Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310results about How to "The group ratio is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

Heat resistant aluminum alloy conductor material and preparation method thereof

ActiveCN102230113AImprove conductivityLow conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorManganese

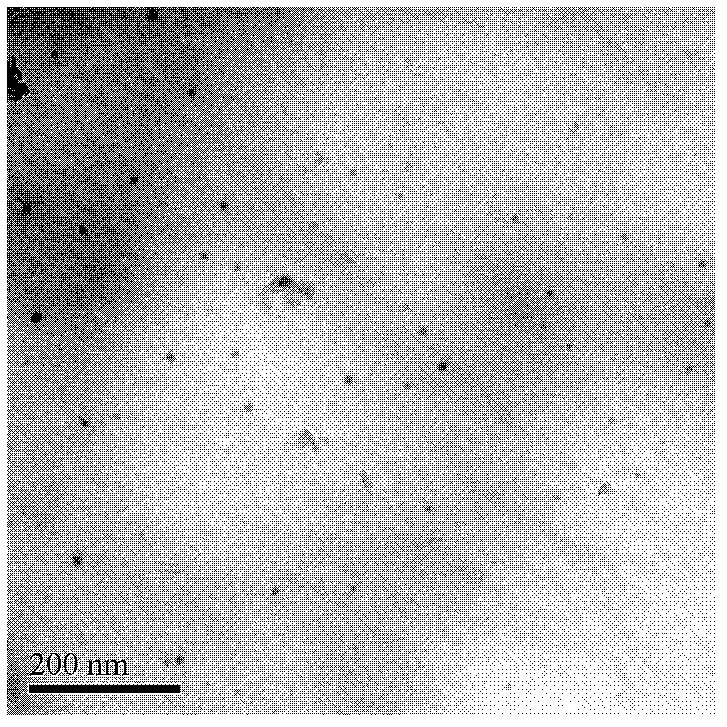

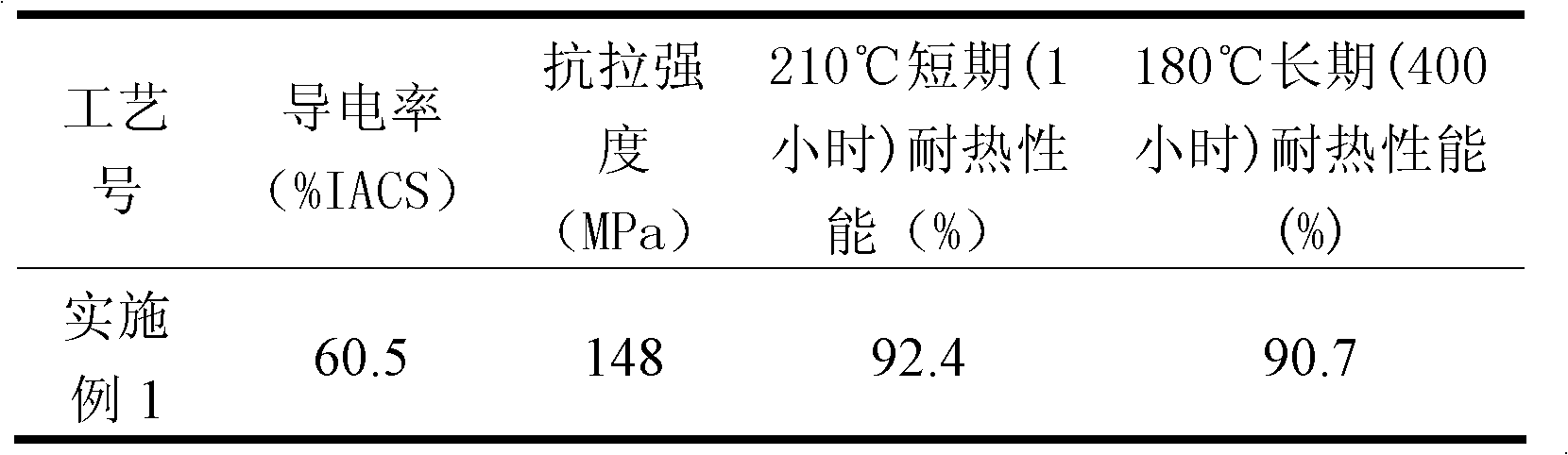

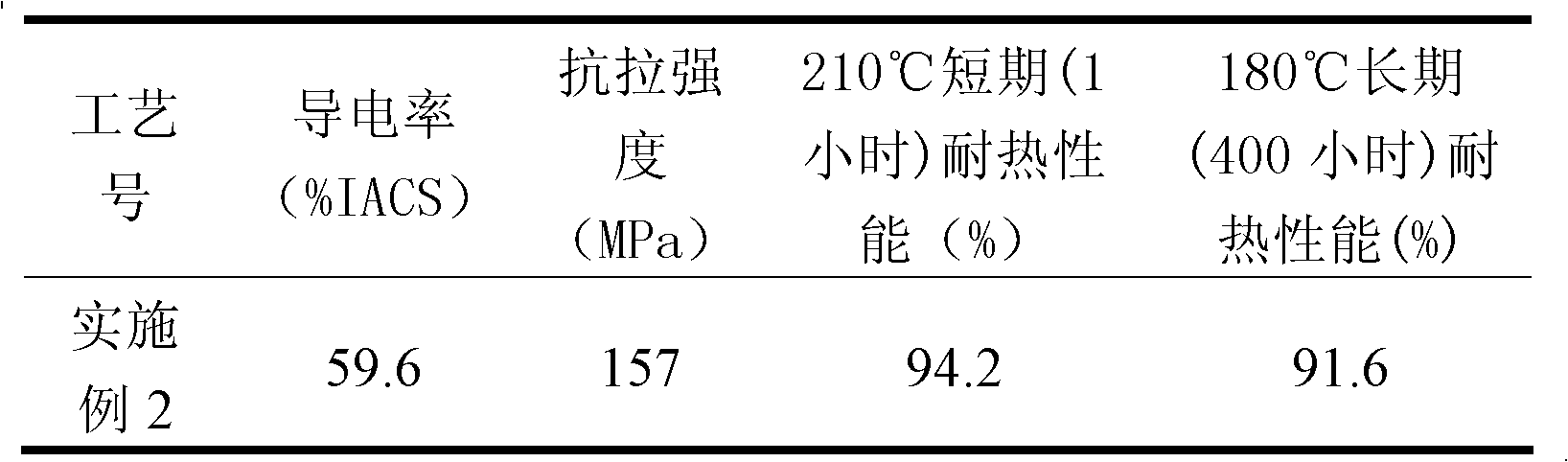

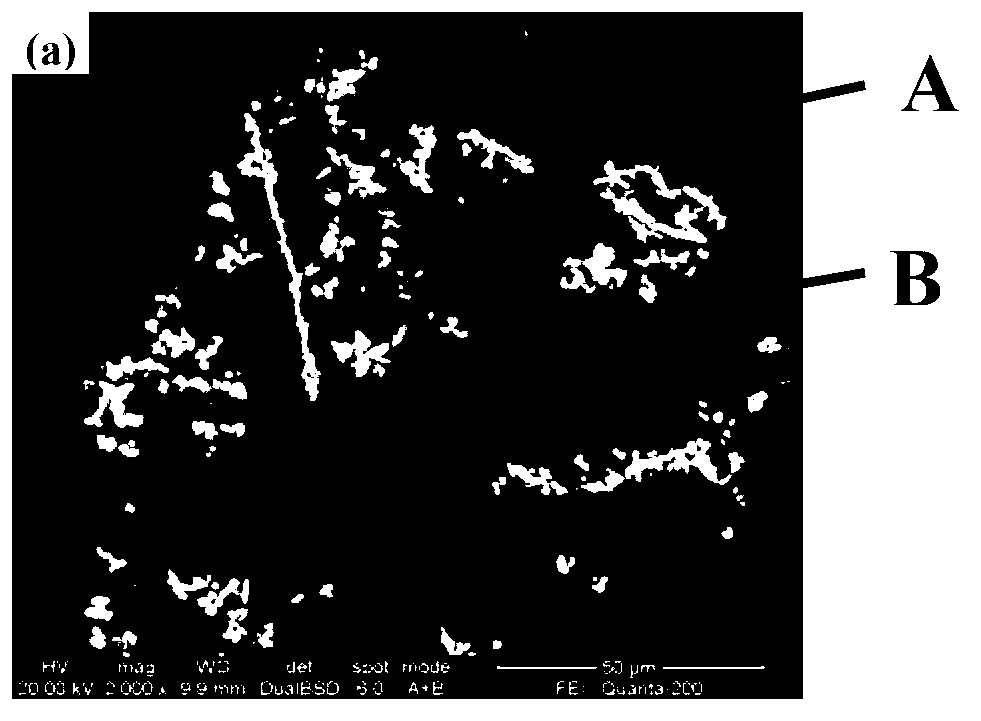

The invention provides a heat resistant aluminum alloy conductor material and a preparation method thereof. The heat resistant aluminum alloy conductor material comprises the following components of 0.06-0.15 % of zirconium, 0.15-0.30 % of erbium, 0.10-0.20 % of iron, less than 0.05 % of silicon, less than 0.01 % of inevitable impurities like titanium, vanadium, chromium, manganese and the like and the balance of aluminum. According to the preparation method, the heat resistant aluminum alloy conductor material is directly rolled after each component is fused and cast. The conductor material can realize that the electric conductivity can reach 59.5-60.5 % IACS (International Association Of Classification Societies), the long-term heat resistance temperature can reach 180 DEG C and the short-term heat resistance temperature can reach 210 DEG C without heat treatment; therefore, the conductor material is an electric wire and cable conductor material with great potential. The conductor material can be widely used for construction and capacity expansion reconstruction of electric power engineering; and by using the conductor material, the transmission line capacity is largely increased, the transmission line loss is reduced, the distance between poles of the transmission line can be increased, the line building cost is reduced, the tense corridor resources are saved and obvious economic benefit and energy-saving and environment-friendly significance are obtained. The heat resistant aluminum alloy conductor material provided by the invention has the advantages of reasonable component mixing ratio, simple preparation process, convenience for realizing continuous production and suitability for industrial application; and the production cost and the energy consumption of the heat resistant aluminum alloy can be effectively reduced.

Owner:CENT SOUTH UNIV

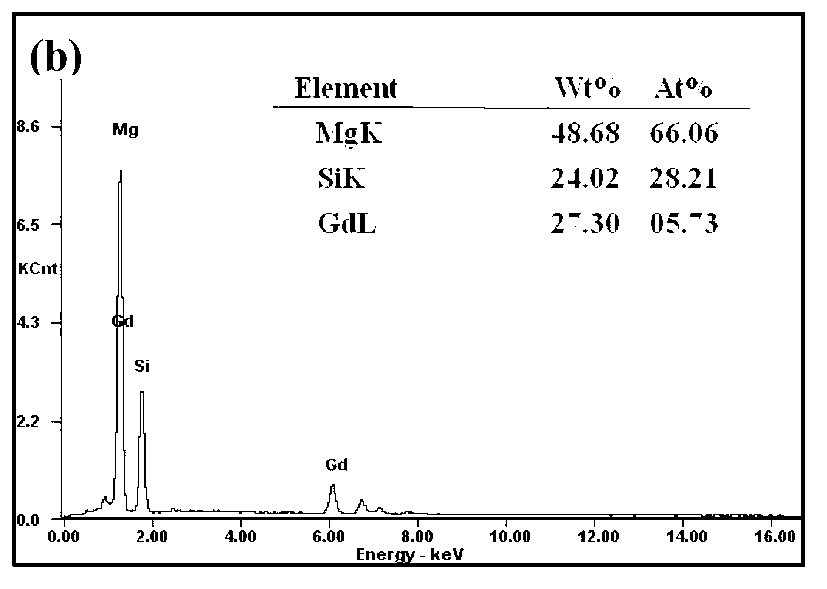

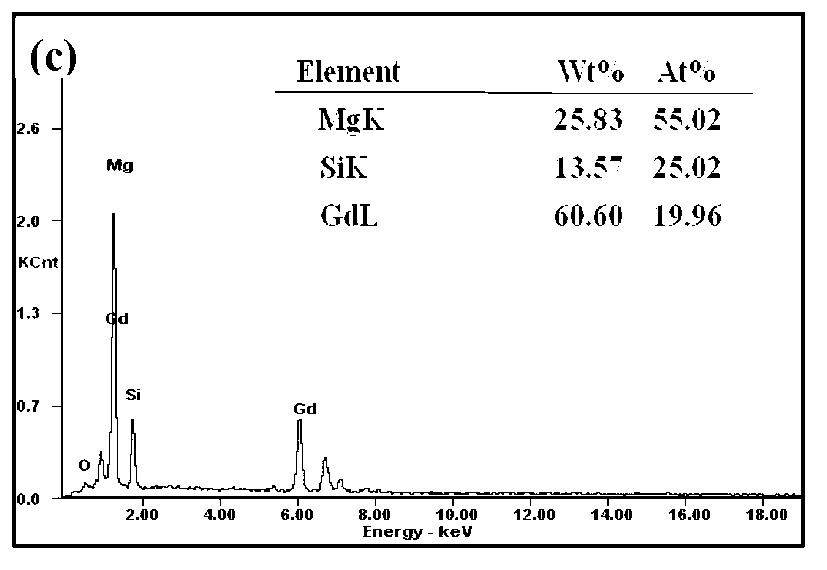

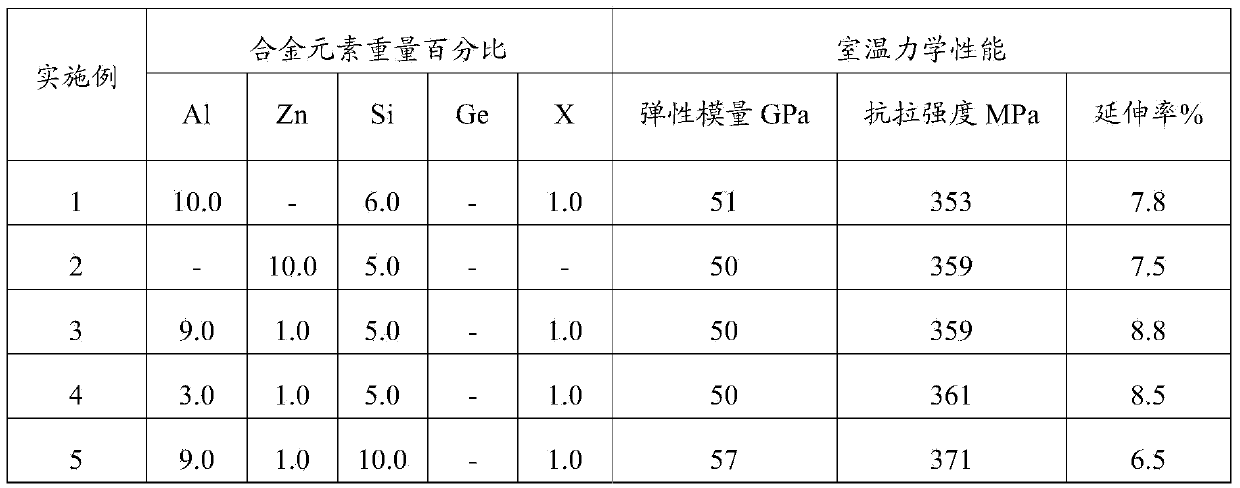

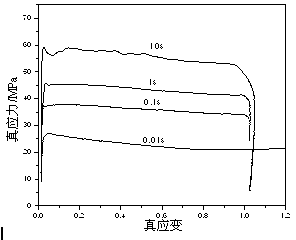

High-strength high-modulus magnesium alloy and preparation method

A high-strength high-modulus magnesium alloy comprises 3-20% of alloying element and the balance of magnesium substrate, wherein the alloying element comprises heavy rare earth, silicon and / or germanium, and tin and / or antimony and / or zinc; Si and Ge as well as Sn, Sb and Zn can be simultaneously added and can also be added individually; and the heavy rare earth is selected from at least one of gadolinium, dysprosium, terbium, holmium erbium, thulium, ytterbium and lutetium. The preparation method comprises the steps of: heating and melting pure magnesium in protective atmosphere, adding pure silicon to the pure magnesium melt, stirring, dissolving, heating-up to 20-30 DEG C, sequentially adding an interalloy of the other components, stirring, controlling the interalloy to be completely molten until the casting time is less than or equal to 4min, and casting to obtain a cast ingot. The high-strength high-modulus magnesium alloy is reasonable in component proportioning, and easy to process and manufacture; and the prepared high-strength high-modulus magnesium alloy has high room-temperature strength and elasticity modulus and better plasticity, and comprehensive performances apparently higher than those of the existing magnesium-rare earth, and is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

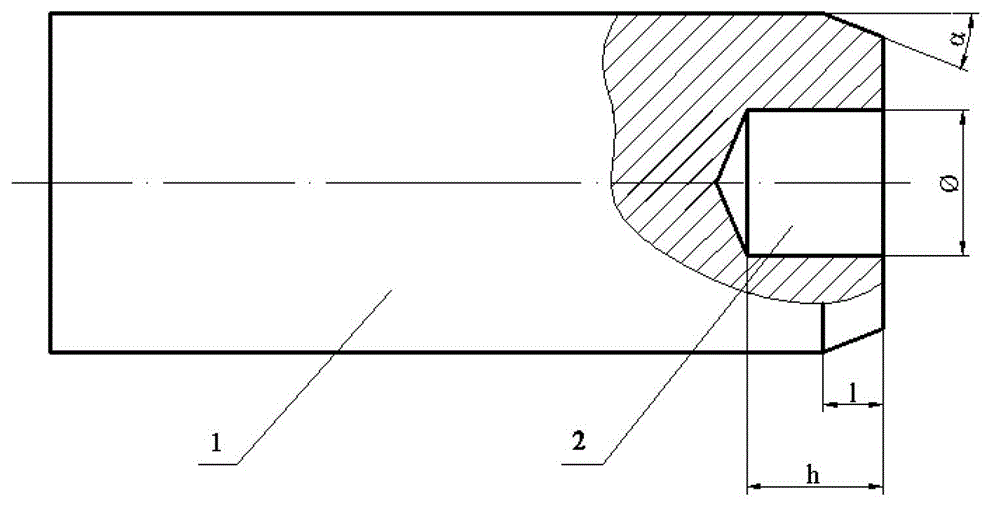

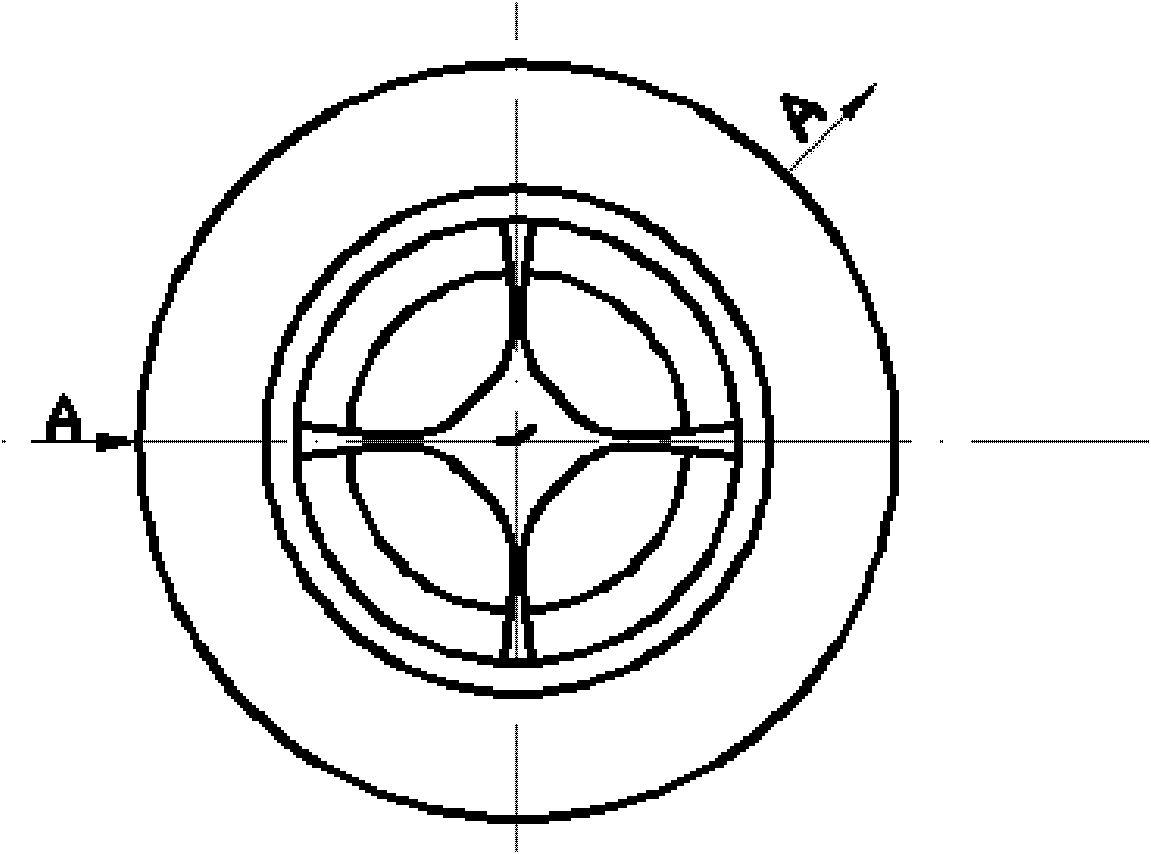

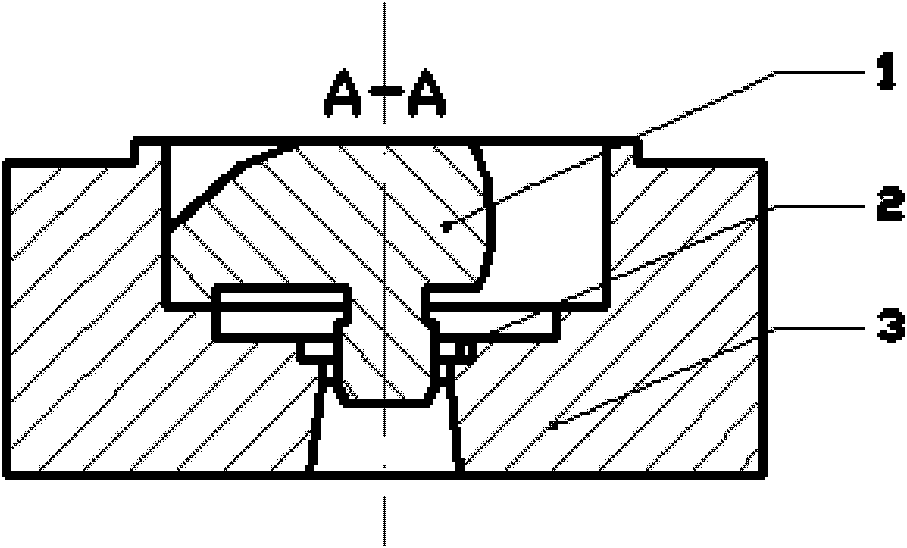

Titanium alloy pipe and manufacturing method

ActiveCN103146956AThe group ratio is reasonableHigh strengthMetal rolling arrangementsNon destructiveTitanium alloy

The invention belongs to the technical field of titanium alloy pipe pressure processing, and specifically relates to a titanium alloy pipe and a manufacturing method. The pipe is a seamless pipe, the outer diameter of the pipe is 140-300mm, and the wall thickness is 10-30mm. The manufacturing method is as follows: manufacturing a titanium alloy stick blank, machining the outer surface of the stick blank, and performing ultrasonic non-destructive testing on the stick blank; cutting the qualified stick blank in fixed length according to the weight requirement on the finished product pipe to manufacture a bar, machining at the centre of the head part of one end of the rod to obtain a guiding hole and an excircle chamfer, uniformly coating a layer of titanium alloy antioxidant protective coating on the surface of the bar, heating to 950-1100 DEG C after the bar coating is dried, and then keeping the temperature so that the temperature of the bar is uniform and consistent, rolling the bar on a cone mill. The titanium alloy pipe provided by the invention is simple in production process, short in flow, low in production cost and high in yield, the produced pipe is good in surface quality and high in wall thickness uniformity.

Owner:WUCHANG SHIPBUILDING IND

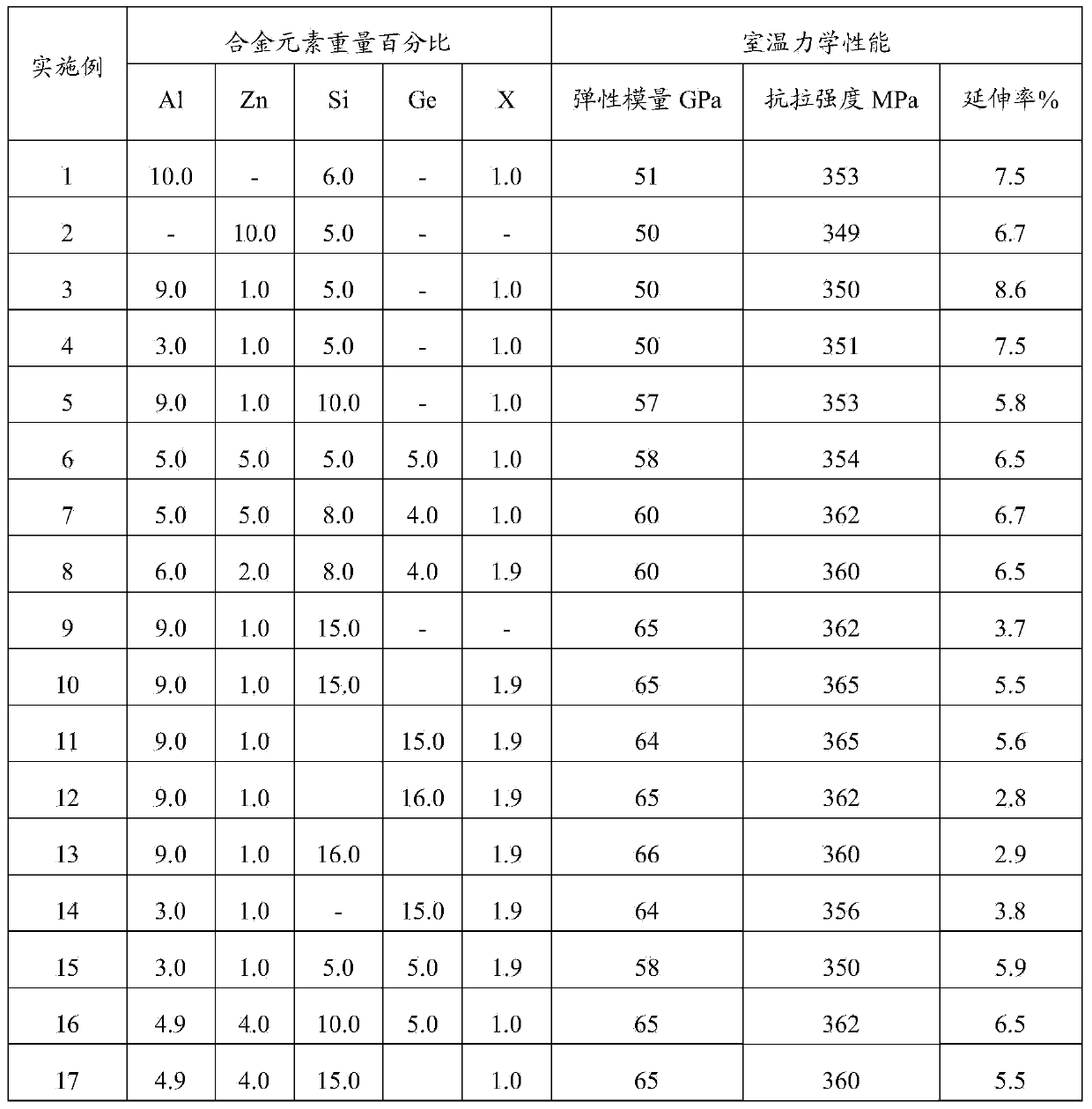

High-elasticity-modulus magnesium alloy and preparation method thereof

The invention discloses a high-elasticity-modulus magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by weight: 1.0-10.0% of aluminum and / or zinc, 1.0-15.0% of silicon and / or germanium, and the balance of magnesium. The preparation method comprises the following steps: heating and melting pure magnesium under the protection atmosphere, adding pure silicon into a pure magnesium melt, stirring and dissolving, warming, adding other components and stirring, controlling intermediate alloy to be completely molten until the pouring time is less than or equal to 3 minutes, refining and drossing, pouring to obtain an ingot. The high-elasticity-modulus magnesium alloy is reasonable in component matching, easy to process and manufacture, and low in price, the prepared high-elasticity-modulus magnesium alloy has high room-temperature intensity and elasticity modulus and good plasticity and is suitable for industrial production, and the comprehensive performance is obviously higher than that of the existing common magnesium alloy.

Owner:BAIC MOTOR CORP LTD

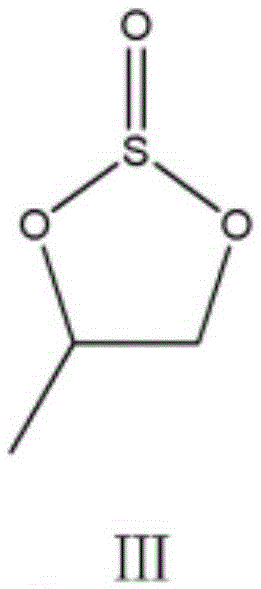

Low temperature electrolyte for lithium ion battery

InactiveCN101252207AExcellent low temperature charge and discharge performanceLow melting point boiling pointOrganic chemistrySecondary cellsDielectricAluminium-ion battery

The invention provides low temperature electrolyte for lithium ion batteries, consisting of basal solvent, low viscosity carbonic esters, low viscosity and low melting point addition agent and lithium salts, by studying on main parameters of the electrolyte such as the melting point, the boiling point, the viscosity and the dielectric constant, etc., proper components and rates of the solvent are selected, and the particular addition agent of the low temperature electrolyte is selected, which obtains the electrolyte having desirable high temperature and low temperature charge-discharge performances and low temperature multiplying factor performance. The low temperature electrolyte for lithium ion batteries has the advantages of reasonable ratios of components, desirable normal temperature and low temperature charge-discharge performances, good normal temperature cyclical stability and good low temperature multiplying factor performance, and is applied to the industrialized production and can also be used as a renewal product for the low temperature electrolyte of the prior lithium ion batteries.

Owner:CENT SOUTH UNIV

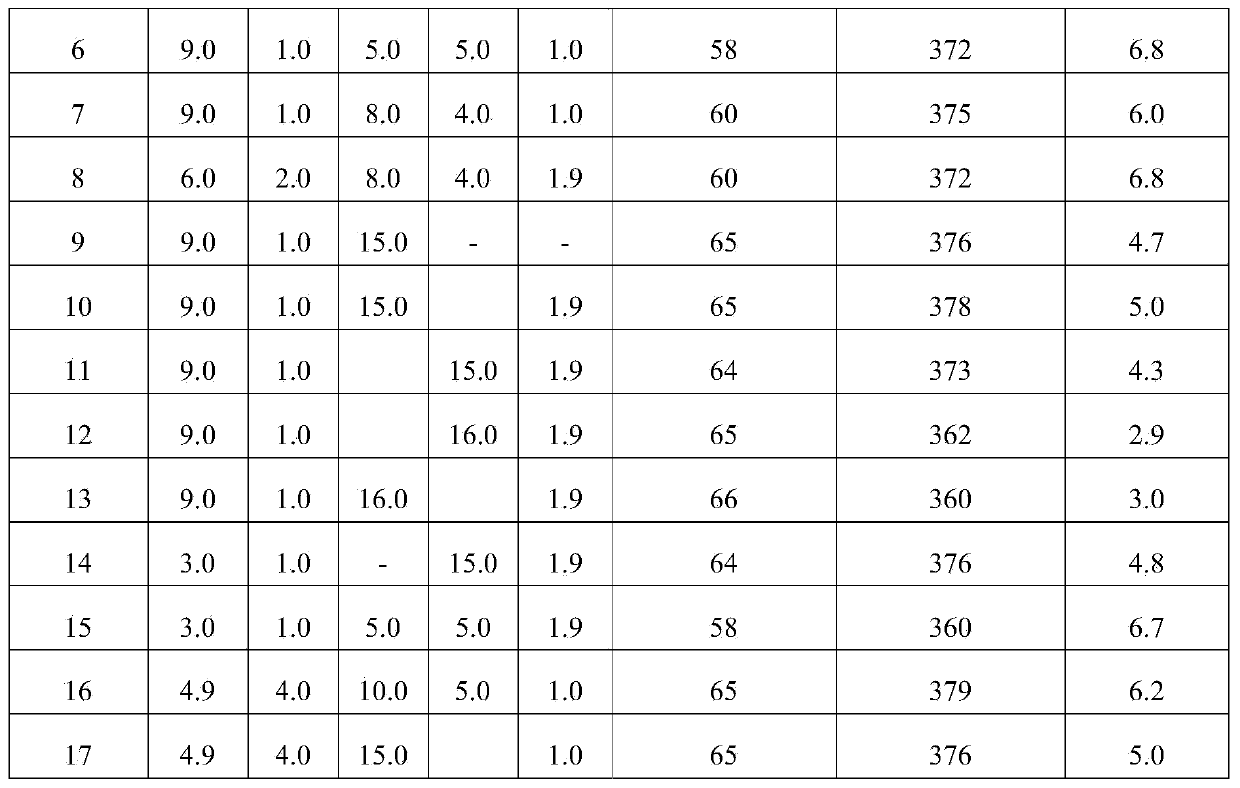

Airplane skin external surface cleaning compound

InactiveCN107254367AImprove wettabilityImprove solubilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsJet aeroplaneSurface cleaning

The invention relates to an airplane skin external surface cleaning compound. The airplane skin external surface cleaning compound comprises a surfactant, a chelating agent, a corrosion inhibitor, inorganic base and a solvent. The airplane skin external surface cleaning compound comprises the following components by mass percentage: 18-34% of the surfactant, 8-13% of the complexing agent, 5-9% of the corrosion inhibitor, 3-8% of the inorganic base, and the balance of the solvent. The cleaning compound employs a complex formulation technology, the components ratio is reasonable, a pollutant deposited on the airplane skin external surface is thoroughly cleaned, effect is good, efficiency is high, the cost of the cleaning compound is low, no corrosion is generation on a body of the airplane, no pollution is generated on human body and environment, the cleaning waste liquid can be directly discharged, and the cleaning compound has the advantages of safety and environmental friendliness.

Owner:AIR FORCE UNIV PLA

Corundum breathable seat brick with high thermal shock resistance and production method thereof

The invention discloses a corundum breathable seat brick with high thermal shock resistance. The brick consists of mixed corundum, a magnesium-containing material, a binding agent, chromium oxide, a water reducing agent and an explosion-proof agent. The production method of the corundum breathable seat brick comprises the following steps: dosing, and mixing to prepare mud; placing the mud in a mould, performing shake densification, demoulding, and drying to obtain a breathable seat green brick; and heating the breathable seat green brick, and roasting to obtain the corundum breathable seat brick with thermal shock resistance. The component ratio is reasonable, the production and preparation method is simple, the prepared breathable seat brick has good high-temperature strength and thermal shock resistance; and the service life of the breathable seat brick can be effectively prolonged, the use security of the breathable brick can be increased, the replacement times of the breathable brick can be reduced, the production cost of enterprises can be reduced and the production efficiency of ferrous metallurgy can be increased. The corundum breathable seat brick can replace the existing breathable seat brick and be suitable for industrial production.

Owner:CENT SOUTH UNIV

High-energy-absorptivity aluminum alloy for automobile bodies

The invention relates to a high-energy-absorptivity aluminum alloy for automobile bodies, which comprises the following components in percentage by weight: 0.56%-0.64% of Mg, 0.42%-0.50% of Si, 0.17%-0.19% of Cu, 0.20%-0.22% of Fe, 0.028%-0.032% of Mn, 0.028%-0.032% of Cr, 0.028%-0.032% of Zn, 0.29%-0.31% of Ti, 0.29%-0.31% of Zr and the balance of Al. The preparation method comprises the following steps: preparing components according to weight percents, melting by heating to 740-750 DEG C, cooling, standing,, refining, and casting into a 250-300 DEG C iron mold; and carrying out homogenizing treatment on the cast ingot at 560 DEG C for 9 hours, quickly cooling with water, heating, extruding, carrying out water or fog quenching, and carrying out artificial aging at 180 DEG C. The invention has the advantages of reasonable component proportion, simple operating technique and favorable hot extrusion formability.

Owner:HUNAN UNIV

Method for preparing coconut palm plate for mattress

InactiveCN102660842ANo glue smellNot susceptible to moisture and mildewStuffed mattressesSpring mattressesCold airPolyester

The invention discloses a method for preparing a coconut palm plate for a mattress. The method comprises the steps as follows: performing opening treatment on two-composition sheath-core fiber, coconut palm fiber and hollow polyester fiber; mixing the two-composition sheath-core fiber and coconut palm fiber to obtain a synthetic fiber A; mixing the two-composition sheath-core fiber and the hollow polyester fiber to obtain a synthetic fiber B; combing the synthetic fiber A and the synthetic fiber B; lapping; fusing the sheath of the two-composition sheath-core fiber by utilizing the hot air penetration technology together with the hollow polyester fiber and the coconut palm fiber; cooling and curing the sheath of the two-composition sheath-core fiber by utilizing the cold air penetration technology, and leading the fiber of the three layers to be bonded together to form a platy structure; and cutting into certain specification. The coconut palm plate for the mattress, prepared by adopting the preparation method, has the advantages of having no formaldehyde release and no glue smell, being not easy to moisture and mould, and being smooth in surface and uniform for thickness.

Owner:昆山吉美川纤维科技有限公司

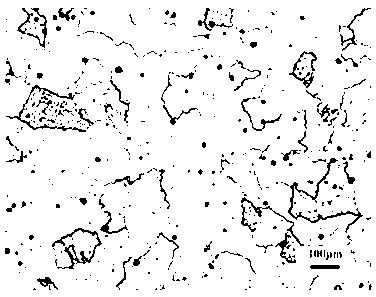

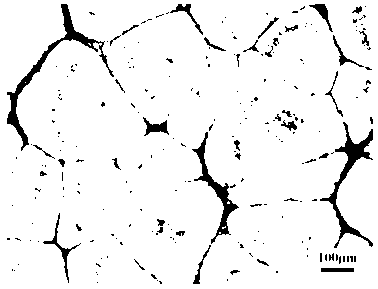

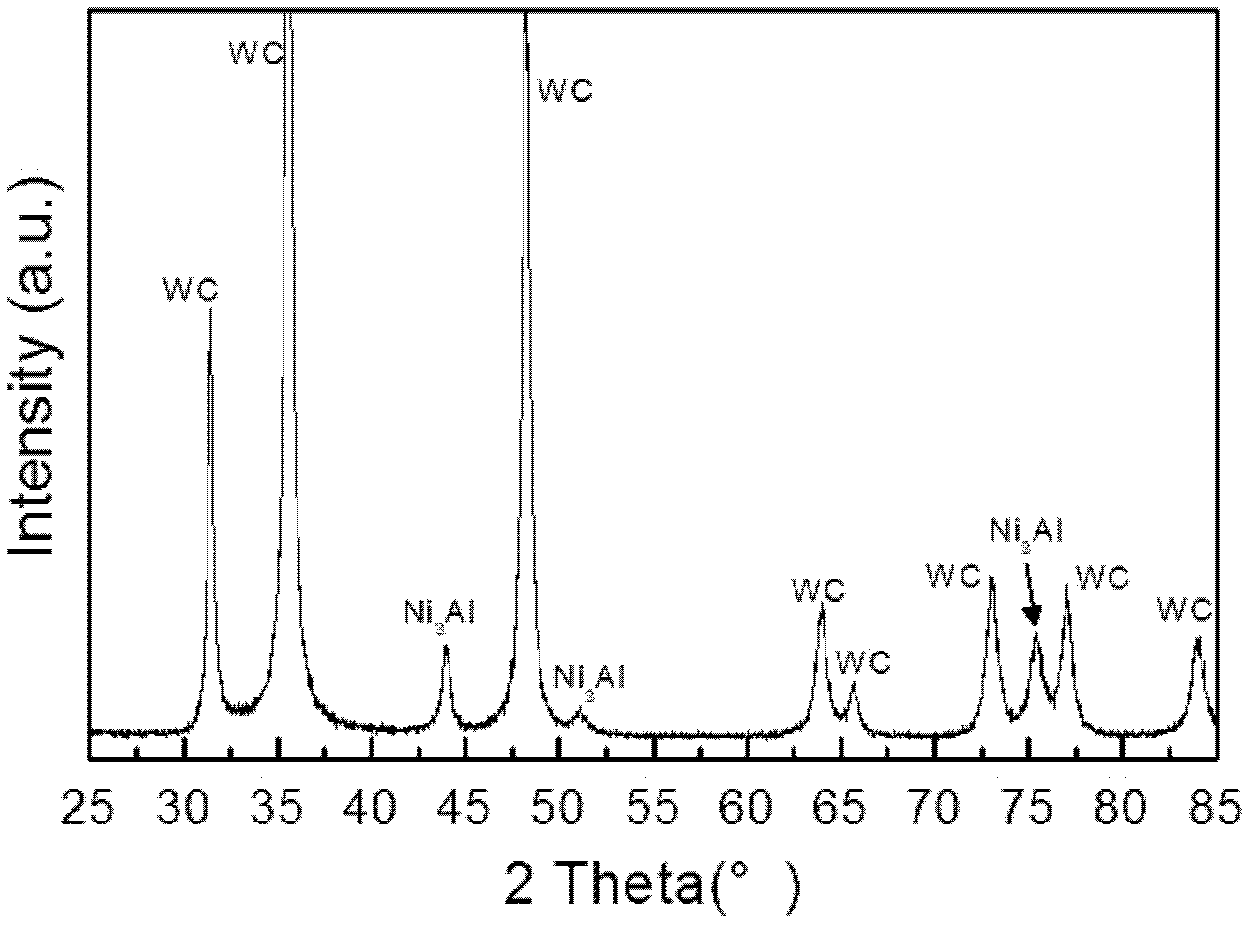

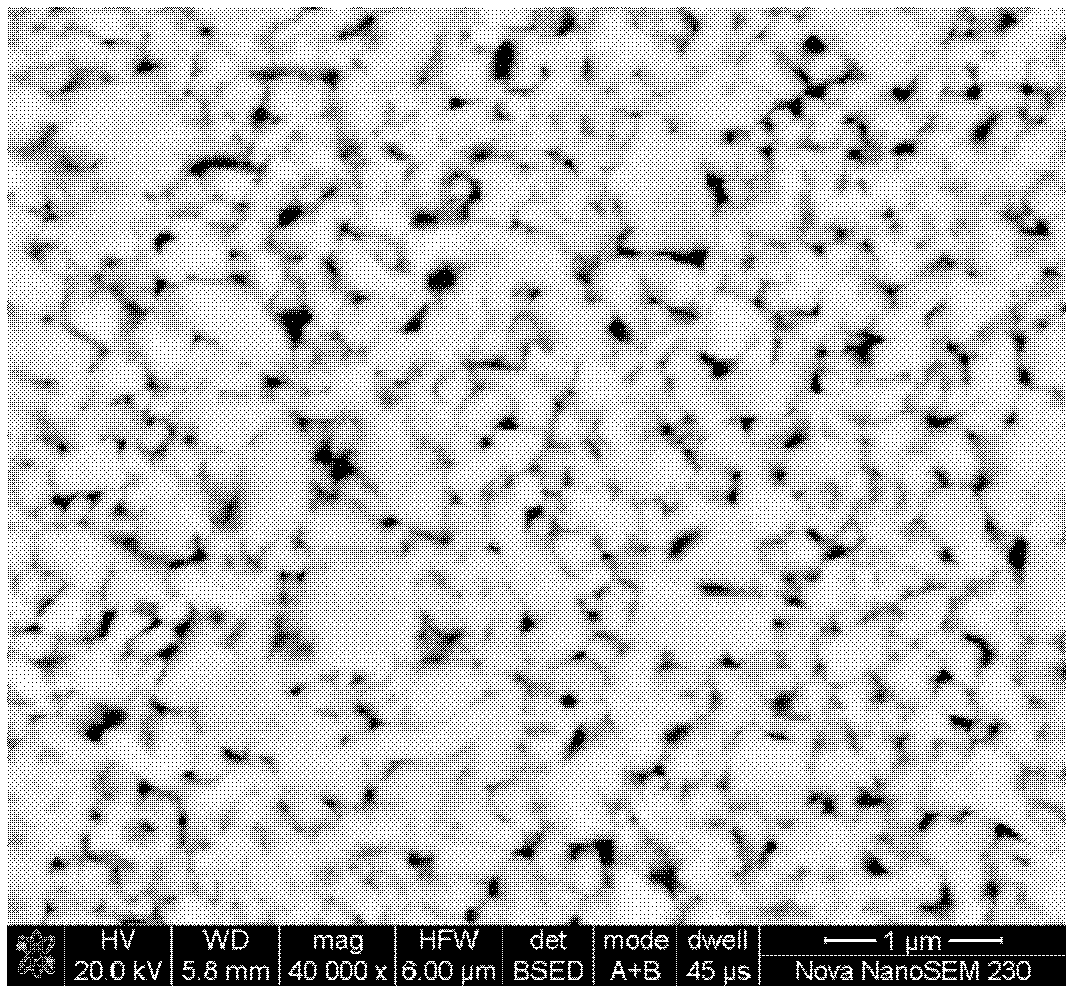

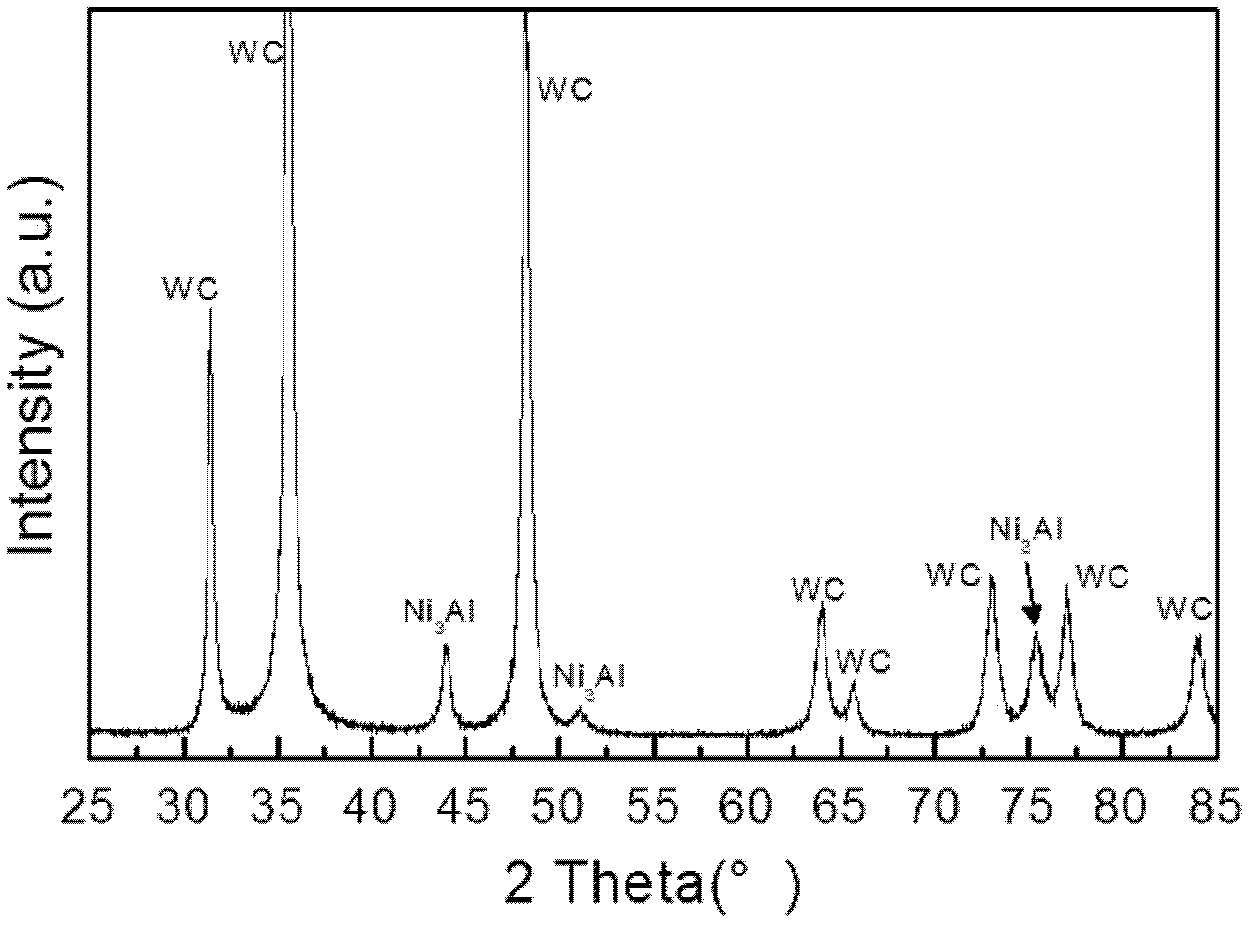

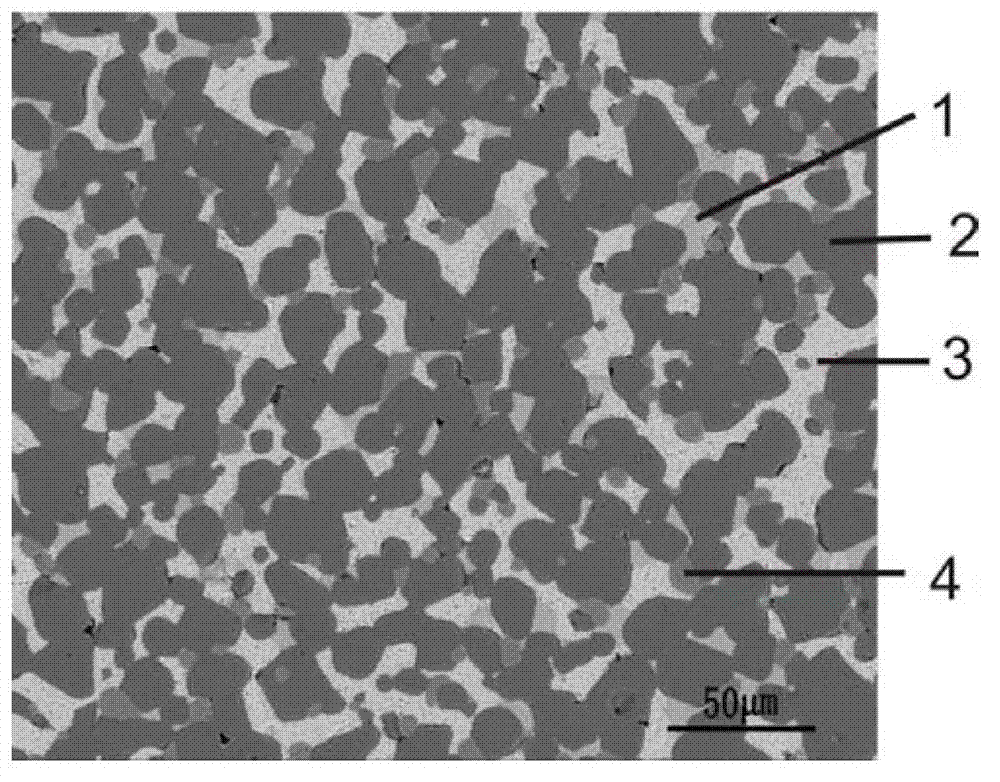

Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy and preparation method thereof

The invention provides a Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy and a preparation method thereof, and belongs to the field of high-performance structural materials. The hard alloy comprises the following components in percentage by mass: 0.01 to 0.1 percent of rare earth hexaboride (ReB6), 0.05 to 0.5 percent of chromium carbide (Cr2C3), 0.05 to 0.5 percent of vanadium carbide (VC), 5 to 40 percent of nickel aluminum (Ni3Al) and the balance of tungsten carbide powder. The method comprises the following steps of: weighing the tungsten carbide powder, nickel powder, aluminum powder, ReB6 powder, Cr2C3 powder and VC powder with certain granularity in a weight percent ratio, uniformly mixing the powder by a mixing method, and pressing by a compression molding process to obtain a blank with a certain shape; and degreasing the blank, putting into a low-pressure sintering furnace, sintering, and cooling with the furnace to obtain the Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy. The alloy prepared by the method is fine grained and has a uniform structure, high density and strength, corrosion resistance and high-temperature resistance, the process is simple, preparation cost is low, and industrial production can be implemented.

Owner:CENT SOUTH UNIV

Continuous extrusion preparation process of a high-strength weldable zinc alloy and its pipe

The invention relates to a high-strength weldable zinc alloy, which is composed of the following components: aluminum, copper, titanium, magnesium, chromium, rare earth, and the balance is zinc. The preparation process of the pipe includes the following steps: batching, melting and casting; and continuous extrusion; the invention prepares a high-strength weldable zinc alloy by optimizing the ratio of alloy elements, and then continuously extrudes to form a zinc alloy pipe. The extrusion process does not need to heat the zinc alloy billet, so that the zinc alloy is directly formed in the mold by split extrusion through continuous large shear deformation. The composition ratio of the invention is reasonable, the prepared alloy material has good mechanical properties, is easy to realize extrusion forming, has good weldability, the raw material is cheap and easy to obtain, the preparation process design of the zinc alloy pipe is reasonable, the operability is strong, and the processing efficiency is high. It also solves the outstanding problems of the conventional pipe extrusion process, such as long process flow, high energy consumption, low material utilization rate, and high production cost, and has a good application prospect.

Owner:CENT SOUTH UNIV

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

Cosmetic flavor beef sausage

Owner:牛岷

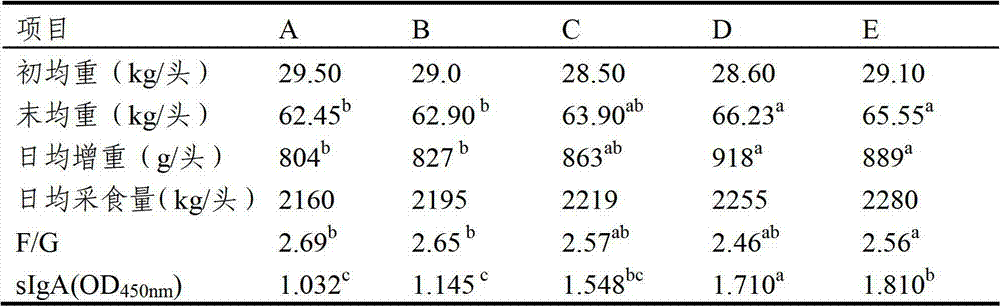

Compound premix for pigs and mixed batch of compound premix

InactiveCN102813091ARemove heavy metal poisoningAvoid fighting each otherAnimal feeding stuffDisease occurrencePantothenic acid

The invention provides a compound premix which contains selenium-enriched yeast, ferrous-enriched yeast and zinc-enriched yeast, and belongs to the field of premixes. The premix is mainly prepared from the following ingredients of the selenium-enriched yeast, the ferrous-enriched yeast, the zinc-enriched yeast, ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, potassium iodide, cobalt chloride, organic trace minerals, multivitamin, pantothenic acid, nicotinic acid, folic acid, biotin, lysine, compound microecologics, ethoxyquin, antioxidant, 50% choline chloride, bentonite and rice chaff. The premix is reasonable in formula, is not added with antibiotics, and contains multi-active probiotics and selenium-enriched yeast powder, ferrous-enriched yeast powder and zinc-enriched yeast powder, the pig survival rate is high, the pig weight is quickly increased, and the feed conversion efficiency is increased. The premix is contributed to improving the intestinal microecological environment of the pig, the intestinal health is maintained, the pig immunity function is improved, the disease occurrence is reduce, and the pig growth is promoted.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

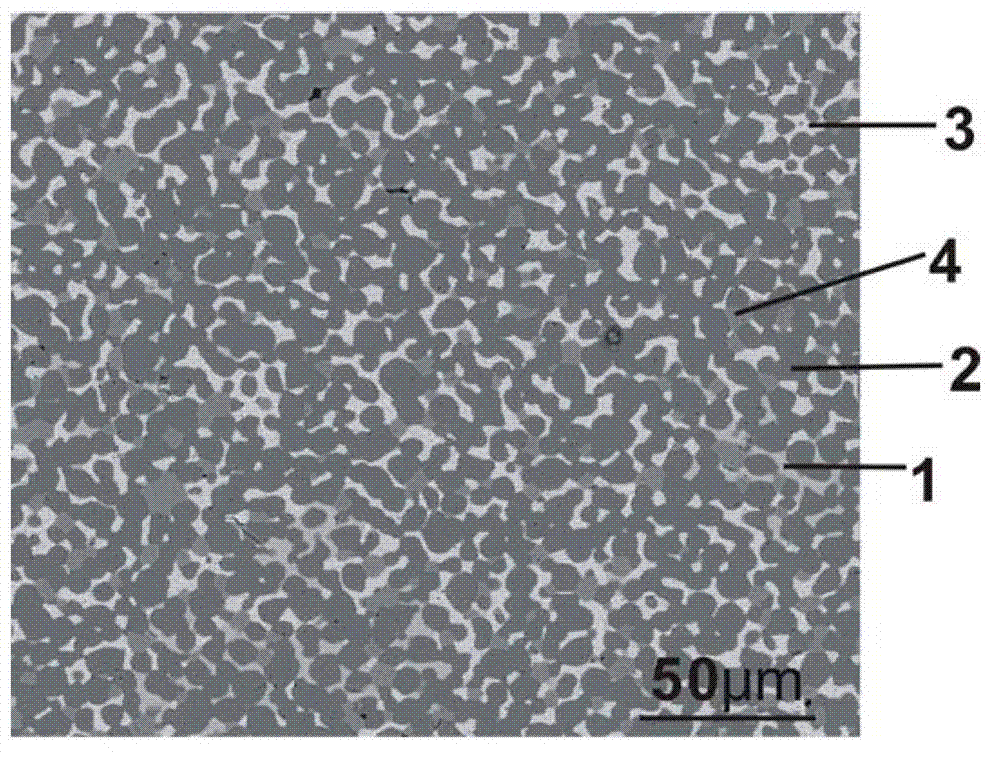

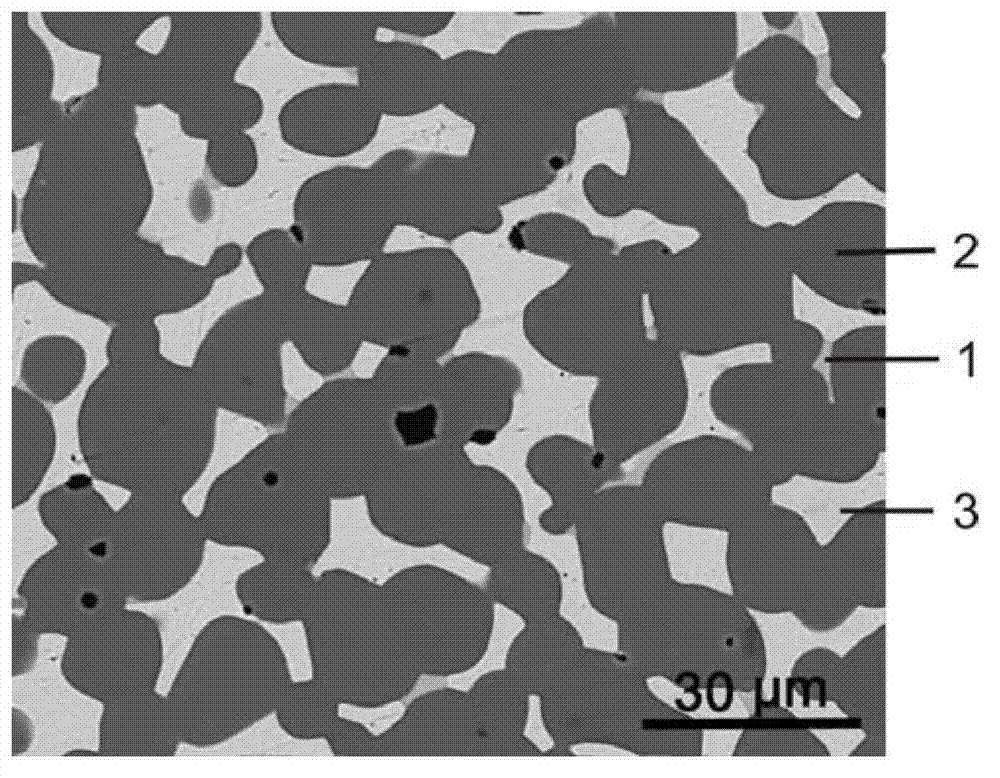

Nickel ferrite-copper metal ceramic inert anode material and preparation method

The invention relates to a nickel ferrite-copper metal ceramic inert anode material which comprises a ceramic phase and a metal phase, wherein the ceramic phase is nickel ferrite or nickel ferrite base composite ceramic; and the metal phase consists of metal copper and cuprous oxide, and the cuprous oxide accounts for 1-20% of the total mass of the metal phase. In the preparation process, the content of the cuprous oxide in the metal phase is controlled through controlling the oxygen partial pressure of a nitrogen protection atmosphere so as to improve the wettability of the nickel ferrite and the copper and achieve the sintering infiltration preparation of the ceramic phase and the metal phase. The metal phase and the ceramic phase of the nickel ferrite-copper metal ceramic inert anode material are in a three-dimensional reticular through structure, wherein the sintering density is higher than 98%, the electric conductivity of the metal ceramic material is more than 200S / cm at a temperature of 900 DEG C, the heat conductivity is up to 40W / (m.K) at the room temperature, and the metal ceramic material cannot be cracked through temperature difference thermal shock at the temperature of 400 DEG C. The problems of difficult sintering densification of the nickel ferrite and the copper, sintering overflow of the metal phase and material thermal shock and cracks are effectively solved, and compared with a material prepared by a conventional mixed powder sintering process, the electric conductivity and the thermal shock resistance of the nickel ferrite-copper metal ceramic material are greatly improved.

Owner:CENT SOUTH UNIV

Composite antioxidant applied to copper powder

InactiveCN101736338APrevent oxidationLow oxygenMetallic material coating processesElectrolysisAntioxidant

The invention relates to a composite antioxidant applied to copper powder, comprising the following components: benzotriazole, hard soap, ethanol and balance of pure water. Electrolytic copper powder is washed until pH value thereof is 1.0-3.0, adding the components to detergent, thus forming a layer of organic antioxidation protective film on the surface of copper powder, contact between the surface of the copper powder and oxygen in the water is cut off to prevent the copper powder from being oxidized in the follow-up washing process. Oxygen content of the copper powder in the invention reaches national standards; in addition, reduction process after washing the electrolytic copper powder, thus greatly saving product cost and lowering energy consumption. The components of the invention features reasonable proportioning, convenient use and can effectively copper powder oxidation resistance, save energy and simplify electrolytic copper powder production technology, reduce production cost and realize industrialized production, thus being suitable for industrialized application and enjoying fine industrialization prospect; in addition the composite antioxidant can not only serve as antioxidation protective agent in the process of producing electrolytic copper powder but also as the antioxidation protective agent in the process of storing copper powder produced by other means.

Owner:CENT SOUTH UNIV

Desulphurization and denitration agent based on waste biomass and preparation method thereof

ActiveCN103495434AHas sulfur fixationEmission reductionMolecular sieve catalystsDispersed particle separationMixed materialsPollution

The invention discloses a desulphurization and denitration agent based on waste biomass and a preparation method thereof. The desulphurization and denitration agent contains zeolite catalysts loaded with metal oxides, modified active carbon, waste biomass and a biomass binder. The preparation method of the desulphurization and denitration agent based on the waste biomass comprises the following main steps: firstly, crushing the solid-state biomass waste, the zeolite catalysts and the active carbon to obtain powder; then, uniformly mixing the crushed materials in the biomass binder; and finally, drying and forming the mixed materials to obtain the desulphurization and denitration agent disclosed by the invention. The desulphurization and denitration agent disclosed by the invention not only can be directly used for purifying a high-temperature flue gas of over 600 DEG C, but also can be used for effectively realizing treatment of wastes with processes of wastes against one another, i.e., the biomass waste including crop straws, crop processing waste, timber processing waste or municipal domestic waste, and the like are effectively used to govern flue gas pollution.

Owner:北京绿洁美科技有限公司

3D printing material for gelatinized confections and preparation method of 3D printing material

InactiveCN107668306AFlexible textureThe group ratio is reasonableConfectioneryFood preservationGellan gumRoom temperature

The invention relates to the technical field of food, in particular to a 3D printing material for gelatinized confections and a preparation method of the 3D printing material. Starch and low-acyl gellan gum in the 3D printing material are taken as gel, remelting is facilitated, rapid gelling at room temperature can be realized, smooth discharge can be guaranteed during 3D printing, stability of the printing material can be improved with application of plant extract, so that the printed confections can be stored for a long time, and sugar crystals are avoided. Experiments prove that the 3D printing material can be printed successfully, sensory evaluation of the obtained products is good, and sugar crystals or sugar dissolution does not occur when the products are placed at room temperaturefor 60 d.

Owner:INFINITUS (CHINA) CO LTD

Abrasion-resistant and corrosion-resistant molybdenum alloy and preparation method thereof

ActiveCN107245621AThe group ratio is reasonableRaise the recrystallization temperatureAlloyUltimate tensile strength

The invention relates to an abrasion-resistant and corrosion-resistant molybdenum alloy and a preparation method thereof. The abrasion-resistant and corrosion-resistant molybdenum alloy comprises the following components by volume percent: 0.2% to 10% of ZrO2 and 0.05% to 1% of Y2O3, and the balance being molybdenum. According to the abrasion-resistant and corrosion-resistant molybdenum alloy provided by the invention, ZrO2 is adopted as dispersed phases and is added into the molybdenum alloy, Y2O3 is added to stabilize tetragonal phases ZrO2 in the molybdenum alloy, crystal transition of ZrO2 under the high temperature is prevented, and plasticity and toughness are guaranteed; and the components in the alloy are reasonable in proportion and cooperate to act, recrystallization temperature of the molybdenum alloy is increased, grain-boundary strength of the molybdenum alloy is improved while processing performance is improved, and high-temperature creep resistance, abrasion resistance and corrosion resistance of the molybdenum alloy are strengthened.

Owner:HENAN UNIV OF SCI & TECH

Disease-resistant and fattening sheep breeding feed composition

InactiveCN104351532AThe group ratio is reasonableFull of nutritionFood processingAnimal feeding stuffSunflower seedAntibody

The invention discloses a disease-resistant and fattening sheep breeding feed composition. The sheep breeding feed composition comprises the following components in parts by weight: 25 to 35 parts of maize straws, 4 to 6 parts of selenium -enriched yeast, 0.5 to 0.8 part of salt, 8 to 12 parts of wheat bran, 10 to 20 parts of corns, 8 to 12 parts of soybean straws, 4 to 6 parts of sorghum roots, 4 to 6 parts of soya-bean cakes, 2 to 4 parts of peanut leaves, 2 to 4 parts of liquorices, 2 to 4 parts of yam peel, 2 to 4 parts of loofah sponges, 4 to 6 parts of grass, 2 to 4 parts of tomatoes, 2 to 4 parts of collagen protein powder, 3 to 5 parts of tea seeds, 2 to 4 parts of saffron, 2 to 4 parts of mint leaves, 1 to 3 parts of caulis spatholobi, 2 to 4 parts of coffee beans, 2 to 4 parts of green tea, 1 to 3 parts of fish skin, 2 to 4 parts of sunflower seed meals, 2 to 4 parts of white hyacinth beans, 0.5 to 1 part of pepper, 2 to 3 parts of honey, 3 to 5 parts of purple potatoes, 1 to 3 parts of linden leaves. The disease-resistant and fattening sheep breeding feed composition has rational proportion in components and rich nutrition, can ensure that the sheep have antibodies against germs when being used for feeding for a long time, and improves the survival rate of lambs, and sheep fed with the feed composition is good in meat quality and body condition, the slaughter rate can be improved, the sheep grow faster and reach market weight much earlier and the feed investment is reduced.

Owner:申保林

Environmentally-friendly heat-insulating nanometer coating and preparation method thereof

InactiveCN102002320ASimple processing technologyThe group ratio is reasonableCoatingsEnvironmentally friendlyWetting

The invention relates to an environmentally-friendly heat-insulating nanometer coating and a preparation method thereof. The environmentally-friendly heat-insulating nanometer coating comprises the following components: nanometer pigment and filler slurry, synthetic waterborne resin, a film-forming aid, a coupling agent, an antifoaming agent, a leveling agent and a wetting agent. The preparation method of the environmentally-friendly heat-insulating nanometer coating comprises the following steps of: adding the nanometer pigment and filler slurry into the synthetic waterborne resin, sequentially adding the film-forming aid, the coupling agent, the antifoaming agent, the leveling agent and the wetting agent, and quickly stirring. The processing technology is simple, the components have a reasonable proportion, and the coating has high thermal resistance, reflectivity and radiative heat transfer performance.

Owner:长沙华润涂料有限公司

Rice wine lees biscuit and preparation method thereof

InactiveCN102812983AThe group ratio is reasonableUnique flavorBakery productsAdditive ingredientSnack food

A rice wine lees biscuit consists of the following ingredients: rice wine lees, water, shortening and wheat flour. The preparation method includes the following steps: after the filtered rice wine lees, the water content of which is less than or equal to 5 percent, is pasteurized, the rice wine lees, the shortening, the water and the wheat flour are uniformly mixed, shaped and baked in an oven, so that the rice wine lees biscuit is produced. Since the invention adopts the rice wine lees as main material to produce the biscuit, the good interior and exterior morphological characteristics of the biscuit are kept, the biscuit is given the unique rice wine flavor, accords with the pursuit of young people for health and green, and is low in sugar content and rich in amino acid, vitamins and other nutrient substances, and therefore the high fat content and high sugar content of the food are prevented. The rice wine lees is utilized to the max, resource waste is prevented, and the invention provides an approach to comprehensively utilize the rice wine lees as the byproduct of rice wine, and prepares the snack food with unique flavor. The invention is applicable to mass production.

Owner:HUNAN AGRICULTURAL UNIV

Porous concrete waterproofing agent and preparation method thereof

The invention discloses a porous concrete waterproofing agent and a preparation method thereof. The waterproofing agent is prepared from, by weight, 25-40 parts of modified gel, 4-6 parts of an oxidizing agent, 5-9 parts of a cross-linking agent and 3-5 parts of a photoinitiator; the modified gel is prepared from, by weight, 30-40 parts of pretreated microspheres, 25-30 parts of 3,4-dihydroxyphenylacetic acid, 15-20 parts of N-hydroxysuccinimide, 15-20 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 18-25 parts of sodium alginate and 10-14 parts of propyne. According to the porous concrete waterproofing agent and he preparation method thereof, process design is simple, and component proportion is reasonable; chitosan and sodium alginate are modified, and a Michael addition reaction and a chemical click reaction are used for forming a compact double-gel network, so the waterproof and seepage-proof performance of concrete can be effectively improved in use, meanwhile, the waterproofing agent can be self-repaired, and the waterproofing agent can be widely applied to concrete construction and has high practicability.

Owner:佛山市志必合材料有限公司

Low-lead aviation gasoline and production method thereof

ActiveCN104673410ABoost Octane IndexImprove securityLiquid carbonaceous fuelsAviationCombustion chamber

The invention belongs to the technical field of aviation fuel, and discloses a low-lead aviation gasoline and a production method thereof. The low-lead aviation gasoline comprises the following components in percentage by volume: 25%-60% of front-fraction alkylate oil, 18%-60% of super fraction alkylate oil, 10%-22% of methylbenzene, 3%-14% of dimethylbenzene, 10%-21% of carbon-5 and less than 0.53ml / l of lead tetraethyl. These components are mixed under a stirring condition; the isopentane content in the obtained low-lead aviation gasoline reaches 0.5%-22%; the content of isooctane reaches 20%-80%; and the motor octane number is greater than 99.5. The front-fraction alkylate oil and the super fraction alkylate oil are obtained by rectifying alkylate oil; the octane number index in the aviation gasoline is effectively improved; components with relatively much colloid are eliminated; carbon formation in a combustion chamber of an aircraft engine is avoided; and the security of the aircraft is improved.

Owner:DONGYING HUAYA GUOLIAN AVIATION FUEL CO LTD

Aqueous flame-retardant coating and preparation method thereof

ActiveCN102167920AImprove flame retardant performanceSimple processing technologyCoatingsEmulsionNitrogen

The invention discloses an aqueous flame-retardant coating and a preparation method thereof. The aqueous flame-retardant coating comprises following compositions: aqueous acrylic emulsion, amino resin, deionized water, nitrogen flame retardants, substrate lubricants, leveling agents, defoamers and catalysts. The preparation method of the aqueous flame-retardant coating comprises the following steps of: firstly adding the amino resin into the aqueous acrylic emulsion; then adding the substrate lubricants, the leveling agents, the nitrogen flame retardants, the defoamers and the catalysts in sequence; and stirring quickly to obtain the aqueous flame-retardant coating. The processing technology disclosed by the invention is simple, the composition ratio is rational, and the produced coating has a good flame-retardant effect, and can be widely applied to the places having fireproof demands, such as KTV (Karaoke Television) clubs, movie theaters and the like.

Owner:HUNAN FUXIANG WOOD

Ganoderma lucidum spore composite fish sausage

The invention discloses a ganoderma lucidum spore composite fish sausage which is prepared by 50-100g of pork, 50-100g of pigskin, 20-25g of sugar, 30-40g of salt, 3-4g of ground pepper, 3-4g of five spice powder, 25-35ml of dark soy sauce, 10-15g of reishi shell-broken spore powder, 10-25g of pumpkin freeze-dried powder and 30-40g of mushroom wine in every1000g of fish paste. The mushroom wine is prepared by 60-100g of dried mushroom, 30-50g of dried lemon and 10-15g of rhizoma polygonati in every 1500g of white spirit. The ganoderma lucidum spore composite fish sausage is reasonable in component distribution ratio, enables the sausage to be mellow in taste, and is delicate in meat while suffusing an exquisite fragrance all around.

Owner:ANHUI HAOSHIYUAN FOOD

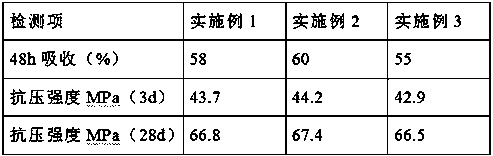

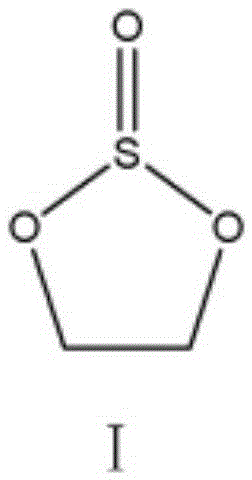

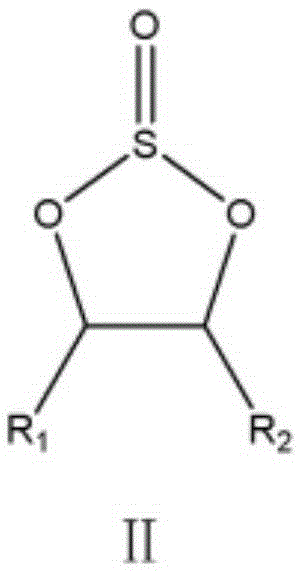

Lithium ion battery electrolyte and preparation method thereof

InactiveCN105355977AThe group ratio is reasonableIncrease capacitySecondary cellsElectrolytesOrganic solventPhysical chemistry

The invention provides a lithium ion battery electrolyte and belongs to the technical field of lithium secondary batteries. The lithium ion battery electrolyte is composed of organic solvents, additives and lithium salt. The organic solvents are composed of a solvent A and a solvent B. According to the principle that the total mass of the organic solvents and the additives is 100%, the lithium ion battery electrolyte is prepared from, by mass, 20-30% of the solvent A, 30-69.5% of the solvent B and 0.5-50% of the additives. The solvent A is ethylene carbonate. The solvent B is one or more of methyl ethyl carbonate, dimethyl carbonate and diethyl carbonate, The additives are sulfite organic solvents. The concentration of the mass of lithium salt in the electrolyte is 0.6-1.5 mol / L. The invention further provides a preparation method of the lithium ion battery electrolyte and a lithium secondary battery. The compatible characteristic between the lithium ion battery electrolyte and electrode materials is good, the temperature adaption characteristic of the electrolyte materials is widened, and by means of the lithium ion battery electrolyte, the circulation performance, the rate performance and the temperature adaptability of the lithium secondary battery can be effectively improved.

Owner:百顺松涛(天津)动力电池科技发展有限公司

TiAl-based alloy high-temperature oxidation resistant coating and method for implementing same

InactiveCN101519274AEasy to implementThe implementation process is simpleMetallurgyOxidation resistant

The invention discloses a TiAl-based alloy high-temperature oxidation resistant coating, which comprises the following components: SiO2, Na2O and CaO. The method for implementing the TiAl-based alloy high-temperature oxidation resistant coating comprises the following steps of: firstly, taking the components of the TiAl-based alloy high-temperature oxidation resistant coating according to a proportion; heating the components to about 1,500 DEG C, keeping the temperature, and allowing the components to cool to obtain a raw material of the oxidation resistant coating; heating the raw material of the oxidation resistant coating till the raw material of the oxidation resistant coating is in a viscous state; and coating the raw material in the viscous state on the surface of TiAl-based alloy or completely immersing the TiAl-based alloy in the raw material in the viscous state to apply oxidation resistant protection to the TiAl-based alloy during processing at a high temperatue of 1,300 DEG C. The coating is reasonable in component mixing ratio, simple in production process, convenient in operation and use and low in cost, effectively prevents the oxidization of TiAl-based alloy, avoids influencing the high-temperature deformation capacity of the TiAl-based alloy, separates conveniently from a substrate at normal temperature, effectively overcomes the drawbacks of uneven deformation of easy cracking of the TiAl-based alloy, and difficult separation of a covering sleeve and the alloy in the prior art, is applicable to industrial application, and can replace the prior TiAl-based alloy high-temperature oxidation resistant process.

Owner:CENT SOUTH UNIV

Feed for culturing special type wild boars

InactiveCN105767549AFull of nutritionIncrease appetiteFood processingAnimal feeding stuffBody shapeBrassica

The present invention provides a feed for culturing special type wild boars. The feed is prepared from the following raw materials in parts by weight: 70-80 parts of corn, 15-20 parts of bran, 6-8 parts of potatoes, 5-10 parts of sorghum stalks, 10-15 parts of tofu residues, 6-8 parts of peanut shells, 12-16 parts of sweet potatoes, 12-18 parts of pumpkins, 10-15 parts of rice bran, 55-65 parts of soybean straws, 5-6 parts of ryegrass, 2-3 parts of medicago sativa, 7-10 parts of saxifraga sarmentosa, 5-7 parts of brassica campestris, 1-2 parts of apple pomace, 0.5-0.8 part of alpinia japonica rhizome, 12-15 parts of pumpkins, 1-1.5 parts of premix and 1.5-2 parts of edible salt. The feed for culturing special type wild boars is reasonable in component ratio and rich in nutrition. After the pigs are fed with the feed, the live pig meat quality is good, the fat condition is good, the weight gain is more rapid, the slaughtering time is early, the body shape is even, and the investment of feed is reduced. The present invention also provides a preparation method of the feed for culturing special type wild boars.

Owner:TONGLING JINPUTE ECOLOGICAL AGRI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com