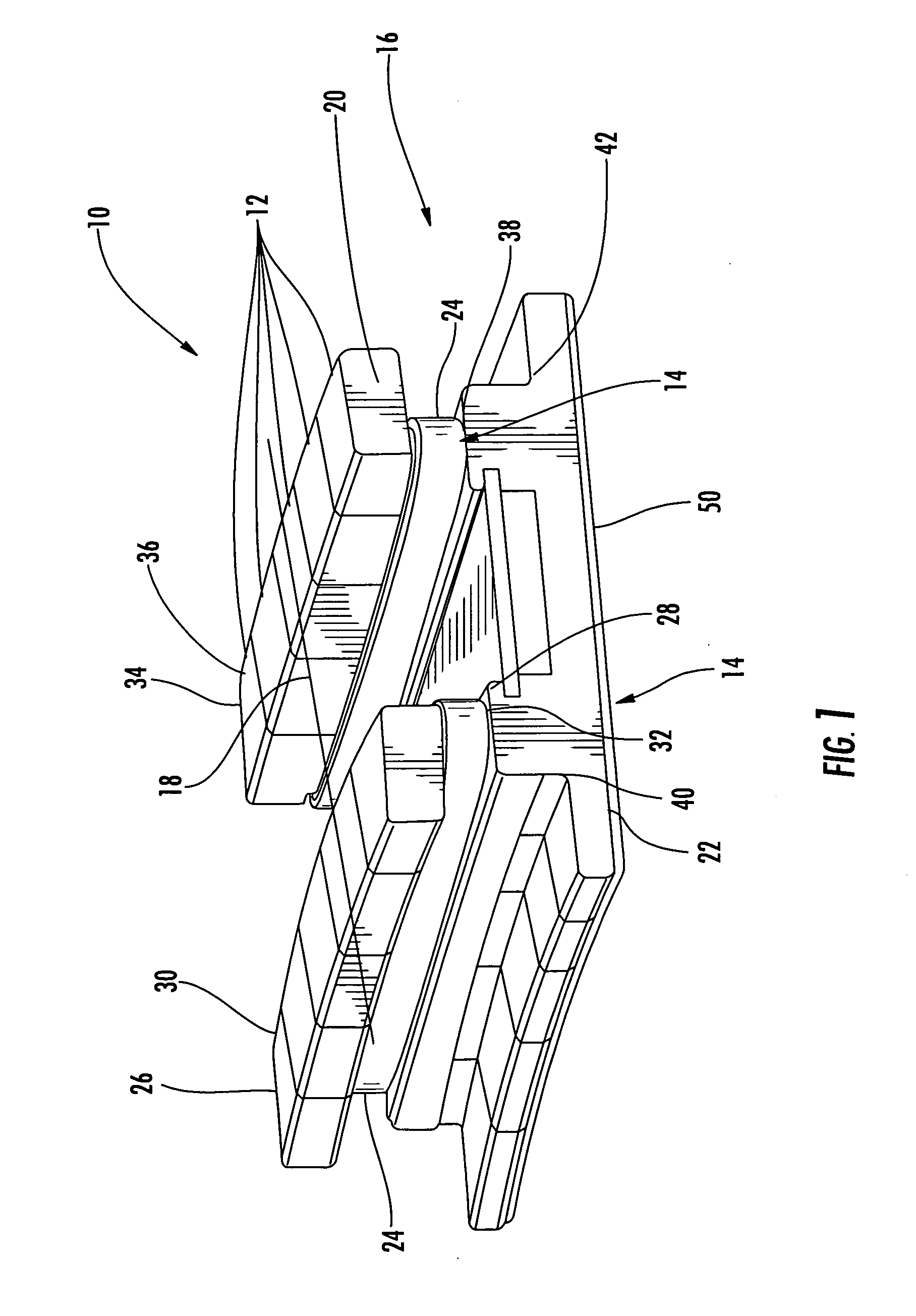

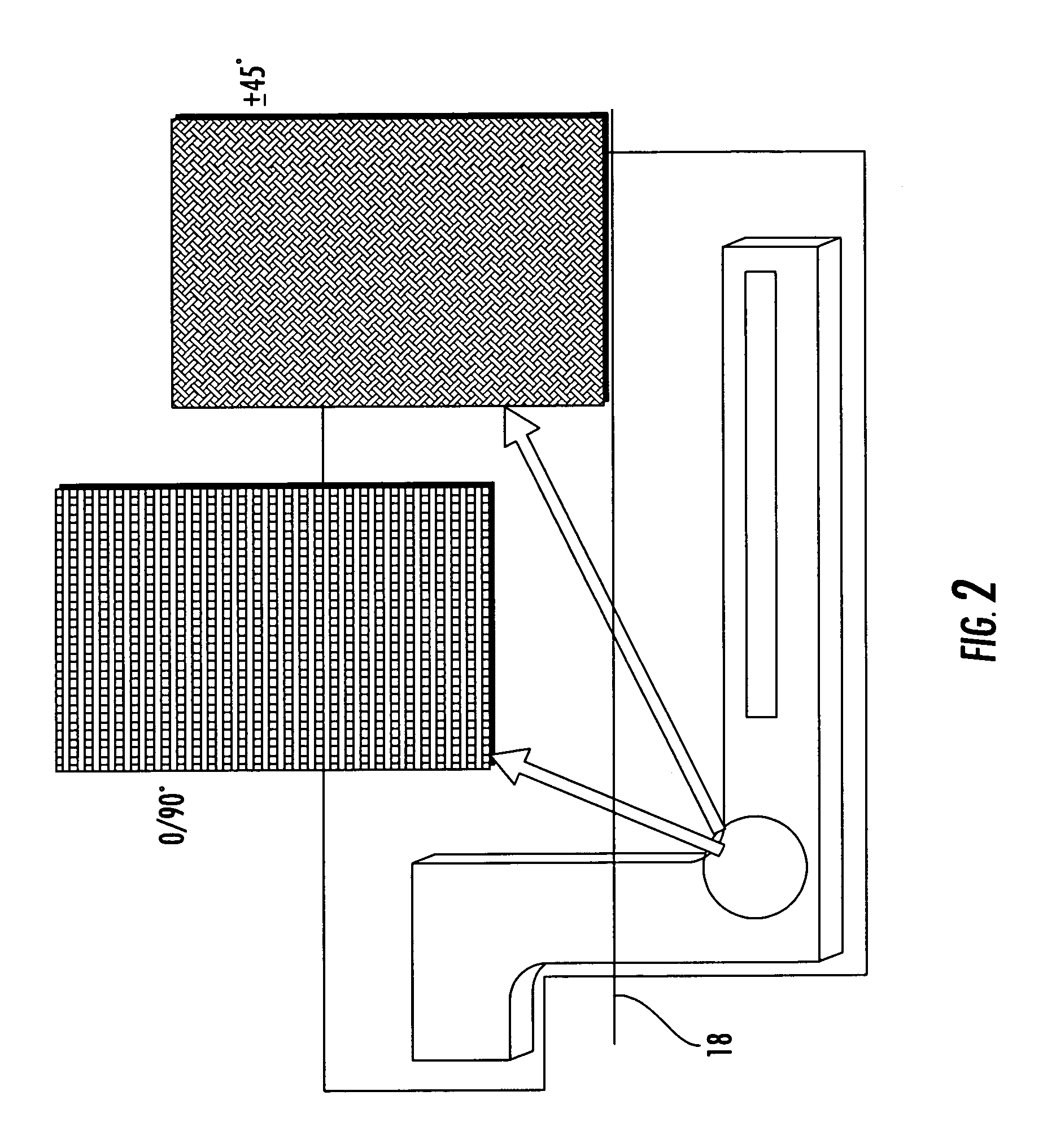

Stacked laminate fiber wrapped segment

InactiveUS20080107521A1High strengthHigh temperature capacityPump componentsBlade accessoriesTurbineOverwrap

A ceramic ring segment for a turbine engine that may be used as a replacement for one or more metal components. The ceramic ring segment may be formed from a plurality of ceramic plates, such as ceramic matrix composite plates, that are joined together using a strengthening mechanism to reinforce the ceramic plates while permitting the resulting ceramic article to be used as a replacement for components for turbine systems that are typically metal, thereby taking advantage of the properties provided by ceramic materials. The strengthening mechanism may include a ceramic matrix composite overwrap or plurality of overwraps designed to help prevent delamination of the ceramic plates when the ceramic article is in use by placing the plates in compression.

Owner:SIEMENS ENERGY INC

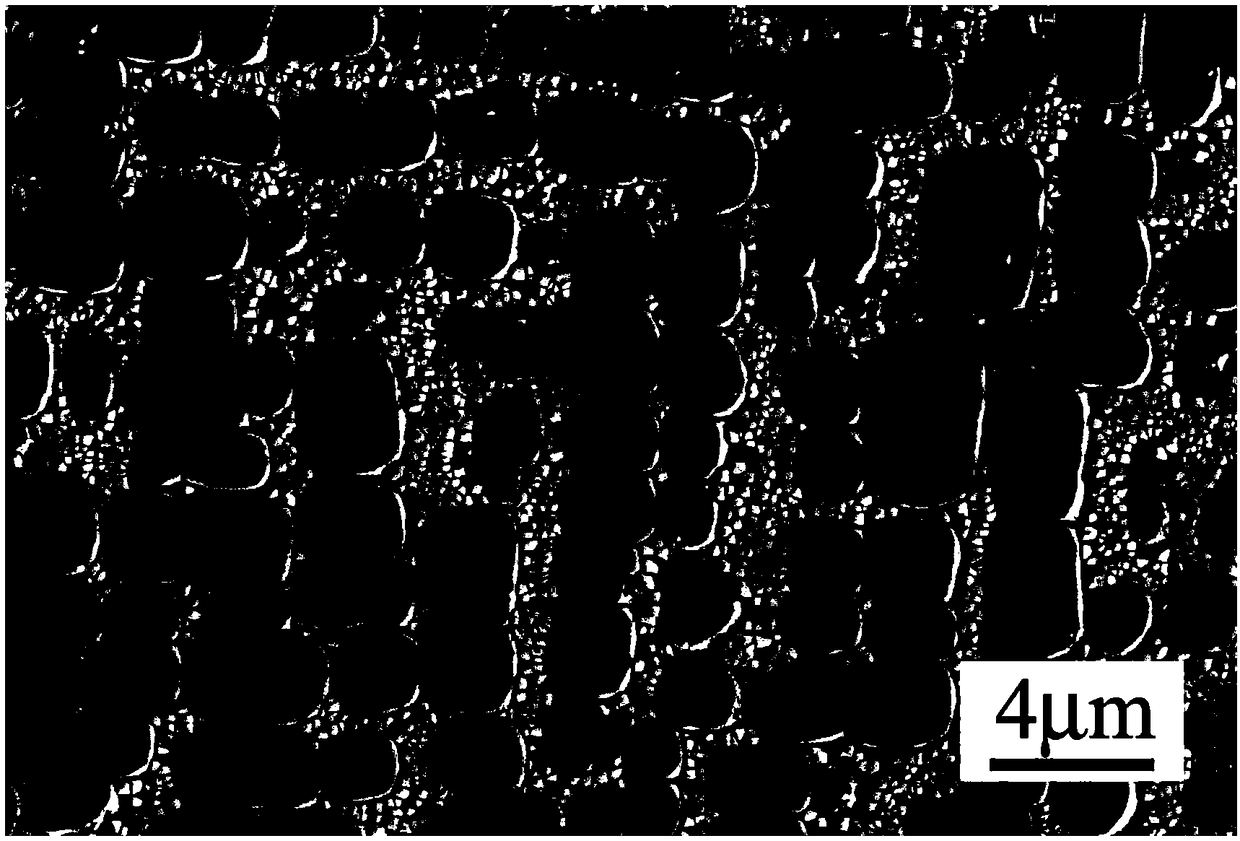

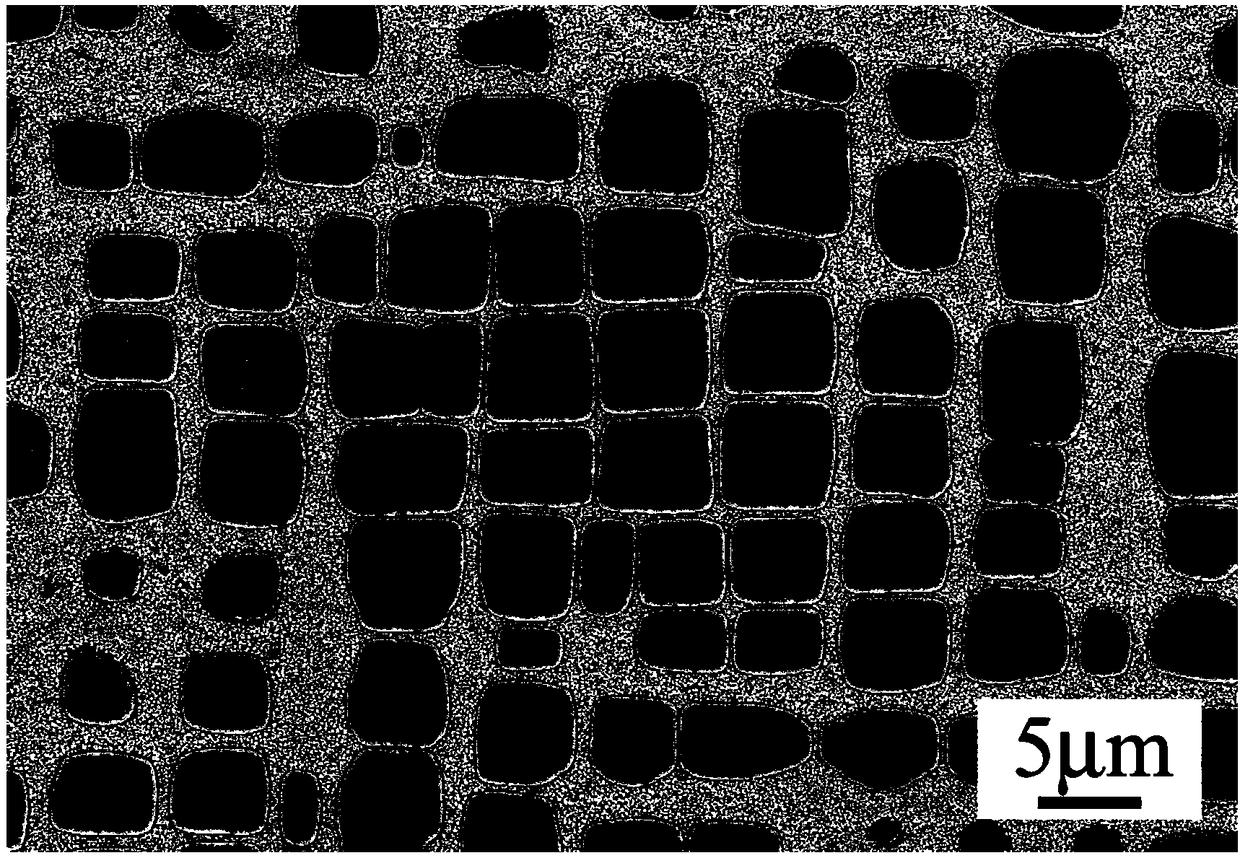

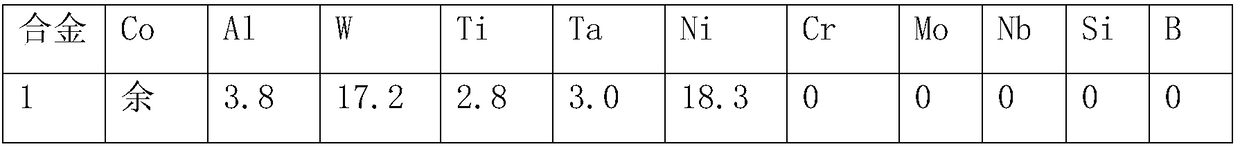

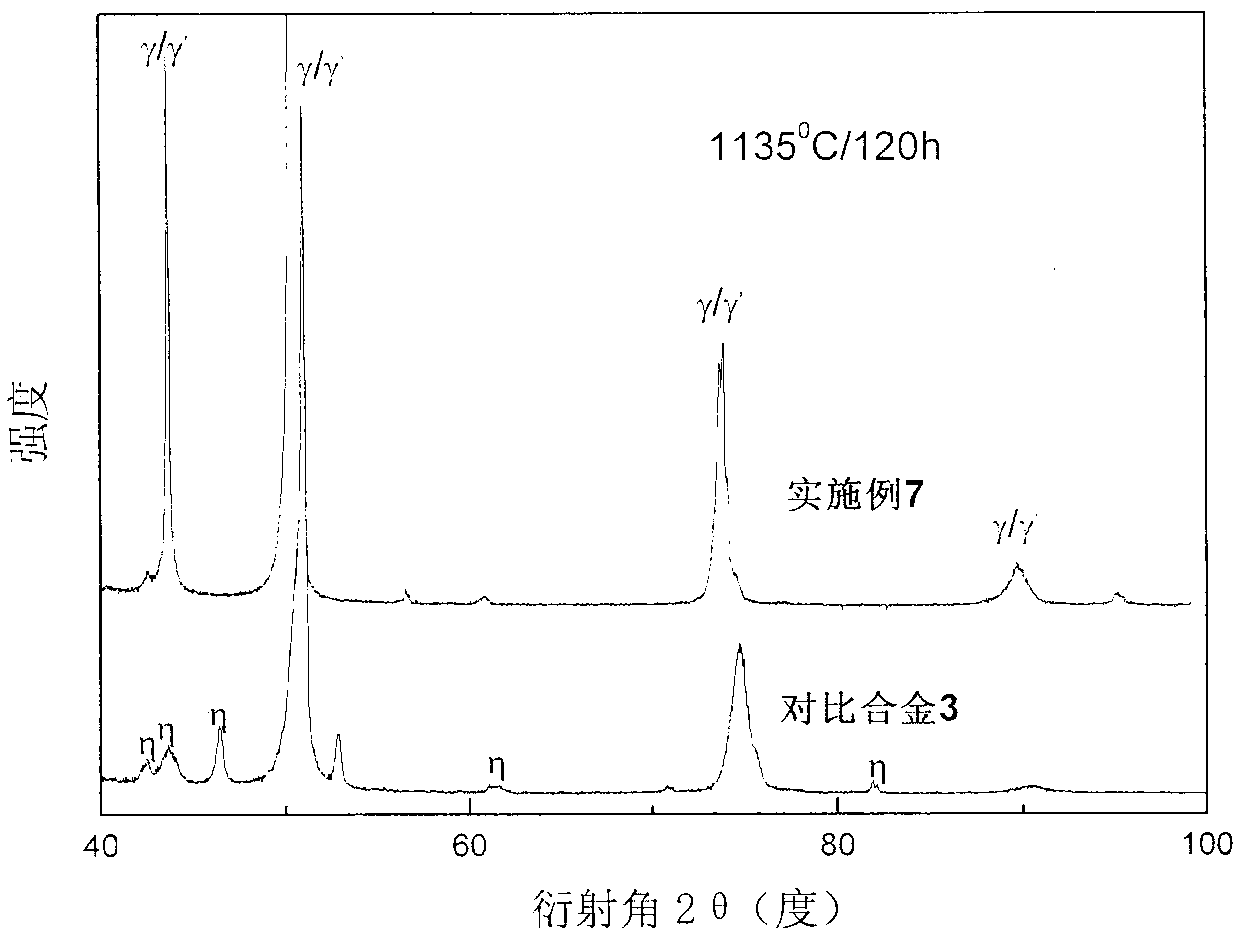

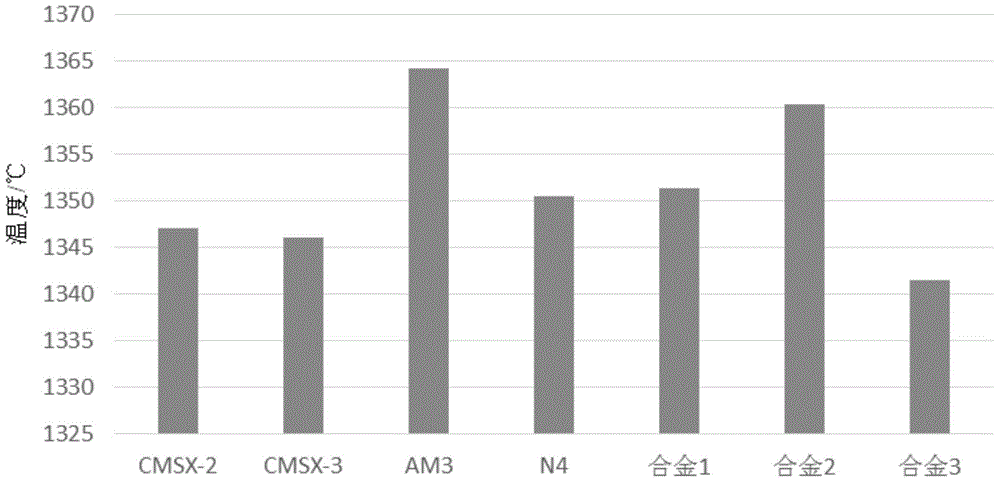

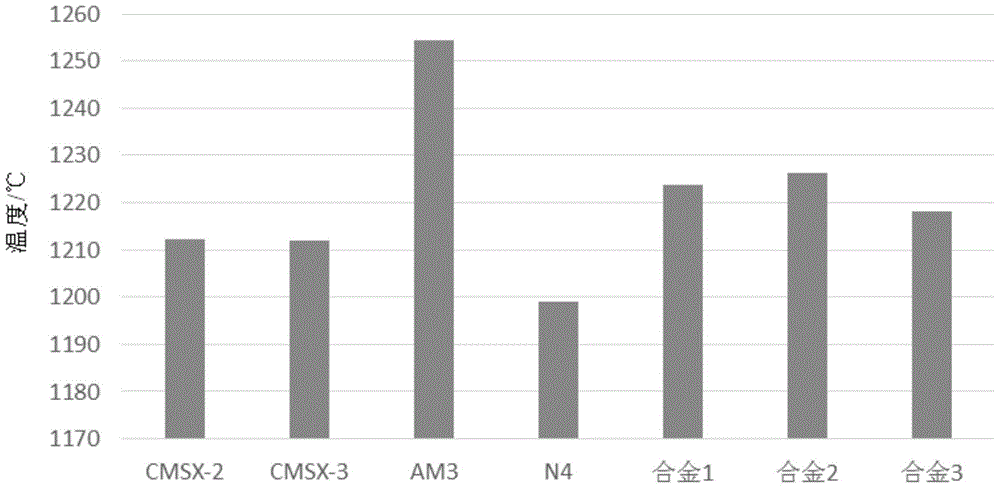

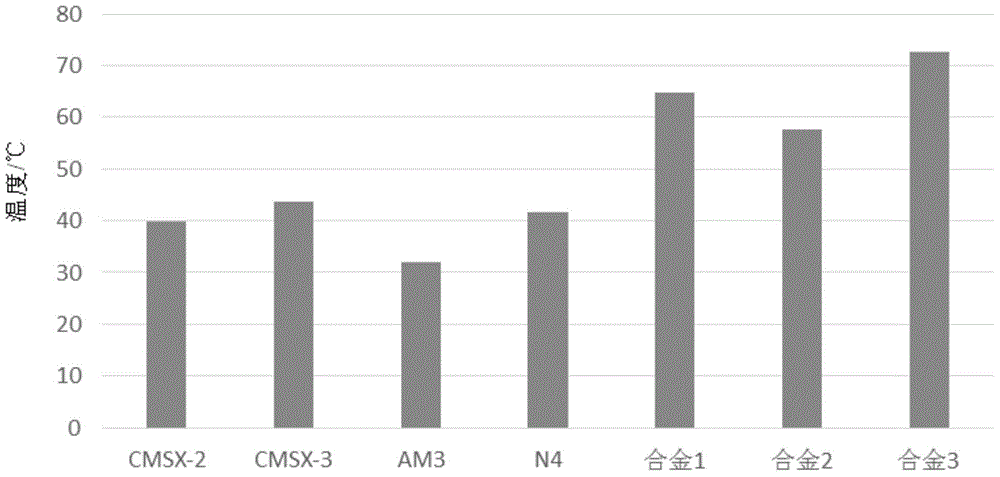

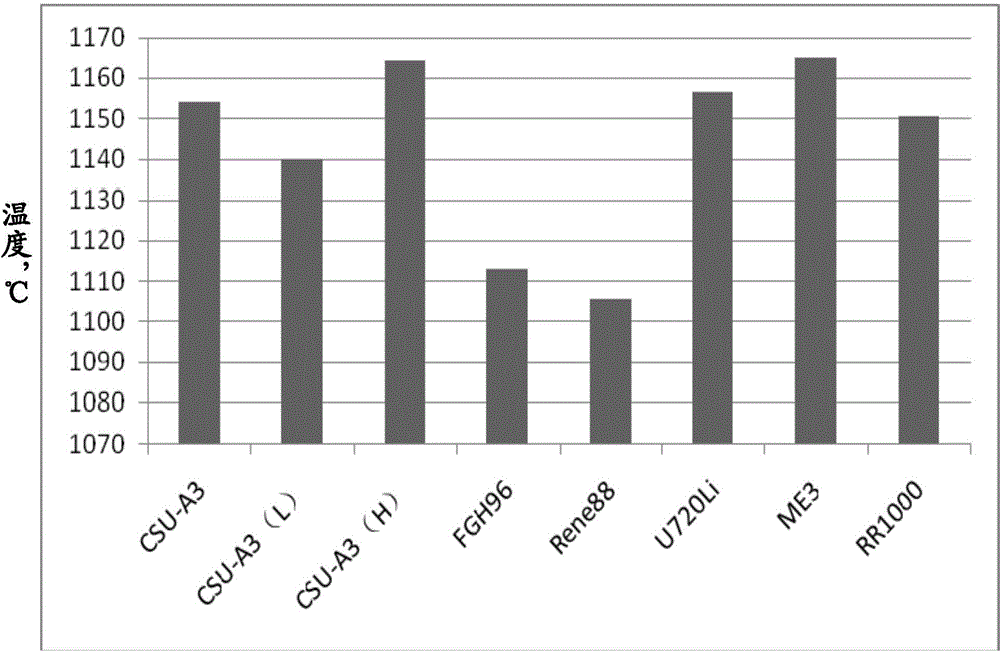

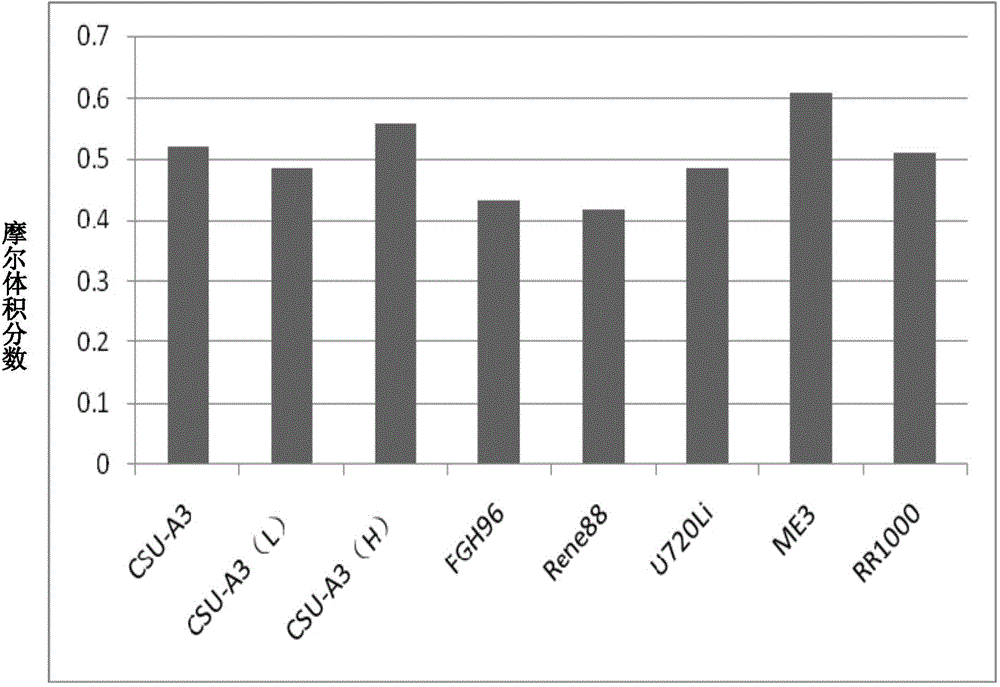

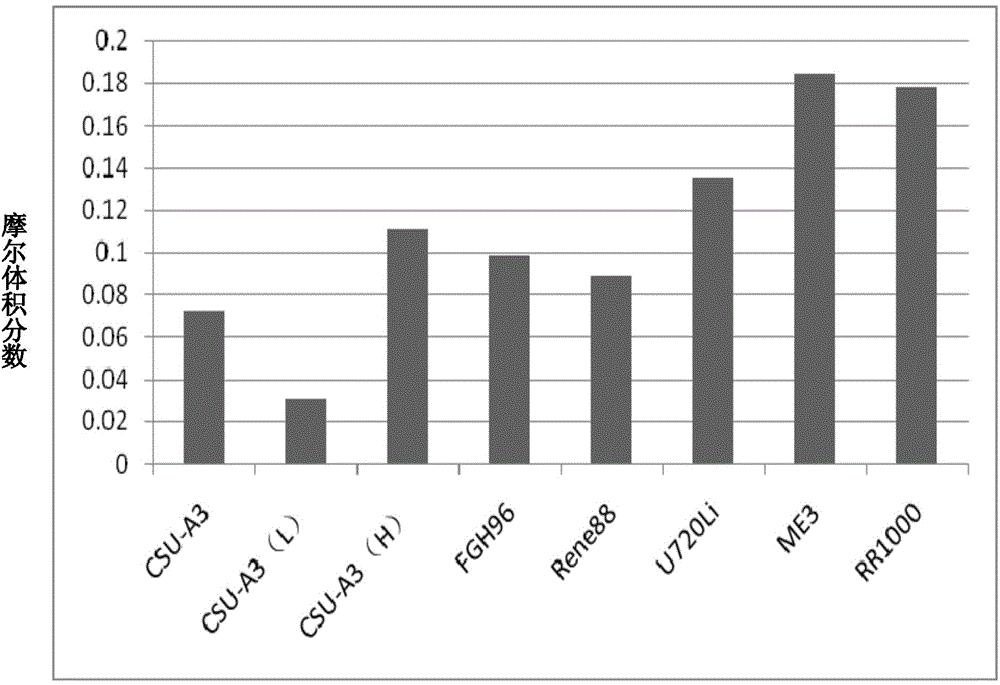

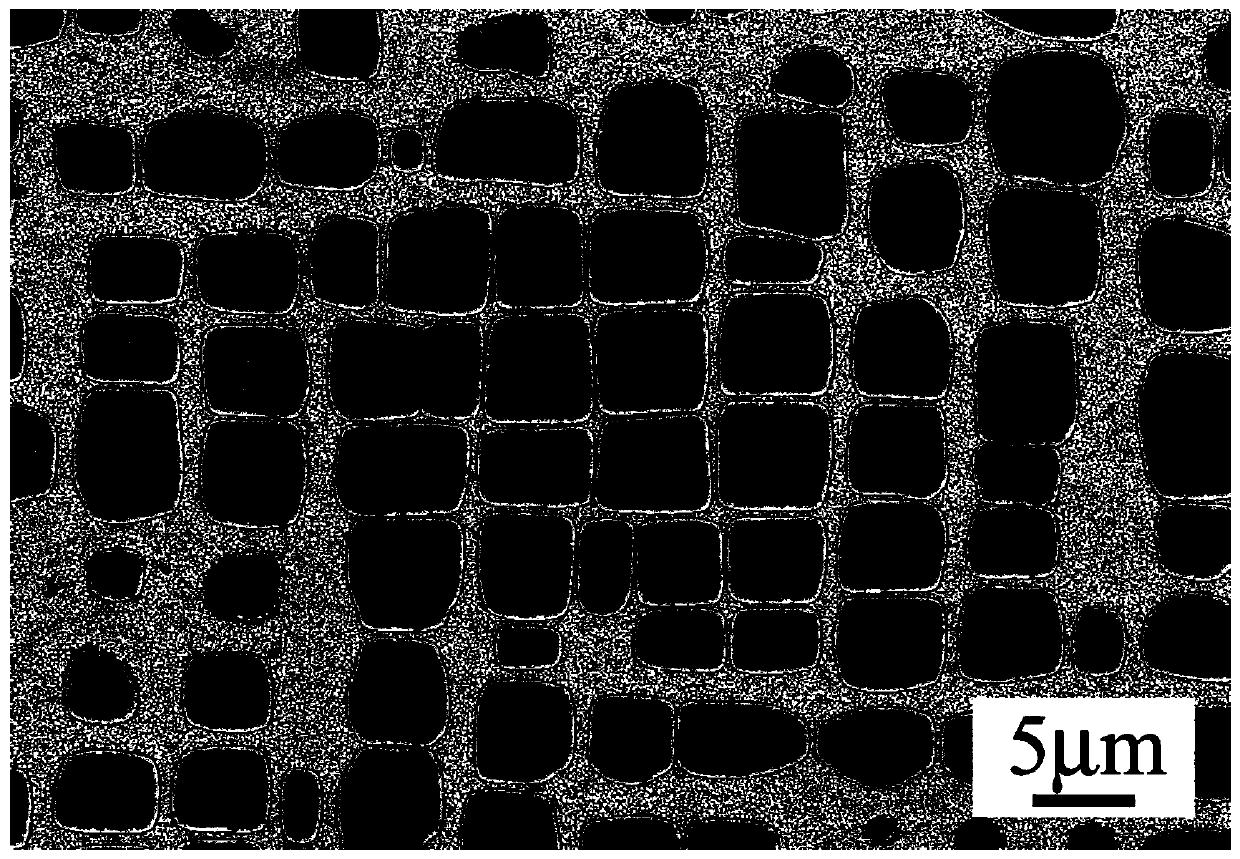

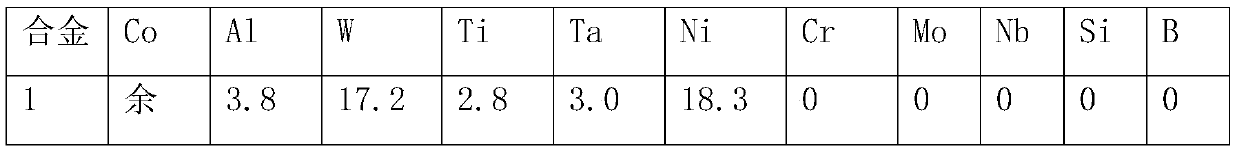

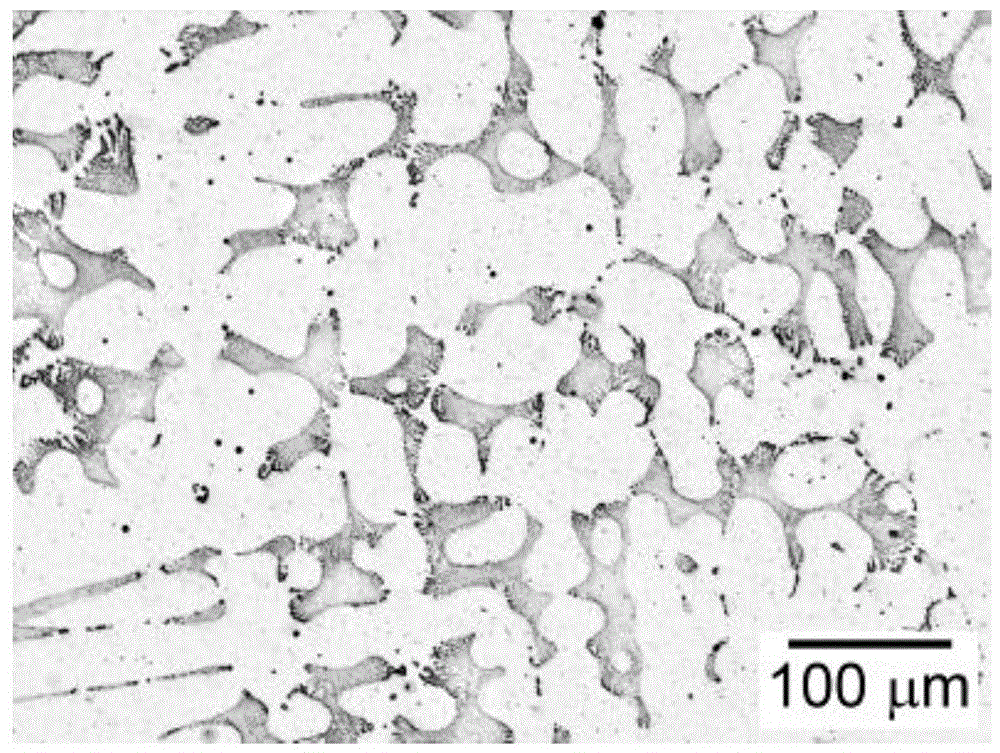

Gamma'-phase intensified cobalt-based superalloy and preparation method thereof

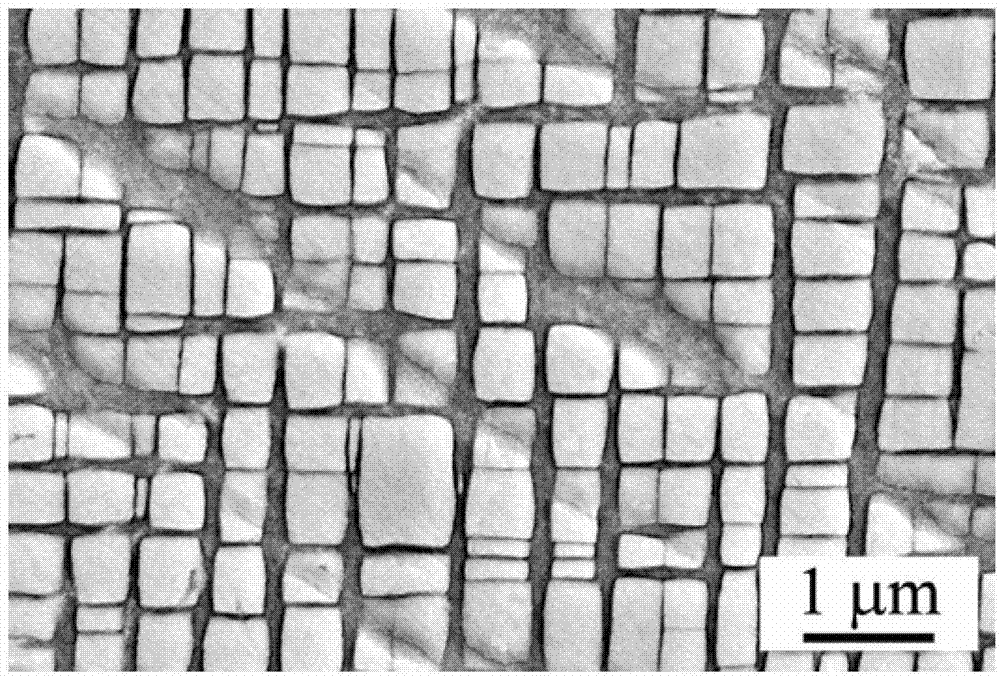

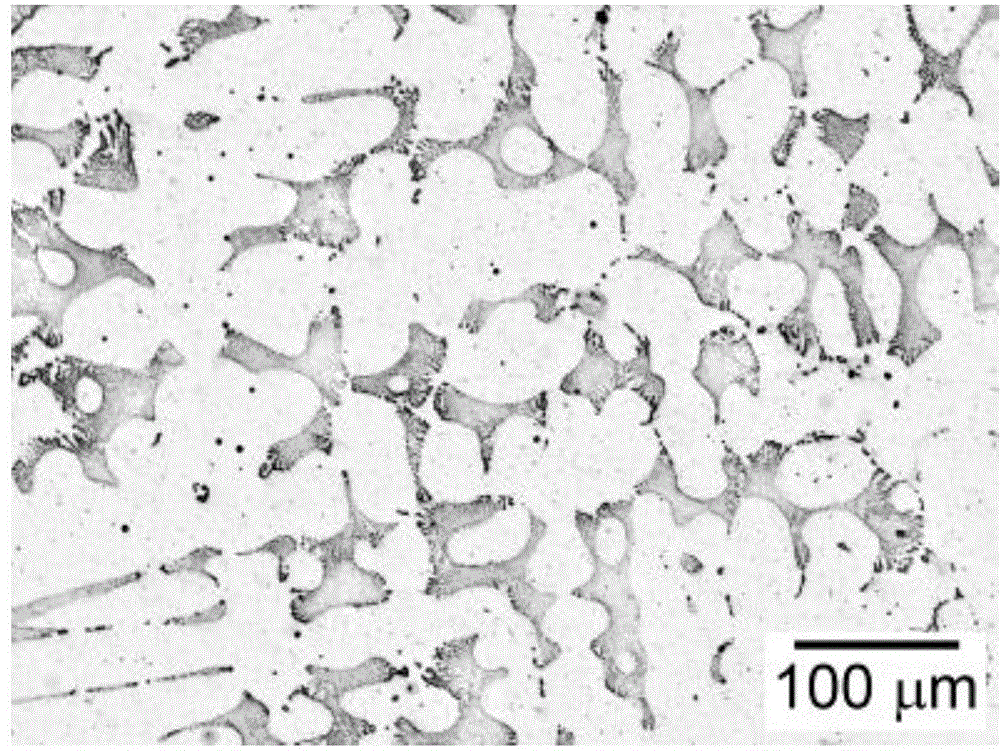

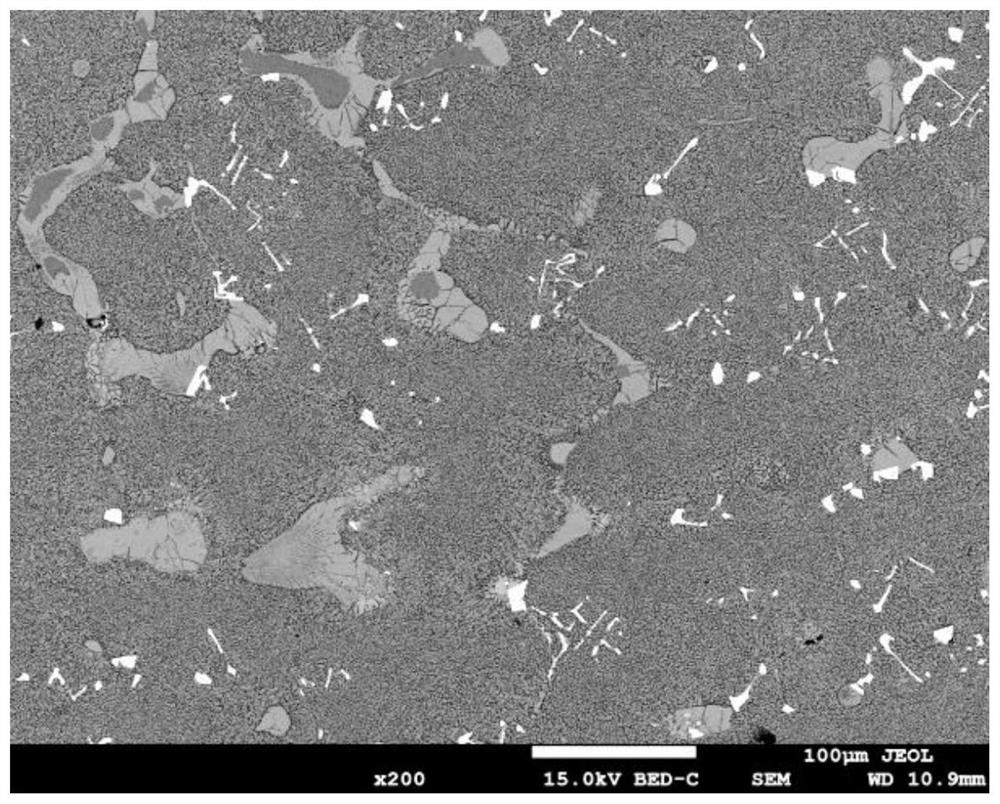

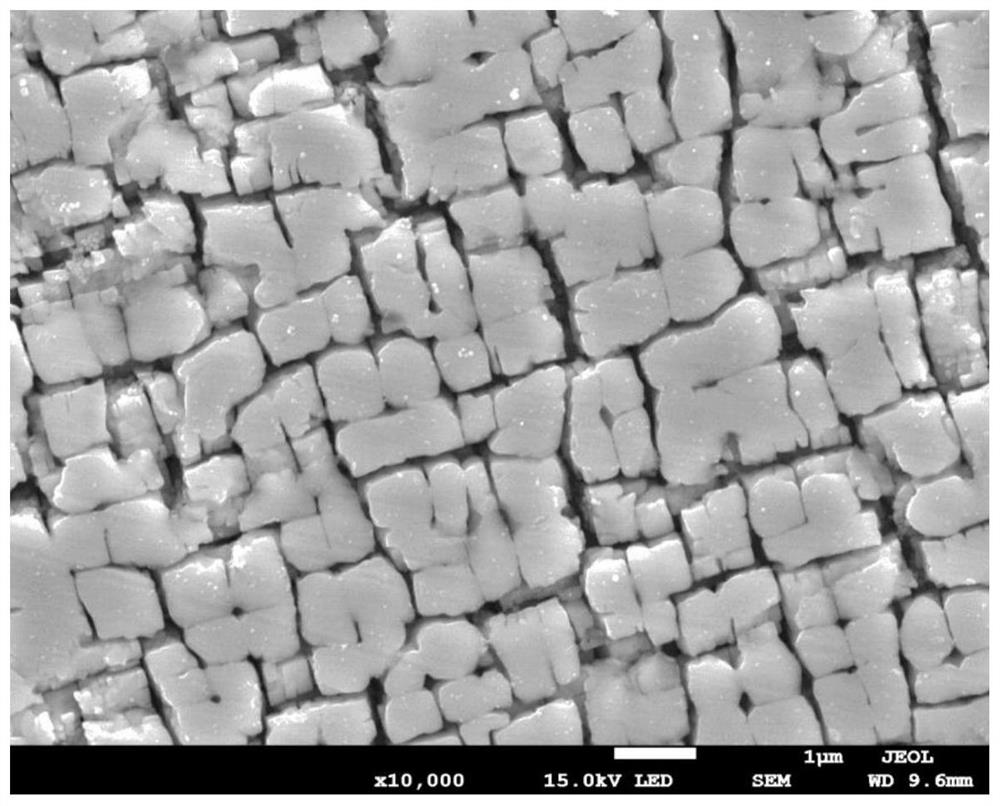

The invention discloses gamma'-phase intensified cobalt-based superalloy and a preparation method thereof, and belongs to the field of superalloy. The gamma'-phase intensified cobalt-based superalloyis prepared from the following alloy chemical components in percentage by weight: 3 to 6 percent of Al, 6 to 20 percent of W, 2 to 6 percent of Ti, 2 to 6 percent of Ta, 18 to 38 percent of Ni, 0 to 10 percent of Cr, 0 to 5 percent of Mo, 0 to 2 percent of Nb, 0 to 2 percent of Si and the balance of Co. The preparation method is characterized by melting by adopting a vacuum arc furnace, carrying out solid solution heat treatment at 1250 to 1300 DEG C, and carrying out aging heat treatment at 900 to 1150 DEG C. The gamma'-phase intensified cobalt-based superalloy disclosed by the invention is intensified by a gamma' phase having an L12 crystal structure and has a cubic shape, the volume fraction is greater than 65 percent, and the gamma'-phase intensified cobalt-based superalloy is uniformly distributed in a gamma matrix having an A1 crystal structure. A Gamma / gamma' two-phase structure of the gamma'-phase intensified cobalt-based superalloy disclosed by the invention stably exists at 900 to 1150 DEG C, no secondary phase is separated out, and the gamma'-phase intensified cobalt-based superalloy is a candidate material for hot end components of an aircraft engine and an industrial gas turbine.

Owner:UNIV OF SCI & TECH BEIJING

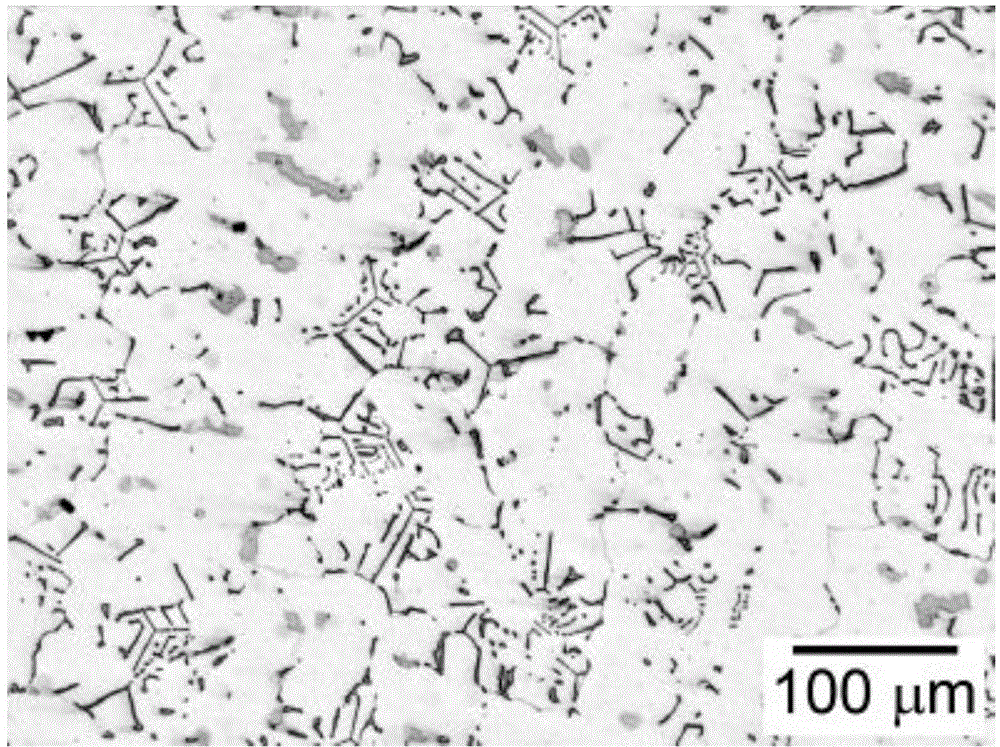

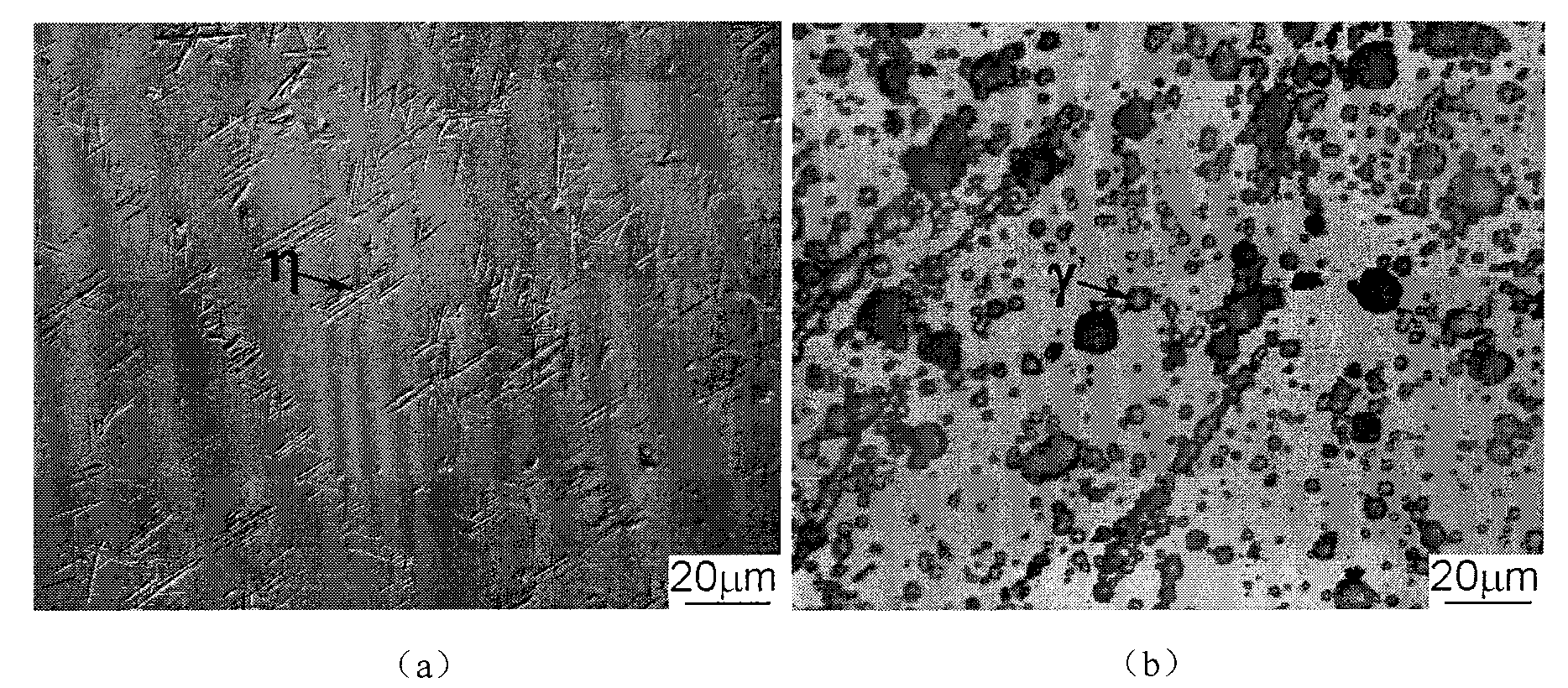

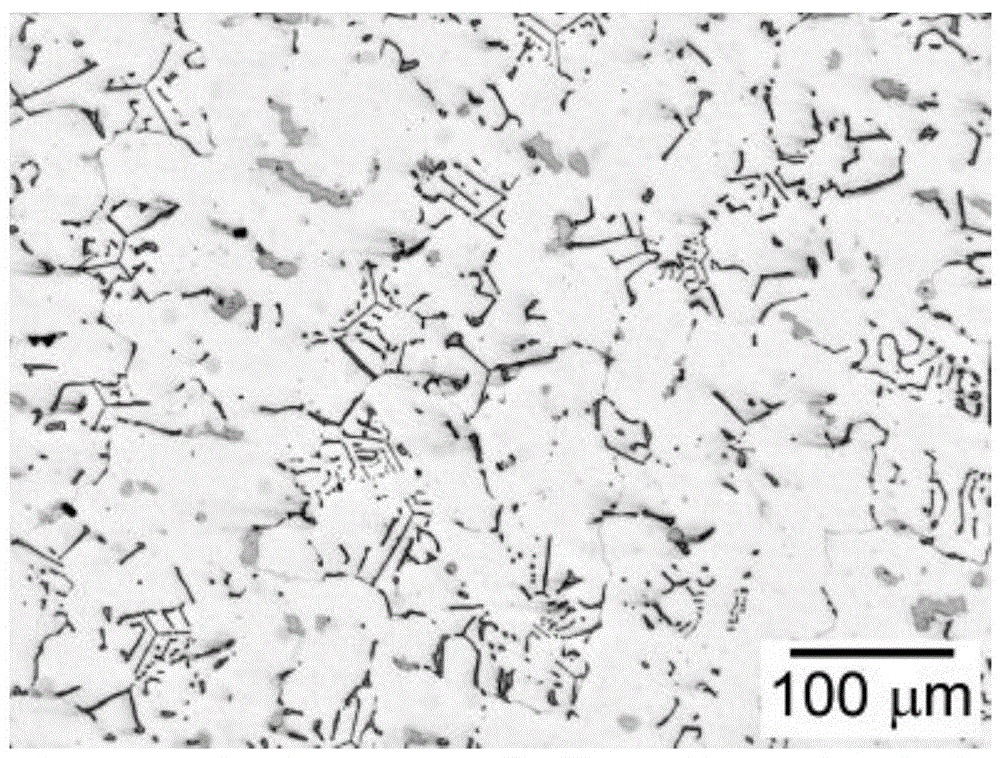

Heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties

The invention belongs to the technical field of new materials, and provides a heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties, which is mainly used in automobile engine exhaust system components of which the exhaust temperature exceeds 1000 DEG C, including exhaust manifolds, turbine casings and the like. The heat-resistant cast austenitic stainless steel comprises the following alloy components in percentage by mass: 0.1%-0.6% of C, 0.1%-0.5% of N, 0.4%-1.5% of Si, less than 1.5% of Mn, 17.5%-22.5% of Cr, 8.0%-13.0% of Ni, 1.0%-3.0% of Nb, less than 5.0% of W, less than 6.5% of Mo and the balance of matrix element Fe and impurity elements, including less than 0.04% of P, less than 0.03% of S, less than 0.04% of O and less than 0.05% of Al. The heat-resistant austenitic stainless steel is produced by a casting method without later-period heat treatment, and has the advantages of lower production cost, higher temperature resistance and higher durability as compared with like heat-resistant cast steel.

Owner:UNIV OF SCI & TECH BEIJING

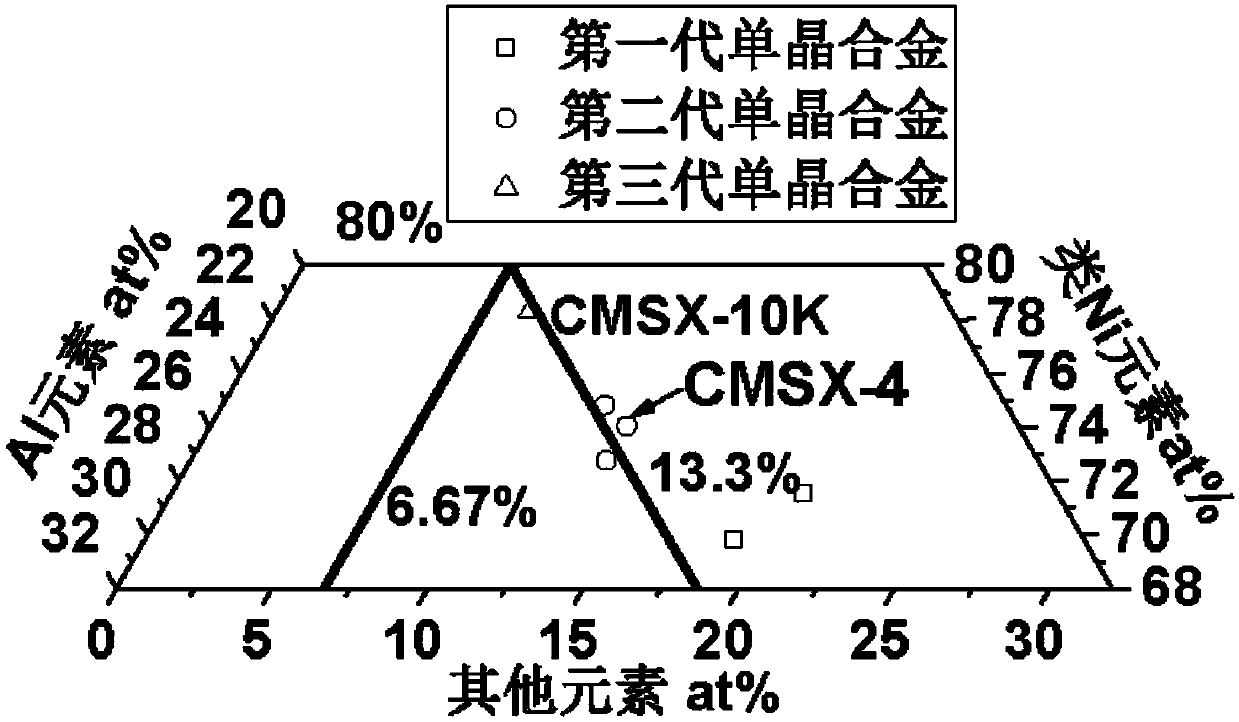

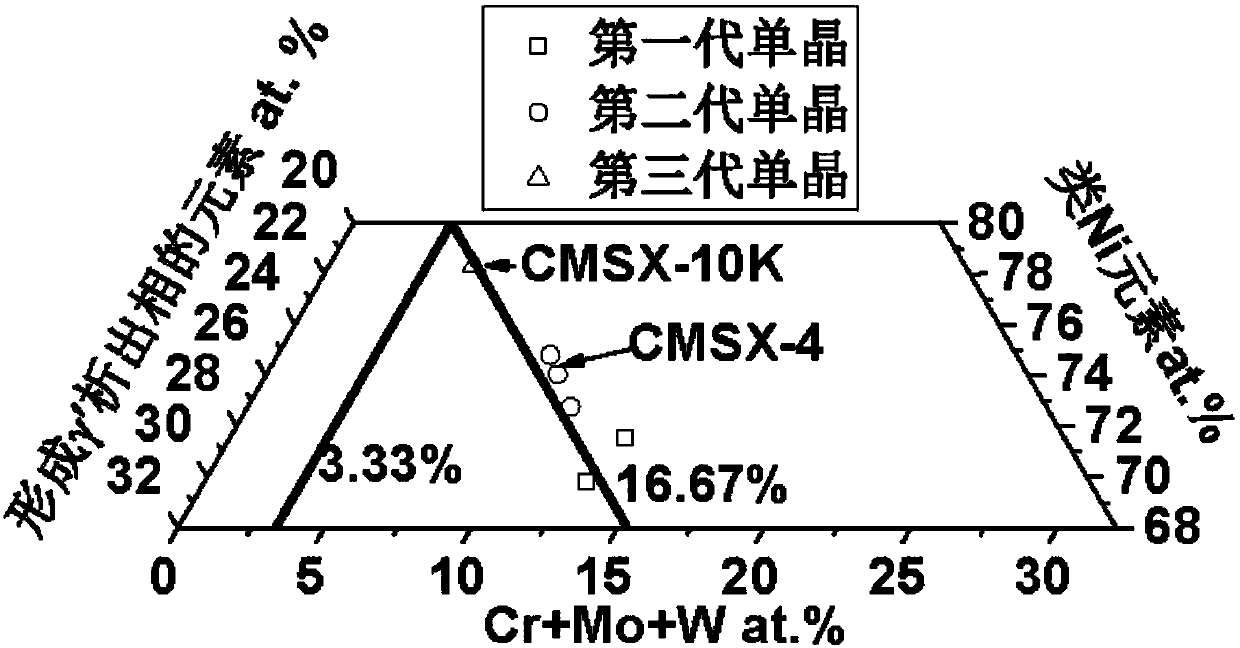

Nickel base single crystal high-temperature alloy series Nideal2 alloy series and application thereof

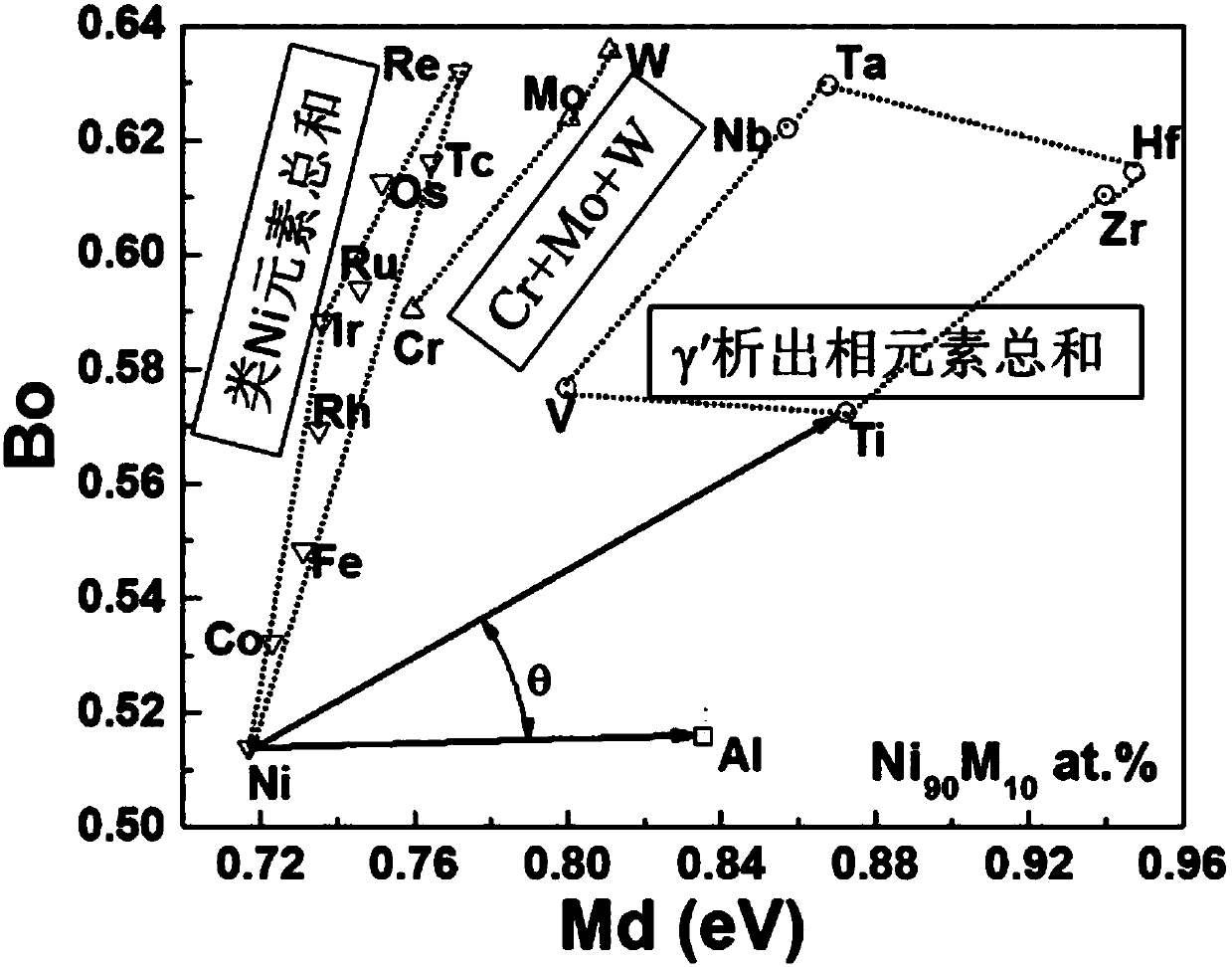

InactiveCN107904447ASolution to short lifeLong lasting lifePolycrystalline material growthSingle crystal growth detailsRare earthSingle crystal

The invention discloses a nickel base single crystal high-temperature alloy series Nideal2 alloy series and application thereof, and belongs to the technical field of high-temperature alloys. The alloy series comprises main alloy components of a similar Ni element, an element forming a gamma' precipitated phase, an element forming a gamma basal body, and an Al element; and the similar Ni element is selected from one or several of Ni, Co, Re, Ru, Ir, Fe, Pt, Pd, Os, Rh and Tc, and is 80+-1.5 at.%. The element forming the gamma' precipitated phase is selected from one or several of Ti, V, Nb, Ta, Zr and Hf, and is 3.3+-0.1 at.%. The element forming the gamma basal body is selected from one or several of Cr, Mo and W, and is 3.3+-0.1 at.%. The atomic percentage sum of the Al element is 13.3+-0.2 at.%; the alloy components need to be met synchronously; and after components of main alloys are determined, Mg, Si, C, B and one or several of La, Ce and Y rare earth are selected within 0.5 at.%. The alloy series constructed by an ideal ratio is called as the Nideal2 alloy series; and the alloy series achieves high temperature bearing capacity and long service life.

Owner:DALIAN UNIV OF TECH

Re/Ru-containing monocrystal nickel-based superalloy with high temperature resistant capability and high creep resistance

InactiveCN104911407AHigh temperature capacityImprove thermal stabilityPolycrystalline material growthSingle crystal growth detailsOxidation resistantGas turbines

The invention relates to a Re / Ru-containing monocrystal nickel-based superalloy with high temperature resistant capability and high creep resistance, belonging to a new material with a special purpose. The alloy consists of the following components in percentage by weight: 5.6-6.4% of Al, 7.2-8.2% of Ta, 2.2-3.2% of Cr, 2.5-3.5% of Mo, 6.5-7.5% of Co, 3.8-4.6% of W, 4.2-4.8% of Re, 2.8-3.5% of Ru, 0.05-0.15% of Hf and the balance of nickel. The monocrystal nickel-based superalloy has good high-temperature oxidation resistance and the advantages of high temperature resistant capability, high creep strength, long service life and the like, and is applicable to the production of blades of the hot-end components of aero-engines and gas turbines.

Owner:SHENYANG POLYTECHNIC UNIV

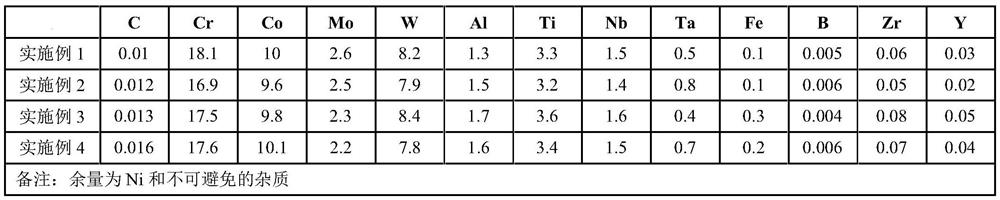

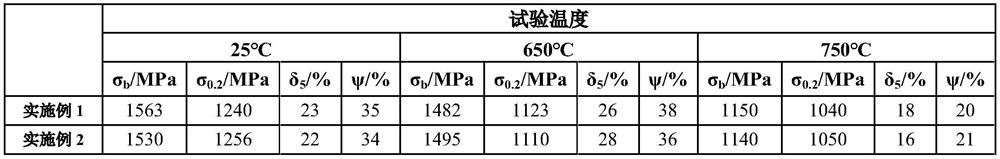

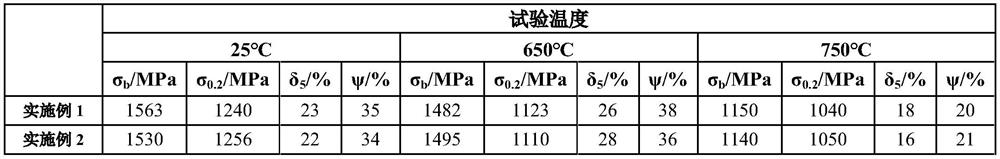

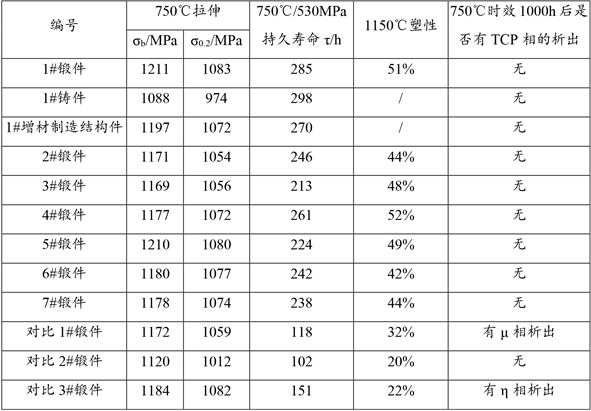

High-strength difficult-to-deform nickel-based superalloy and preparation method thereof

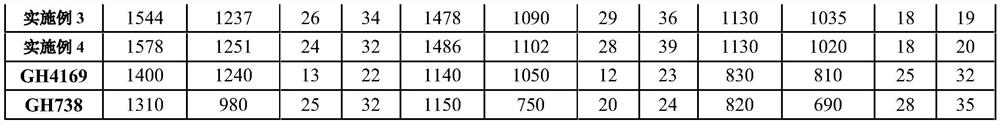

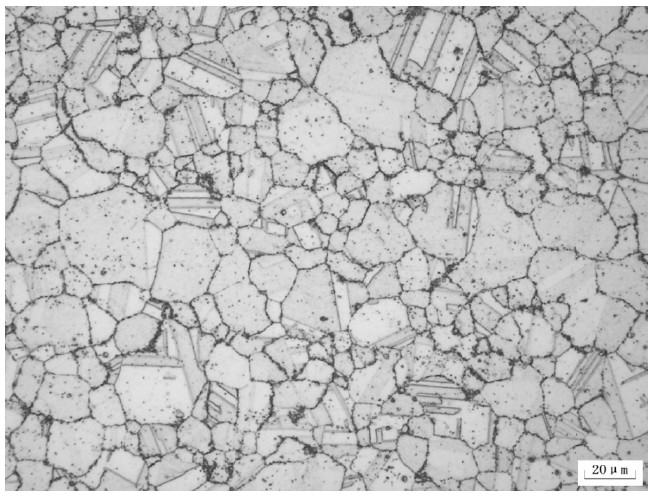

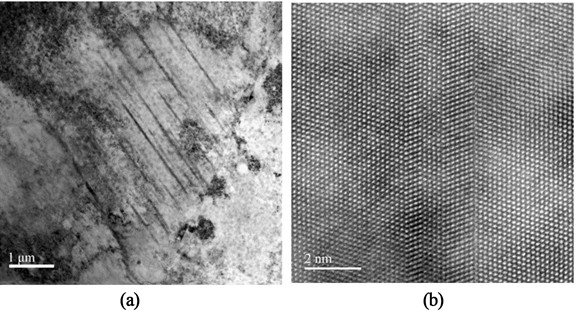

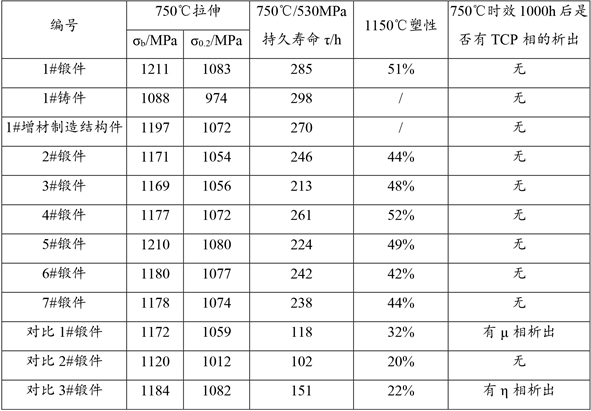

According to the high-strength and difficult-to-deform nickel-based superalloy and the preparation method thereof, the feasibility of engineering application of the high-strength and difficult-to-deform nickel-based superalloy is guaranteed by optimizing alloy components, adopting the processes of vacuum induction smelting, electroslag remelting, vacuum consumable remelting, forging, heat treatment and the like and controlling the process parameters of all the processes; the high-strength difficult-to-deform nickel-based superalloy with high strength, high structure stability and better hot working performance is prepared, the tensile strength and durability of the high-strength difficult-to-deform nickel-based superalloy at 650 DEG C are superior to those of a GH4169 alloy, the tensile strength and durability of the high-strength difficult-to-deform nickel-based superalloy at 750 DEG C are superior to those of a GH738 alloy, the use temperature reaches 700 DEG C or above, and the high-strength difficult-to-deform nickel-based superalloy is expected to become an alternative material of a superalloy for a next

Owner:宝武特种冶金有限公司

High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

The invention belongs to the technical field of new materials, and relates to a gamma'-phase high-temperature-stability cobalt-base high-temperature alloy with gamma / gamma' two-phase structure, which is a candidate material for high-temperature hot end components of gas turbines for aviation, spaceflight, vessels, power generation and the like. The alloy comprises the following components in atomic percentage: 4-12% of Al, 4-12% of W, 1-4% of Ta, 1-6% of Ti, 0-10% of Cr, 0-3% of Mo, 0-2% of Hf, 0-1% of C, 0-1% of B and the balance of Co. The preparation method comprises the following steps: smelting in a vacuum induction furnace, carrying out solid solution heat treatment at 1250-1300 DEG C, and carrying out aging heat treatment at 1000-1100 DEG C. After carrying out L12-type gamma'-phase high-temperature reinforcement, the gamma' shape is cubic, the volume percent is higher than 60%, and the gamma'-phase is uniformly distributed in the gamma-phase. Compared with the traditional cobalt-base high-temperature alloy, the alloy provided by the invention has higher application temperature; and compared with the recently developed similar cobalt-base alloys, the alloy provided by the invention has higher gamma'-phase solution temperature and gamma / gamma' two-phase structure stable existence temperature.

Owner:UNIV OF SCI & TECH BEIJING

Nickel-cobalt-based high-temperature alloy with favorable structure stability and easiness for processing

Owner:辽宁红银金属有限公司

Nickel-based alloy and article formed thereby

ActiveCN106191529AHigh temperature capacityImprove mechanical propertiesMachines/enginesEngine componentsAlloyHafnium

The invention provides a nickel-based alloy. The nickel-based alloy comprises 7-8wt% of cobalt, 12-13wt% of chromium, 6.35-6.65wt% of aluminum, 5.25-5.75wt% of tantalum, 5.25-5.75wt% of tungsten, 0.57-0.63wt% of hafnium, 0.04-0.06wt% of carbon, 0.003-0.005wt% of boron, 0.02-0.10wt% of silicon and the balance nickel. According to the invention, the alloy has excellent oxidization resistance, corrosion resistance and temperature bearing performance by balancing the contents of strengthening elements such as W, Mo, Ta, Al and Co in the alloy and improving the content of Cr. The nickel-based alloy can maintain good structure stability in a high-temperature environment and does not contain Re, and the cost of the alloy is lowered.

Owner:CENT SOUTH UNIV +1

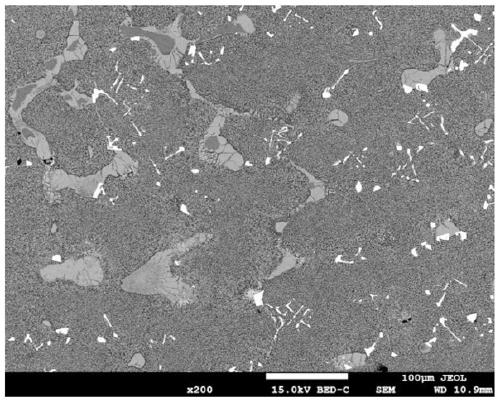

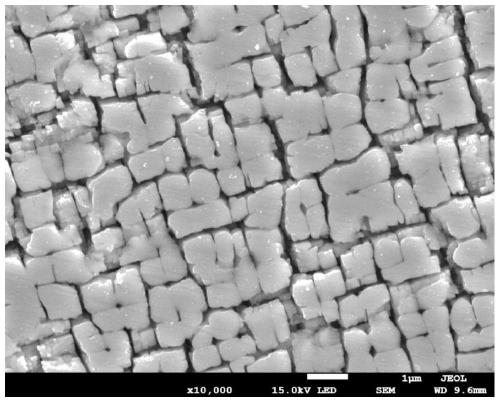

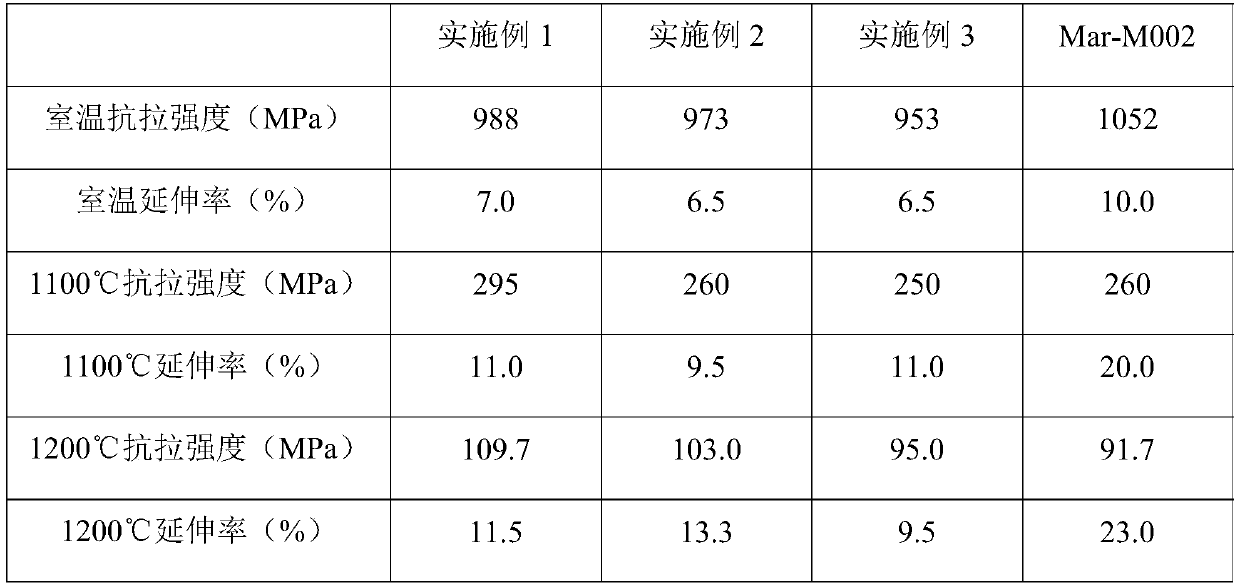

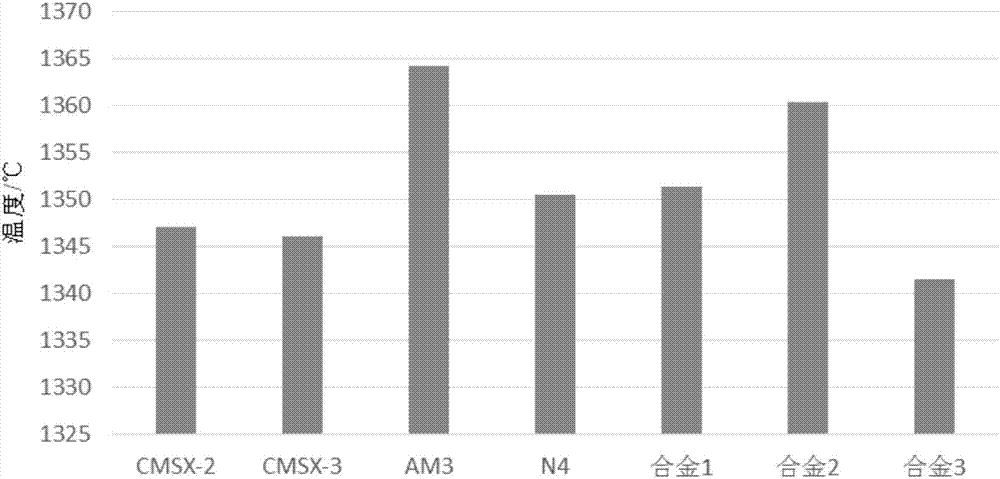

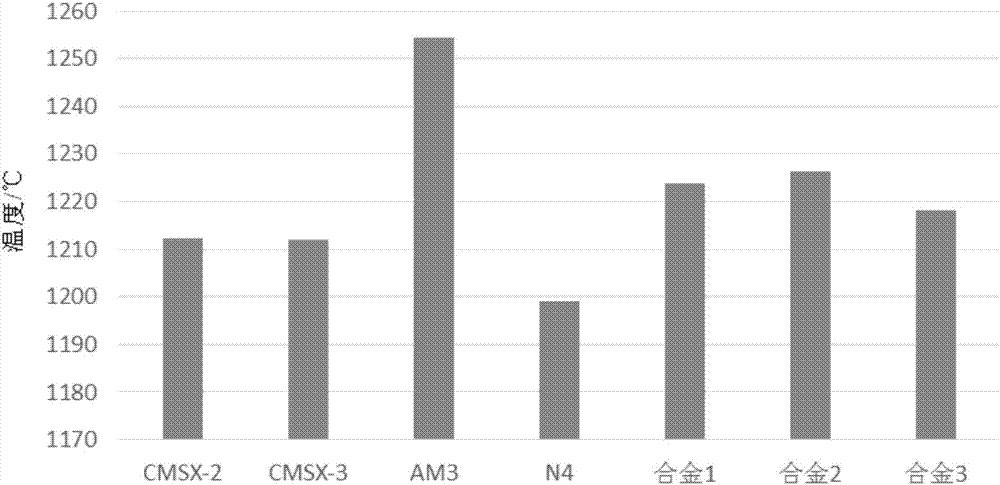

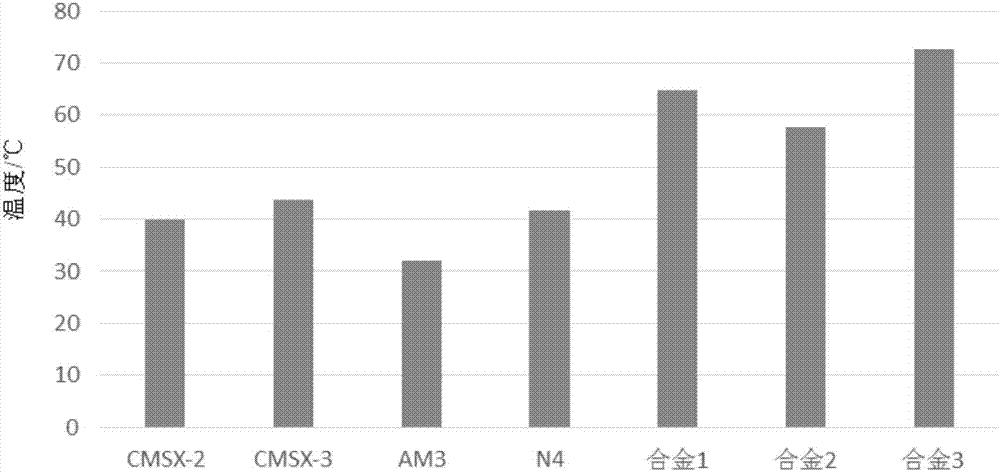

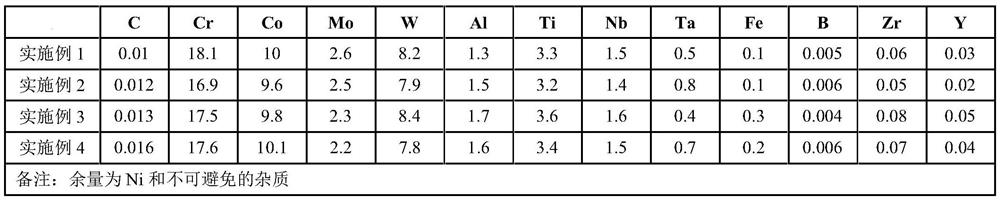

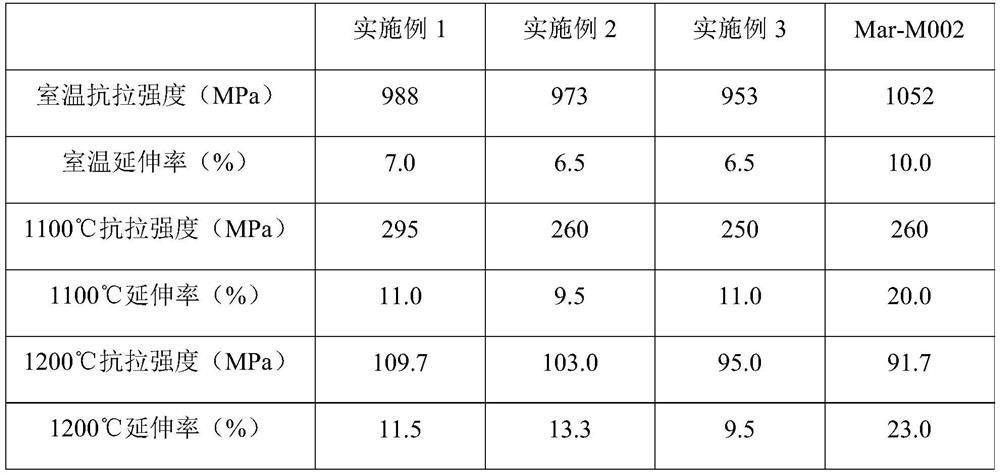

Nickel-based casting alloy and preparation method thereof

ActiveCN111254317AImprove antioxidant capacityGood tensile properties at room temperatureRamjetInvestment casting

The invention belongs to the technical field of new materials, and provides a nickel-based casting alloy and a preparation method thereof, which are mainly applied to a high-temperature bearing structural member, such as an air inlet channel structural member, of a ramjet engine with the wall surface temperature reaching 1200 DEG C. The alloy comprises the following components of, by mass, 0.1%-0.25% of C, 7.5%-10.7% of Cr, 8%-12% of Co, 8%-12% of W, larger than 6.25% of Al, 0.75%-2% of Ti, 2%-3% of Ta, 0.8%-2.5% of Hf, 0.01%-0.15% of Zr and 0%-0.2% of B, and the balance a matrix element Ni and impurity elements. The nickel-based casting alloy is produced through adopting an investment casting method, and has higher temperature bearing capacity and durability than similar casting high-temperature alloys after being subjected to 870 DEG C / 16 h of standard heat treatment.

Owner:BEIJING CISRI GAONA TECH

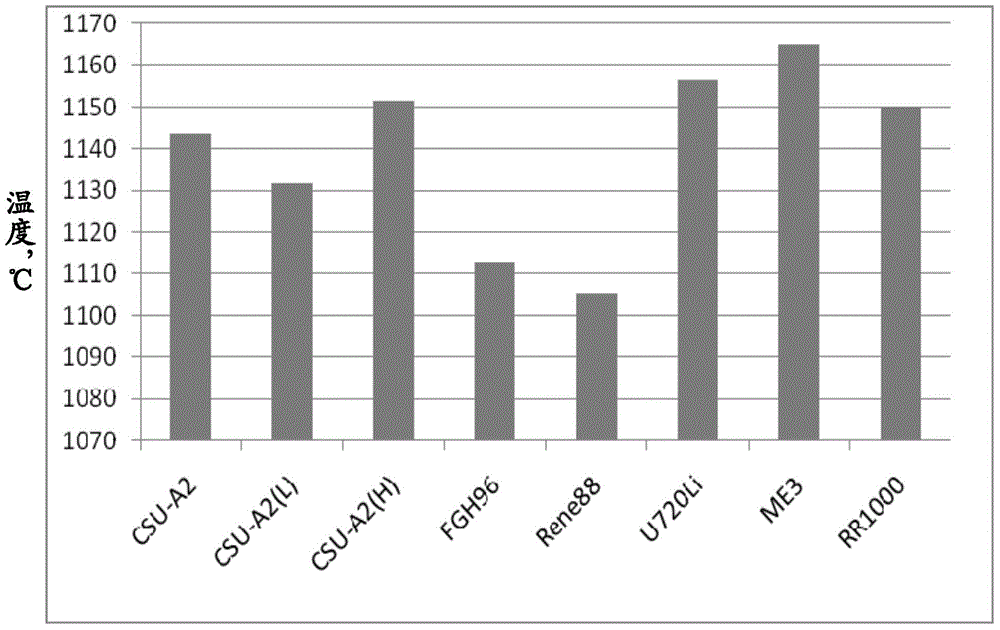

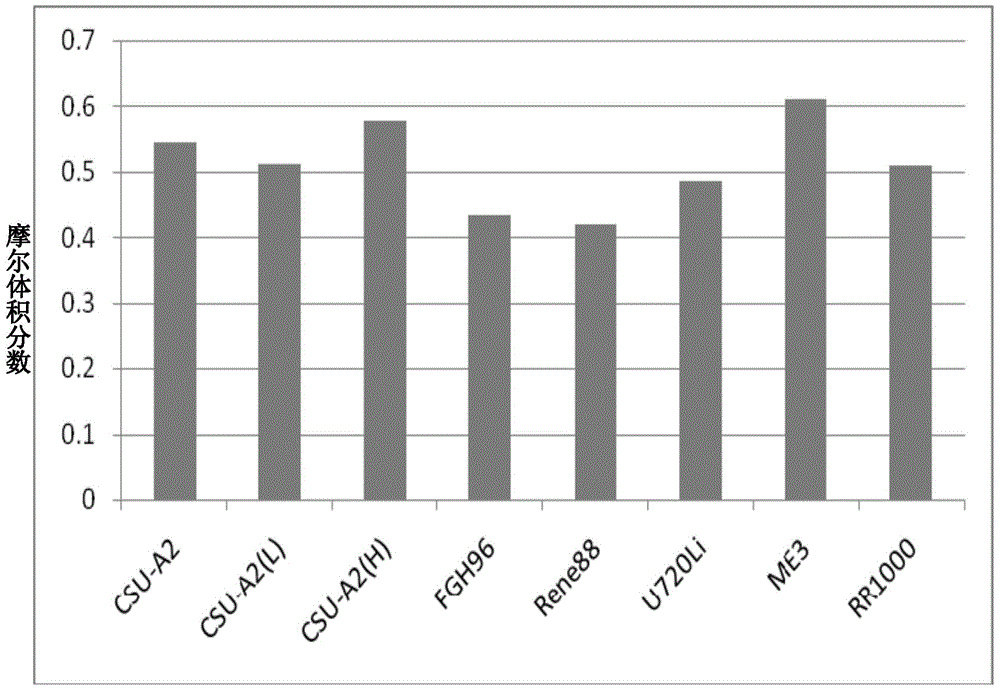

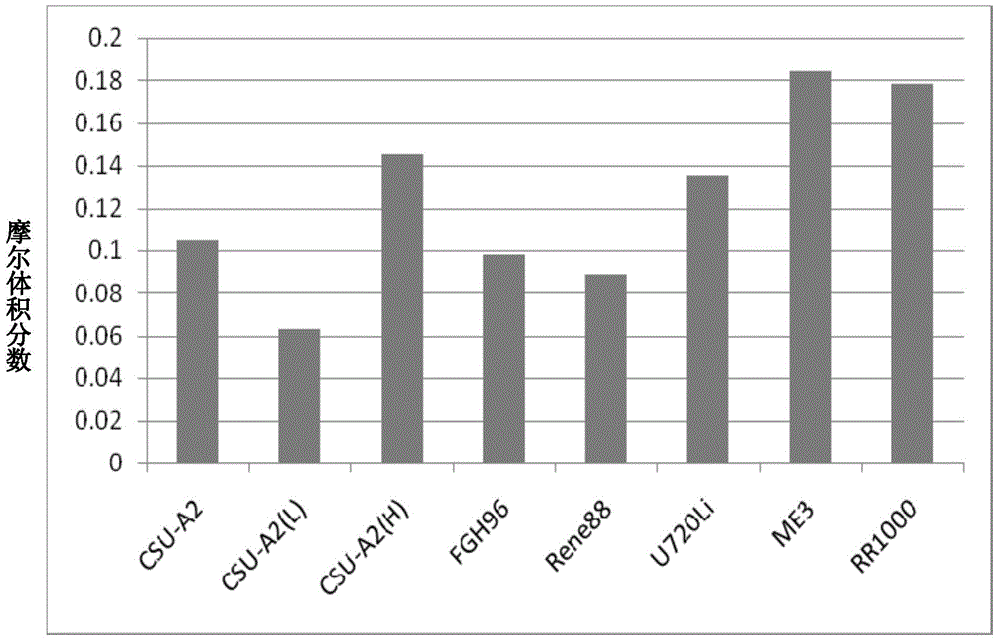

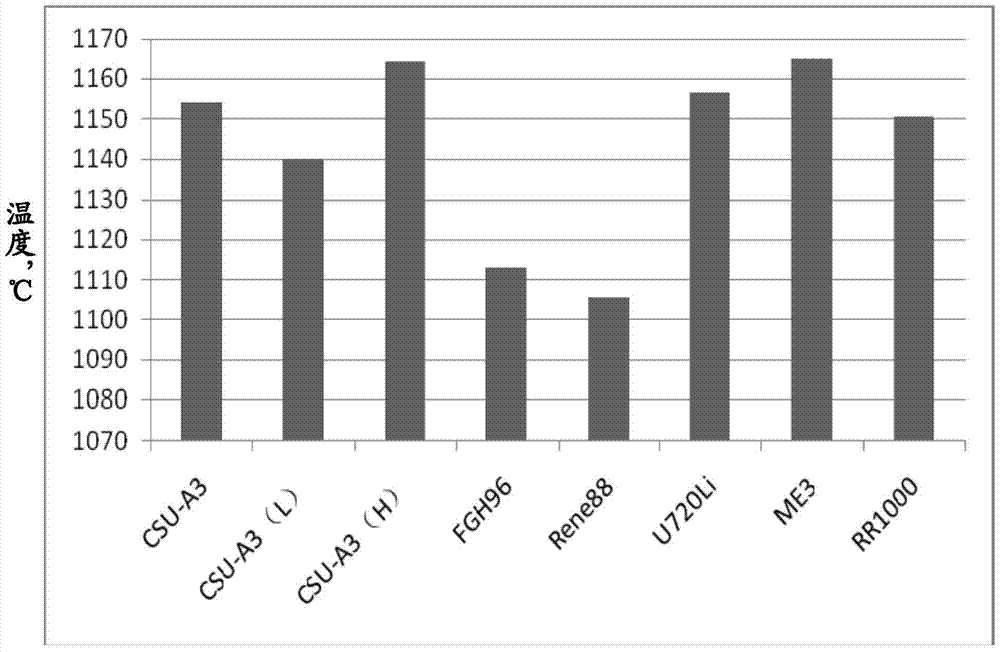

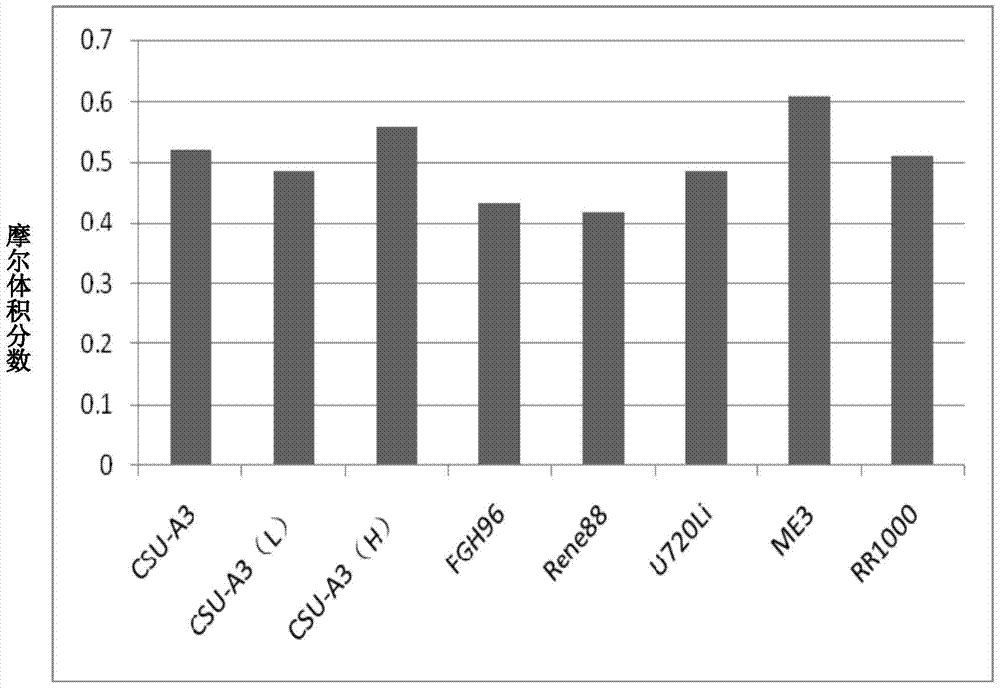

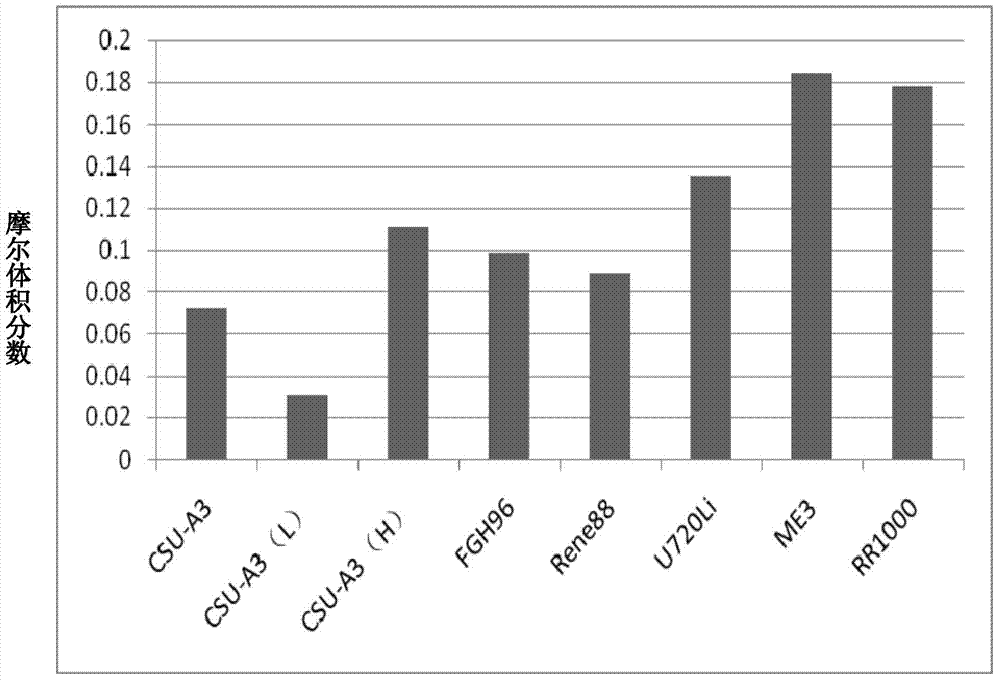

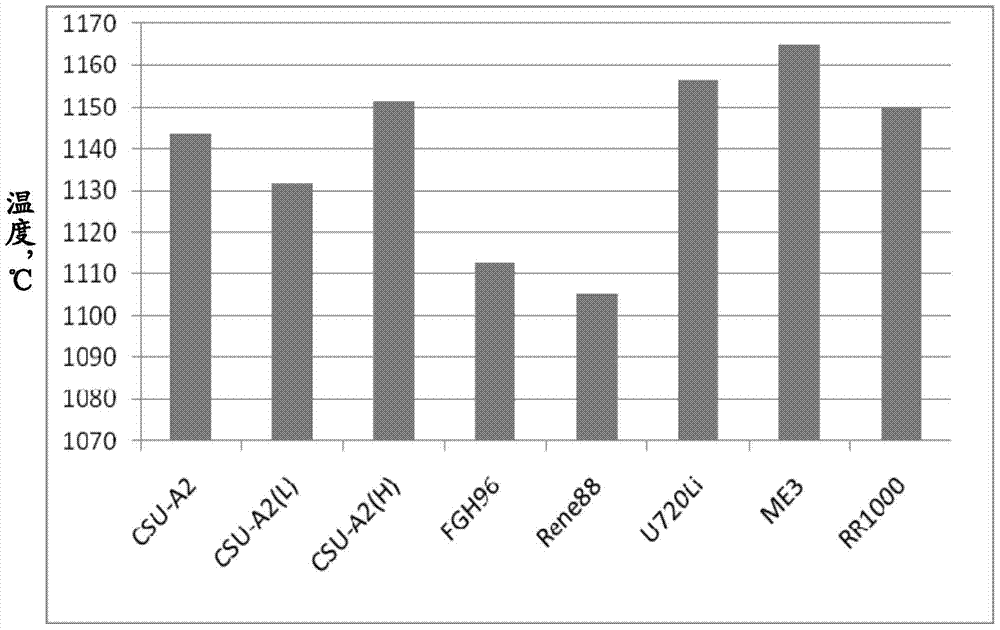

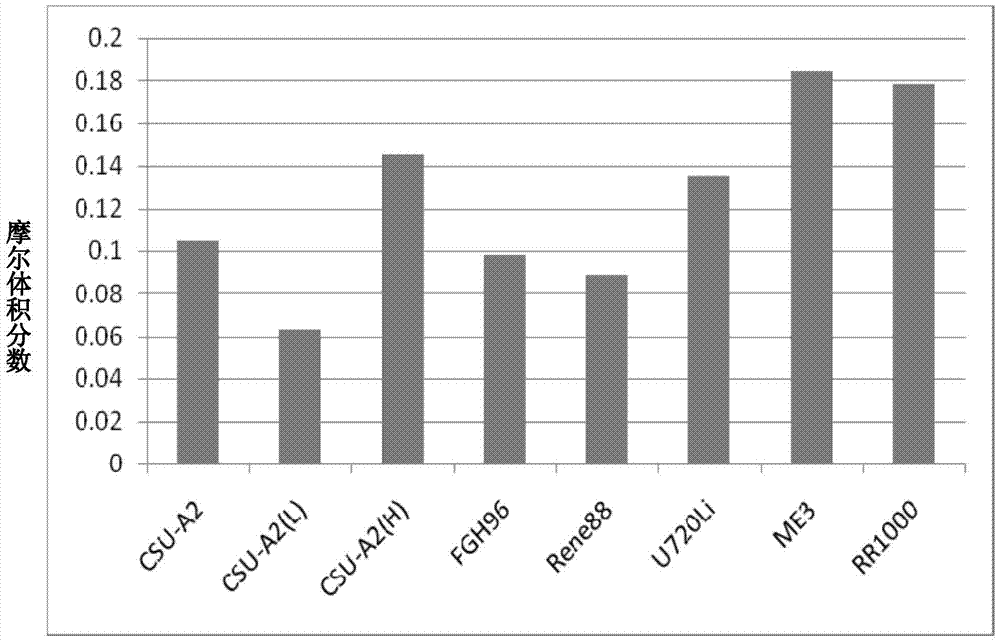

Nickel-base superalloy and preparation method thereof

ActiveCN106282667AMaintain solid solution strengthening effectReduce leachingNickel alloyPowder metallurgy

The invention provides nickel-base superalloy and a preparation method thereof, and in particular relates to powder metallurgy nickel alloy with high stability, and articles made from the powder metallurgy nickel alloy. The nickel-base superalloy is prepared from the following components by mass percent: 18.5-19.5% of Co, 12.75-13.25% of Cr, 2.8-3.2% of Al, 3.5-3.9% of Ti, 3.75-4.25% of W, 3.75-4.25% of Mo, 0.9-1.1% of Ta, 1.1-1.3% of Nb, 0.17-0.23% of Hf, 0.04-0.06% of C, 0.003-0.015% of B, 0.03-0.07% of Zr and the balance of Ni. The superalloy designed by the invention has better structure stability and high-temperature strength, and the temperature tolerance of the alloy is further improved.

Owner:CENT SOUTH UNIV +1

High-strength creep-resistant high-temperature alloy and preparation method thereof

InactiveCN114737084AHigh strengthImprove creep resistanceMetal-working apparatusEfficient propulsion technologiesPhase formationSuperalloy

The invention provides a high-strength creep-resistant high-temperature alloy and a preparation method thereof, and belongs to the technical field of metallurgy. The alloy comprises the following components in percentage by mass: 10.00%-12.00% of Cr, 12.00%-18.00% of Co, 5.50%-7.50% of W, 1.50%-3.50% of Mo, 3.00%-4.20% of Al, 3.00%-4.20% of Ti, 1.00%-2.20% of Nb, 0.40%-1.50% of Ta, 0.01%-0.04% of C, 0.01%-0.04% of B, 0.09%-1.20% of Zr, less than 0.10% of Hf and the balance of Ni, and the total mass percentage of gamma'phase forming elements Al, Ti, Nb and Ta in the high-temperature alloy is as follows: 9.5% < = (Al + Ti + Nb + Ta) < = 10.3%; the mass percentage content of a gamma'phase in the high-temperature alloy is 50%-55%, and the mass ratio of Al to Ti in the high-temperature alloy is that (Al / Ti) is larger than or equal to 0.9 and smaller than or equal to 1.0. The alloy and the disc piece of the alloy can be manufactured through the method, and the disc piece of the alloy can meet the requirements of future aviation turboshaft engines for high temperature resistance, high strength and creep resistance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

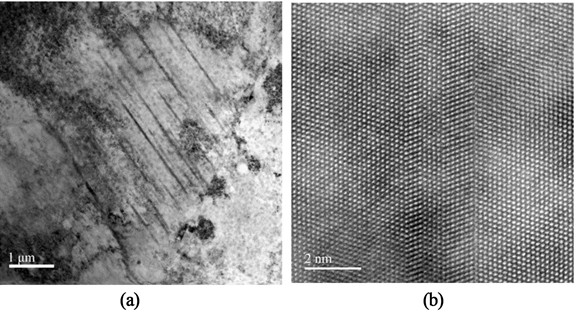

High-temperature alloy with low stacking fault energy, structural part and application of high-temperature alloy

ActiveCN112981186AHigh temperature capacityHigh temperature strengthAdditive manufacturing apparatusBlade accessoriesCombustion chamberMetallurgy

The invention relates to the technical field of high-temperature alloys, in particular to a high-temperature alloy with low stacking fault energy, a structural part and application of the high-temperature alloy. The high-temperature alloy comprises, in percentage by mass, 0.01%-0.09% of C, 23.5%-27.5% of Co, 11%-15% of Cr, 0.1%-1.8% of W, 2.2%-2.6% of Al, 3.5%-5.5% of Ti, 0%-2% of Nb, 0%-2% of Ta, 2.1%-3.5% of Mo, 0.0001%-0.05% of B, 0.0001%-0.05% of Zr, 0%-2.5% of Fe, 0%-0.04% of Mg and the balance of Ni, wherein the sum of the mass fractions of Nb and Ta is greater than or equal to 0.8%. The high-temperature alloy has both service performance at 750 DEG C or above and good hot working characteristics, and can be applied to structural parts such as a turbine disc, a blade, a casing and a combustion chamber for long-time use.

Owner:BEIJING CISRI GAONA TECH +1

Material for casting exhaust manifold

InactiveCN107939501AImproved and increased wear resistanceImprove and enhance oxidation corrosion resistanceExhaust apparatusSilencing apparatusChemical compositionNitrogen

The invention provides a material for casting an exhaust manifold. The material for casting the exhaust manifold is composed of the following chemical ingredients of, in percentage by mass, 0.2-0.6% of C, 1.2-2.6% of Si, 0.1-0.5% of Al, 0.1-0.3% of Mn, 20-24% of Cr, 22-26% of Ni, 0.6-0.8% of Mo, 0.7-1.1% of Ba, 4-7% of Ce, 0.9-1.6% of N, 1.5-1.9% of Nb, 0.02-0.05% of P, 0.11-0.16% of S, 5-7% of Ti, 6-8% of V and the balance ferrum. The material for casting the exhaust manifold has the beneficial effects that (1), an appropriate amount of alloying elements of chromium, nickel, molybdenum, nitrogen, aluminum and silicon and the like are added in the exhaust manifold material, and the abrasive resistance and oxidation corrosion resistance of final exhaust manifold products are improved and enhanced to a certain extent; (2), automobile exhaust manifolds fabricated by the material for casting the exhaust manifold have higher temperature bearing capacity and durability, the quality of products is improved, the service life of products is prolonged, and to some extent, the cost is also saved.

Owner:绩溪县徽洋车桥有限责任公司

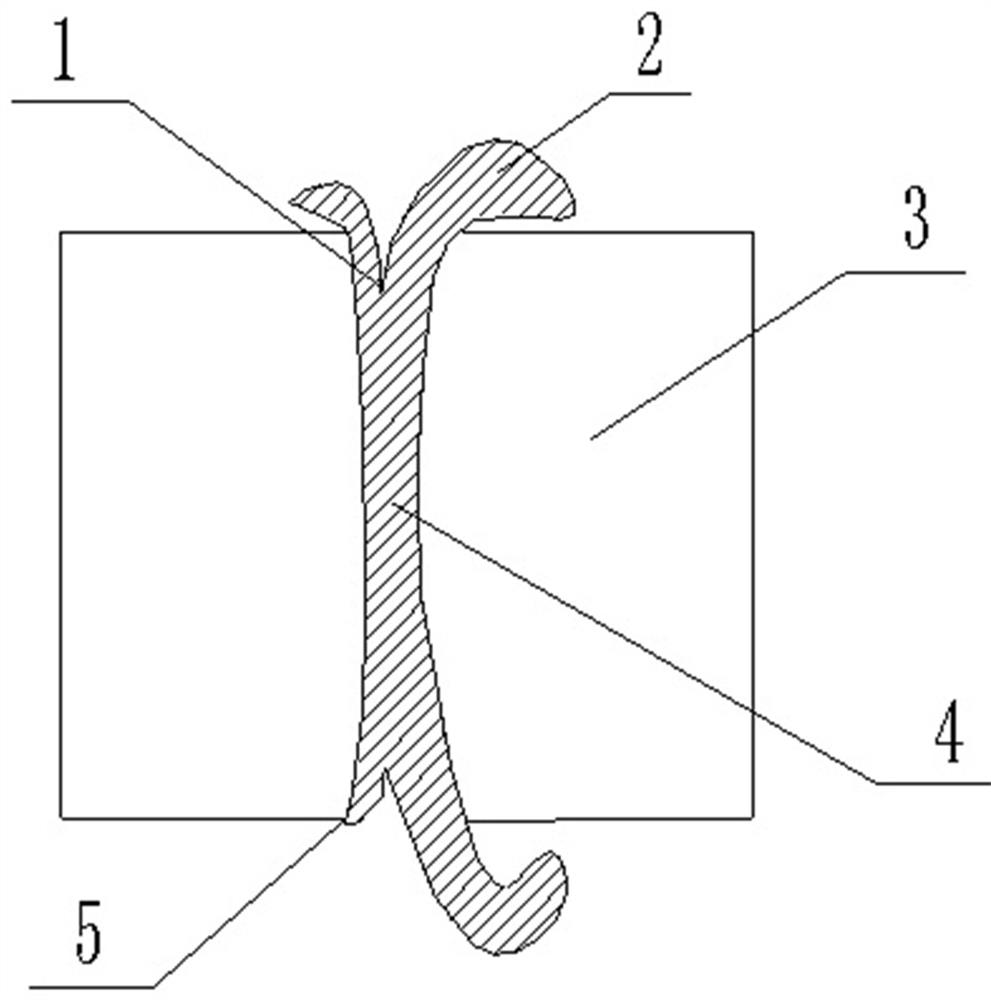

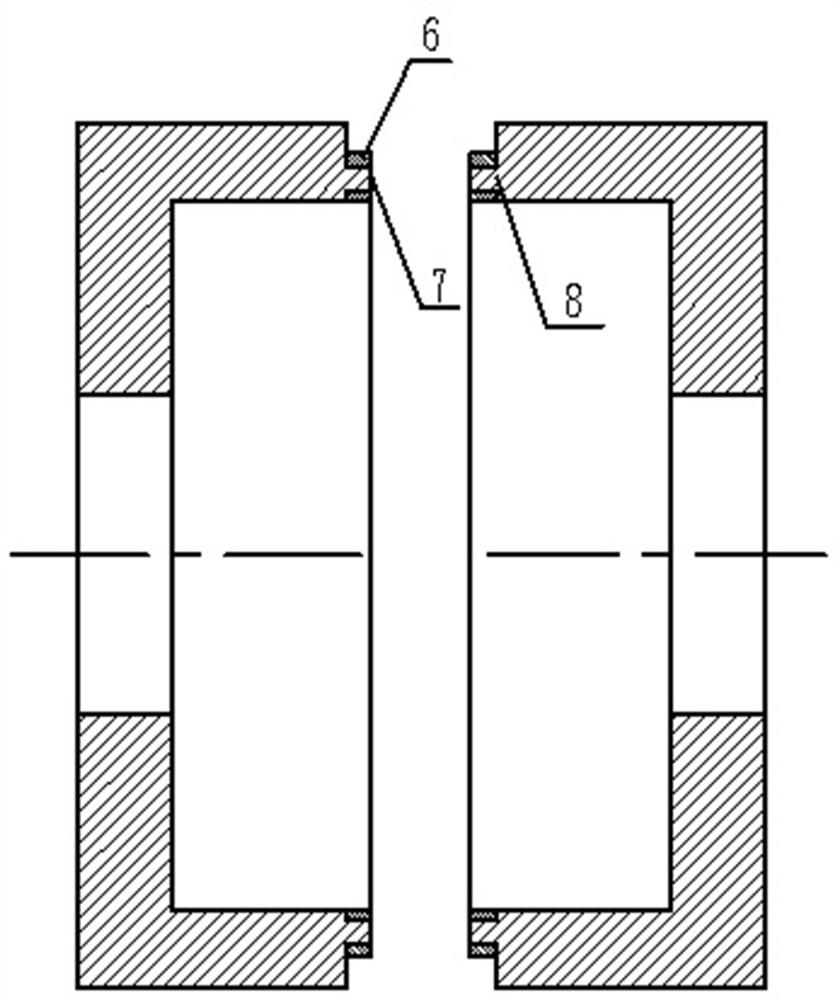

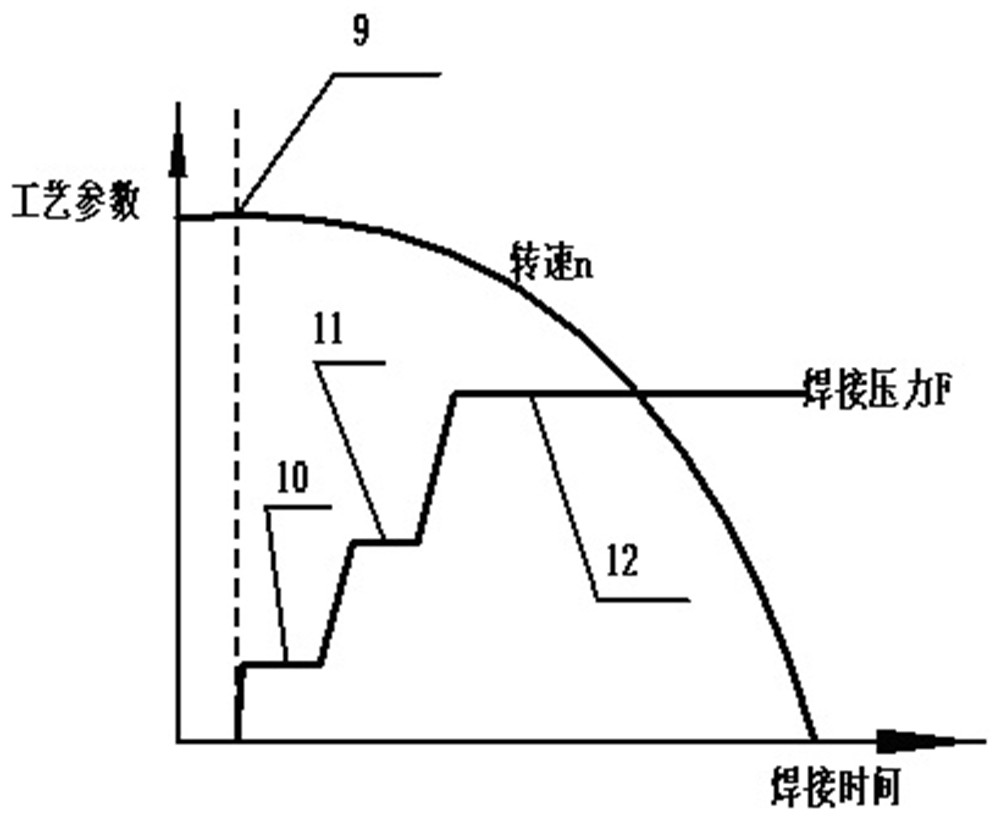

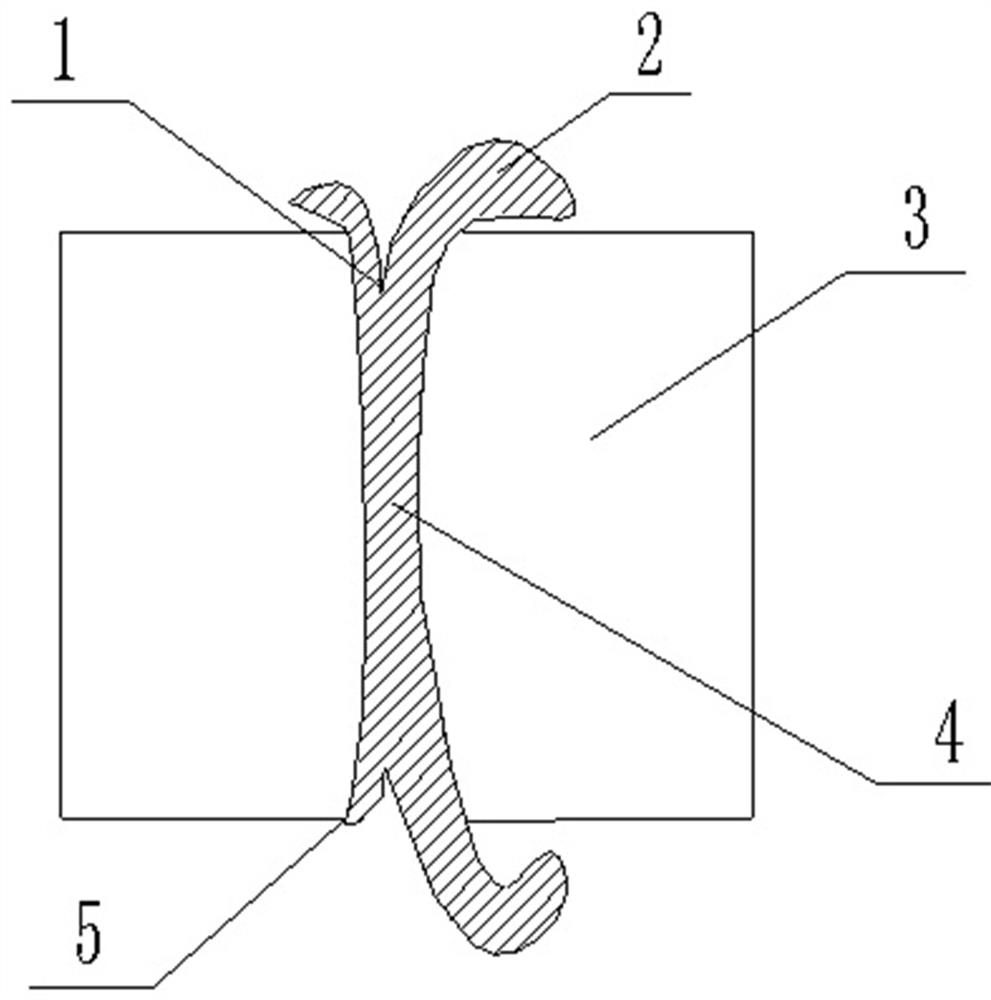

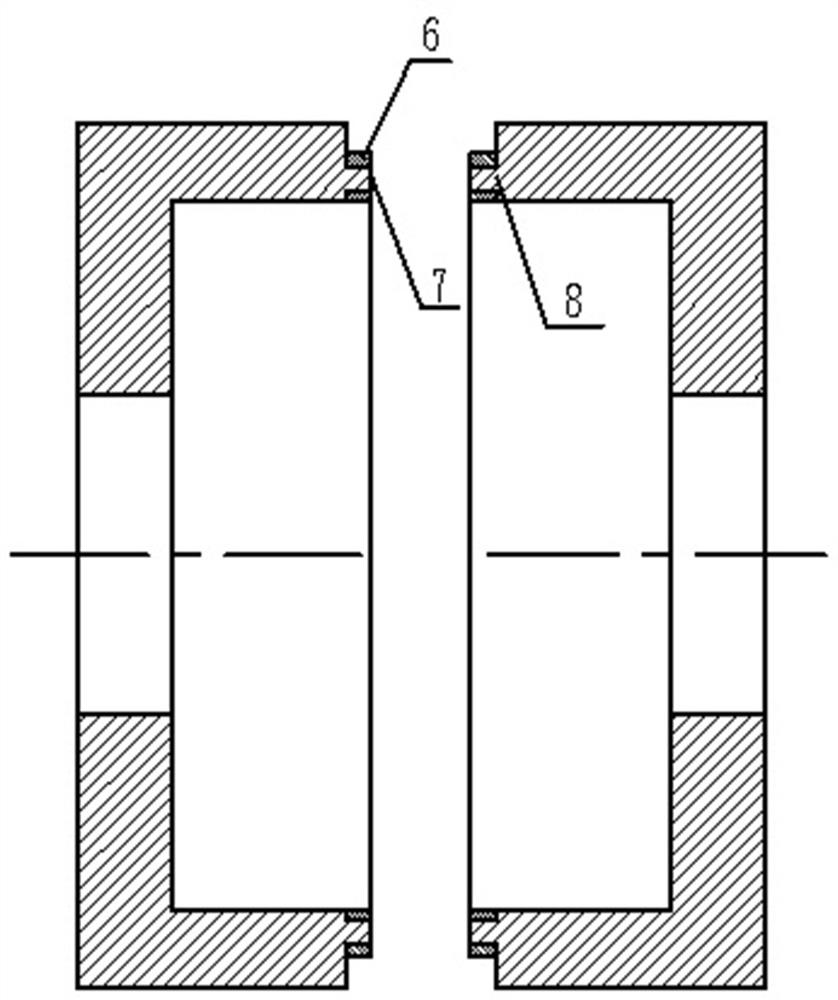

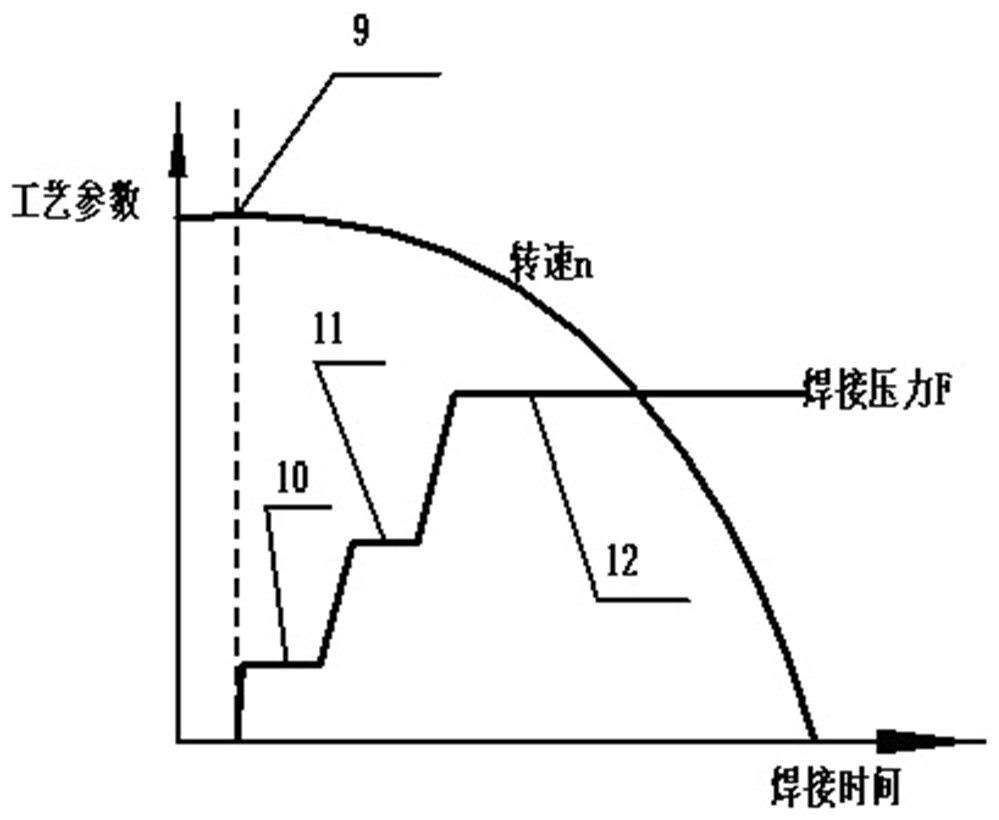

Process method for improving inertia friction welding weld joint quality of GH4151

ActiveCN113770508AHigh temperature capacityIncrease thrustAnalysing solids using sonic/ultrasonic/infrasonic wavesFluorescence/phosphorescenceFriction weldingStructural engineering

The invention relates to a process method for improving inertia friction welding weld joint quality of GH4151, and belongs to the technical field of welding of GH4151 alloy for aero-engine core rotor parts and plate-shaft type parts. According to the process method, an inertia friction welding three-stage pressure method is adopted, machining allowance is reserved on the inner face and the outer face of a boss relative to the final part size before welding, flash removal and heat treatment work are completed within limited time after welding is completed, and defect detection is conducted according to the sequence. By the adoption of the three-stage pressure process method, tip cracks of the welding flash do not go deep into a weld joint matrix, and the flash is continuous. Before welding, the machining allowance is reserved on the inner face and the outer face of the welding boss relative to the final part size, the possible flash tip defect can be thoroughly machined and removed, and the final weld joint quality of the part is guaranteed. Comprehensive quality detection is carried out on the surface, shallow surface and interior of the weld joint by using different detection sequences, so that the quality of the weld joint and the defect detection level are effectively improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A γ' phase strengthened cobalt-based superalloy and its preparation method

The invention discloses gamma'-phase intensified cobalt-based superalloy and a preparation method thereof, and belongs to the field of superalloy. The gamma'-phase intensified cobalt-based superalloyis prepared from the following alloy chemical components in percentage by weight: 3 to 6 percent of Al, 6 to 20 percent of W, 2 to 6 percent of Ti, 2 to 6 percent of Ta, 18 to 38 percent of Ni, 0 to 10 percent of Cr, 0 to 5 percent of Mo, 0 to 2 percent of Nb, 0 to 2 percent of Si and the balance of Co. The preparation method is characterized by melting by adopting a vacuum arc furnace, carrying out solid solution heat treatment at 1250 to 1300 DEG C, and carrying out aging heat treatment at 900 to 1150 DEG C. The gamma'-phase intensified cobalt-based superalloy disclosed by the invention is intensified by a gamma' phase having an L12 crystal structure and has a cubic shape, the volume fraction is greater than 65 percent, and the gamma'-phase intensified cobalt-based superalloy is uniformly distributed in a gamma matrix having an A1 crystal structure. A Gamma / gamma' two-phase structure of the gamma'-phase intensified cobalt-based superalloy disclosed by the invention stably exists at 900 to 1150 DEG C, no secondary phase is separated out, and the gamma'-phase intensified cobalt-based superalloy is a candidate material for hot end components of an aircraft engine and an industrial gas turbine.

Owner:UNIV OF SCI & TECH BEIJING

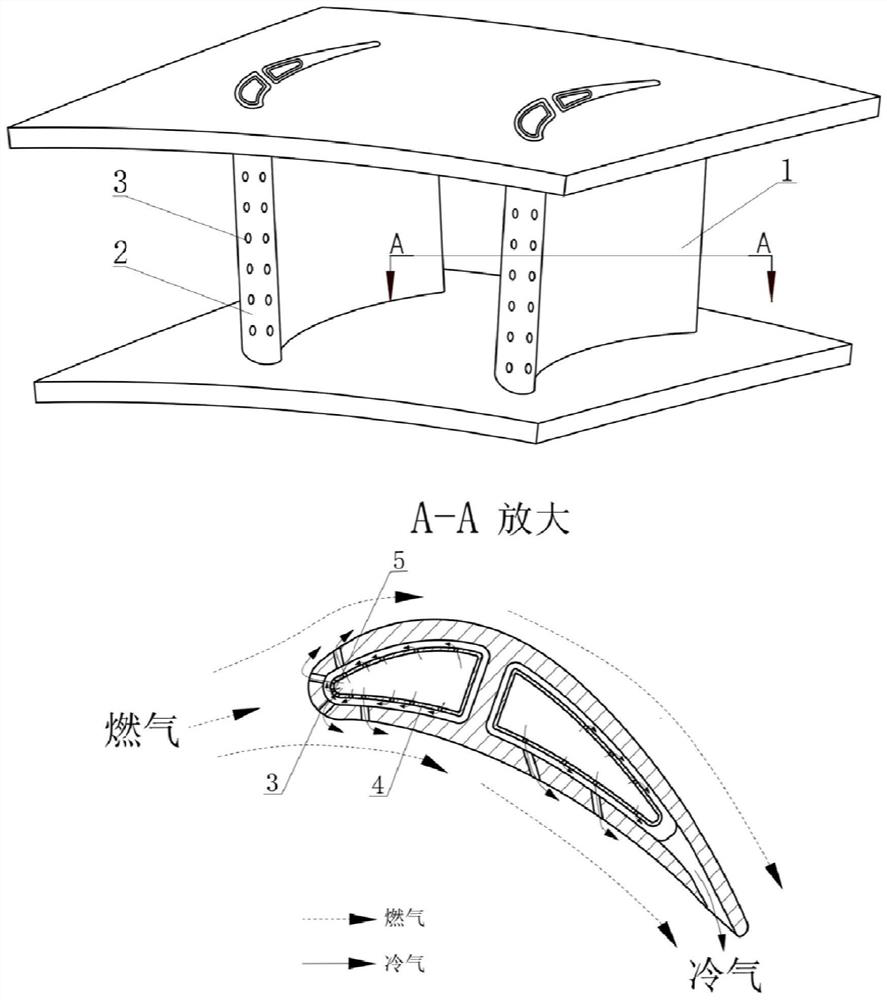

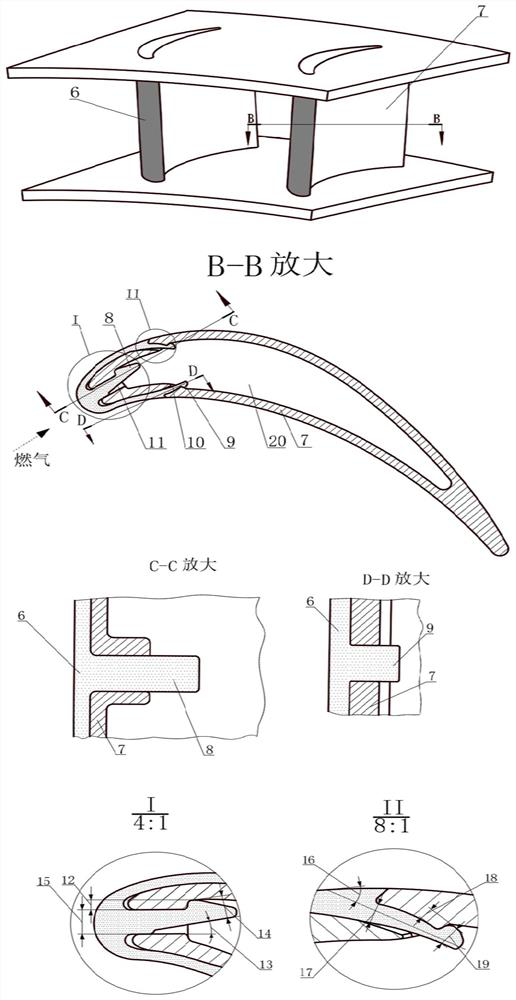

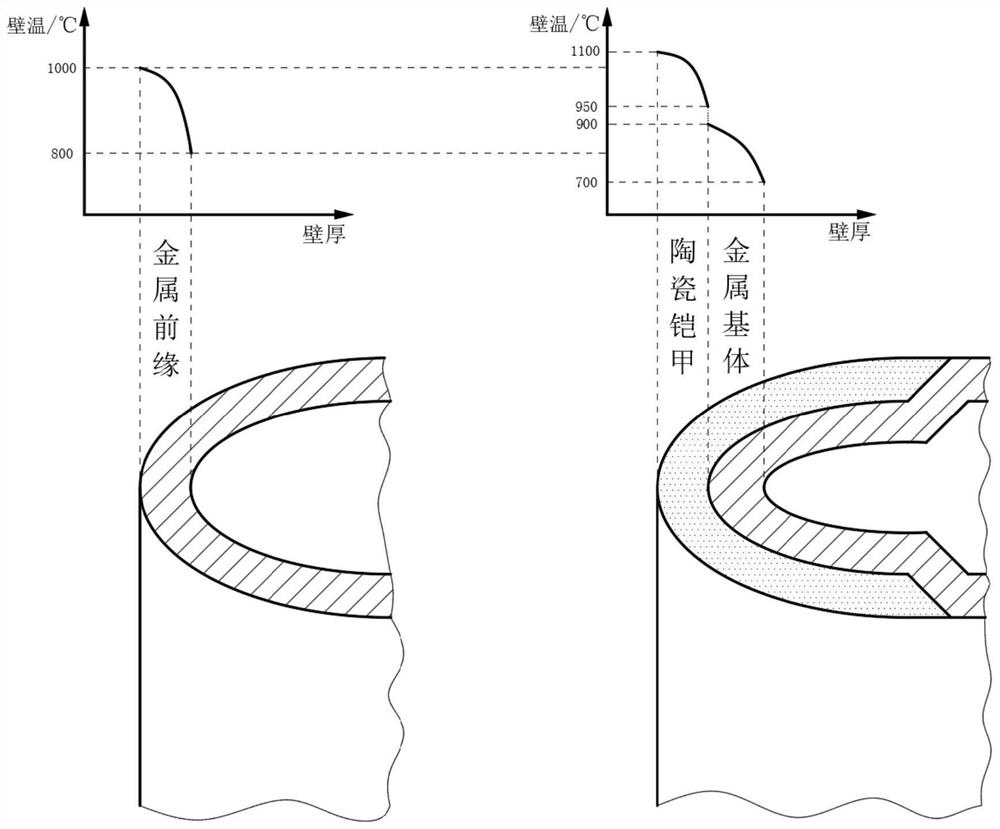

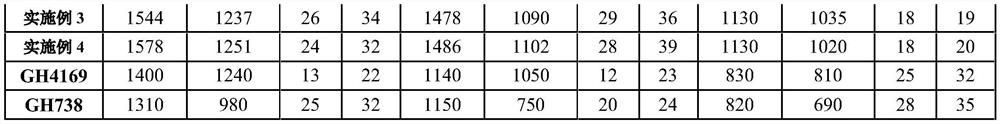

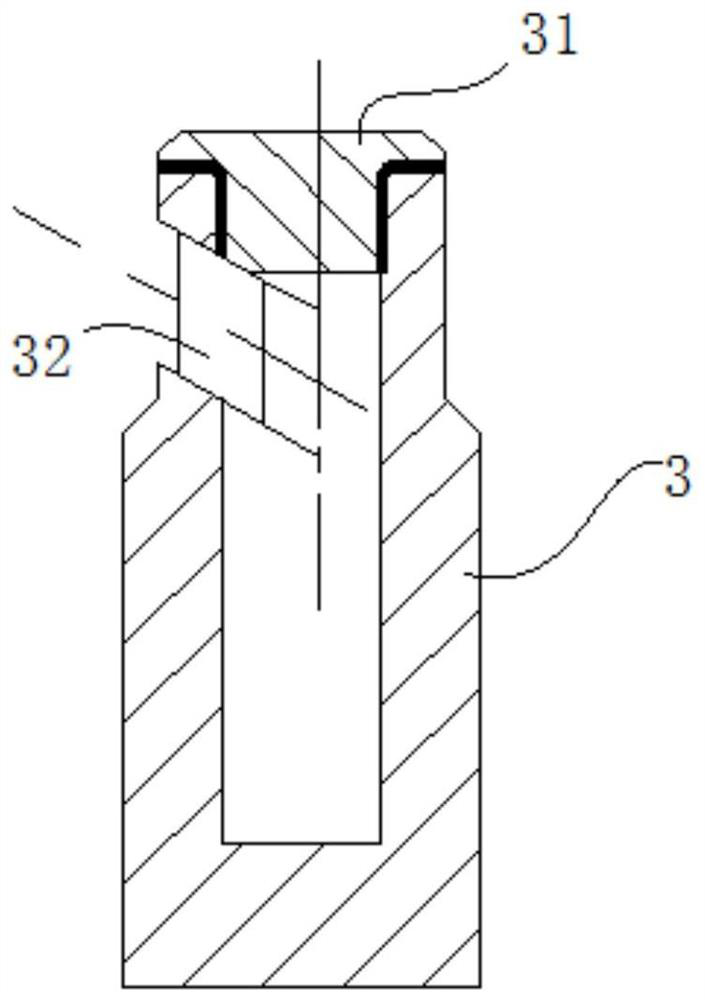

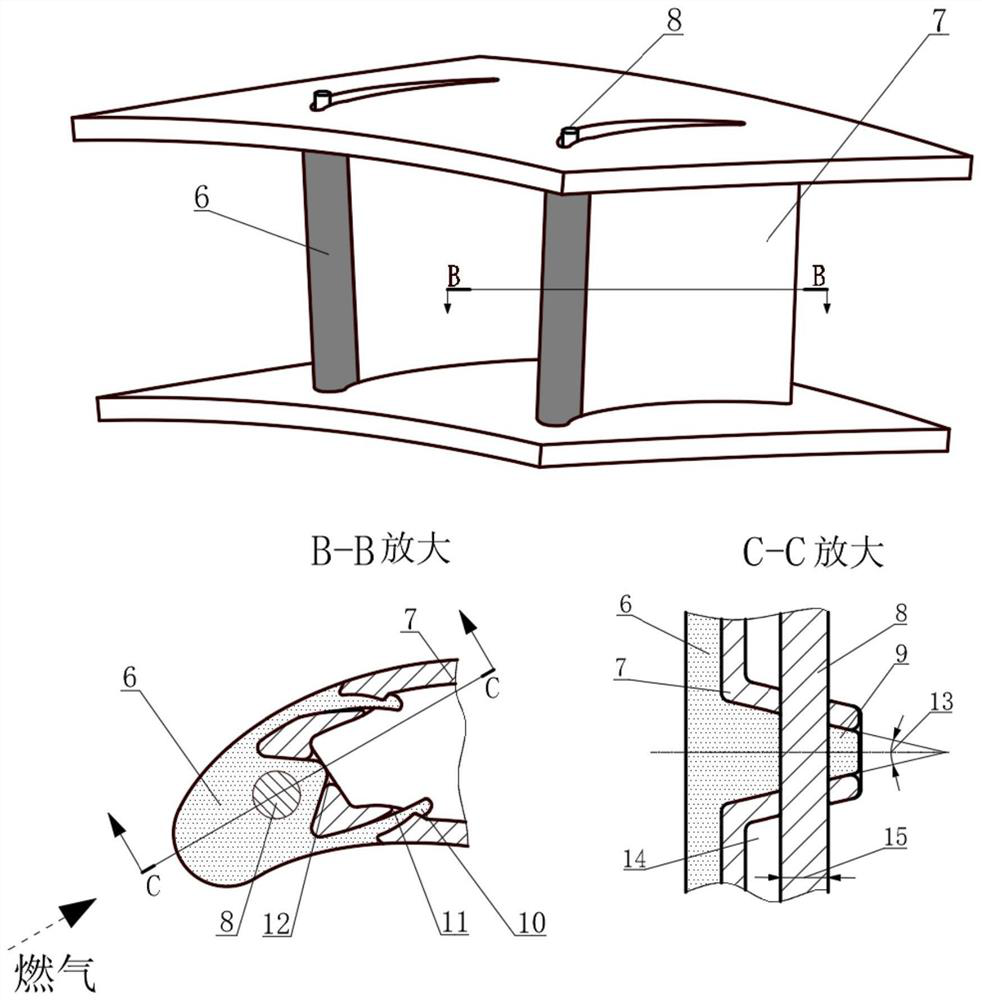

Turbine blade adopting buckle fixing type ceramic armor

ActiveCN112901278AHigh temperature capacityIncrease thrustBlade accessoriesMachines/enginesTurbine bladeFront edge

The invention belongs to the technical field of turbine blades of aero-engines, and relates to a turbine blade adopting a buckle fixing type ceramic armor. The invention discloses the turbine blade adopting the buckle fixing type ceramic armor. According to the structural scheme of the turbine blade, for the front edge area of the turbine blade, a ceramic matrix composite component and a blade metal matrix can be rapidly and stably connected, in addition, on the premise that the original pneumatic shape of the blade is not damaged, the front edge area of the turbine blade is effectively protected, use of cooling gas is reduced, so that the high-temperature resistance of the blade is improved, and the thrust performance of the engine is improved; and meanwhile, after the ceramic armor is damaged, the ceramic armor can be conveniently replaced in the maintenance process, in addition, the high-value blade metal matrix can be recycled, the service life is prolonged, and therefore the use and maintenance economical efficiency of the engine is greatly improved.

Owner:DALIAN UNIV OF TECH

Nickel-based alloys and articles formed from alloys

ActiveCN106191529BHigh temperature capacityImprove mechanical propertiesMachines/enginesEngine componentsHafniumCobalt

The invention provides a nickel-based alloy, comprising: 7wt%-8wt% cobalt; 12wt%-13wt% chromium; 6.35wt%-6.65wt% aluminum; 5.25wt%-5.75wt% tantalum; 5.25wt% %~5.75wt% tungsten; 0.57wt%~0.63wt% hafnium; 0.04wt%~0.06wt% carbon; 0.003wt%~0.005wt% boron; 0.02wt%~0.10wt% silicon; balance of nickel. In this application, by balancing the content of strengthening elements W, Mo, Ta, Al, Co and other elements in the alloy, and increasing the content of Cr, the alloy has excellent oxidation resistance, corrosion resistance and temperature-bearing performance. It can maintain good structural stability and does not contain Re, which reduces the cost of the alloy.

Owner:CENT SOUTH UNIV +1

A kind of high-strength refractory nickel-based superalloy and preparation method thereof

The invention discloses a high-strength refractory nickel-based superalloy and a preparation method thereof. By optimizing the alloy composition, vacuum induction smelting, electroslag remelting, vacuum consumable remelting, forging and heat treatment are adopted, and the processes of each process are controlled. The parameters ensure the feasibility of the engineering application of the high-strength refractory nickel-based superalloy, so as to obtain a high-strength refractory nickel-based superalloy with high strength, high microstructure stability and good hot workability. , its tensile strength and durability at 650 °C are better than those of GH4169 alloy, and its tensile strength and durability at 750 °C are better than those of GH738 alloy.

Owner:宝武特种冶金有限公司

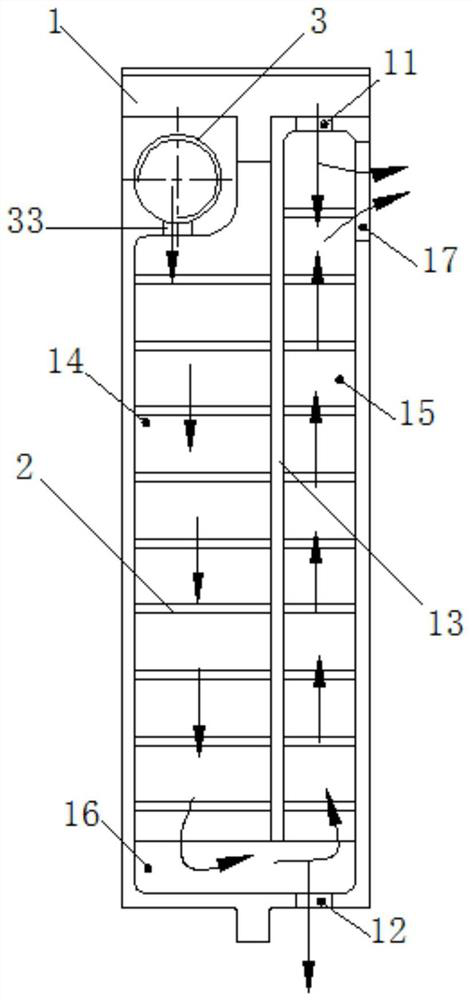

Self-circulation cooling honeycomb seat structure

ActiveCN113586178AImprove cooling effectHigh temperature capacityLeakage preventionMachines/enginesHoneycombCooling effect

The invention discloses a self-circulation cooling honeycomb base structure. The self-circulation cooling honeycomb base structure comprises a base body of a honeycomb base, and ribs distributed on the bottom surface of a top groove of the base body at intervals, a front end inlet groove and a rear end outlet groove for air to flow are correspondingly formed in the front wall face and the rear wall face of the base body, after air enters the top groove of the base body, turbulent flow is formed on the ribs distributed at intervals, and the top groove of the base body between adjacent honeycomb bases conducts air exchange flow through the front end inlet groove and the rear end outlet groove. Therefore, heat exchange is enhanced, the heat exchange efficiency is improved, The top groove of the base body between the honeycomb bases carry out gas exchange flow through the front end inlet groove and the rear end outlet groove, and gas can carry out efficient heat exchange among the honeycomb bases, so that the cooling effect of the honeycomb bases is improved, the temperature bearing capacity of the honeycomb bases is improved, and the problem that gas cannot perform efficient heat exchange among a plurality of honeycomb bases is solved.

Owner:中国航发贵阳发动机设计研究所

A heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties

The invention belongs to the technical field of new materials, and provides a heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties, which is mainly used in automobile engine exhaust system components of which the exhaust temperature exceeds 1000 DEG C, including exhaust manifolds, turbine casings and the like. The heat-resistant cast austenitic stainless steel comprises the following alloy components in percentage by mass: 0.1%-0.6% of C, 0.1%-0.5% of N, 0.4%-1.5% of Si, less than 1.5% of Mn, 17.5%-22.5% of Cr, 8.0%-13.0% of Ni, 1.0%-3.0% of Nb, less than 5.0% of W, less than 6.5% of Mo and the balance of matrix element Fe and impurity elements, including less than 0.04% of P, less than 0.03% of S, less than 0.04% of O and less than 0.05% of Al. The heat-resistant austenitic stainless steel is produced by a casting method without later-period heat treatment, and has the advantages of lower production cost, higher temperature resistance and higher durability as compared with like heat-resistant cast steel.

Owner:UNIV OF SCI & TECH BEIJING

Nickel-based high temperature alloy and preparing method thereof

The invention provides a nickel-based high temperature alloy and a preparing method thereof, and specifically a metallurgical nickel alloy with powder not containing the element Nb and objects manufactured from the metallurgical nickel alloy. The nickel-based high temperature alloy comprises, by mass, 12.5-13.5% of Co, 13.75-14.25% of Cr, 2.8-3.2% of Al, 3.8-4.2% of Ti, 3.75-4.25% of W, 3.75-4.25% of Mo, 2.8-3.2% of Ta, 0.17-0.23% of Hf, 0.04-0.06% of C, 0.003-0.015% of B, 0.03-0.07% of Zr and the balance Ni. The high temperature alloy has better structure stability and high-temperature strength, and temperature capability of the alloy is further improved.

Owner:CENT SOUTH UNIV +1

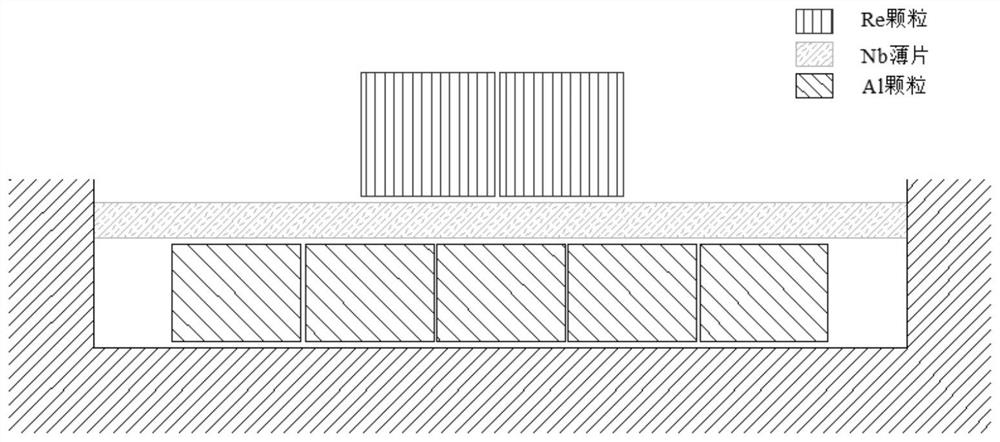

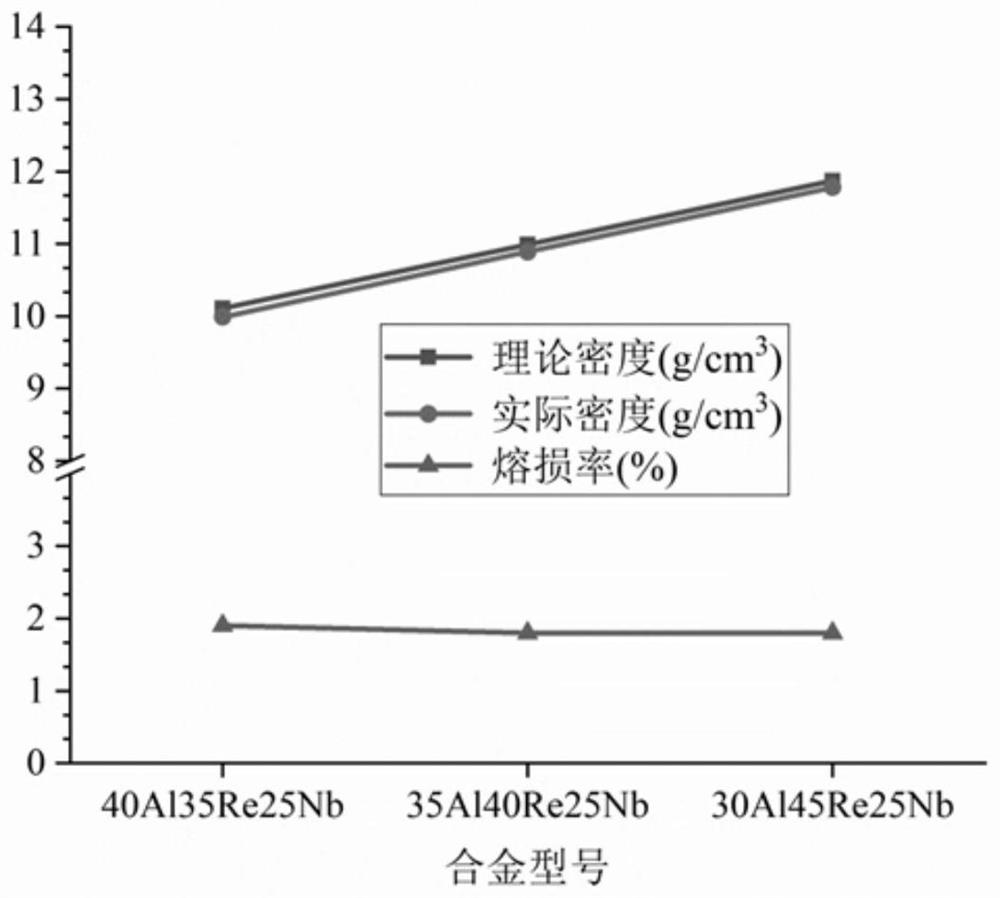

A kind of al-re-nb ternary alloy containing both high melting point and low boiling point elements and preparation method thereof

The invention discloses an Al-Re-Nb ternary alloy containing elements with high melting point and low boiling point and a preparation method thereof, wherein the melting point of the Re element is 3180°C, the melting point of the Nb element is 2467°C, and the boiling point of the Al element is 2467°C ℃. Al-Re-Nb ternary alloys are smelted by using three elements of Al, Re and Nb with a purity of 99.99%. The preparation process of the alloy of the invention is simple and convenient, and the price is low. The amount of melting loss of the alloy prepared by the invention is greatly reduced, the actual density of the obtained alloy is close to the theoretical density, and the melting loss rate of the alloy is less than 1.9%.

Owner:XIANGTAN UNIV

A method for improving the seam quality of gh4151 inertial friction welding

ActiveCN113770508BHigh temperature capacityIncrease thrustAnalysing solids using sonic/ultrasonic/infrasonic wavesFluorescence/phosphorescenceFriction weldingEngineering

The patent of the present invention relates to a process method for improving the quality of GH4151 inertial friction welding seam, which belongs to the field of welding technology of GH4151 alloy used for core rotor parts and disk shaft parts of aero-engines; the process method includes three-stage pressure method of inertial friction welding , Before welding, the machining allowance is reserved for the inside and outside of the welding boss and the final part size. After the welding is completed, the flash removal and heat treatment are completed within a limited time, and the defect detection is carried out in sequence. The three-stage pressure process method can prevent the tip cracks of the welding flash from penetrating into the weld matrix and make the flash continuous. Before the welding, the machining allowance is reserved on the inside and outside of the welding boss and the final part size, which can completely remove the possible flash edge defects and ensure the final weld seam quality of the parts. The invention also utilizes different detection sequences to carry out overall quality inspection on the surface of the weld seam, the shallow surface and the inside of the weld seam, thereby effectively improving the quality of the weld seam and the level of defect detection.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A kind of nickel base superalloy and preparation method thereof

ActiveCN106282667BMaintain solid solution strengthening effectReduce leachingNickel alloyUltimate tensile strength

The invention provides nickel-base superalloy and a preparation method thereof, and in particular relates to powder metallurgy nickel alloy with high stability, and articles made from the powder metallurgy nickel alloy. The nickel-base superalloy is prepared from the following components by mass percent: 18.5-19.5% of Co, 12.75-13.25% of Cr, 2.8-3.2% of Al, 3.5-3.9% of Ti, 3.75-4.25% of W, 3.75-4.25% of Mo, 0.9-1.1% of Ta, 1.1-1.3% of Nb, 0.17-0.23% of Hf, 0.04-0.06% of C, 0.003-0.015% of B, 0.03-0.07% of Zr and the balance of Ni. The superalloy designed by the invention has better structure stability and high-temperature strength, and the temperature tolerance of the alloy is further improved.

Owner:CENT SOUTH UNIV +1

A kind of nickel base superalloy and preparation method thereof

The invention provides a nickel-based high temperature alloy and a preparing method thereof, and specifically a metallurgical nickel alloy with powder not containing the element Nb and objects manufactured from the metallurgical nickel alloy. The nickel-based high temperature alloy comprises, by mass, 12.5-13.5% of Co, 13.75-14.25% of Cr, 2.8-3.2% of Al, 3.8-4.2% of Ti, 3.75-4.25% of W, 3.75-4.25% of Mo, 2.8-3.2% of Ta, 0.17-0.23% of Hf, 0.04-0.06% of C, 0.003-0.015% of B, 0.03-0.07% of Zr and the balance Ni. The high temperature alloy has better structure stability and high-temperature strength, and temperature capability of the alloy is further improved.

Owner:CENT SOUTH UNIV +1

A turbine blade with bolt-on ceramic armor

ActiveCN112901279BHigh temperature capacityIncrease thrustBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention belongs to the technical field of aero-engine turbine blades, and relates to a turbine blade adopting a bolt-fixed ceramic armor. The structural scheme of the present invention is aimed at the leading edge area of the turbine blade, which can realize the fast and stable connection between the ceramic matrix composite material component and the metal matrix of the blade, and effectively protect the leading edge area of the turbine blade without destroying the original aerodynamic appearance of the blade And reduce the use of cooling gas to improve the high temperature resistance of the blades, as well as the thrust performance of the engine. At the same time, after the ceramic armor is damaged, it can be easily replaced during maintenance, and the high-value blade metal substrate can be reused to prolong its life, thereby greatly improving the economy of engine use and maintenance.

Owner:DALIAN UNIV OF TECH

Low stacking fault energy superalloys, structural parts and their applications

ActiveCN112981186BHigh temperature capacityHigh temperature strengthAdditive manufacturing apparatusBlade accessoriesCombustion chamberSuperalloy

The invention relates to the technical field of high-temperature alloys, in particular to a high-temperature alloy with low stacking fault energy, structural parts and applications thereof. The superalloy includes: C0.01%~0.09%, Co23.5%~27.5%, Cr11%~15%, W0.1%~1.8%, Al2.2%~2.6%, Ti3.5 %~5.5%, Nb0%~2%, Ta0%~2%, Mo2.1%~3.5%, B0.0001%~0.05%, Zr0.0001%~0.05%, Fe0%~2.5%, Mg0%~ 0.04%, the balance is Ni; the sum of the mass fractions of Nb and Ta≥0.8%. The superalloy of the present invention can take into account the service performance above 750°C and good thermal processing characteristics, and can be used as structural parts such as turbine disks, blades, casings, and combustion chambers for a long time.

Owner:BEIJING CISRI GAONA TECH +1

A kind of nickel base casting alloy and preparation method thereof

The invention belongs to the technical field of new materials, and provides a nickel-based casting alloy and a preparation method thereof, which are mainly applied to high-temperature load-bearing structural parts of ramjet engines whose wall surface temperature reaches 1200°C, such as air intake structural parts. The alloy composition contains C: 0.1‑0.25%, Cr: 7.5‑10.7%, Co: 8‑12%, W: 8‑12%, Al: more than 6.25%, Ti: 0.75‑2%, Ta: 2‑3%, Hf: 0.8‑2.5%, Zr: 0.01‑0.15%, B: 0‑0.2%, and the remainder is matrix element Ni and impurity elements. The nickel-based casting alloy of the invention is produced by investment casting method, and after being subjected to standard heat treatment at 870°C / 16h, it has higher temperature bearing capacity and durability than similar casting superalloys.

Owner:BEIJING CISRI GAONA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com