Titanium alloy pipe and manufacturing method

A manufacturing method, titanium alloy technology, applied in the direction of metal rolling, etc., can solve problems such as difficulty in meeting application requirements, limited pipe length, long production process, etc., and achieve low production cost, reasonable component distribution ratio, and large single weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

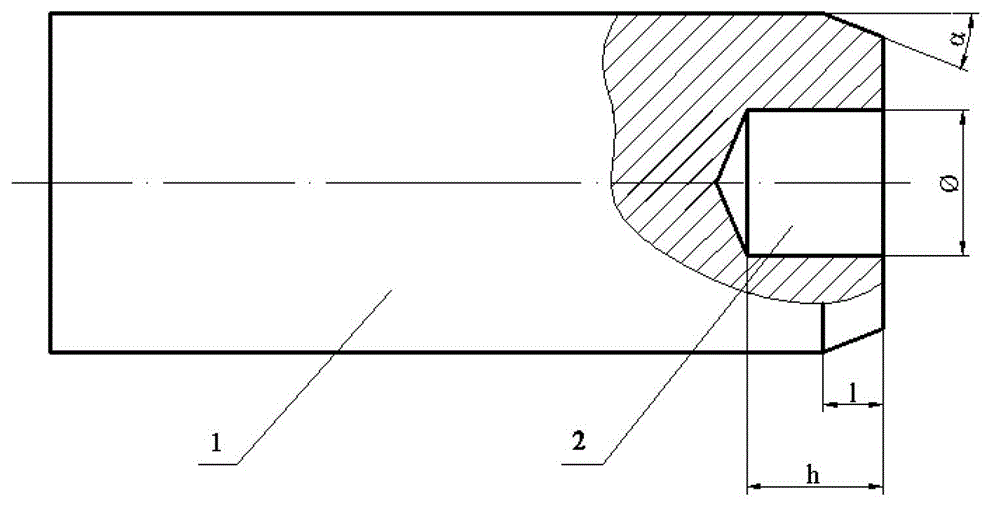

Image

Examples

Embodiment 1

[0025] A titanium alloy seamless pipe, the alloy composition of the pipe is: Al5.0%, Zr1.0%, Nb2.0%, Mo0.3%, and the impurity elements are controlled according to the following requirements: Fe≤0.25%, C≤0.10 %, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is Ti; the unit weight of the pipe is 165Kg, and the specification is Φ145mm×15mm.

[0026] Its specific preparation process is as follows:

[0027] Step 1. Prepare raw materials such as sponge titanium, sponge zirconium, aluminum foil, NbTi, AlMo master alloy, etc., and prepare the chemical composition to meet Al5.0%, Zr1.0%, Nb2.0%, Mo0 through two vacuum consumable arc melting .3%, impurity elements are controlled according to the following requirements Fe≤0.25%, C≤0.10%, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is Ti alloy ingot, Adopt conventional titanium alloy bar production method to produce Φ140±1.5mm polished bar blank, and conduct ultrasonic non-destructive testing on the bar blank;

[0028] Step 2....

Embodiment 2

[0035] A titanium alloy seamless pipe, the alloy composition of the pipe is: Al6.0%, Zr2.5%, Nb3.0%, Mo1.0%, and the impurity elements are controlled according to the following requirements: Fe≤0.25%, C≤0.10 %, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is Ti; the unit weight of the pipe is 160Kg, and the specification is Φ185×17mm.

[0036] Its specific preparation process is as follows:

[0037] Step 1. Prepare raw materials such as sponge titanium, sponge zirconium, aluminum foil, NbTi, AlMo master alloy, etc., and prepare the chemical composition satisfying Al6.0%, Zr2.5%, Nb3.0%, Mo1. 0%, impurity elements are controlled according to the following requirements: Fe≤0.25%, C≤0.10%, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is titanium alloy ingots of Ti, using The conventional titanium alloy bar production method produces a Φ175±2.0mm polished bar blank, and conducts ultrasonic non-destructive testing on the bar blank;

[0038] Step 2. Cut the titanium allo...

Embodiment 3

[0045] A titanium alloy seamless pipe, the alloy composition of the pipe is: Al7.5%, Zr2.0%, Nb3.5%, Mo1.5%, and the impurity elements are controlled according to the following requirements: Fe≤0.25%, C≤0.10 %, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is Ti; the unit weight of the pipe is 480Kg, and the specification is Φ219×20mm.

[0046] Its specific preparation process is as follows:

[0047] Step 1. Prepare raw materials such as sponge titanium, sponge zirconium, aluminum foil, NbTi, AlMo master alloy, etc., and prepare the chemical composition satisfying Al7.5%, Zr2.0%, Nb3.5%, Mo1. 5%, impurity elements are controlled according to the following requirements: Fe≤0.25%, C≤0.10%, Si≤0.15%, N≤0.05%, H≤0.015%, O≤0.20%, the balance is titanium alloy ingots of Ti, using Conventional titanium alloy bar production method, producing Φ205±2.5mm polished or polished bar blanks, and performing ultrasonic non-destructive testing on the bar blanks;

[0048] Step 2. Cut the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com