Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Purify grain boundaries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low alloy steel resisting CO2 and H2S corrosion

The present invention is one kind of low alloy steel capable of being used in oil well pipe to resist CO2 and H2S corrosion. Chemically, its consists of C 0.01-0.30 wt%, Si 0.10-1.0 wt%, Mn 0.10-2.0, Cr 0.50-3.0 wt%, Mo 0.01-1.0 wt%, Ce 0.01-0.25 wt%, V 0.005-0.1 wt%, Cu 0.05-1.0 wt%, Al 0.01-0.10 wt% and small amount of Nb if necessary, except Fe and inevitable impurity, with impurity elements being less than 0.05 wt%. The alloy steel of the present invention after hardening and tempering has mechanical performance reaching the requirement on API 80 and 90 level steel but obviously improved CO2 and H2S corrosion resistance, and is economic oil well pipe steel with moderate cost.

Owner:BAOSHAN IRON & STEEL CO LTD

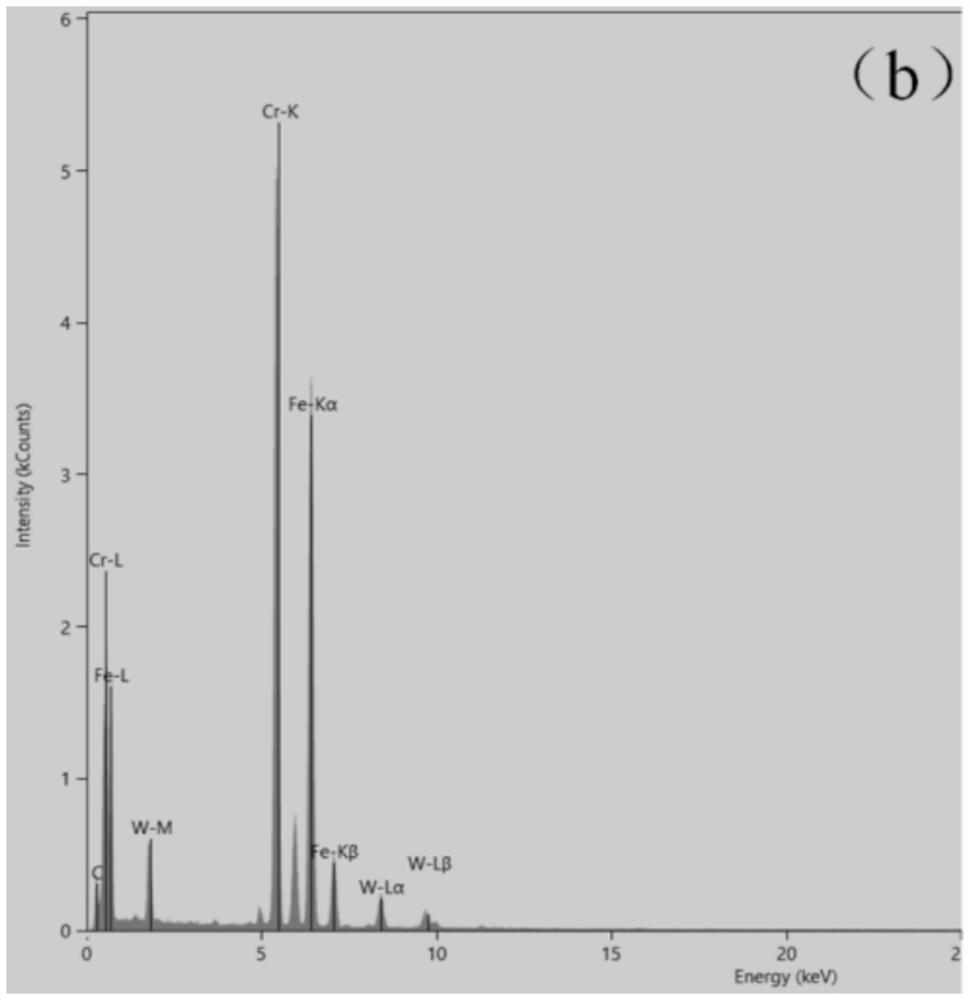

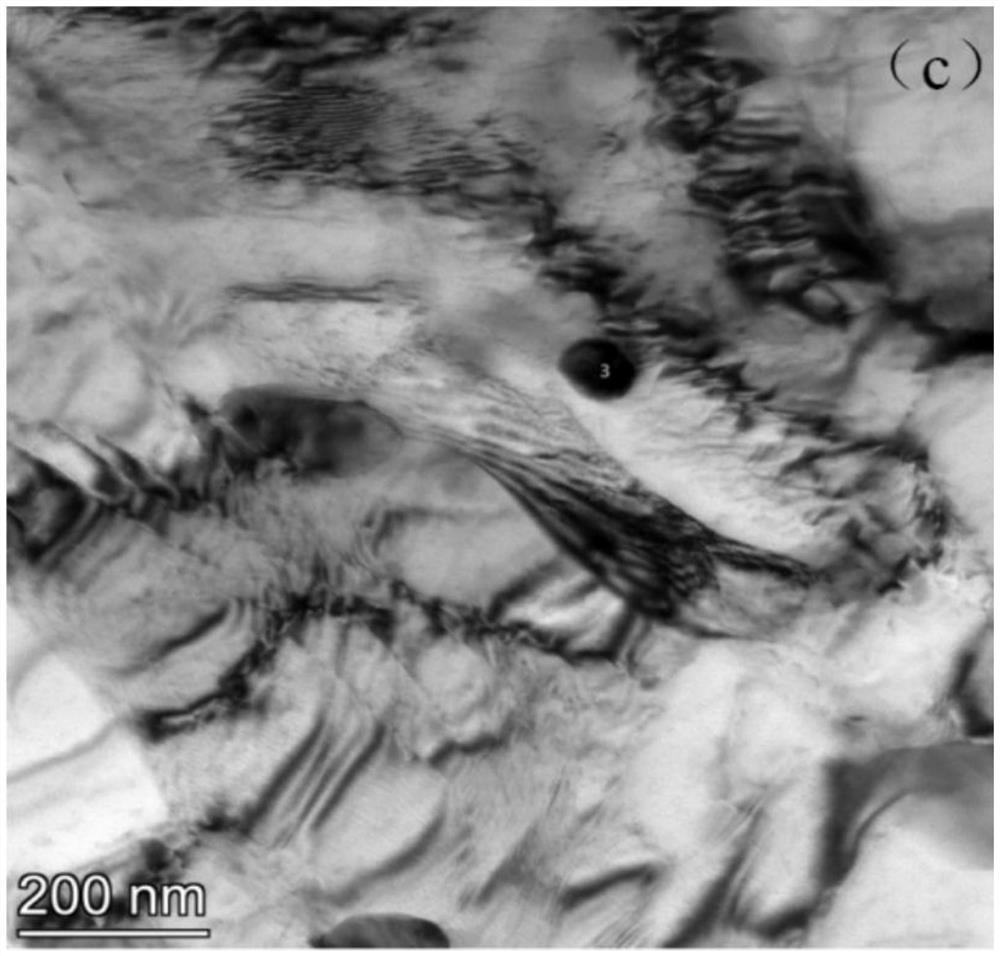

Ultrafine grain wolfram carbide/ cobalt hard alloy and preparation method thereof

The invention discloses an ultrafine grain wolfram carbide (WC) / cobalt hard alloy containing rare-earth hexaboride and a preparation method thereof and belongs to the field of high-performance powder metallurgy materials. The hard alloy comprises the following components in percentage by weight: 0.1 to 2 percent of the rare-earth hexaboride, 0.1 to 0.6 percent of chromium carbide, 0.1 to 0.4 percent of vanadium carbide, 5 to 15 percent of cobalt powder, and the balance of wolfram carbide powder. The preparation method comprises the following steps of: weighing the wolfram carbide powder, the cobalt powder, the rare-earth hexaboride powder, the chromium carbide powder and the vanadium carbide powder with certain granularity in percentage by weight; uniformly mixing the powder by ball milling; pressing the mixture by a mold pressing process to form a green ware body in a certain shape; degreasing the green ware body and sintering the degreased green ware body in a high-temperature low-pressure sintering furnace; and cooling the obtained product along with the furnace to obtain the ultrafine grain wolfram carbide / cobalt hard alloy. The hard alloy has the advantages of rational proportion of the components, simple production process, effective reduction in the grain size of the WC in the hard alloy and improvement on the hardness and fracture toughness of the hard alloy by adulterating the rare-earth hexaboride to inhibit the growth of the wolfram carbide grains in the sintered hard alloy, achievement of high hardness and fracture toughness and application in industrial production.

Owner:昆山长鹰硬质材料科技股份有限公司

Iron-based high-titanium wear-resistant surfacing flux-cored welding wire

InactiveCN101664862AAchieving wear resistanceImprove performanceWelding/cutting media/materialsSoldering mediaBorideCrazing

The invention relates to an iron-based high-titanium wear-resistant surfacing flux-cored welding wire. Among a plurality of types of the prior wear-resistant surfacing welding wires and alloys, some alloys have favorable wearing resistance, and some alloys have great brittleness, lower toughness and easy cracking and are not suitable for the existence of low-impact grinding wear working condition.The iron-based high-titanium wear-resistant surfacing flux-cored welding wire comprises a low-carbon steel ladle clad and core powder as well as the following alloy elements in percentage by weight:1.0-3.0 C, 1.0-12.0 Ti, 0.5-9.0 V, 0.1-1.5 Si, 0.2-2.0 Mn, 0-3.0 B, 0.00-0.10 RE, 0-13.0 Cr, 0-1.0 Mo, 0-1.0 W, 0-2.0 Ni, 0-0.5 Nb and 0-0.5 Zr. The iron-based high-titanium wear-resistant surfacing flux-cored welding wire realizes the wear-resistant performance of the alloys mainly by carbides and borides formed by the alloy elements of C, Ti, V, and the like as well as a small amount of B element and adjusts the combination of the elements of C, Ti, V, Si, Mn, B, and the like to adjust the alloy hardness, enhance the toughness and lower the crack sensitivity.

Owner:王新虎

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

Copper-nickel-tin alloy bar and manufacturing method thereof

The invention discloses a copper-nickel-tin alloy bar. The copper-nickel-tin alloy bar comprises, by mass, 14%-16% of nickel, 7%-9% of tin, 0.05%-0.3% of yttrium, 0.8%-1.0% of aluminum, 0.2%-1.0% of niobium, and the balance copper and other impurities. The invention further discloses a manufacturing method of the copper-nickel-tin alloy bar. The method comprises the steps that alloy powder is prepared according to the ingredients and the mass percentages through a gas atomization method, then an alloy ingot blank is prepared through the methods of cold isostatic pressing molding, vacuum sintering and ingot blank covering, and finally the high-quality copper-nickel-tin alloy bar is obtained through the processes of water-sealing hot extrusion, cold rotary swaging, aging treatment and the like. By means of the method, the problems of composition segregation and the like generated in the casting process of a copper-nickel-tin alloy can be avoided, and the yield is high; the copper-nickel-tin alloy bar can have high strength, high toughness and excellent abrasion and corrosion resistance at the same time, and the overall performance is higher than that of beryllium bronze. The copper-nickel-tin alloy bar can be widely applied to manufacturing of bearings, shaft sleeves, bearing bushes and other wear-resisting components which are used in high-load, high-speed and high-corrosion environments like space flight and aviation and oil drilling platforms.

Owner:CENT SOUTH UNIV +1

Abrasion-resistant cast iron material

The invention provides an abrasion-resistant cast iron material, and belongs to the technical field of cast iron materials. The cast iron material consists of the following components in percentage by weight: 2.0 to 3.2 percent of C, 0.6 to 1.2 percent of Si, 2.0 to 3.5 percent of Mn, 12 to 22 percent of Cr, 0 to 0.6 percent of Cu, 0.06 to 0.3 percent of V, 0.02 to 0.15 percent of Ti, 0.001 to 0.003 percent of B, 0.02 to 0.06 percent of Al, 0.02 to 0.15 percent of RE, less than or equal to 0.06 percent of S, less than or equal to 0.1 percent of P, and the balance of iron. In the abrasion-resistant cast iron material, noble metal elements such as molybdenum, tungsten, nickel and the like are substituted by adopting proper manganese (Mn) and trace boron (B), so that the production cost of the cast iron material is greatly reduced; and meanwhile, by adopting the alloy of the proper manganese (Mn) and the trace boron (B), the quenching property and the hardening capacity of the cast iron material are improved. The cast iron material can be used for preparing abrasion-resistant components of lining plates, hammers, steel balls, metallurgical rollers, impurity pumps, overflow componentsand the like.

Owner:驻马店市三山耐磨材料有限公司

High-entropy ceramic composite material with high strength as well as preparation method and application thereof

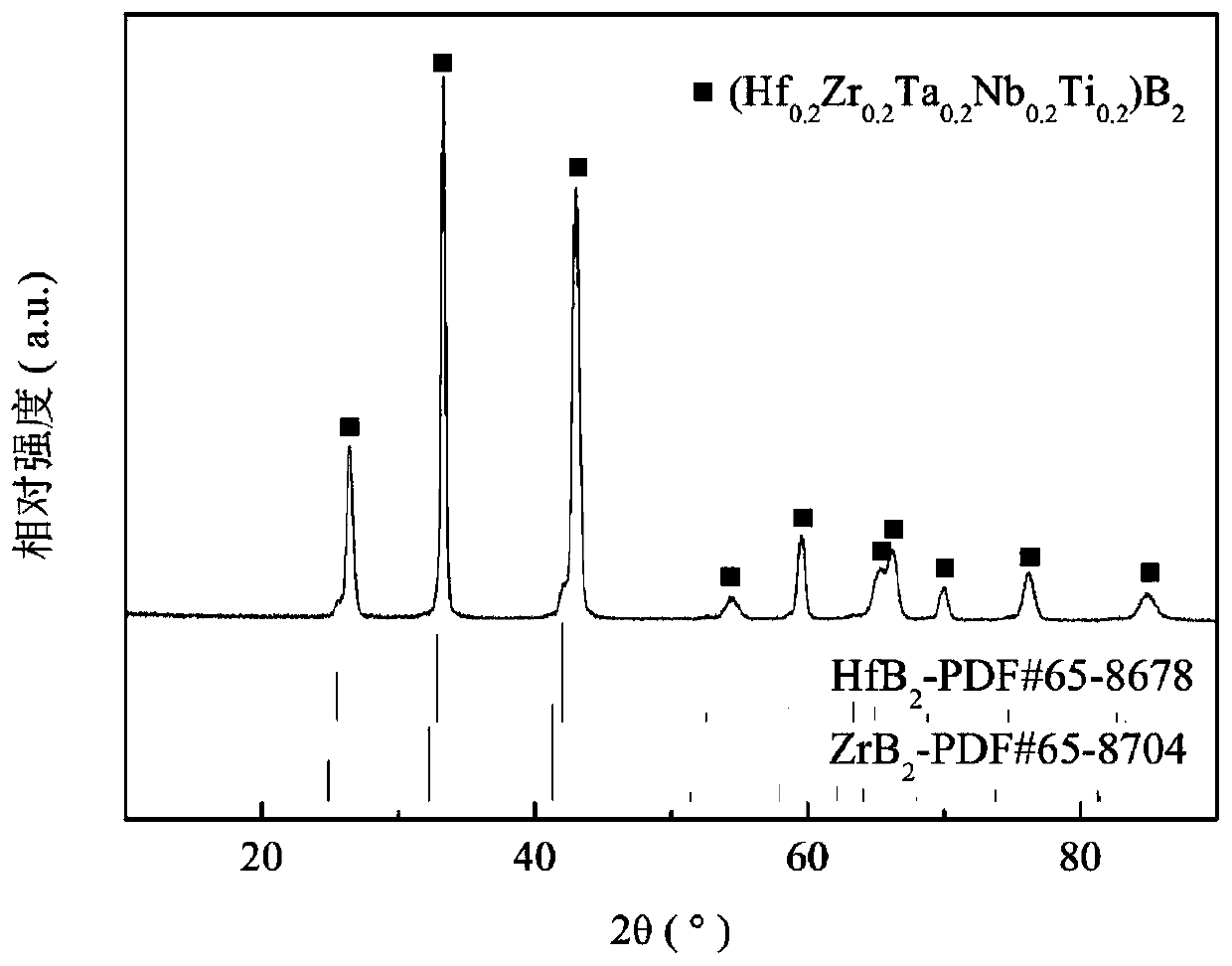

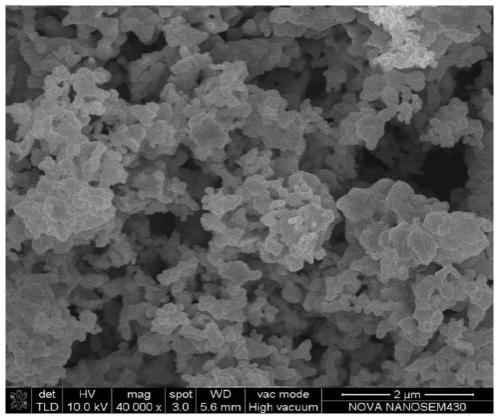

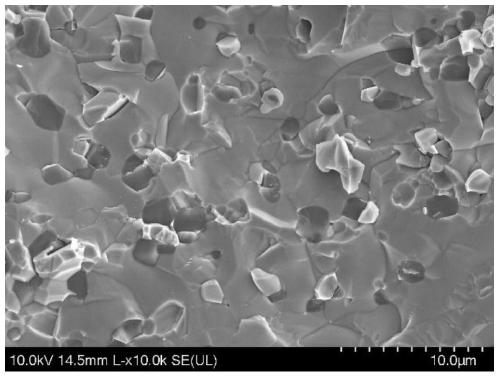

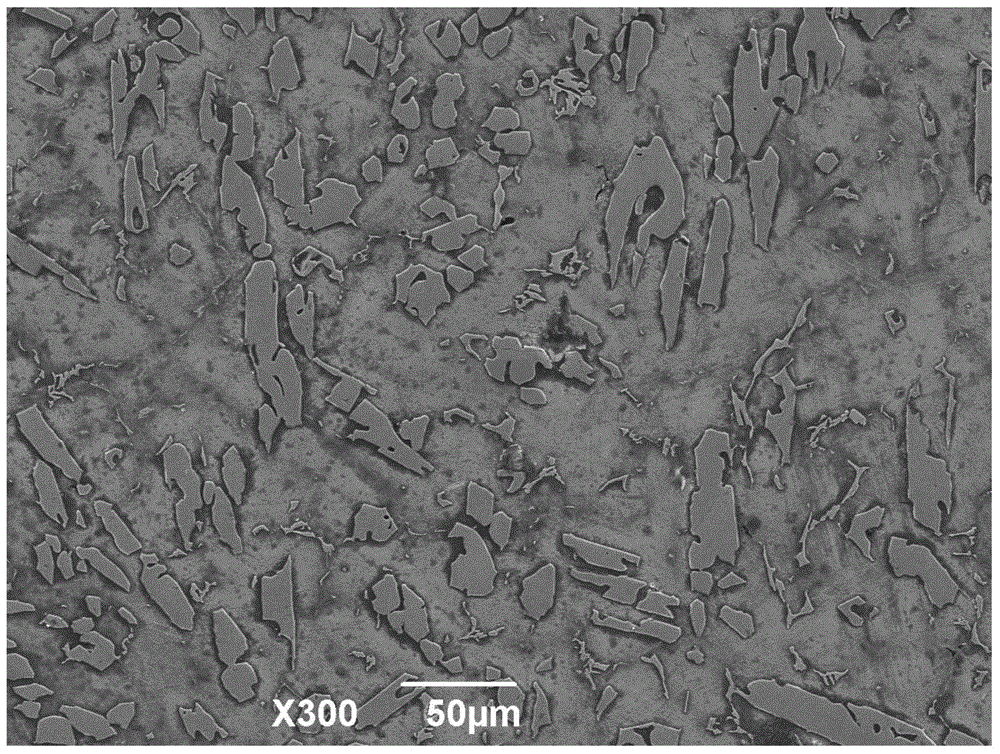

The invention belongs to the technical field of ceramic materials and discloses a high-entropy ceramic composite material with high strength as well as a preparation method and application thereof. The ceramic composite material is prepared through the following steps: Adding a solvent into metal oxide and amorphous boron powder and mixing and drying to prepare high-entropy solid solution powder under a vacuum condition; firstly, raising the temperature to 1000 to 1200 DEG C and then raising the temperature to 1600 to 1800 DEG C; then adding WC to prepare (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)B2-x mol% WC high-entropy composite material powder; when discharging plasmas are heated to 1000 to 1400 DEG C, filling protection gas; then raising the temperature to 1800 to 2200 DEG C and calcining, wherein xis equal to or greater than 0 and less than or equal to 30. The relative density of ceramic provided by the invention is greater than 94 percent and the rigidity is 20 to 45 GPa; the bending strengthof the ceramic composite material and the high-temperature strength at 1200 to 1800 DEG C are 1000 to 1600 MPa.

Owner:GUANGDONG UNIV OF TECH

Novel high-strength corrosion-resistant rare earth aluminum alloy material and preparation method

The invention provides a novel high-strength corrosion-resistant rare earth aluminum alloy material and a preparation method. Based on a high-strength Al-Zn-Mg alloy, a proper amount of elements of Cu, rare earth Ce, rare earth Sc and rare earth Er are added, and the novel Al-Zn-Mg-Cu-Ce-Sc-Er aluminum alloy material is prepared. The material has the beneficial effects of being high in strength, good in plasticity and toughness, resistant to corrosion, good in fatigue resistance and the like. The material is a structural material which can be widely applied to aviation, spaceflight, ships and warships and means of conveyance. The production and preparation method of the material is simple and easy to practice, the processing technology of the material is easy to control, raw materials are sufficient and easy to obtain, the production cost is low, and the material has very wide production and application prospects.

Owner:HEFEI UNIV OF TECH

Method for improving toughness of boracic high-entropy alloy by adding rare earth

ActiveCN104451351APromotes toughening effectImprove comprehensive mechanical propertiesRare-earth elementHigh entropy alloys

The invention discloses a method for improving the toughness of a boracic high-entropy alloy by adding rare earth, belonging to the technical field of alloy materials. According to the component design idea of the invention, a boron element with the mole fraction of 0.1-8% is added into a high-entropy alloy consisting of five or more than five elements, and meanwhile 0.1-4% of a rare earth element such as Y or Ce is added together. Due to addition of the rare earth elements, the gap solid solution reinforcement effect of the small atom boron element in the high-entropy alloy is improved, and the separation content, the morphology and the distribution of rigid boride hard phase are improved, so that the strength and the toughness of the boracic high-entropy alloy are synchronously improved.

Owner:江苏康柏斯机械科技有限公司

Preparation method of silicon nitride-silicon carbide-titanium carbide micro-nano composite material

The invention discloses a preparation method of a silicon nitride-silicon carbide-titanium carbide micro-nano composite material, belonging to the technical field of material science. According to the invention, nano-scale Si3N4 and SiC particles are added to micro-scale Si3N4 and TiC particles, the raw materials are subjected to acid washing, nano particle dispersion and mixing, then through segmental temperature rise and segmental pressurizing vacuum hot pressed sintering process, the transgranular / grain boundary type composite material, of which the length-diameter ratio of silicon nitride grains in a matrix is in bimodal distribution, is prepared, and at the same time, the nano Si3N4 and SiC particles produce a good grain toughening effect, so that the micro-nano composite material has high strength, tenacity and hardness. The micro-nano composite material has hardness HV of up to 19.5Gpa, flexural strength of up to 970Mpa, and fracture toughness of up to 9.5Mpa.m<1 / 2>.

Owner:SHANDONG JIANZHU UNIV

Grate of heat, wear and corrosion-resisting large mechanical reciprocating incinerator and manufacture method of grate

ActiveCN102330036AMeet the design requirementsImprove adhesionIncinerator apparatusImpurityIncineration

The invention discloses a grate of a heat, wear and corrosion-resisting large mechanical reciprocating incinerator and a manufacture method of the grate. The grate comprises the following components in percent by weight: 0.4-1.9 percent of C, 1.0-2.0 percent of Si, 1.0-1.5 percent of Mn, not more than 0.03 percent of P, not more than 0.03 percent of S, 25-28 percent of Cr, 3-4 percent of Ni, 0.02-0.08 percent of Mo, less than 0.1 percent of B, 0.1-0.5 percent of V, 0.01-0.04 percent of Ce and the balance of Fe and inevitable trace impurities. The grate gives consideration to excellent heat, wear and corrosion properties, meets the design requirement of the large mechanical reciprocating incinerator, has lower cost and long service life, can effectively reduce production cost of the waste incineration company, is especially suitable for large garbage incinerators in cities in China, and can have better popularization and application prospect.

Owner:SOUTH CHINA UNIV OF TECH +1

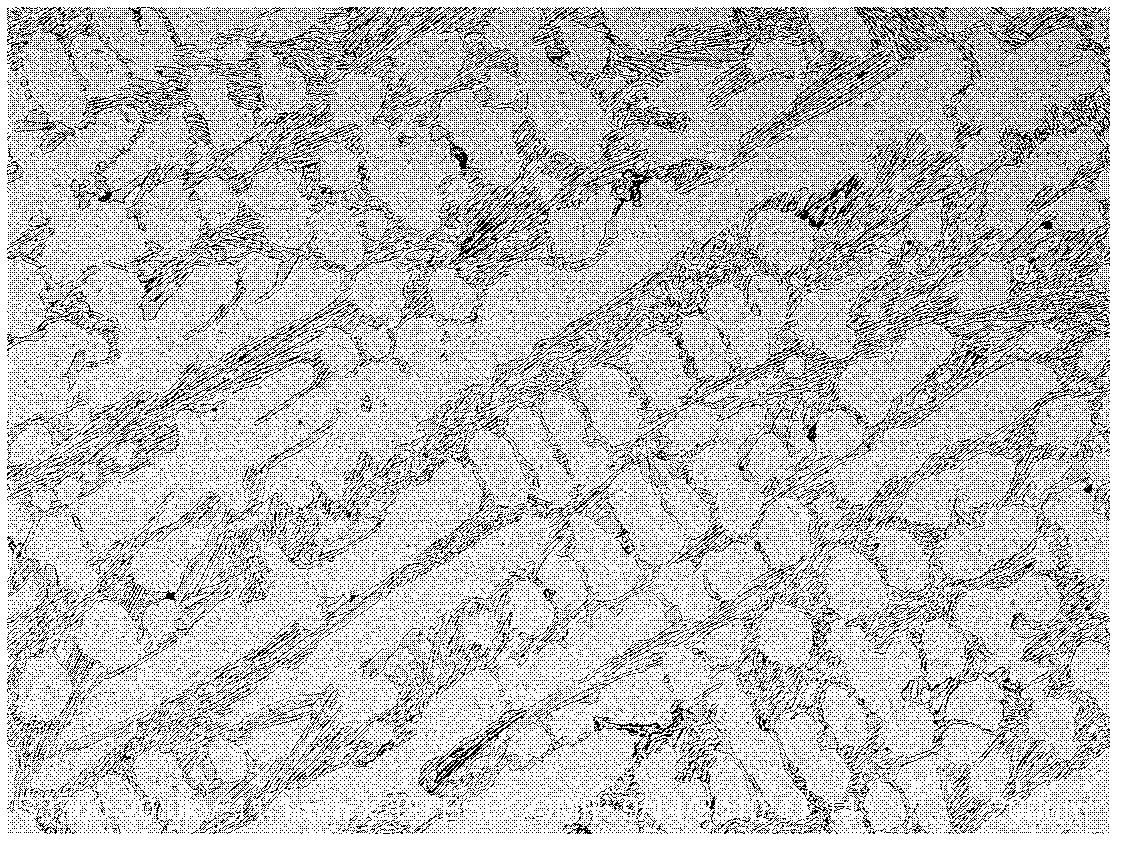

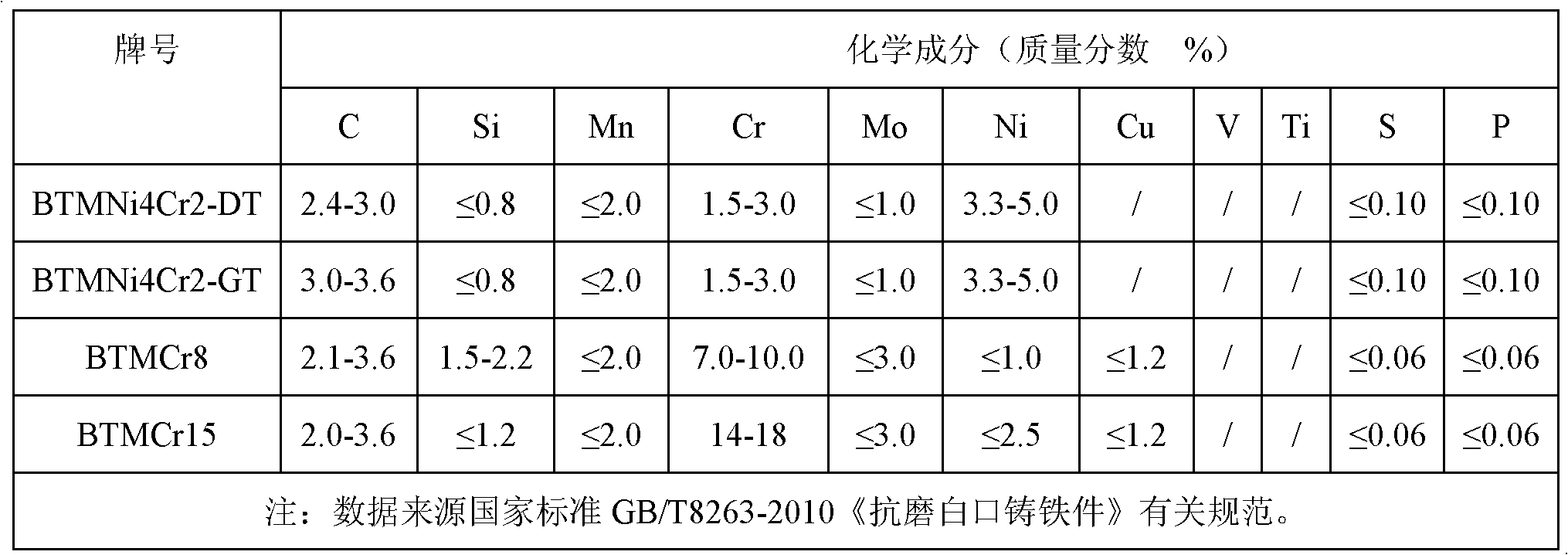

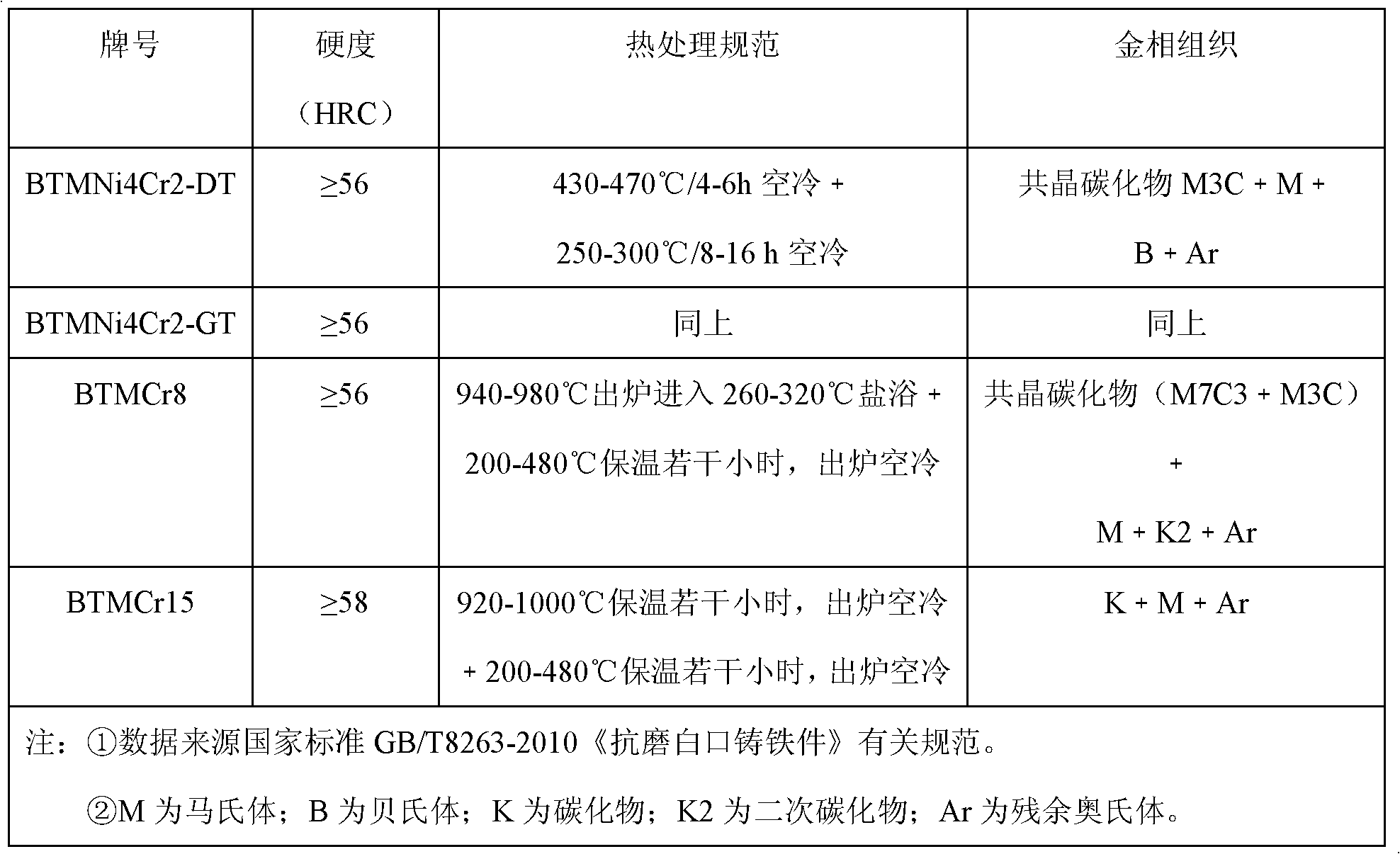

Wear-resistant white cast iron material and preparation method thereof

The invention discloses a wear-resistant white cast iron material, which consists of the following elements in percentage by weight: 2.2 to 3.2 percent of C, less than or equal to 1.2 percent of Si, 2.0 to 3.5 percent of Mn, 7.0 to 10.0 percent of Cr, 0.2 to 1.2 percent of Cu, 0.06 to 0.3 percent of V, 0.02 to 0.15 percent of Ti, 0.001 to 0.003 percent of B, 0.02 to 0.06 percent of Al, 0.02 to 0.15 percent of RE, less than or equal to 0.06 percent of S, less than or equal to 0.06 percent of P, and the balance of Fe. The wear-resistant white cast iron material has the hardness (HRC) of more than or equal to 56, the impact toughness aK of more than or equal to 6J / cm<2>, and a metallographic structure consisting of martensite, carbide (M7C3+a small amount of M3C), secondary carbide and a small amount of retained austenite. The wear-resistant white cast iron material does not contain noble metals such as molybdenum, nickel and the like; and compared with the traditional medium-chromium cast iron material, the wear-resistant white cast iron material has the advantages that the production cost can be greatly saved and the material has good economic benefit.

Owner:驻马店市三山耐磨材料有限公司

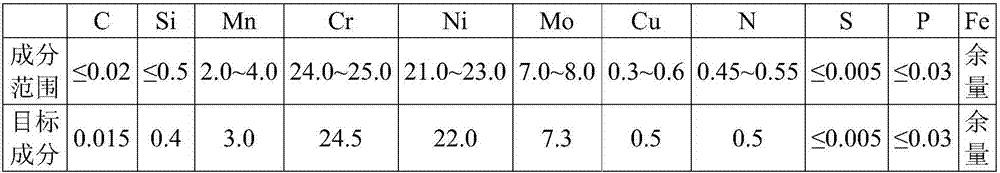

Method for improving thermoplasticity of super austenitic stainless steel

The invention belongs to the field of super austenitic stainless steel smelting and processing and provides a method for improving the thermoplasticity of super austenitic stainless steel. The method is suitable for smelting the super austenitic stainless steel with smaller than or equal to 0.02% of C, smaller than or equal to 0.5% of Si Mn, 2.0-4.0% of Mn, 24.0-25.0% of Cr, 21.0-23.0% of Ni, 7.0-8.0% of Mo, 0.3-0.6% of Cu, 0.45-0.55% of N, smaller than or equal to 0.005% of S, smaller than or equal to 0.03% of P and the balance Fe and other inevitable impurity elements, and 0.01-0.10% of rare earth and 0.001-0.008% of boron are added into the steel on the basis. The method is characterized by comprising the steps of preparing and placing materials; vacuumizing a furnace until the pressure is less than 5 Pa, and electrifying and heating the furnace; introducing nitrogen into the furnace after melting down until the pressure is 0.08-0.10 MPa, and sequentially adding chromium nitride, a deoxidizing agent and a desulfurizing agent; after deep deoxidation and desulfurization, sequentially adding the rare earth and the boron; and filling the furnace with the nitrogen again until the pressure is 0.10-0.12MPa, and carrying out casting. The method has the advantages that by adopting the mode of compound addition of the boron and the rare earth, the plasticity of the steel is remarkably improved, the hot working performance of the steel is improved, the technical bottleneck of hot rolling cracking is broken through, and a technical support is provided for obtaining a super austenite stainless steel product with high surface quality and excellent performance.

Owner:NORTHEASTERN UNIV

Composite hard alloy material and preparation method thereof

The invention discloses a composite hard alloy material and a preparation method thereof. The composite hard alloy material is prepared from the following components in parts by weight: 35-40 parts of nano titanium carbide, 5-15 parts of nano titanium nitride, 7-9 parts of tungsten carbide, 5-8 parts of niobium carbide, 3-7 parts of silicon carbide, 3-5 parts of cobalt powder, 1-3 parts of yttrium oxide, 1-3 parts of aluminium carbide and 1-5 parts of titanium powder. The composite hard alloy material has high strength, good toughness and good wear resistance and thermal shock resistance.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

Preparation method for molybdenum and molybdenum alloy part

ActiveCN105798295AImprove plasticityImprove production efficiencyAdditive manufacturing apparatusTransportation and packagingRare-earth elementUltraviolet lights

The invention discloses a preparation method for a molybdenum and molybdenum alloy part. The preparation method comprises the following steps that molybdenum powder or molybdenum alloy powder is taken and mixed with rare earth element powder to obtain mixed powder, the mixed powder is added into an organic binder to be mixed evenly under the dark condition, and then a defoaming agent is added to remove foams to obtain a mixed sizing agent; the mixed sizing agent is contained in 3D printing forming equipment, controllable ultraviolet light beams are utilized, a face exposure or spot scanning manner is adopted, printing is carried out layer by layer according to a three-dimensional model of the part, and a molybdenum or molybdenum alloy part rough blank is prepared; and the rough blank is subjected to low-temperature ungrease treatment and hot isostatic pressing treatment, and the compact molybdenum or molybdenum alloy part is obtained. According to the method, the 3D printing rapid forming principle is utilized, the shape of the part is not constrained, the working procedure is simplified, the manufacturing period is shortened, and the product compactness is good.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Magnesium smelting reduction pot and preparation method thereof

InactiveCN101805833APrevent oxidationImprove high temperature resistanceFoundry mouldsFoundry coresPOWDERED CELLULOSEEmulsion

The invention relates to a magnesium smelting reduction pot and a preparation method thereof, which belong to the technical field of metal smelting. The magnesium smelting reduction pot comprises a pot body and an external application coating layer, and is characterized in that: the pot body comprises the following components in percentage by weight: 0.2 to 0.4 percent of C, 1.0 to 2.0 percent of Mn, 0.6 to 2.0 percent of Si, 24.0 to 26.0 percent of Cr, 6.0 to 8.0 percent of Ni, 0.015 to 0.05 percent of Ti, 0.03 to 0.10 percent of Re, and the balance of iron; and the external application coating layer comprises the following components in percentage by weight: 47.9 to 74.1 percent of zircon powder or graphite with the particle size of 200 to 270 meshes, 1.5 to 3.8 percent of bentonite, 1.5 to 2.9 percent of powdered cellulose (carboxymethylcellulose sodium), 0.7 to 2.4 percent of white latex (polyvinyl acetate emulsion), and 22.2 to 43.0 percent of ethanol. All types of the components of the pot body are put into an intermediate frequency furnace and are melted for pouring, and are brushed with a coating according to the component proportion after being cooled. Starting from each process step of preparing the magnesium smelting reduction pot, the components of materials of the reduction pot, a melting process and a centrifugal casting process are optimized and adjusted, and a high-temperature resistant coating is brushed on the surface of the reduction pot to effectively promote the oxidation resistance of the reduction pot at a high temperature, so the service life of the pot body is prolonged.

Owner:BAOTOU BINGKE SILICON MAGNESIUM MATERIAL ENG TECH RES CENT

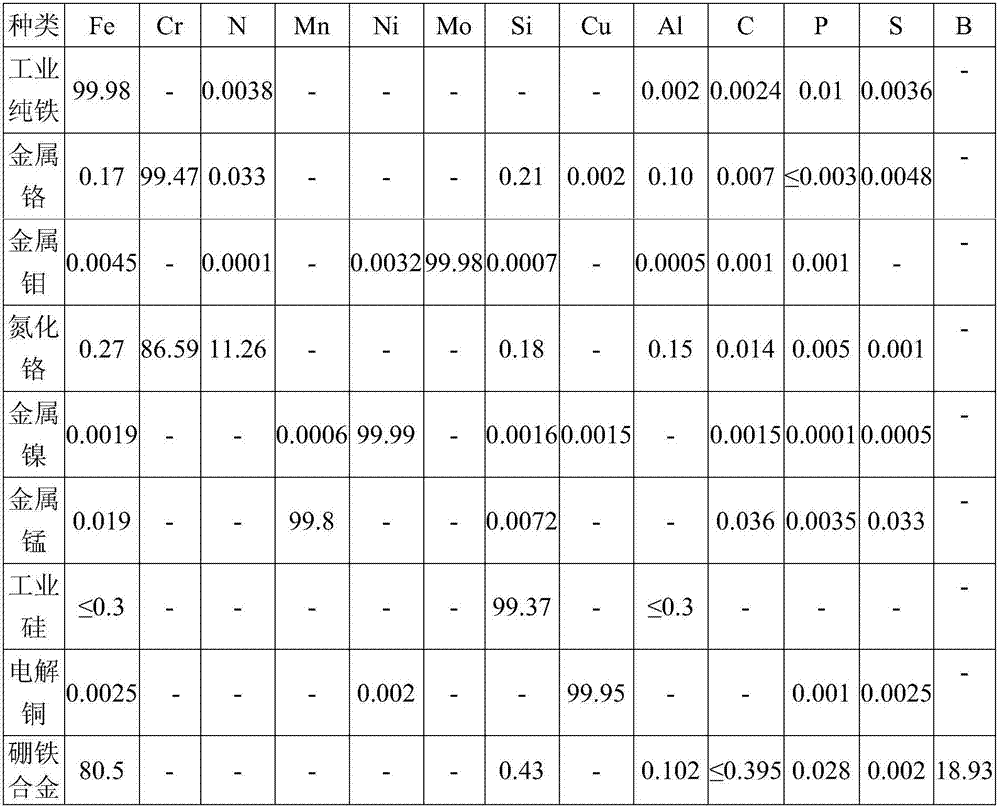

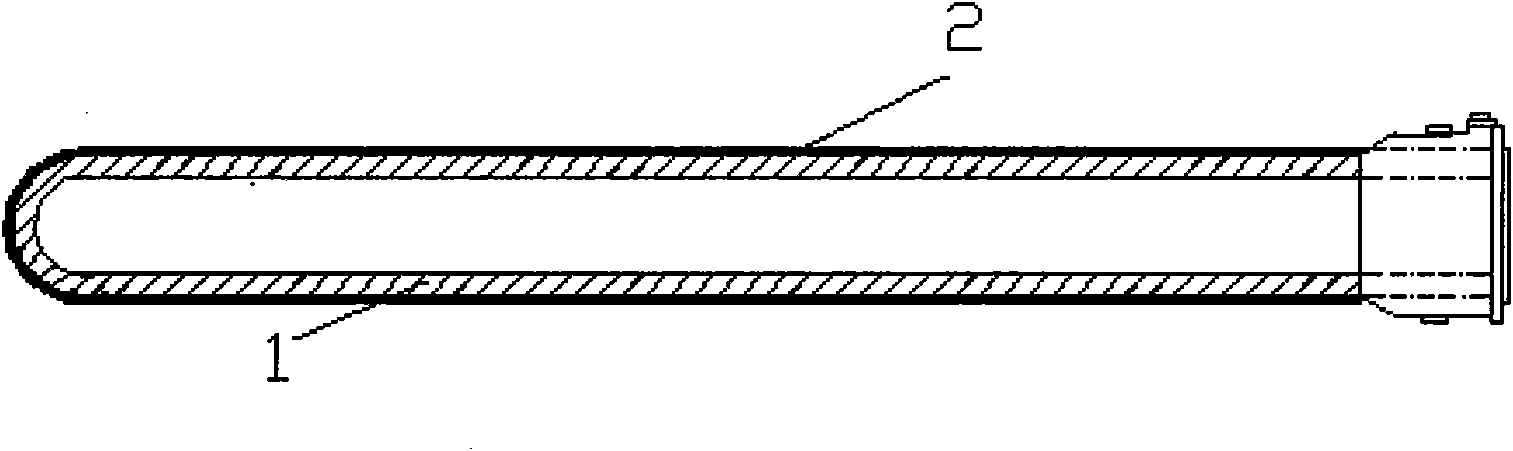

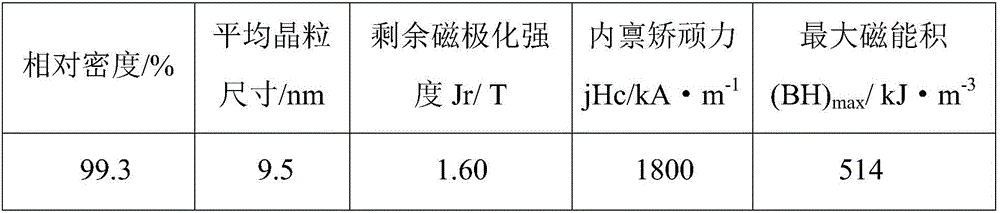

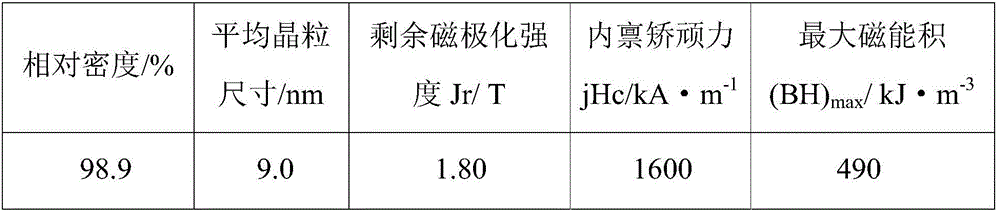

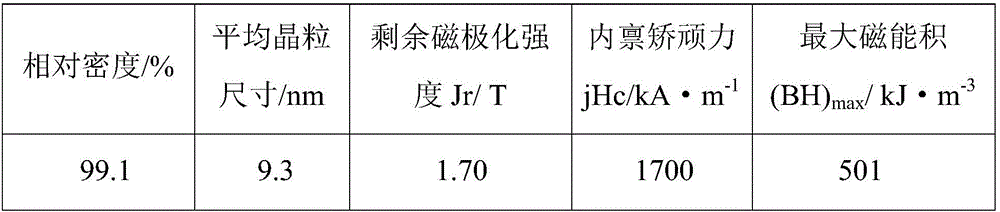

Fabrication method of nanometer composite phase rare-earth permanent magnet material

ActiveCN106128668AHigh densityHigh remanent magnetic polarizationMagnetic materialsRare earthGrain boundary

The invention provides a fabrication method of a nanometer composite phase rare-earth permanent magnet material. The fabrication method comprises the following steps of providing amorphous-state hard magnetic alloy powder and amorphous-state soft magnetic alloy powder; enabling the amorphous-state hard magnetic alloy powder to be crystallized to nanometer crystal hard magnetic powder, and enabling the amorphous-state soft magnetic powder to be crystallized to nanometer crystal soft magnetic powder; and obtaining the nanometer composite phase rare-earth permanent magnet material through discharging plasma sintering on the nanometer crystal hard magnetic powder and the nanometer crystal soft magnetic powder. By the fabrication method of the nanometer composite phase rare-earth permanent magnet material, the mixing proportion of the nanometer crystal hard magnetic powder and the nanometer crystal soft magnetic powder which are prepared in advance can be effectively controlled, and the change range of magnetic performance can be further accurately controlled; and low-temperature and fast sintering is achieved by a discharging plasma sintering technology, the grain growth can be effectively prevented, the grain boundary is purified, the compactness of a sintering material can also be substantially improved, and the nanometer composite phase rare-earth permanent magnet material having remanent magnetic polarization, high density and high magnetic energy product is fabricated.

Owner:SHENZHEN WAVE MULTIMEDIA

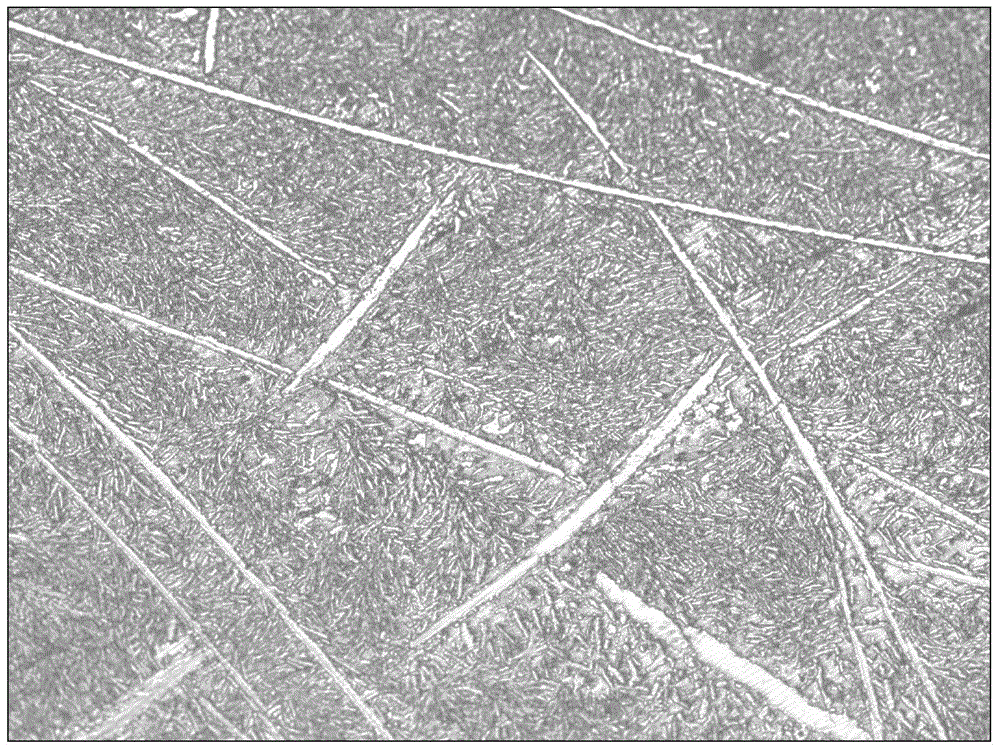

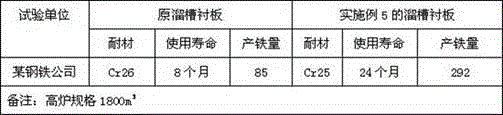

Hypereutectic high-chromium alloy white cast iron chute lining plate and preparation method thereof

ActiveCN106591689ACreativeHigh hardnessBell-and-hopper arrangementProcess efficiency improvementChromium AlloysChemical Ingredients

The invention relates to a hypereutectic high-chromium alloy white cast iron chute lining plate and a preparation method thereof. The chute lining plate is prepared from a high-hardness hypereutectic high-chromium abrasion-resistant white alloy cast iron material which comprises the following chemical ingredients: 3.5-5.0% of C, 0.3-0.8% of Si, 0.5-1.0% of Mn, 25.0-35.0% of Cr, 0.8-1.2% of Mo, 0.2-0.6% of Cu, 1.0-1.8% of W, 0.3-0.5% of V, 0.1-0.3% of Ti, 0.1-0.3% of Nb, 0.03-0.08% of Zr, 0.001-0.003% of B, 0.02-0.08% of Re, 0.02-0.08% of Y, no less than 0.06% of S, no less than 0.06% of P and the balance of Fe. Compared with a conventional chute lining plate, the chute lining plate prepared by adopting the material involved in the invention has the advantages that the service life is greatly prolonged and the iron yield is greatly improved; the product manufacturing cost of the chute lining plate provided by the invention is basically equal to that of the conventional chute lining plate; and the cost performance advantage is obvious.

Owner:YINGKOU LONGCHEN MINE VEHICLE MFG CO LTD

Low-silver-content cadmium-free solder

InactiveCN103909361AImprove wettability and joint strengthImprove plasticityWelding/cutting media/materialsSoldering mediaSolderingZinc

The invention discloses low-silver-content cadmium-free solder and relates to the technical field of soldering. The low-silver-content cadmium-free solder is prepared by proportionally smelting raw materials comprising silver, copper, zinc, manganese and nickel, uniformly stirring, casting, and subjecting a cast ingot to squeezing and drawing so as to obtain a needed solder wire material. The low-silver-content cadmium-free solder comprises, by weight, 24%-26% of the silver, 31.5%-35% of the zinc, 0.8%-2.5% of the manganese, 0.5%-2.0% of the nickel, and the balance copper. By adding small amounts of the nickel and the manganese in the silver solder, wettability and joint strength of the solder can be enhanced, good effects on crystal boundary purification, plasticity improvement and strength enhancement can be achieved, processability of the low-silver-content cadmium-free solder can be improved, and production cost is lowered since silver content is reduced.

Owner:JINHUA SANHUAN WELDING MATERIALS

Preparation method for WC-Co cemented carbide nozzle for oil field

The invention provides a preparation method for a WC-Co cemented carbide nozzle for an oil field. Co powder, WC powder, TaC and NbC are mixed and then subjected to wet grinding, drying, plasticizer adding, pressing forming, plasticizer removal and sintering, so that WC-Co cemented carbide is obtained; during mixing, based on the total weight 100% of the mixed materials, Co powder accounts for 8.5-13wt%, TaC / NbC accounts for 0.35-0.55wt%, and the rest is WC. The synergism of the materials and proportioning in the mixing process is favorable for inhibiting growth of grains and improving the alloy structure after sintering, thereby improving the toughness, high-temperature strength and hardness of the alloy, improving the heat impact resistance and heat fatigue resistance of the alloy, purifying the grain boundary, and increasing the interface binding force. Distribution of the Co phase is more uniform, and the toughness and abrasion resistance of the alloy are greatly unified.

Owner:单麒铭

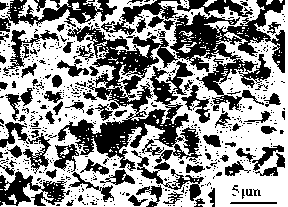

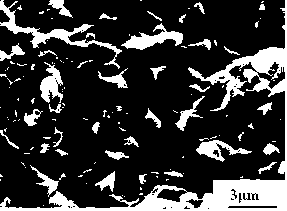

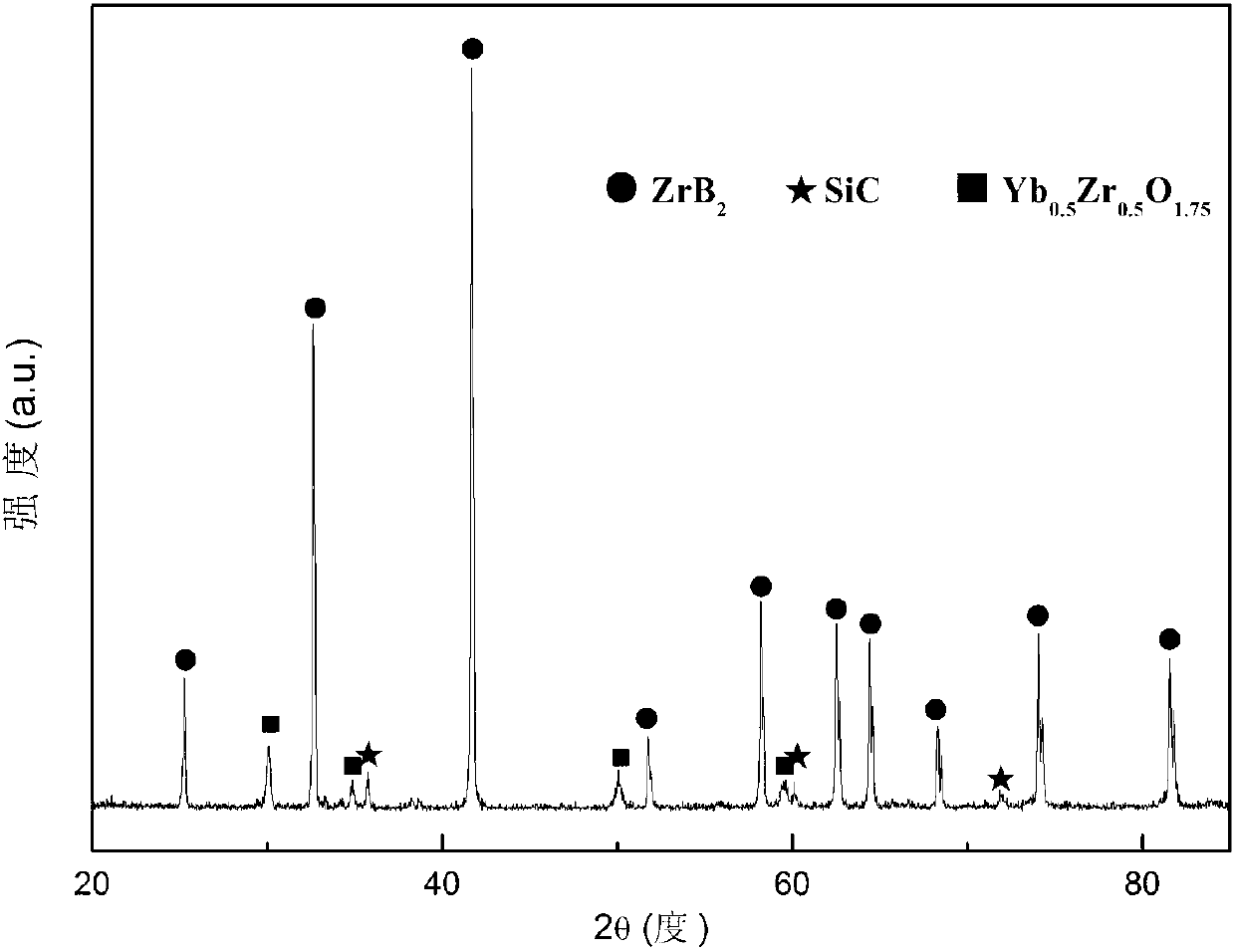

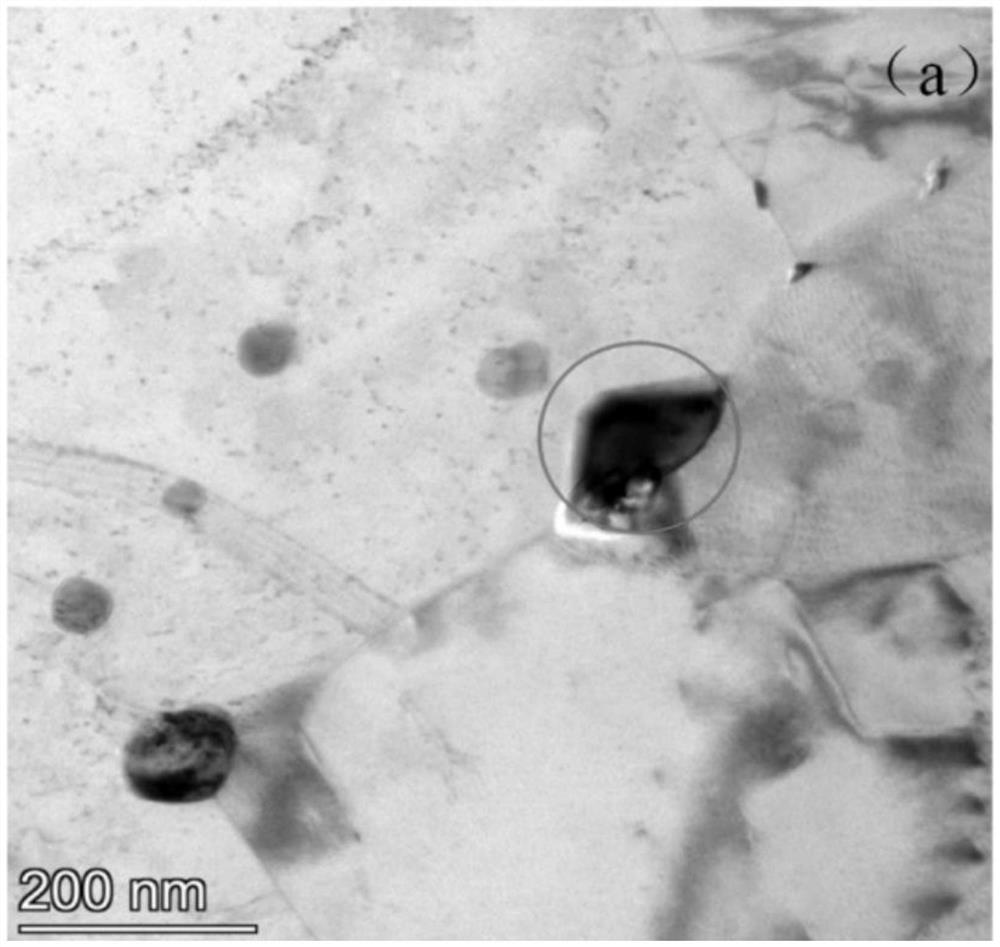

RE2O3-added ZrB2-SiC composite ceramic material and preparation method thereof

The invention relates to an RE2O3-added ZrB2-SiC composite ceramic material and a preparation method thereof. According to the preparation method, with ZrB2 powder and SiC powder of which the purities are not lower than 97 percent as raw materials and RE2O3 of which the purity is not lower than 99 percent as an additive and the volume fraction is 0.1-10 percent by volume, the raw materials and the additive are mixed to prepare the material with different components. After being subjected to ball grinding and drying, the raw materials are subjected to hot pressed sintering at the temperature of 1700-1900 DEG C by adjusting the sintering process parameters to obtain the ZrB2-SiC composite ceramic. The prepared RE2O3-added ZrB2-SiC composite ceramic material has the relative density of being larger than 99 percent, the bending strength of 800-1000MPa, the breaking tenacity of 4.5-6MPa.M<1 / 2>, the hardness of 15-20GPa and the thermal conductivity of 80-100W.(m.K)<-1>, and is favorable in anti-oxidation ablation performance.

Owner:FUDAN UNIV

Ferrite martensite steel ladle shell material and preparation method thereof

InactiveCN112695256AImprove high temperature performanceImprove neutron radiation resistance performanceNuclear energy generationFurnace typesLead bismuthMachining deformation

The invention belongs to the technical field of fourth-generation lead bismuth cooling fast reactor structural materials, and particularly relates to a ferrite martensite steel ladle shell material and a preparation method thereof. The ferrite martensite steel ladle shell material comprises the components of 0.08wt%-0.16wt% of C, 0.30wt%- 0.8wt% of Mn, 0.50wt%-1.20wt% of Si, 8.5wt%-10.5wt% of Cr, 1.0wt%-2.5wt% of W, 0.10wt%-0.40wt% of V, 0.10wt%-0.40wt% of Ta, 0.005wt%-0.08wt% of Zr, 0.005wt%-0.05wt% of La, 0.008wt%-0.04wt% of N, and the balance Fe and impurities. The preparation method of the ferrite martensite steel ladle shell material comprises the following process steps of (1) smelting; (2) casting; (3) forging; (4) extruding; (5) pipe blank machining and heat treatment; (6) multi-pass cold rolling and intermediate heat treatment of the alloy; and (7) final heat treatment of the pipe. According to the ferrite martensite steel ladle shell material and the preparation method thereof, through the innovative component design, the optimized pipe machining deformation process and the heat treatment technology, the microstructure of the material is improved, grains are refined, and therefore the comprehensive performance of the alloy is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Preparation method for anticorrosion steel used for water-cooling spray nozzle

ActiveCN106119724AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingMolten stateBoriding

The invention discloses a preparation method for anticorrosion steel used for a water-cooling spray nozzle. The method comprises the following steps that raw materials are heated into a molten state to obtain a liquid alloy, wherein the liquid alloy comprises, by weight, 0.1-0.25% of C, 1.2-1.5% of Cr, 0.3-0.6% of Al, 1.2-1.6% of Mg, 0.2-0.3% of Zr, 0.4-0.6% of Ni, 1.2-1.3% of Mn, 0.08-0.12% of Mo, 0.1-0.13% of V, 0.03-0.06% of Co, 0.02-0.05% of Ga, 1.5-1.6% of T, 0.6-0.8% of Si and the balance Fe; a steel billet is obtained through casting; heat treatment is conducted; boriding is conducted; and the steel billet subjected to heat treatment and boriding is coated with a conversion film.

Owner:滁州帝邦科技股份有限公司

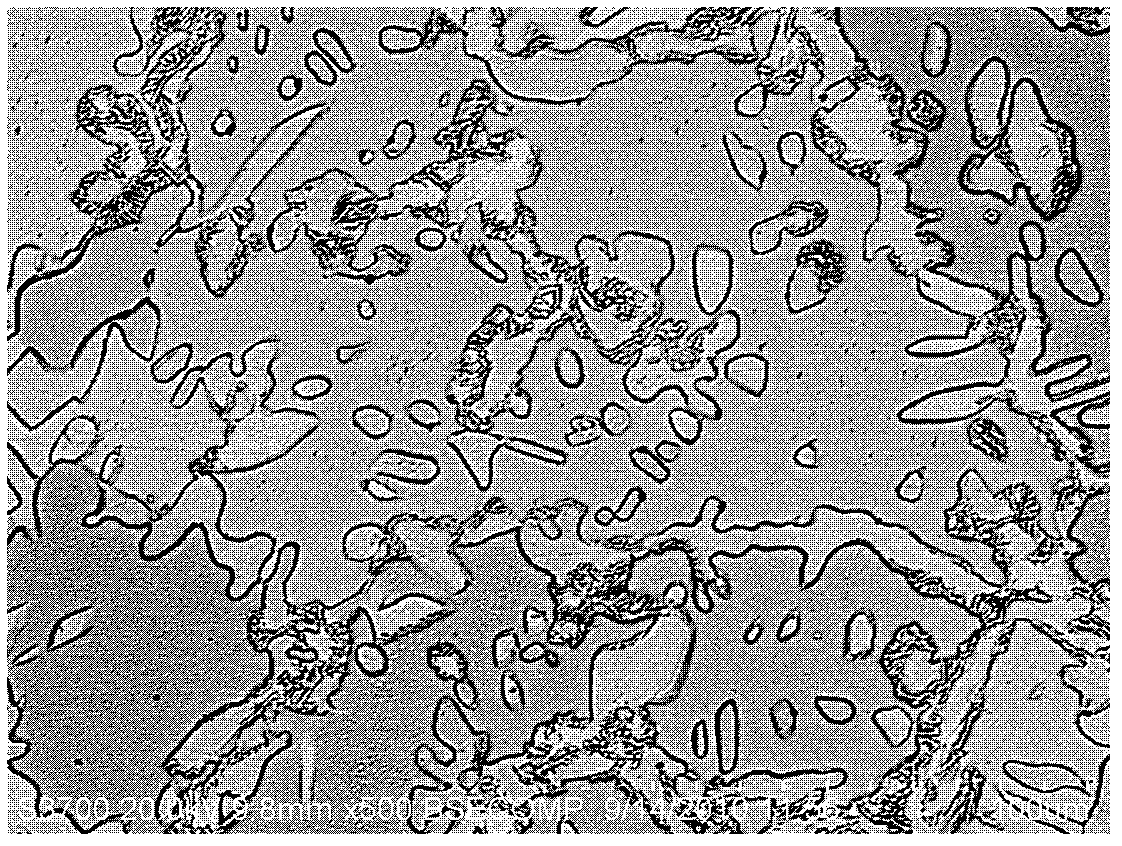

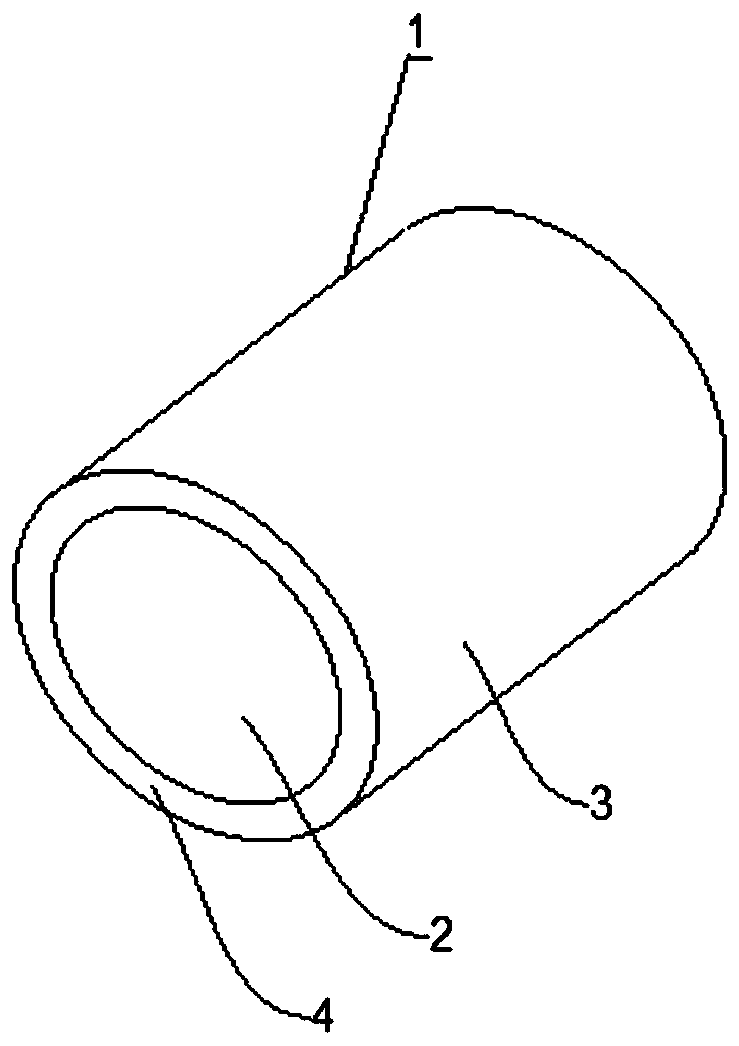

Sliding bearing based on structure energizing material and preparation method thereof

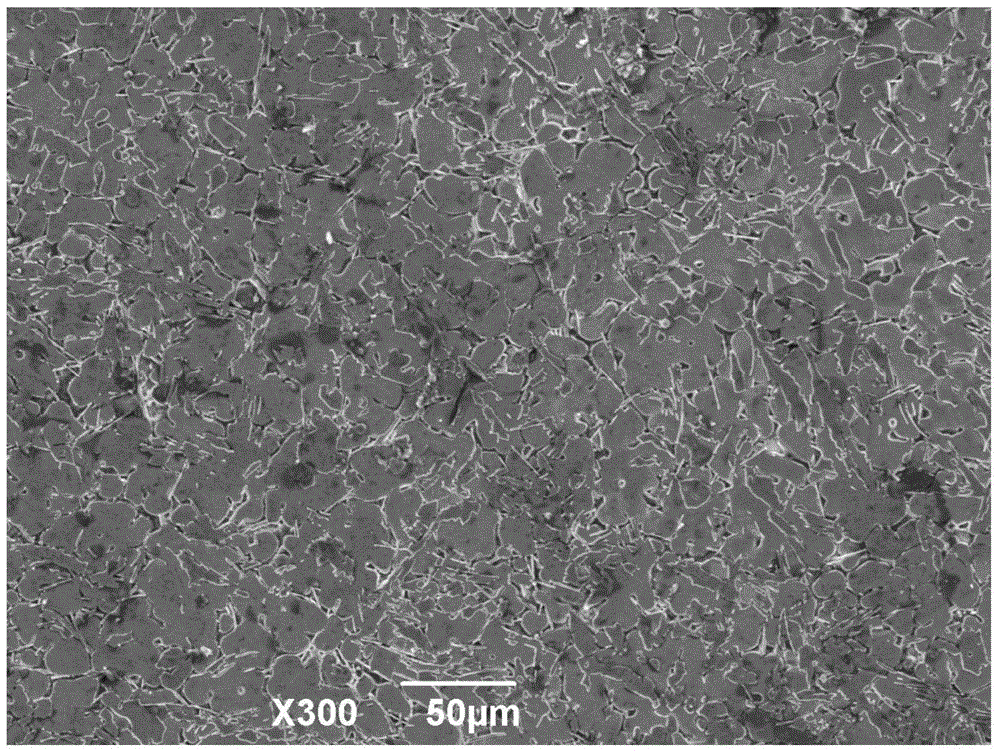

InactiveCN110592465ASelf-lubricatingReduce noiseFurnace typesSliding contact bearingsStructure of the EarthMicrometer

The invention discloses a sliding bearing based on a structure energizing material. The sliding bearing is prepared from the structure energizing material. The matrix structure of the sliding bearingis austenite and graphite spheres. The diameter of graphite spheres is less than or equal to 25 micrometers, the spheroidization rate is 100%, and the density of graphite spheres is 300-600 / mm<2>. According to the preparation method, the components of molten iron are timely regulated and controlled to be within a small range of eutectic components by observing the color of a profile which is justpulled out by one step, so that the spheroidization rate is remarkably increased, and the situation that large blocks of primary graphite appear to cause mechanical property damage is avoided; and thesliding bearing with self-lubricating property is prepared through rough machining and grinding machining. The self-lubricating sliding bearing has self-lubricating property, no oil filling hole or no oil guide groove needs to be machined, sound absorption and shock absorption are realized, the service life is long, and a copper or steel sliding bearing can be replaced.

Owner:XIAN UNIV OF TECH

Joint coating copper-based alloy for silver and preparation method thereof

The invention provides a joint coating copper-based alloy for silver and a preparation method thereof. The copper-based alloy comprises the following components by weight percent: 3-35% of Zn, 0.5-10% of Sn, 0.1-5% of Si, 0-0.1% of B and / or Li, 0.1-2% of In and the balance of composite rare earth elements and Cu. The composite rare earth elements in the copper-based alloy comprise the following components by weight percent: 0.5-5% of Y and 0-2% of La and / or Ce, wherein the contents of La and Ce are not both zero. One of B and Li is selected. The copper-based alloy uses the composite rare earth elements and various elements with oxygen activities to perform multi-component alloying so as to improve the structure of the alloy, refine grains, degas, clean the grain boundary and increase the mechanical properties, castability and machinability. In addition, the alloy does not contain precious metal elements and has lower cost.

Owner:SHENZHEN UNIV +1

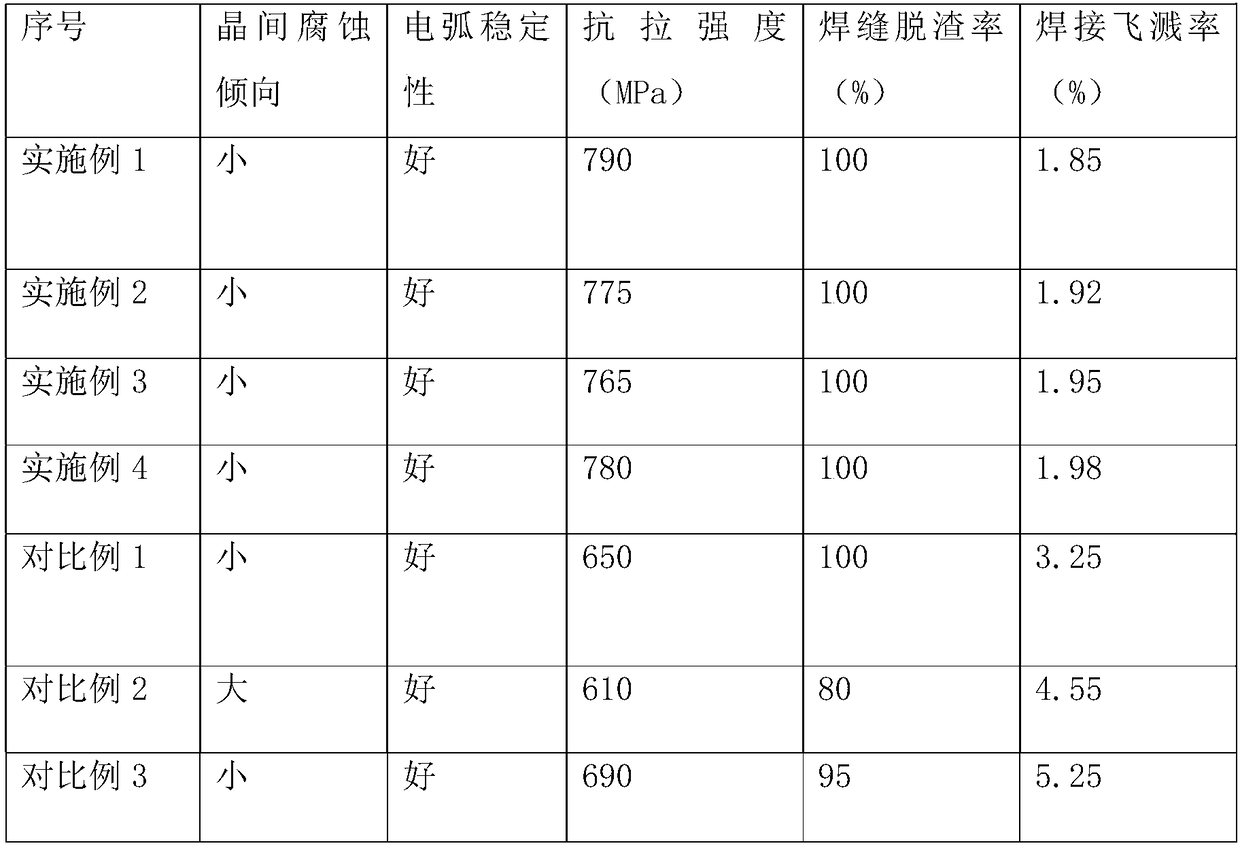

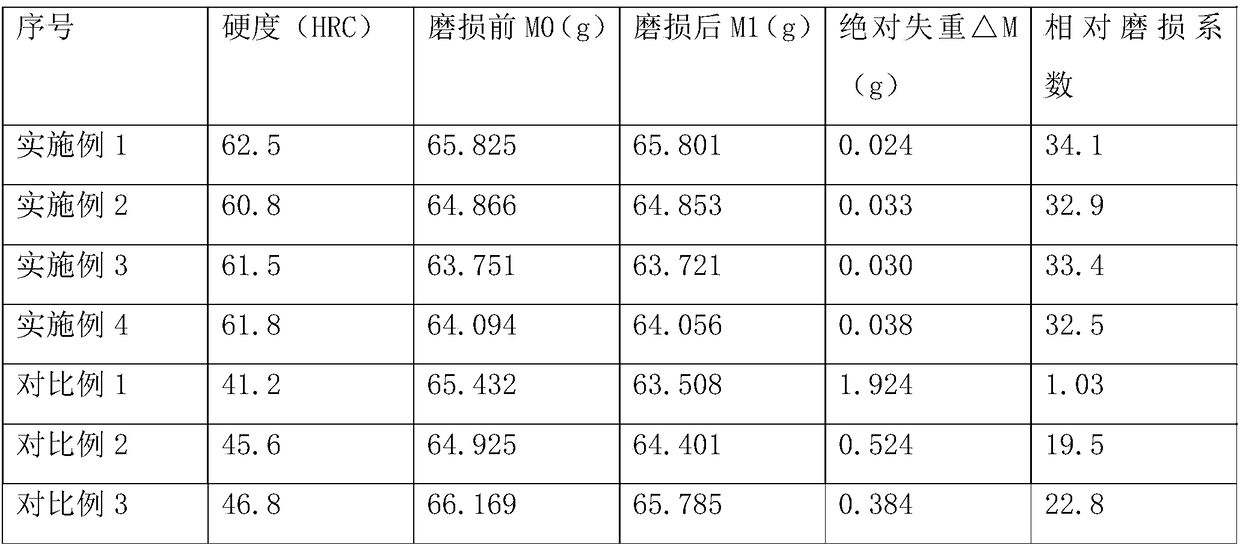

High-strength and high-abrasion-resistance stainless steel surfacing flux-cored wire and application thereof

ActiveCN109048120AImprove crystal phase compositionEvenly dispersedWelding/cutting media/materialsSoldering mediaBrickNiobium

The invention belongs to the field of welding materials, relates to a stainless steel welding wire material, and particularly relates to a high-strength and high-abrasion-resistance stainless steel surfacing flux-cored wire and application thereof. The high-strength and high-abrasion-resistance stainless steel surfacing flux-cored wire comprises a skin and a flux core, and the flux core comprisesthe compositions of, by mass, 25-30% of metal chromium powder, 3-5% of nickel powder, 1-2% of niobium powder, 1-3% of vanadium powder, 8-10% of manganese powder, 5-8% of multi-alloys, 2-6% of rare earth compounds, 5-8% of quartz, 3-5% of magnesia, 3-5% of fluorides, 5-7% of additives, 5-8% of rutile and the balance iron powder. An appropriate amount of particle size controllable hard phases and avariety of synergistic alloy powder are added into the high-strength and high-abrasion-resistance stainless steel surfacing flux-cored wire to change the matrix structure of an existing ferritic stainless steel surfacing alloy, so that the stainless steel surfacing alloy has the advantages of high strength and good abrasion resistance; and meanwhile, preheating and post-weld treatment are not required during surfacing, and no crack is generated. The high-strength and high-abrasion-resistance stainless steel surfacing flux-cored wire is especially suitable for the application of surfacing repair of cutter blades of shield tunneling machines or spiral reamers of brick making machines.

Owner:北京赛亿科技有限公司

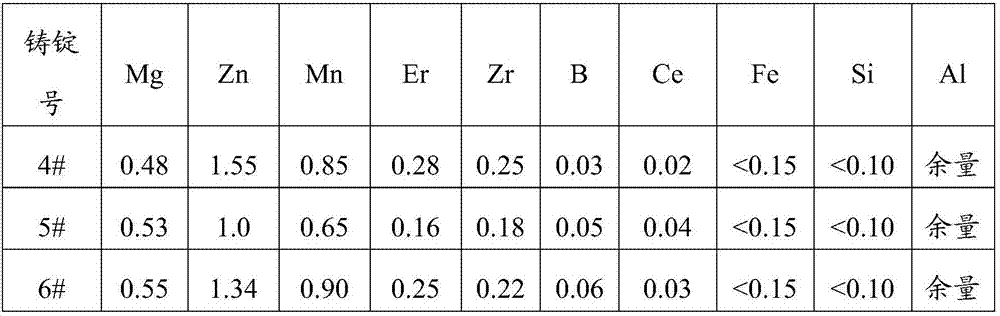

High-strength anti-corrosion aluminum alloy and preparation method thereof

The invention discloses high-strength anti-corrosion aluminum alloy and a preparation method thereof. The high-strength anti-corrosion aluminum alloy comprises, by weight, 4.5-5.5% of Mg, 0.9-1.8% of Zn, 0.4-1.0% of Mn, 0.01-0.05% of rare earth Ce, 0.15-0.35% of Er, 0.10-0.25% of Zr, 0.01-0.06% of B, 0-0.1% of impurity Si, 0-0.15% of Fe, 0-0.15% of other impurity elements, and the balanced element Al. the preparation process of the aluminum alloy comprises the steps of raw material proportioning, raw material smelting, refining, pouring, three-stage homogenizing treatment, compressional deformation treatment, tensile deformation treatment and aging treatment. The preparation process is simple and easy to implement and low in production cost. The aluminum alloy has high corrosion resistance and good mechanical properties.

Owner:FOSHAN UNIVERSITY

Composite hard alloy material and preparing method thereof

The invention discloses a composite hard alloy material and relates to the field of composite materials. The composite hard alloy material comprises, by weight, 35 to 40 parts of nano titanium carbide, 5 to 15 parts of nano titanium nitride, 7 to 9 parts of tungsten carbide, 5 to 8 parts of niobium carbide, 3 to 7 parts of silicon carbide, 1 to 3 parts of yttrium oxide, 1 to 3 parts of aluminum carbide, 1 to 5 pats of titanium powder, 2 to 10 parts of tantalum carbide, 2 to 5 parts of zirconium carbide, 10 to 13 parts of cobalt powder, 0.5 to 1.5 parts of silicon powder, 1 to 2 parts of nickel powder, and 2 to 6 parts of boron carbide. By adding rare-earth elements more active than other elements in the hard alloy and prone to combination with impurities such as oxygen and sulfur in the hard alloy, the crystal boundary is purified, and the defects are eliminated; the prepared alloy has high strength, toughness, wear resistance and good thermal impact performance; the preparing method is suitable for preparation of composite hard alloy materials.

Owner:梅照付

Preparing method for wear-resisting steel used for water-cooling nozzle

InactiveCN106048514AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingSodium bicarbonateBoron carbide

The invention discloses a preparing method for wear-resisting steel used for a water-cooling nozzle. The preparing method includes the following steps that smelting and pouring are conducted; heat treatment is conducted; a steel billet obtained after heat treatment is subjected to pretreatment and then put into a boriding agent, the temperature is increased to 910 DEG C to 930 DEG C, heat insulation is conducted for 6 h to 7 h, and then a steel billet generated after boriding is obtained; and covering of a conversion film is conducted. The use amount of the boriding agent ranges from 1.3 g / cm<2> to 1.6 g / cm<2>, and the boriding agent includes, by weight, 4-6 parts of boron carbide, 10-15 parts of borax, 3-4 parts of potassium fluoborate, 0.5-1 part of sodium fluosilicate, 5-7 parts of sodium bicarbonate, 40-50 parts of silicon carbide and 30-35 parts of activated carbon. Covering of the conversion film includes the specific steps that the steel billet generated after boriding is cleaned and then put into a conversion solution, the temperature is increased to 40 DEG C to 50 DEG C, heat insulation is conducted for 18 min to 22 min, and the wear-resisting steel used for the water-cooling nozzle is obtained through drying. The wear-resisting steel has good wear-resisting performance and is good in corrosion resistance performance and high temperature resistance performance.

Owner:CHUZHOU DIBANG TECH

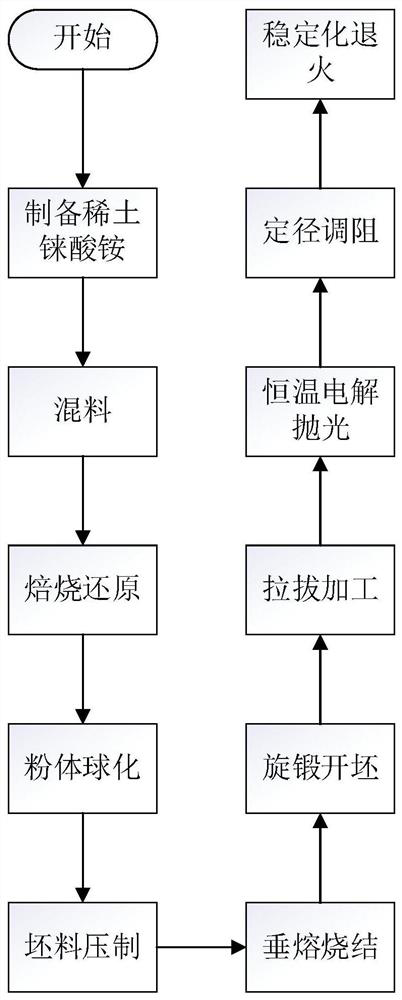

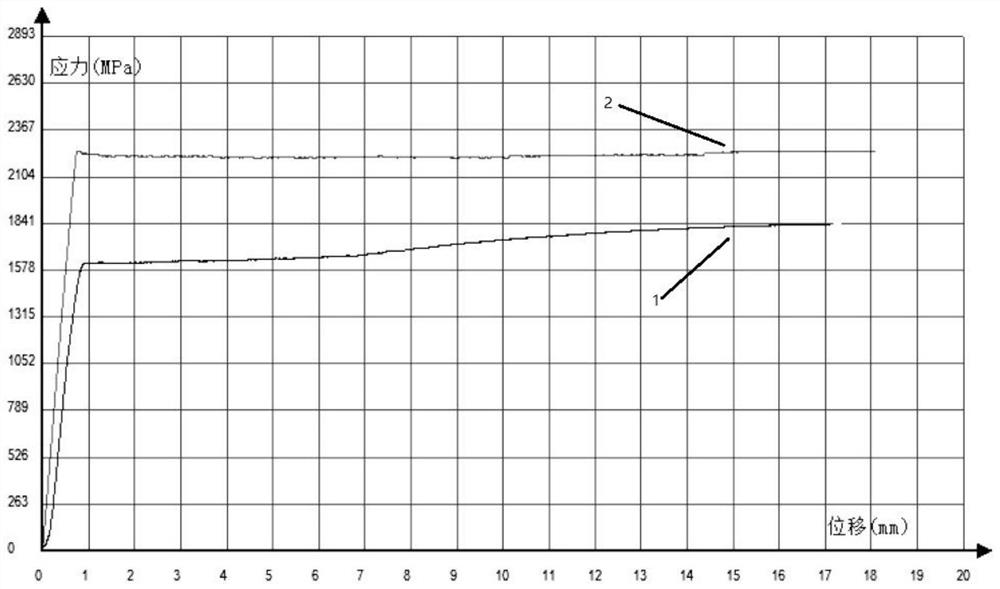

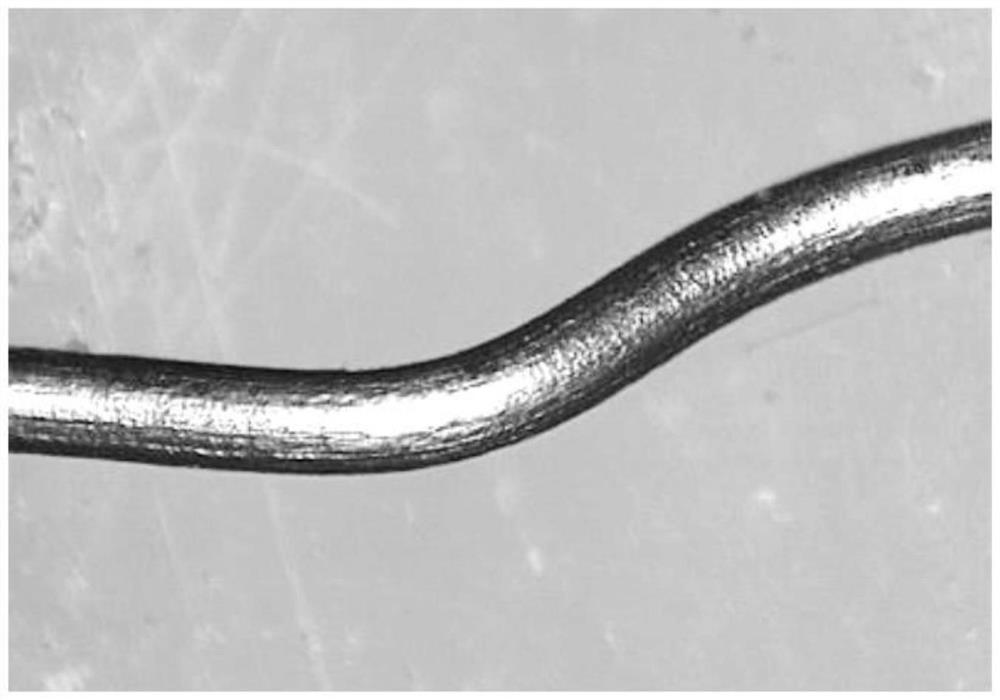

Preparation method of high-performance tungsten-rhenium alloy heating wire

ActiveCN112126837AHigh strengthImprove compactnessResistance/reactance/impedenceFurnace typesRare-earth elementRhenium

The invention relates to the field of metal materials, in particular to a preparation method of a high-performance tungsten-rhenium alloy heating wire. The preparation method comprises the following steps: preparing rare earth ammonium rhenate, mixing, roasting and reducing, spheroidizing powder, pressing a blank, vertically melting and sintering, rotary swaging and cogging, drawing, carrying outconstant-temperature electrolytic polishing, sizing and adjusting resistance, and carrying out stable annealing. According to the preparation method, the technology is optimized by adding lanthanum or / and cerium and other rare earth elements, so that the bending resistance and other mechanical properties of the prepared high-performance tungsten-rhenium alloy heating wire are obviously improved, the service life is long, the reliability is high, the problems of wire splitting, brittle failure and the like are solved, and by combining the continuous test method of resistance per meter and constant-temperature electrolytic polishing, the resistance per meter of the prepared tungsten-rhenium alloy heating wire has high uniformity, and the recrystallization temperature is also raised.

Owner:CHONGQING MATERIALS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com