Grate of heat, wear and corrosion-resisting large mechanical reciprocating incinerator and manufacture method of grate

A technology of large-scale machinery and manufacturing methods, which is applied in the field of heat-resistant, wear-resistant and corrosion-resistant large-scale mechanical reciprocating furnace grate and its manufacturing field, and can solve the problems of high price, heat-resistant temperature not reaching the heat-resistant temperature, complex smelting equipment and processes, etc. Problems, to achieve the effect of improving wear resistance and high temperature structure stability, improving heat resistance, wear resistance and corrosion resistance, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

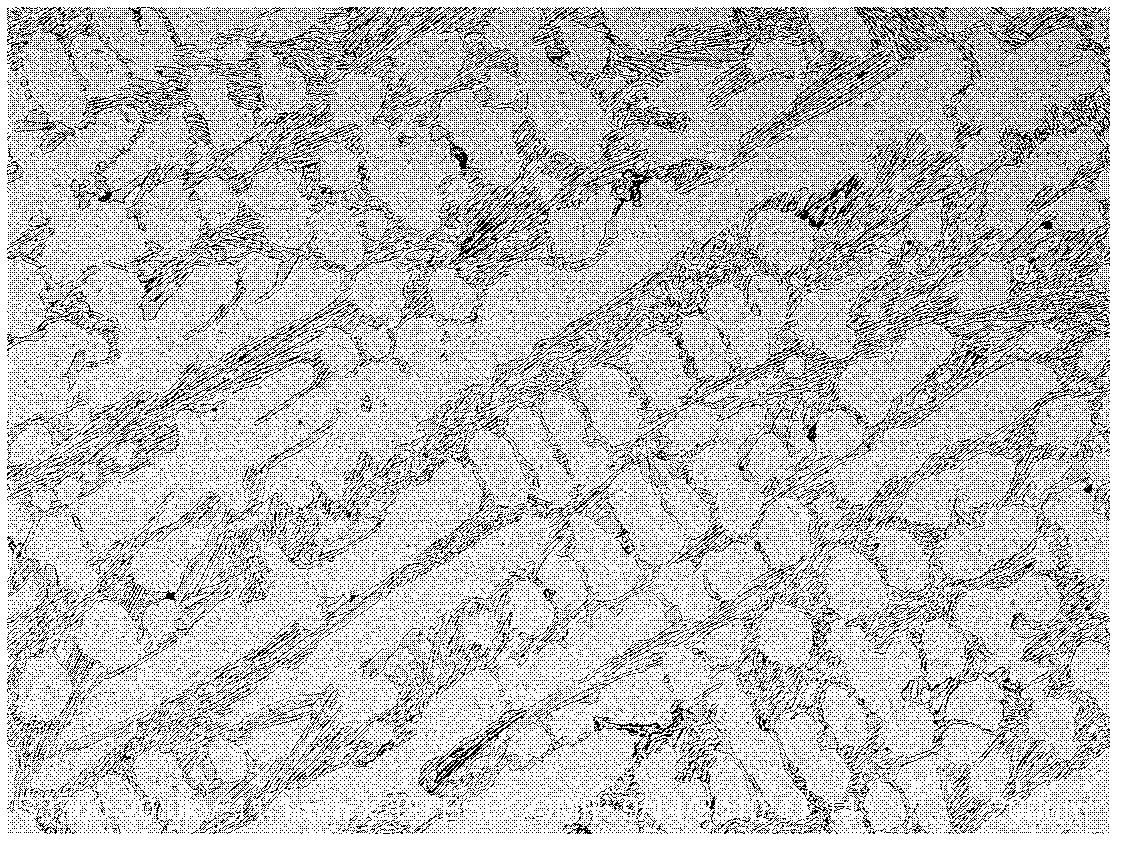

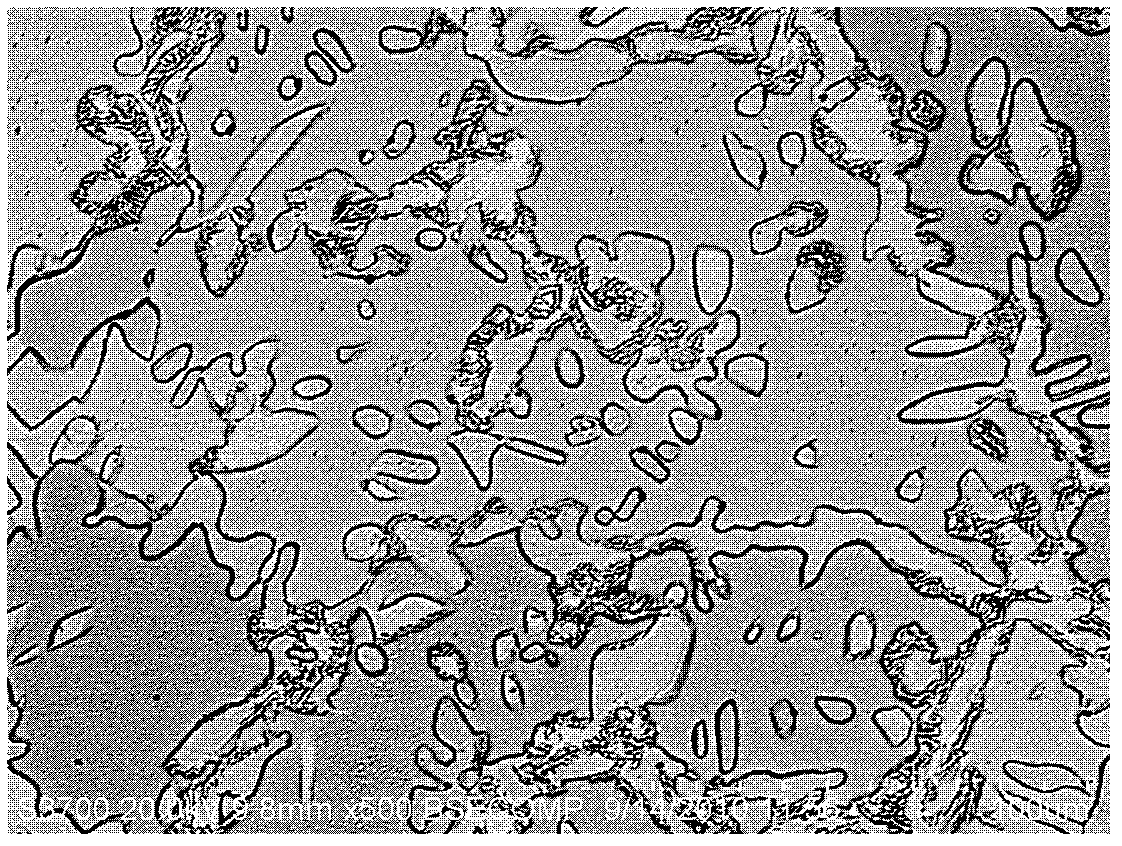

Image

Examples

Embodiment 1

[0032] Step 1: Ingredients

[0033] First use 125Kg waste A3 steel as the base material, then add 78Kg low-carbon ferrochrome, 35Kg high-carbon ferrochrome, then add 10Kg pure nickel, 3.8Kg ferromanganese, 2.8Kg ferrosilicon 70, 1.5Kg ferrovanadium 50, 0.2kg molybdenum Iron 60, 0.2Kg ferroboron 20, 0.8Kg Ce-containing rare earth ferrosilicon; scrap A3 steel contains 99.26% Fe, 0.15% Si, 0.22% C, 0.36% Mn and about 0.01% impurities in the raw material; Ferromanganese contains 75.2% Mn, 1.76% C, 1.98% Si, and the rest is Fe; low-carbon ferrochrome contains 61.4% Cr, 0.24% C, 1.2% Si, and the rest is Fe; high-carbon ferrochrome Contains 61.75% Cr, 8.4% C, and the rest is Fe; wherein, the addition amount of scrap A3 steel, high-carbon ferrochrome and low-carbon ferrochrome in the raw materials is 92.5% of the total weight, and the addition amount of the remaining seven raw materials 7.5%.

[0034] Step 2: Smelting

[0035] (1) Feeding step by step

[0036] Step 1: put the scra...

Embodiment 2

[0045] Step 1: Ingredients

[0046] First use 110Kg waste A3 steel as the base material, then add 78Kg low-carbon ferrochrome, 45Kg high-carbon ferrochrome, then add 9.0Kg pure nickel, 3.3Kg ferromanganese, 2.8Kg ferrosilicon 70, 1.0Kg ferrovanadium 50, 0.3kg Ferromolybdenum 60, 0.2Kg ferroboron 20, 1.2Kg contain Ce rare earth ferrosilicon alloy; Waste A3 steel, ferromanganese, low carbon ferrochrome and high carbon ferrochrome are the same as the raw materials adopted in embodiment one in the raw materials; wherein, The added amount of scrap A3 steel, high-carbon ferrochrome and low-carbon ferrochrome in the raw materials is 92.9% of the total weight, and the added amount of the other seven raw materials is 7.1%.

[0047] Step 2: Smelting

[0048] (1) Feeding step by step

[0049] Step 1: put the scrap A3 steel, pure nickel, high-carbon ferrochrome, and low-carbon ferrochrome mentioned in step 1 into an intermediate frequency induction furnace, and smelt until the raw mater...

Embodiment 3

[0056] Step 1: Ingredients

[0057] First use 120Kg waste A3 steel as base material, then add 110Kg low carbon ferrochrome, 10Kg high carbon ferrochrome, then add 8.0Kg pure nickel, 4.3Kg ferromanganese, 3.3Kg ferrosilicon 70, 1.0Kg ferrovanadium 50, 0.3kg Ferro-molybdenum 60, 0.25Kg ferro-boron 20, 1.5Kg contain Ce rare earth ferrosilicon; Waste A3 steel, ferromanganese, low-carbon ferrochrome and high-carbon ferrochrome are the same as the raw materials adopted in embodiment one in the raw material; wherein , the addition of scrap A3 steel, high-carbon ferrochrome and low-carbon ferrochrome in the raw materials is 92.8% of the total weight, and the addition of the remaining seven raw materials is 7.2%.

[0058] Step 2: Smelting

[0059] (1) Feeding step by step

[0060] Step 1: put the scrap A3 steel, pure nickel, high-carbon ferrochrome, and low-carbon ferrochrome mentioned in step 1 into an intermediate frequency induction furnace, and smelt until the raw materials are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com