RE2O3-added ZrB2-SiC composite ceramic material and preparation method thereof

A rare earth oxide and multiphase ceramic technology is applied in the field of rare earth oxide-added zirconium boride-silicon carbide multiphase ceramic materials and their preparation, which can solve the problems of reduced material properties and no significant improvement in other properties, and is easy to achieve. The effect of realizing, simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] ZrB 2 powder (14μm, >97%), SiC powder (0.45μm, >97%) and ytterbium oxide powder (Yb 2 o 3 , 99%) as the raw material, according to the sintering aid Yb 2 o 3 The volume content of SiC is 3%, the volume content of SiC is 20%, and the volume content of ZrB 2 The volume content is 78% batching, acetone is used as solvent, silicon nitride ball is used as ball milling medium, planetary ball milling is carried out at a speed of 560 rpm for 8 hours, and the obtained slurry is dried by rotary evaporation to obtain a uniformly mixed powder.

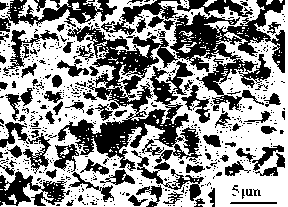

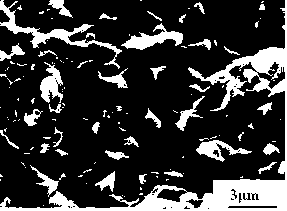

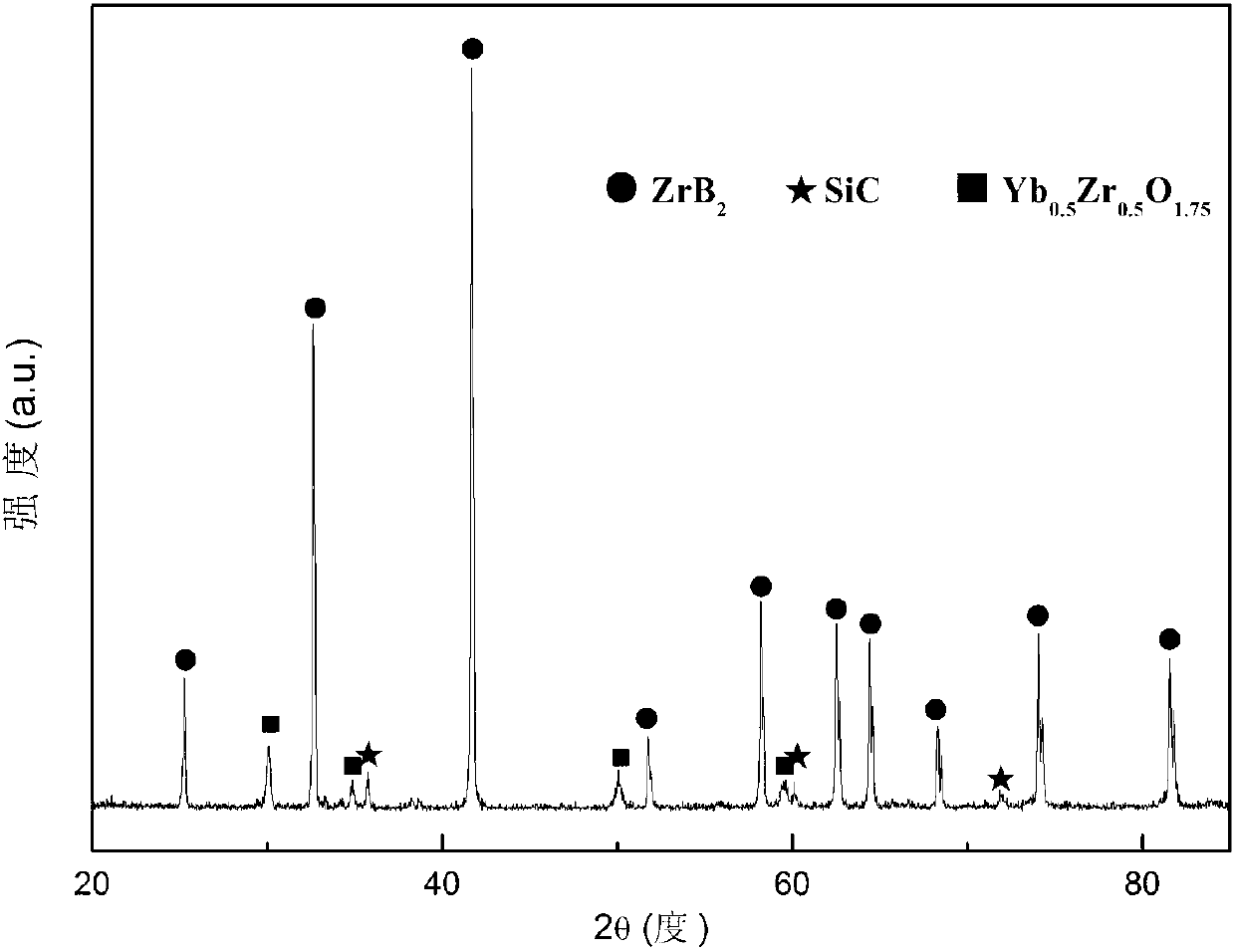

[0023] Put the uniformly mixed powder in a graphite mold coated with BN on the inner wall surface, and perform hot-press sintering. The heating rate at the beginning of hot-pressing sintering is 8°C / min. The temperature is 15°C / min, the temperature is raised to 1900°C, and the pressure of 30MPa is hot-pressed and sintered for 1 hour to obtain a bulk material with a relative density close to 100%. The microscopic appearance of the mater...

Embodiment 2

[0025] Design Yb 2 o 3 The volume content in the matrix is 1%, and the material is prepared according to the method of Example 1, and the relative density of the obtained sample is greater than 99%.

Embodiment 3

[0027] Design Yb 2 o 3 The volume content in the matrix is 3%, the material is prepared according to the method of Example 1, and the sintering temperature is changed to 1700°C, and the relative density of the obtained sample is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com