High-elasticity-modulus magnesium alloy and preparation method thereof

A technology for magnesium alloys and intermediate alloys, applied in the field of magnesium alloys and their preparation, can solve the problems of poor resistance to elastic deformation, low elastic modulus of alloys, and low elastic modulus, and achieve good plasticity, high elastic modulus, and processing Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] According to the above-mentioned components of magnesium alloy preparation, the magnesium ingot is heated to 700-720°C under the protective atmosphere of Ar gas. After the magnesium ingot is melted, silicon is added into the magnesium melt and stirred. After the silicon block is completely dissolved, Raise the temperature to 730-740°C, then add the rest of the components, stir, refine and remove slag, and cast to obtain ingots.

[0073] In the method, Mg is added in the form of pure magnesium, and Si is added in the form of pure silicon, and the silicon is a silicon block with a particle size of 1.0 to 2.0 cm; Zinc is added to the magnesium melt, and the rest of the components are added in the form of magnesium-based master alloys.

[0074] In the method, the complete melting of the magnesium-based master alloy is controlled until the casting time is less than or equal to 3 minutes,

[0075] The method also includes subjecting the ingot to homogenization treatment at 4...

Embodiment

[0077] The percentages described in the following examples are all percentages by weight unless otherwise specified.

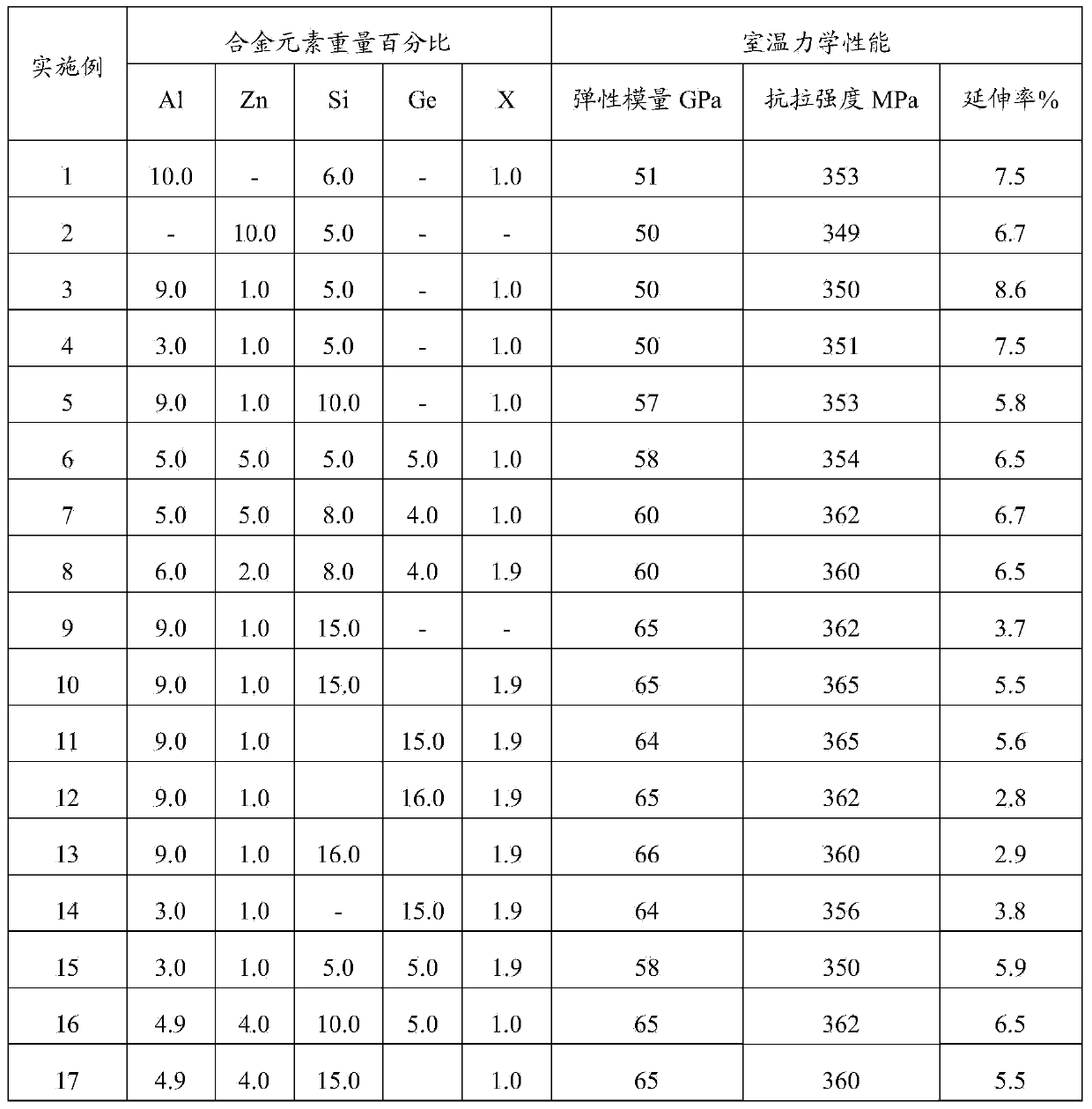

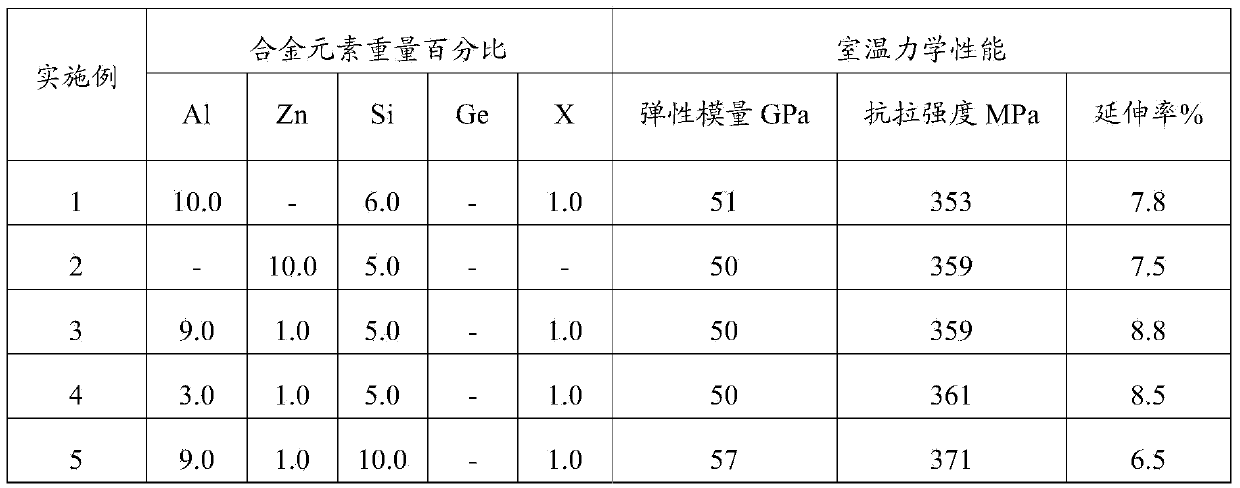

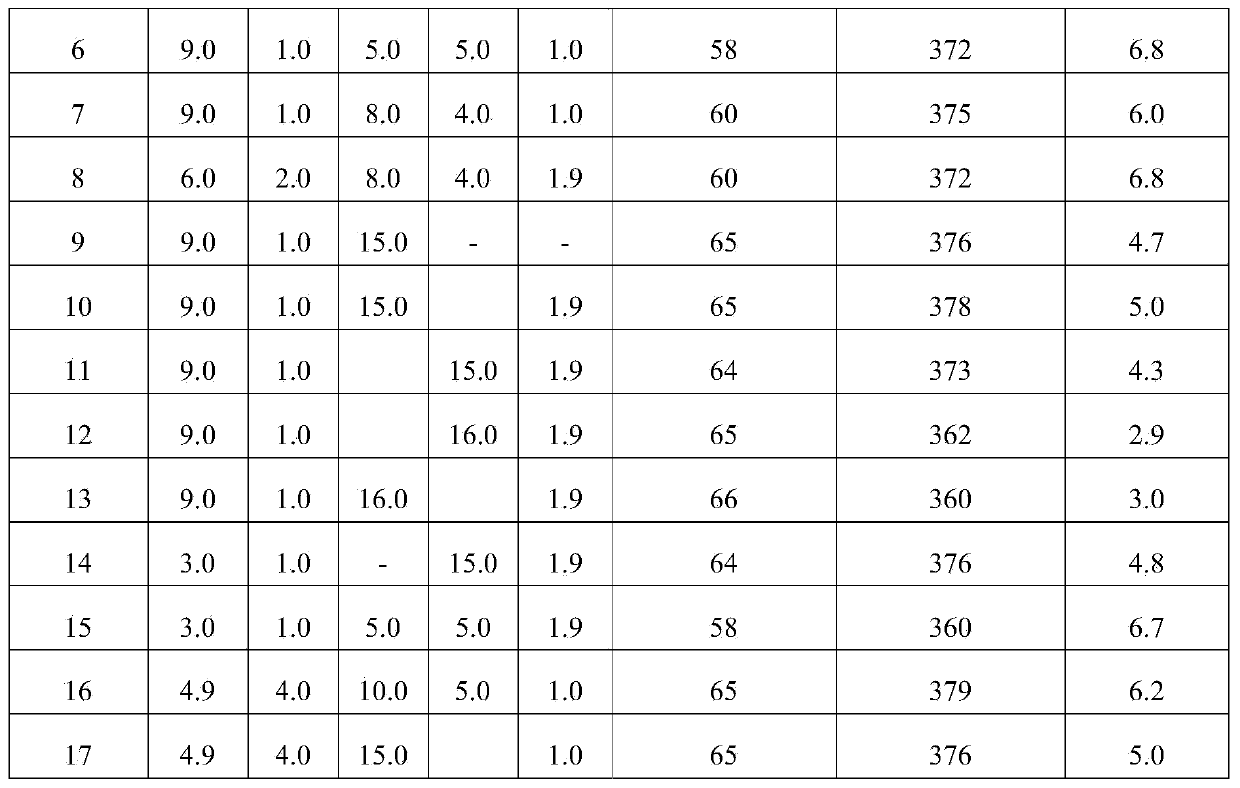

[0078] The present invention provides the proportioning examples of different components shown in Tables 1-4. The impurity content in the components is not more than 0.1%, except for the components listed in the table, the rest is Mg.

[0079] In the embodiment of the present invention, according to Table 1-Table 4 (X is selected from aluminum (Al), titanium (Ti), silver (Ag), zirconium (Zr), calcium (Ca), scandium (Sc), lanthanum (La) , cerium (Ce), europium (Eu), praseodymium (Pr), promethium (Pm), samarium (Sm) any one of the magnesium alloy component distribution ratio) to take each component respectively, prepare magnesium alloy respectively, specifically The preparation method is as follows:

[0080] 1. Take each component separately according to the designed high elastic modulus magnesium alloy component distribution ratio, among which: Mg is added in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com