A kind of nickel base casting alloy and preparation method thereof

A casting alloy and nickel-based technology, which is applied in the fields of nickel-based casting superalloy, nickel-based casting alloy and its preparation, high-temperature load-bearing structural parts, and air intake structural parts, and can solve the problem of not fully meeting the requirements of high-temperature structural parts of ramjet engines and other issues, to achieve high-temperature oxidation resistance and room temperature tensile properties, high temperature-bearing capacity and durability, and to improve work reliability and performance levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The method for preparing the above-mentioned nickel-based casting alloy provided by the present invention comprises: sequentially mixing and melting alloy raw materials, refining and pouring molding under vacuum conditions.

[0028] In the method of the present invention, the vacuum condition may be a condition with a vacuum degree of 10Pa or less (such as 5-10Pa).

[0029] In the method of the present invention, the mixed melting and refining can be carried out in a conventional manner, but preferably, the mixed melting and refining method is as follows: when the vacuum degree is lower than 10Pa, the power transmission starts, the power transmission power is 25-35KW, and the alloy raw material After full melting, reduce the power to 15-25KW for refining until the molten steel surface is clean and free of film. When the molten steel temperature is about 20-30°C higher than the alloy pouring temperature, power off and measure the temperature. Mixed melting and refining c...

Embodiment 1-3

[0036] (1) prepare alloy raw material according to the composition shown in table 1;

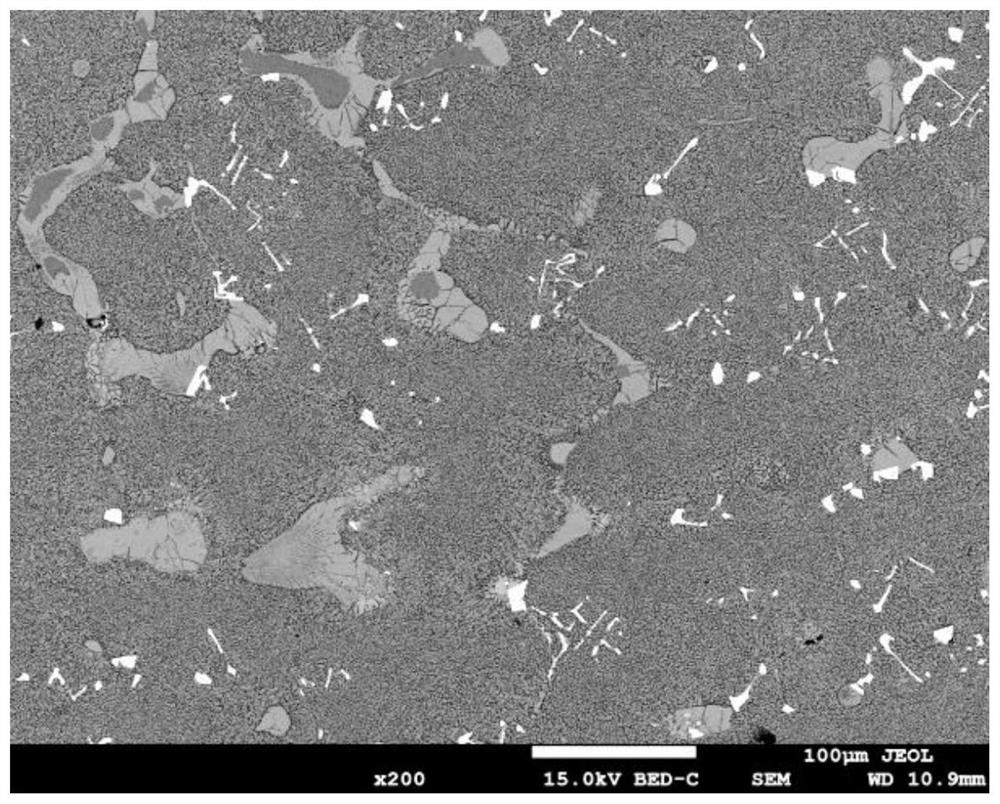

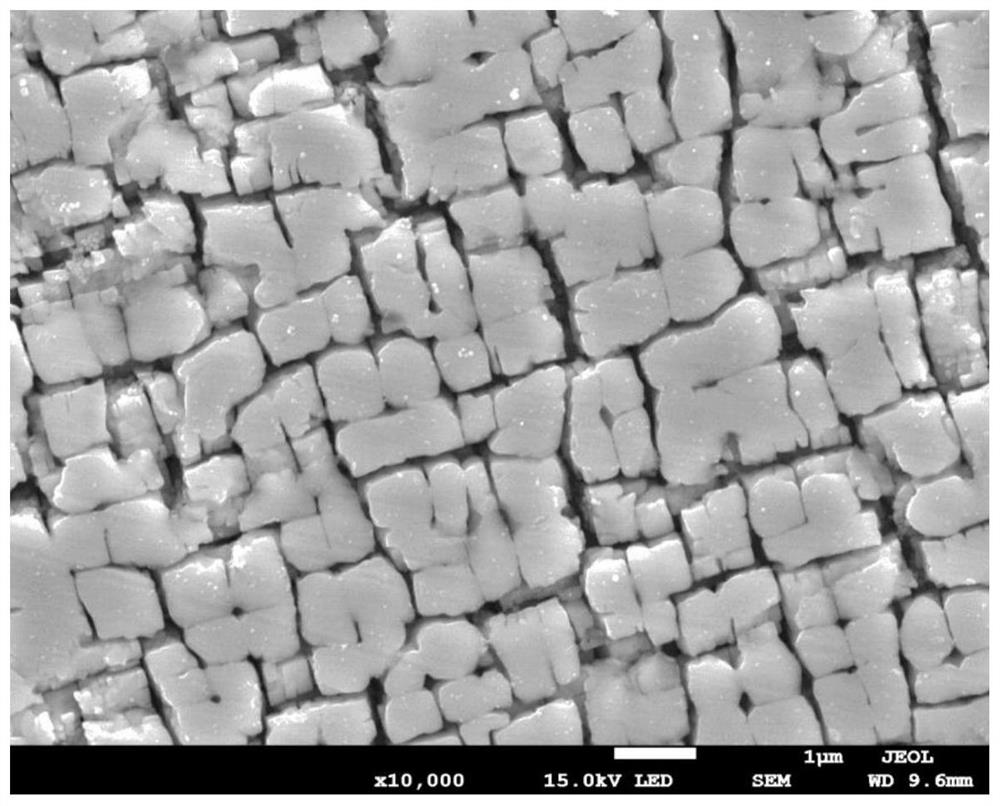

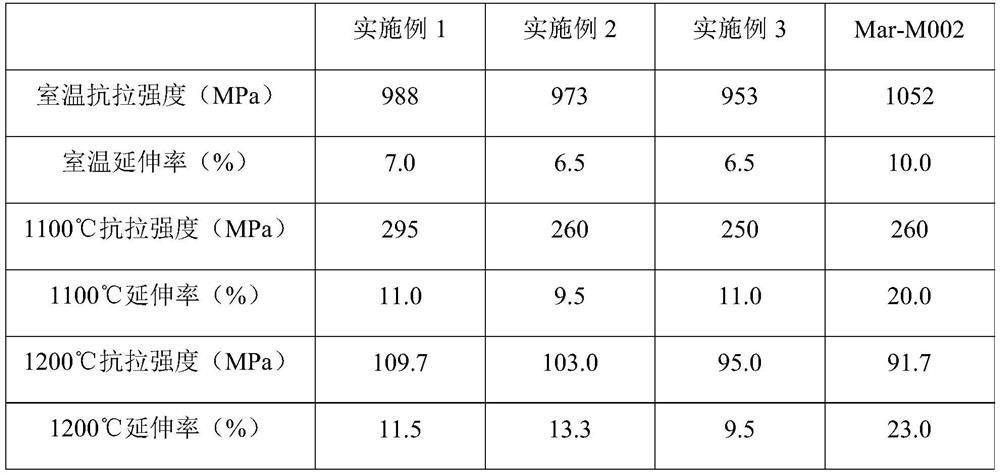

[0037] (2) Put the alloy raw material prepared above into the crucible of the vacuum induction furnace, pump the vacuum to below 10Pa and start power transmission, the power transmission power is 30KW, after the alloy raw material is fully melted, reduce the power to 20KW and refine until the molten steel surface is clean and free of film , When the temperature of the molten steel is about 25°C higher than the pouring temperature of the alloy, the power is cut off to measure the temperature, and the power transmission power is 10KW for pouring molding. The pouring molding temperature is 1480°C, and the mold shell temperature is 900°C; heat treatment at 870°C for 16 hours, and nickel can be obtained. base cast alloy ingots. figure 1 Typical low-magnification (×200 times) microstructure of the alloy obtained in Example 1, figure 2 It is a typical structure of the dendritic stem γ′-strengthen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com