Nickel-based high temperature alloy and preparing method thereof

A high-temperature alloy, mass percentage technology, applied in the field of high-temperature alloys, can solve problems such as mechanical properties decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0189] The present invention has no special limitation on the sources of the raw materials used in the examples, they can be purchased from the market or prepared according to the preparation methods well known to those skilled in the art.

[0190] The present invention has no special restrictions on the preparation method of the powder metallurgy high-temperature nickel alloy without element Nb described in the examples and the source of other raw materials, which can be prepared according to the preparation method well known to those skilled in the art or purchased on the market .

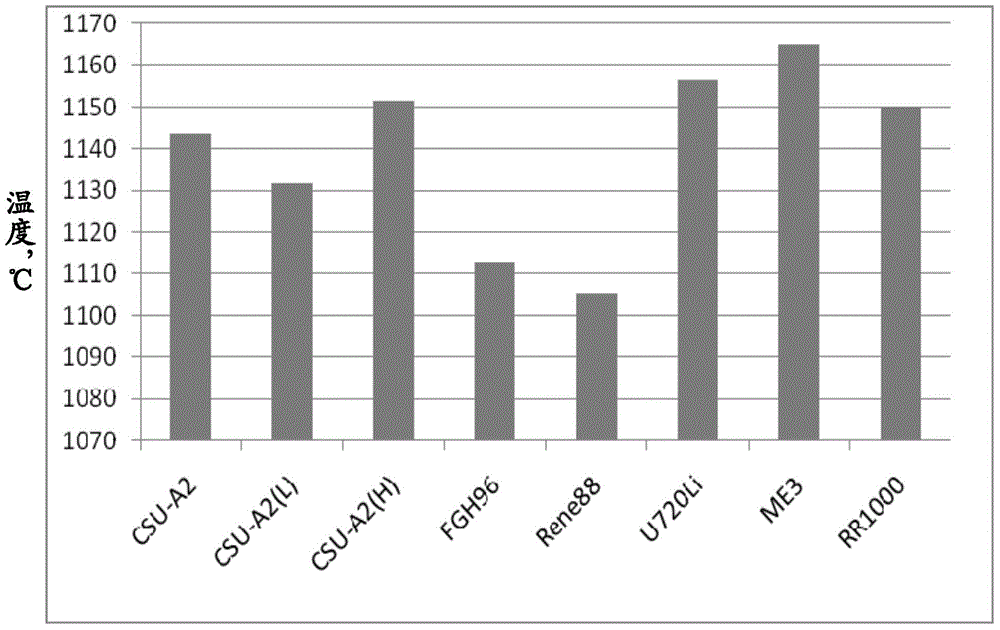

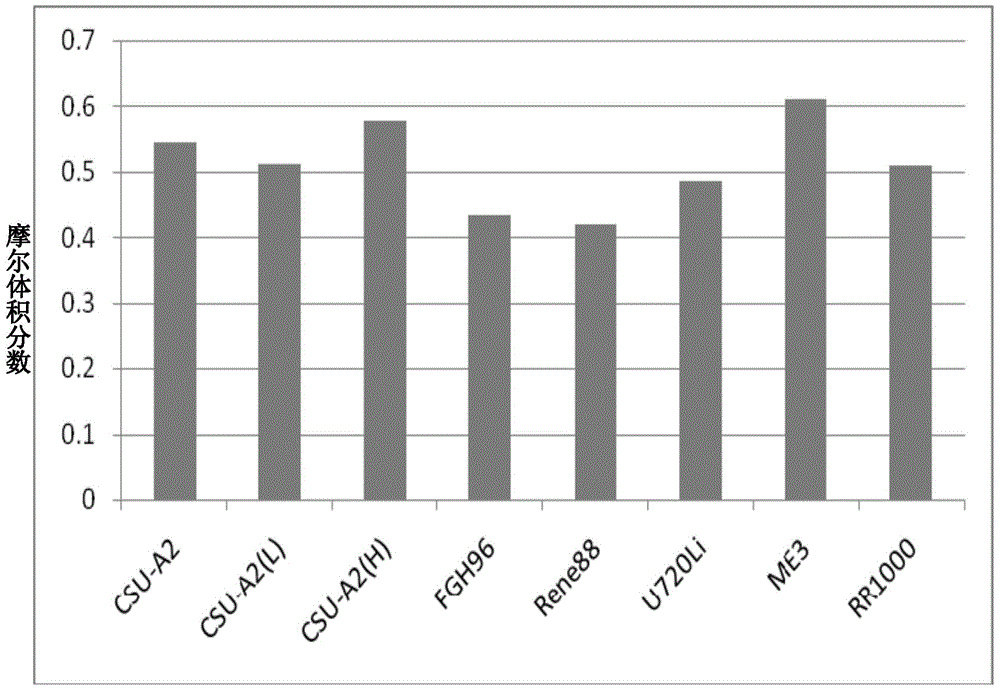

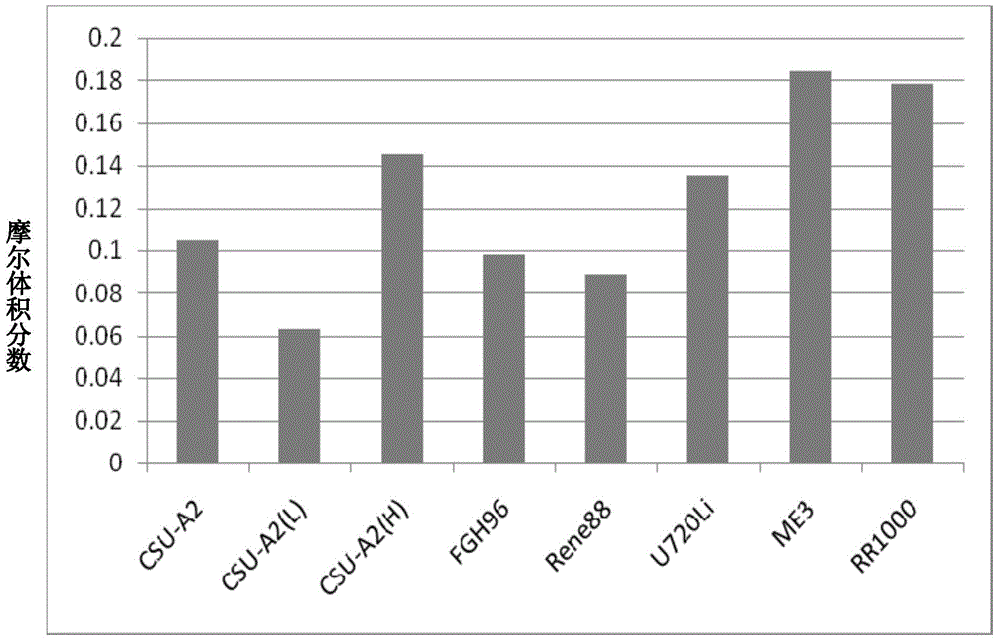

[0191] The present invention prepares the powder metallurgy high-temperature nickel alloy CSU-A2 according to a certain alloy composition ratio, and compares the composition with the existing typical second-generation and third-generation powder metallurgy superalloys. The comparison results are shown in Table 1. 1 is the composition comparison between the superalloy obtained in Example 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com