Nickel-based casting alloy and preparation method thereof

A casting alloy and nickel-based technology, which is applied in the fields of nickel-based casting alloy and its preparation, nickel-based casting high-temperature alloy, air intake structural parts, and high-temperature load-bearing structural parts, and can solve the problem of not fully meeting the requirements of high-temperature structural parts of ramjet engines and other problems, to achieve high-temperature oxidation resistance and room temperature tensile properties, improve work reliability and performance levels, and improve high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The method for preparing the above-mentioned nickel-based casting alloy provided by the present invention includes: mixing, melting, refining and casting the alloy raw materials under vacuum conditions in sequence.

[0028] In the method of the present invention, the vacuum condition may be a condition with a vacuum degree below 10 Pa (eg, 5-10 Pa).

[0029] In the method of the present invention, the mixing melting and refining can be carried out in a conventional manner, but preferably, the mixing melting and refining method is as follows: when the vacuum degree is lower than 10Pa, power transmission is started, the power transmission power is 25-35KW, and the alloy raw materials are After full melting, reduce the power to 15-25KW for refining until the molten steel surface is clean and without film. Mixed melting and refining can be carried out in a vacuum induction furnace crucible.

[0030] In the method of the present invention, conventional methods can be used for...

Embodiment 1-3

[0036] (1) prepare alloy raw material according to the composition shown in Table 1;

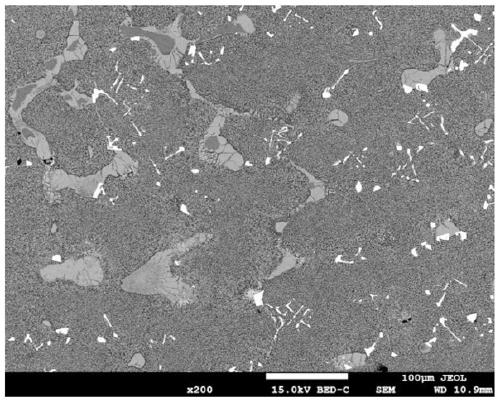

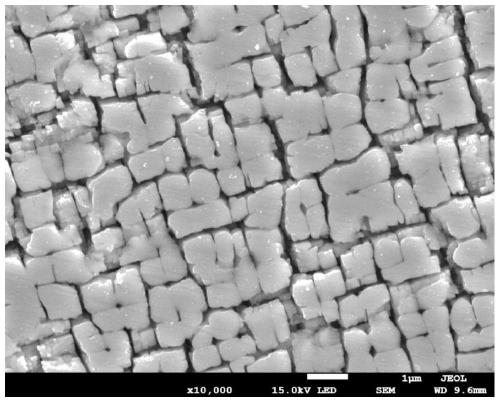

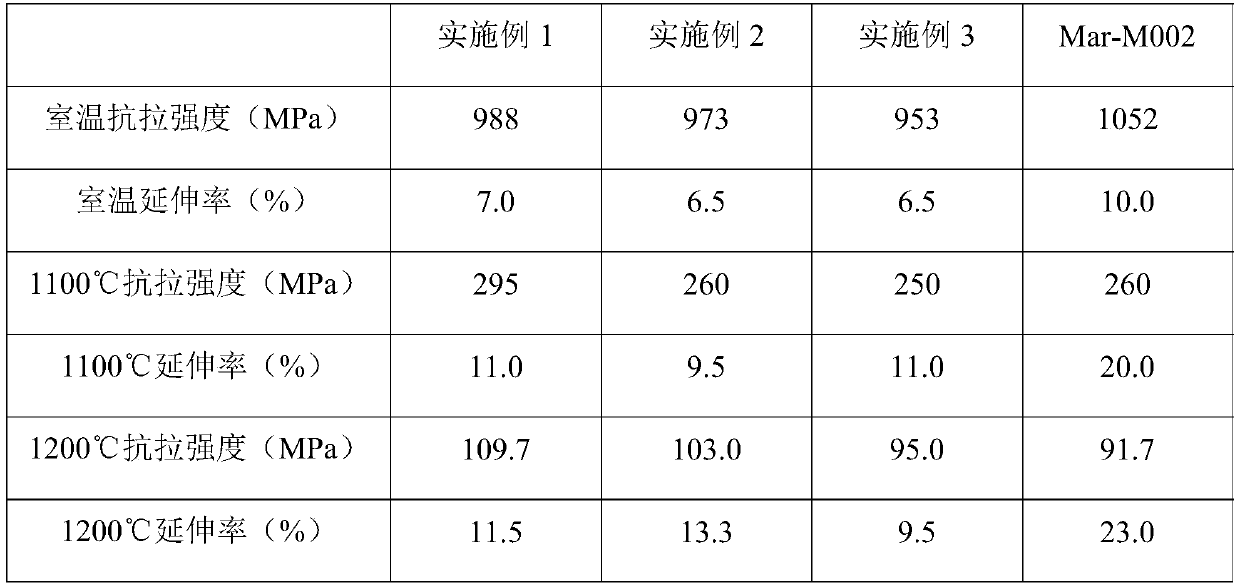

[0037] (2) Put the alloy raw material prepared above into the crucible of the vacuum induction furnace, and start to transmit electricity after the vacuum is below 10Pa. The power transmission power is 30KW. After the alloy raw material is fully melted, the power is reduced to 20KW and refined until the molten steel surface is clean and free of film. , when the molten steel temperature is about 25°C higher than the alloy pouring temperature, the power is cut off and the temperature is measured. The power transmission power is 10KW for casting and molding. Base cast alloy ingots. figure 1 Typical low magnification (×200 magnification) microstructure of the alloy obtained in Example 1, figure 2 The typical structure of the dendritic stem γ' strengthened phase of the alloy obtained in Example 1 was obtained by observation with a field emission scanning electron microscope.

[0038] Mar-M002 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com