Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy and preparation method thereof

A tungsten carbide-based, hard alloy technology, applied in Ni3Al bonded ultra-fine grained tungsten carbide-based cemented carbide and its preparation, ultra-fine grained tungsten carbide-based cemented carbide and its preparation field, can solve the problem of ultra-fine grained hard alloy. The alloy is expensive and the production cost is high, and the production cost is low, the density is improved, and the fine distribution is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

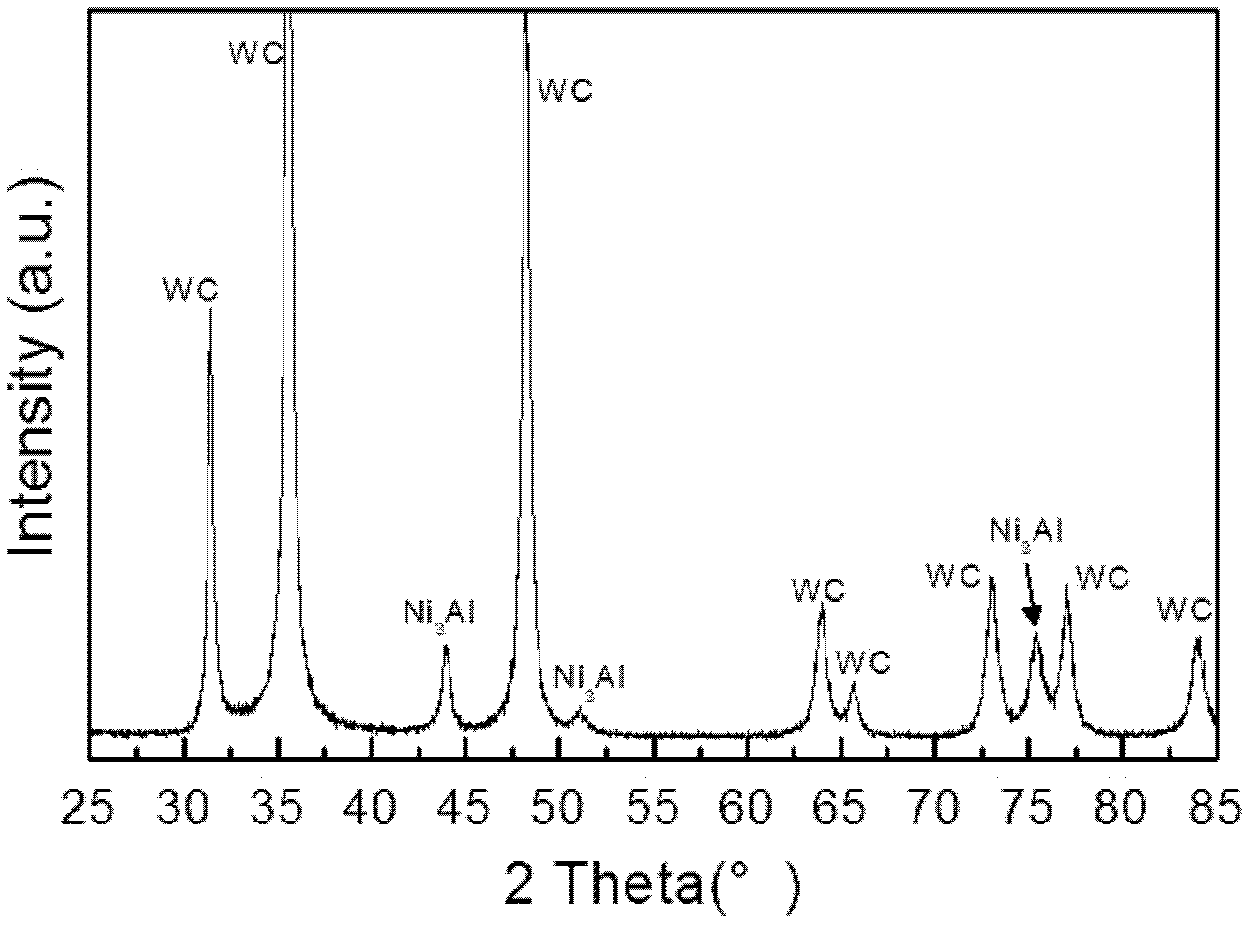

Embodiment 1

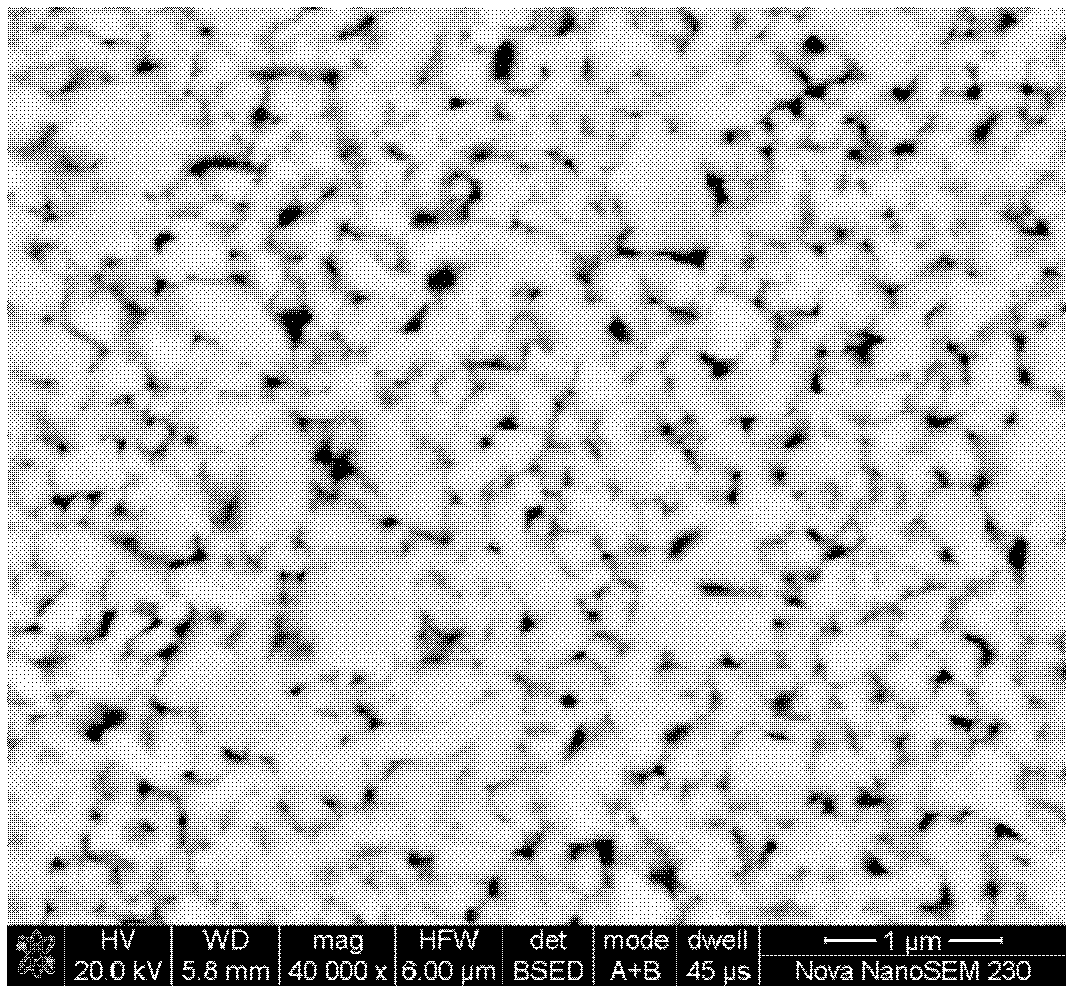

[0036] The preparation composition is WC-5Ni 3 Al-0.08LaB 6 -0.05Cr 3 C 2 -0.05VC (mass fraction, the same below) Ni 3 Al-bonded ultrafine-grained tungsten carbide-based cemented carbide. The raw materials used are 0.5um tungsten carbide powder, 1um nickel powder, 2um aluminum powder, 2.5um vanadium carbide powder, 2.5um chromium carbide powder, and 5um lanthanum hexaboride powder. Weigh the raw material powder according to the alloy ratio, use acetone solution as the ball milling medium, add paraffin wax molding agent, and use argon protection to ball mill at a speed of 600 rpm for 48 hours on a ball mill with a ball-to-material ratio of 5:1. Under the pressure molding of 400MPa. The compact was degreased in a hydrogen furnace at 400°C for 5 hours. Then sinter in a low-pressure sintering furnace, the sintering pressure is 1MPa, the sintering temperature is 1500°C, and the sintering time is 2h, the obtained Ni 3 The average grain size of WC in Al-bonded ultra-fine-grain...

Embodiment 2

[0038] The preparation composition is WC-20Ni 3 Al-0.1CeB 6 -0.25Cr 3 C 2 -0.5VC (mass fraction, the same below) Ni 3 Al-bonded ultrafine-grained tungsten carbide-based cemented carbide. The raw materials used are 0.3um tungsten carbide powder, 2um nickel powder, 1um aluminum powder, 5um vanadium carbide powder, 2.5um chromium carbide powder, and 3.5um cerium hexaboride powder. Weigh the raw material powder according to the alloy ratio, use acetone solution as the ball milling medium, add paraffin wax molding agent, and pass through the protection of argon, ball mill on the ball mill at a speed of 300 rpm for 72 hours, the ball to material ratio is 3:1; then at room temperature Under the pressure molding of 200MPa. The compact was degreased in a hydrogen furnace at 350°C for 15 hours. Then sinter in a low-pressure sintering furnace, the sintering pressure is 5MPa, the sintering temperature is 1550°C, and the sintering time is 5h, the obtained Ni 3 The average grain size...

Embodiment 3

[0040] The preparation composition is WC-40Ni 3 Al-0.01NdB 6 -0.5Cr 3 C 2 -0.25VC (mass fraction, the same below) Ni 3 Al-bonded ultrafine-grained tungsten carbide-based cemented carbide. The raw materials used are 0.1um tungsten carbide powder, 1um nickel powder, 1um aluminum powder, 2.5um vanadium carbide powder, 5um chromium carbide powder, and 2.5um niobium hexaboride powder. Weigh the raw material powder according to the alloy ratio, use acetone solution as the ball milling medium, add paraffin wax molding agent, and under the protection of argon, ball mill on the ball mill at a speed of 450 rpm for 24 hours, the ball to material ratio is 10:1; then at room temperature Under the pressure molding of 300MPa. The compact was degreased in a hydrogen furnace at 450°C for 5 hours. Then sinter in a low-pressure sintering furnace, the sintering pressure is 3MPa, the sintering temperature is 1600°C, and the sintering time is 1h, the obtained Ni 3 The average grain size of W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com