A method for improving the seam quality of gh4151 inertial friction welding

A GH4151, inertial friction welding technology, applied in the direction of welding/welding/cutting items, manufacturing tools, measuring devices, etc., can solve the problems of welding flash fracture, flash discontinuous distribution, etc., and achieve the elimination of welding stress and temperature bearing capacity Improve and solve the effect of defects such as weld cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A welding method for improving the weld seam quality of GH4151 alloy, comprising the steps of:

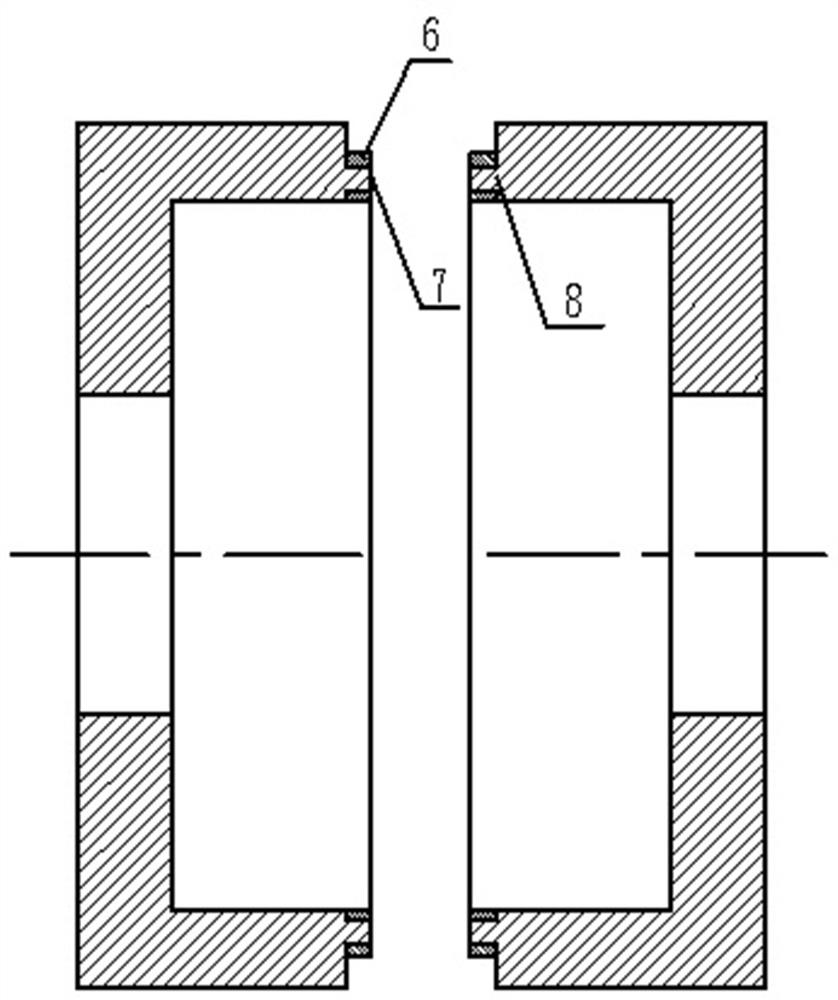

[0029] Step 1: Design the welding structure of the GH4151 alloy inertia friction welding weldment: such as figure 2 As shown, before welding, the inner and outer surfaces of the welding boss 6 and the size of the final part 8 retain a machining allowance, the outer surface retains a 2mm allowance, and the inner surface retains a 1mm allowance;

[0030] Step 2: Process the GH4151 alloy ring to the size of the welded structure, the welded outer diameter is 100mm, and the welded thickness is 8mm, such as figure 2 As shown, the roughness of the welding contact surface 7 is Ra1.6;

[0031] Step 3: Check the fit between the weldment and the tooling before welding, keep the parts in a clamped state, use alcohol to clean the welding surface, and wipe off oil and other foreign matter;

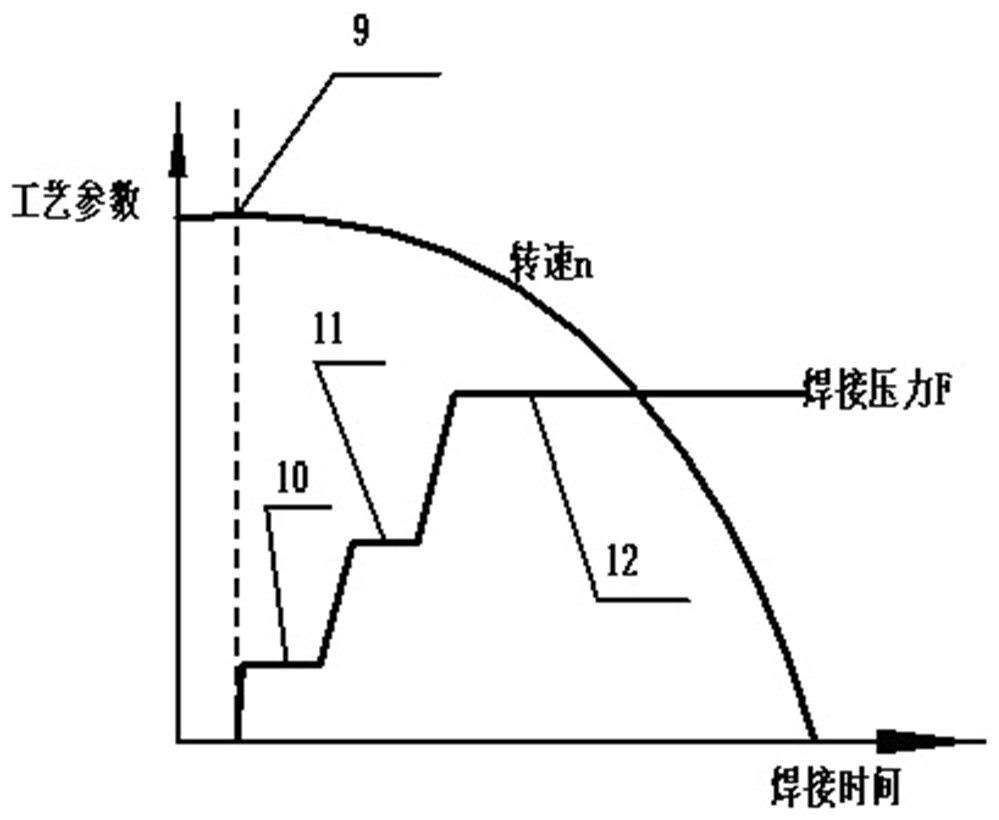

[0032] Step 4: Select the welding parameters, the welding inertia is 600kg. m 2 , Welding sp...

Embodiment 2

[0042] A welding method for improving the weld seam quality of GH4151 alloy, comprising the steps of:

[0043] Step 1: Design the welding structure of the GH4151 alloy inertia friction welding weldment, such as figure 2 As shown, before welding, the inner and outer surfaces of the welding boss 6 and the size of the final part 8 retain a machining allowance, the outer surface retains a 2.5mm allowance, and the inner surface retains a 2mm allowance;

[0044] Step 2: Process the GH4151 alloy ring to the size of the welded structure, the welded outer diameter is 250mm, and the welded thickness is 9mm, such as figure 2 As shown, the roughness of the welding contact surface 7 is Ra2.0;

[0045] Step 3: Check the fit between the weldment and the tooling before welding, keep the parts in a clamped state, use alcohol to clean the welding surface, and wipe off oil and other foreign matter;

[0046] Step 4: Select the welding parameters, the welding inertia is 800kg. m 2 , Welding ...

Embodiment 3

[0056] A welding method for improving the weld seam quality of GH4151 alloy, comprising the steps of:

[0057] Step 1: Design the welding structure of the GH4151 alloy inertia friction welding weldment, such as figure 2 As shown, before welding, the inner and outer surfaces of the welding boss 6 and the size of the final part 8 retain a machining allowance, the outer surface retains a 3mm allowance, and the inner surface retains a 2.5mm allowance;

[0058] Step 2: Process the GH4151 alloy ring to the size of the welded structure, the welded outer diameter is 400mm, and the welded thickness is 10mm, such as figure 2 As shown, the roughness of the welding contact surface 7 is Ra2.5;

[0059] Step 3: Check the fit between the weldment and the tooling before welding, keep the parts in a clamped state, use alcohol to clean the welding surface, and wipe off oil and other foreign matter;

[0060] Step 4: Select the welding parameters, the welding inertia is 1000kg. m 2 , Weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com