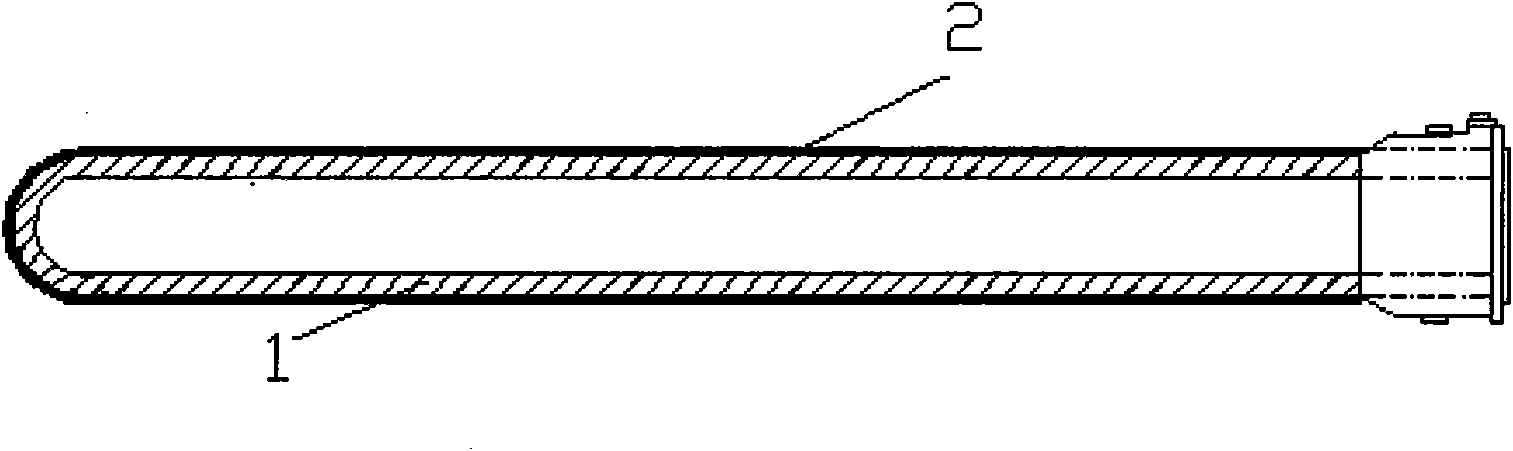

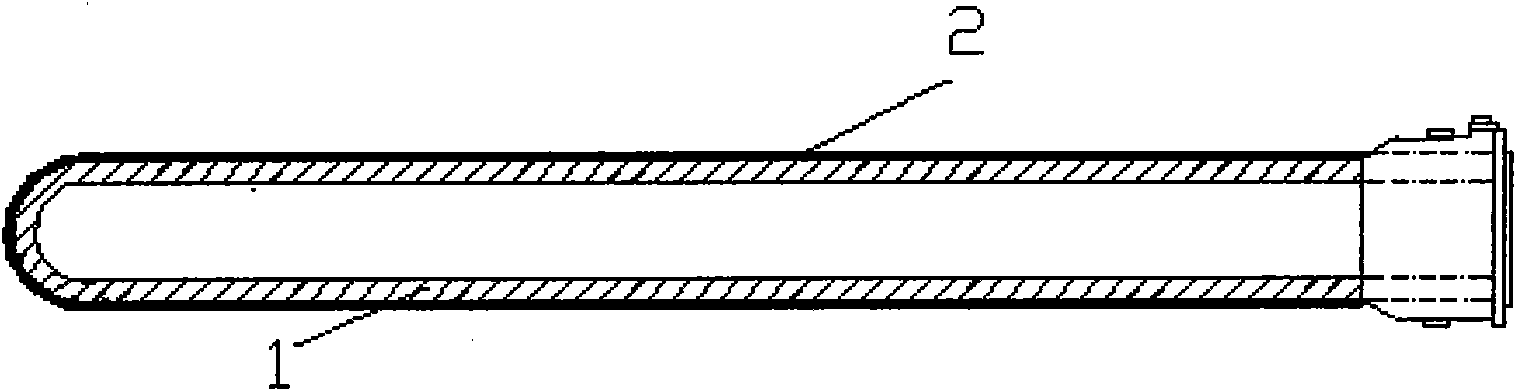

Magnesium smelting reduction pot and preparation method thereof

A technology for reducing tanks and smelting magnesium, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., which can solve problems such as complex procedures and short life of tanks, so as to promote oxidation resistance, improve service life, and extend critical time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of the magnesium refining reduction tank is by weight percentage:

[0026] C: 0.3%, Mn: 1.8%, Si: 1.0%, Cr: 25.5%, Ni7.0%:, Ti: 0.016%, Re: 0.04%, and the balance is iron;

[0027] The composition of the external coating layer is by weight percentage:

[0028] The particle size of zircon powder is 200 mesh, the addition amount is 55.3%, the addition amount of bentonite is 3.1%, powdered cellulose (sodium carboxymethyl cellulose) 2.5%, white latex (polyvinyl acetate emulsion) 1.5%, ethanol 29.5%.

[0029] The preparation method of described magnesium refining reduction tank is:

[0030] 1. According to the ratio of alloy raw materials in the magnesium reduction tank mentioned above;

[0031] 2. Various ingredients are put into the intermediate frequency furnace for melting, and the slag removal process should be strengthened during the smelting and pouring process;

[0032] 3. Preheat the mold barrel to 150°C, control the speed of the mold barrel to 71...

Embodiment 2

[0041] The composition of the magnesium refining reduction tank is by weight percentage:

[0042] C: 0.2%, Mn: 1.6%, Si: 1.5%, Cr: 26.0%, Ni8.0%:, Ti: 0.022%, Re: 0.05%, and the balance is iron;

[0043] The composition of the external coating layer is by weight percentage:

[0044] The particle size of zircon powder is 230 mesh, the addition amount is 63.7%, the addition amount of bentonite is 1.5%, the powdered cellulose (sodium carboxymethyl cellulose) is 2.0%, the white latex (polyvinyl acetate emulsion) is 2.1%, and the ethanol is 36.6%.

[0045] The preparation method of described magnesium refining reduction tank is:

[0046] 1. According to the ratio of alloy raw materials in the reduction tank for magnesium smelting mentioned above,

[0047] 2. Various ingredients are put into the intermediate frequency furnace for melting, and the slag removal process should be strengthened during the smelting and pouring process.

[0048] 3. Preheat the mold barrel to 200°C, contro...

Embodiment 3

[0057] The composition of the magnesium refining reduction tank is by weight percentage:

[0058] C: 0.35%, Mn: 2.0%, Si: 2.0%, Cr: 24.0%, Ni6.0%:, Ti: 0.019%, Re: 0.03%, and the balance is iron;

[0059] The composition of the external coating layer is by weight percentage:

[0060] The particle size of graphite is 250 mesh, the addition amount is 47.9%, the addition amount of bentonite is 3.8%, the powdered cellulose (sodium carboxymethyl cellulose) is 1.5%, the white latex (polyvinyl acetate emulsion) is 0.7%, and ethanol is 22.2%.

[0061] The preparation method of described magnesium refining reduction tank is:

[0062] 1. According to the ratio of alloy raw materials in the magnesium reduction tank mentioned above;

[0063] 2. Various ingredients are put into the intermediate frequency furnace for melting, and the slag removal process should be strengthened during the smelting and pouring process;

[0064] 3. Preheat the mold barrel to 225°C, control the speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com