Continuous extrusion preparation process of a high-strength weldable zinc alloy and its pipe

A preparation process and zinc alloy technology, which is applied in the field of metal materials and forming, and achieves the effects of reasonable preparation process design, broad application prospects and good welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

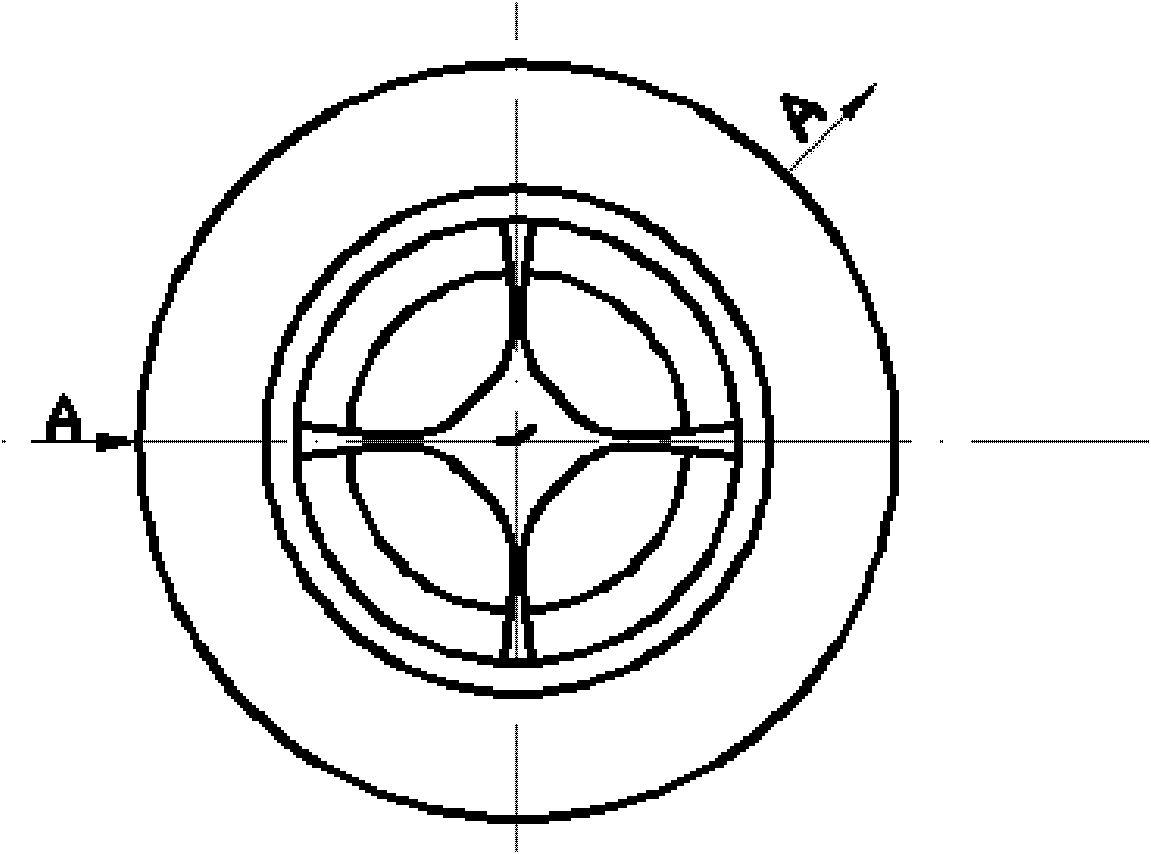

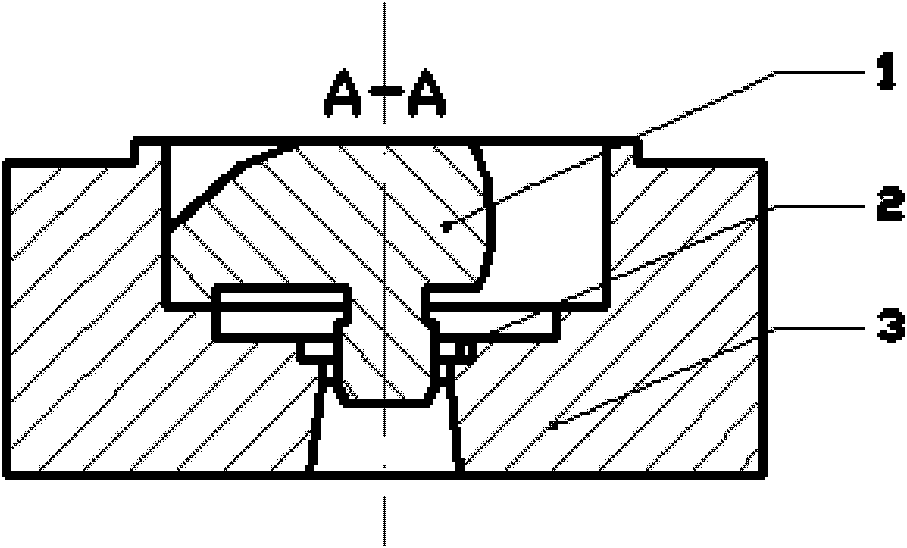

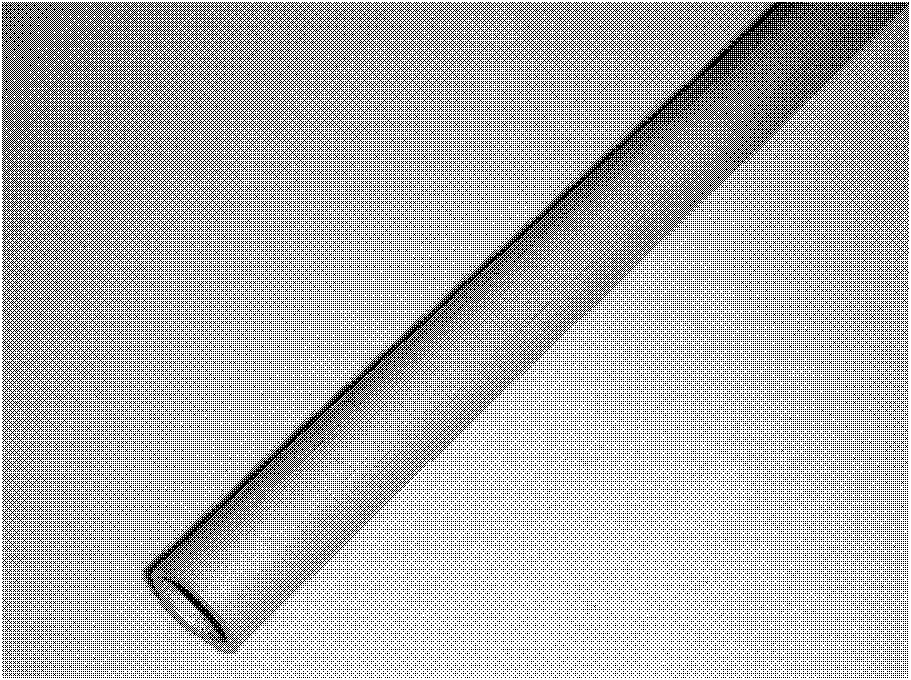

Image

Examples

Embodiment 1

[0039]A composition optimization design of a high-strength weldable zinc alloy and a pipe preparation method thereof, the steps of which are as follows:

[0040] The raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and rare earth are melted in the melting furnace according to the following weight percentages: Al 10%; Cu 3.0%; Ti 0.5%; Mg 0.02%, Cr 0.03%; rare earth 0.15% ; The rest are zinc and unavoidable impurities (impurity content ≤ 0.15%). After smelting, the zinc alloy round rod with a diameter of 9mm is continuously cast horizontally; the zinc alloy round rod is cleaned and sent to the rotary continuous extrusion machine for extrusion through the feeding wheel, and the distance between the extrusion wheel surface and the arc surface of the groove sealing block is controlled. The contact length between them is 220mm ~ 300mm, and the running gap is less than 0.3mm, so that extrusion force and friction will be generated between the deformed zinc ...

Embodiment 2

[0043] A composition optimization design of a high-strength weldable zinc alloy and a pipe preparation method thereof, the steps of which are as follows:

[0044] Raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and pure cerium are melted in a melting furnace according to the following weight percentages: Al 8%; Cu 2.0%; Ti 0.2%; Mg 0.1%, Cr 0.1%; rare earth 0.1% %; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%); melting and casting into a zinc alloy round rod with a diameter of 10.5mm; after cleaning the surface and air drying, it is sent to the rotary continuous extrusion machine for extrusion through the feeding wheel, Control the contact length between the extrusion wheel surface and the arc surface of the groove seal block to 220mm-300mm, and the running gap is less than 0.3mm, so that extrusion force and friction will be generated between the deformed zinc alloy billet and the rotary extrusion with grooves, and heat will ...

Embodiment 3

[0047] A composition optimization design of a high-strength weldable zinc alloy and a pipe preparation method thereof, the steps of which are as follows:

[0048] Raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and pure cerium are melted in a melting furnace according to the following weight percentages: Al 12%; Cu 0.5%; Ti 0.05%; Mg 0.2%, Cr 0.15%; rare earth 0.25% %; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%); melting and casting into a zinc alloy round rod with a diameter of 12mm; after cleaning the surface and air-drying, it is sent to the rotary continuous extrusion machine for extrusion through the feeding wheel, and the control The contact length between the extrusion wheel surface and the arc surface of the groove sealing block is 220mm~300mm, and the running gap is less than 0.3mm, so that extrusion force and friction will be generated between the deformed zinc alloy billet and the rotary extrusion with grooves, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com