Preparation method of high-performance tungsten-rhenium alloy heating wire

A technology of tungsten-rhenium alloy and heating wire, applied in heat treatment equipment, heat treatment furnace, manufacturing tools, etc., can solve the problems of brittle fracture, easy splitting of wire material, large dispersion of meter resistance, etc., to ensure uniformity and improve compactness and mechanical properties, the effect of preventing missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

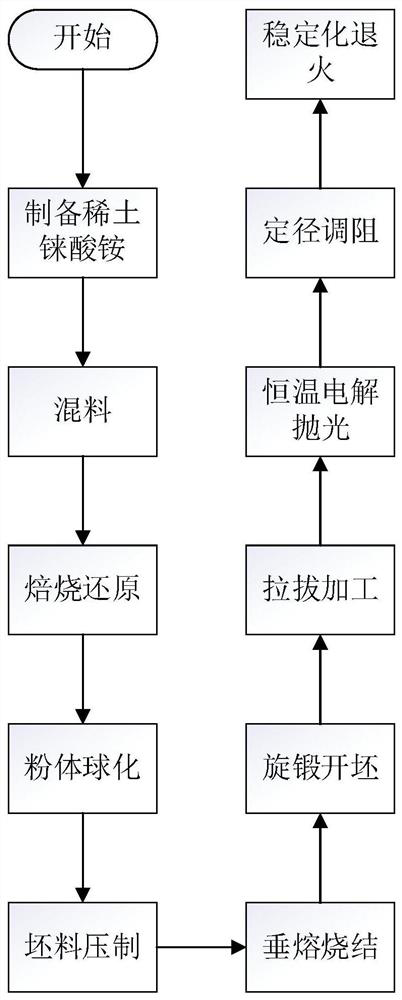

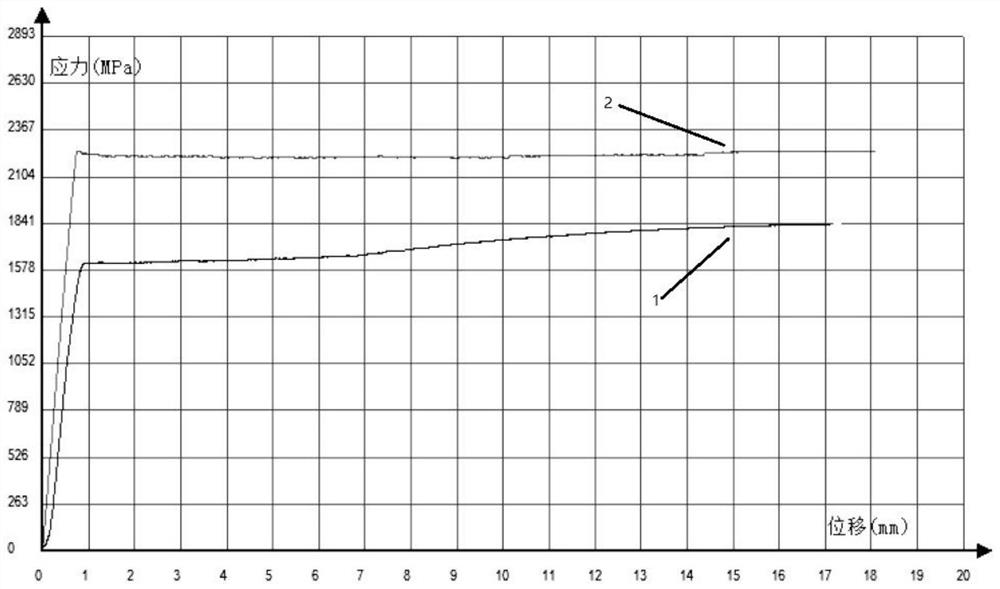

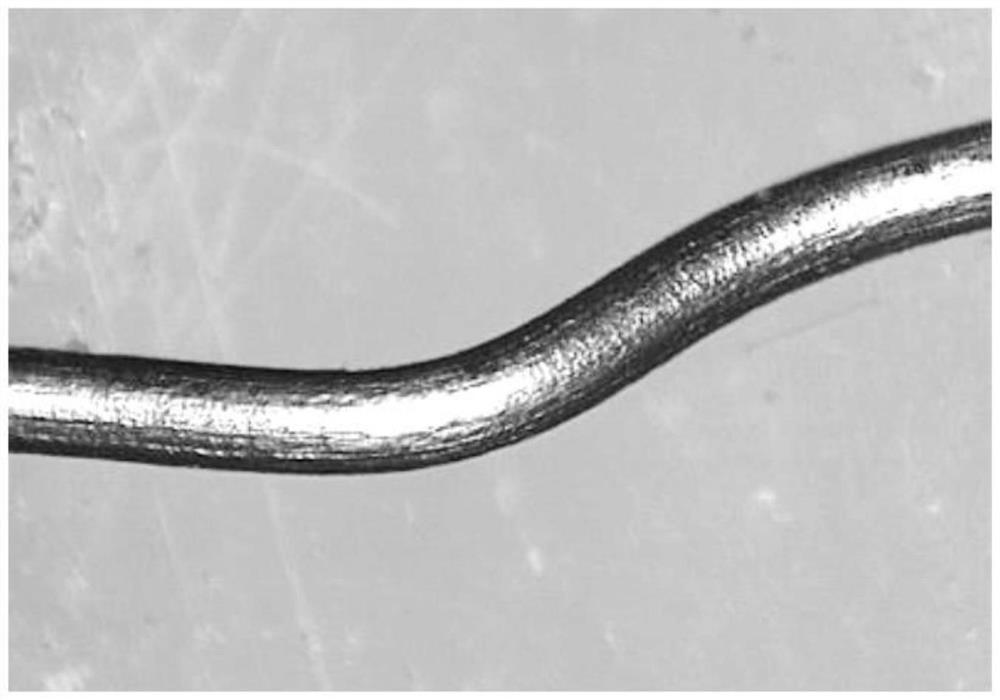

[0035] Such as Figure 1 to Figure 4 Shown, a kind of preparation method of high-performance tungsten-rhenium alloy heating wire comprises the following steps:

[0036] 1) The weight percent content of each component in the high-performance tungsten-rhenium alloy heating wire: rhenium is 3% to 26%, rare earth element is 0.03% to 0.20%, and the balance is tungsten;

[0037] Among them, the rhenium element is ammonium perrhenate, and the rare earth element is the nitrate of the corresponding element;

[0038] The rare earth element in step 1) is one or both of lanthanum and / or cerium.

[0039] 2) Preparation of rare earth ammonium rhenate: Dissolve ammonium perrhenate and nitrate in deionized water according to the components and substances in the high-performance tungsten-rhenium alloy heating wire described in step 1), and stir and heat until crystallization produces powder Finally, evaporate the water to dryness, put the powder into an oven at 50-60°C and dry for 36-72 hour...

Embodiment 1

[0061] Embodiment 1: weigh 2.6 grams of La (NO 3 ) 3 ·6H 2 O and 300 g NH 4 ReO 4 , completely dissolved in 800ml of deionized water, continue to heat and stir to condense into a fine powder, move it into a 60°C oven and dry for 36 hours, then move the dried powder into a ball mill jar and add 825 grams of tungsten powder, and add 450 grams of grinding balls, Put it on a ball mill and disperse at a speed of 150r / min. for 12 hours, take out the mixed powder and put it in 300°C and 400°C H 2 The materials were reduced under the atmosphere for 1 hour, and the materials were passed through a 60-mesh sieve and then dispersed again on a ball mill, adding 450 grams of balls, the dispersion speed was 150 r / min, and the dispersion time was 12 hours. 2 Atmosphere reduction for 3 hours to obtain tungsten-rhenium pre-alloyed powder.

[0062] Spherical powder was prepared at an argon flow rate of 6L / min. The tungsten-rhenium pre-alloyed powder was pressed on an isostatic press with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com