Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239 results about "Lead bismuth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

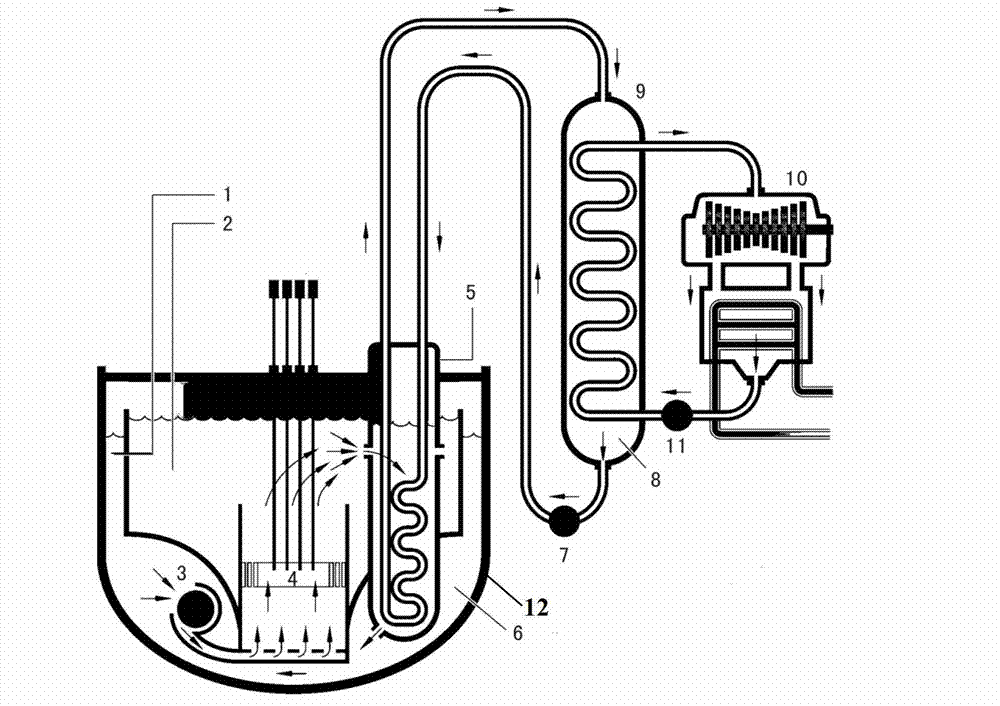

Liquid metal cooling reactor experimental system capable of realizing critical and subcritical running test

ActiveCN104167226AImprove usabilityReduce experiment costNuclear energy generationSubcritical reactorsLead bismuthNuclear engineering

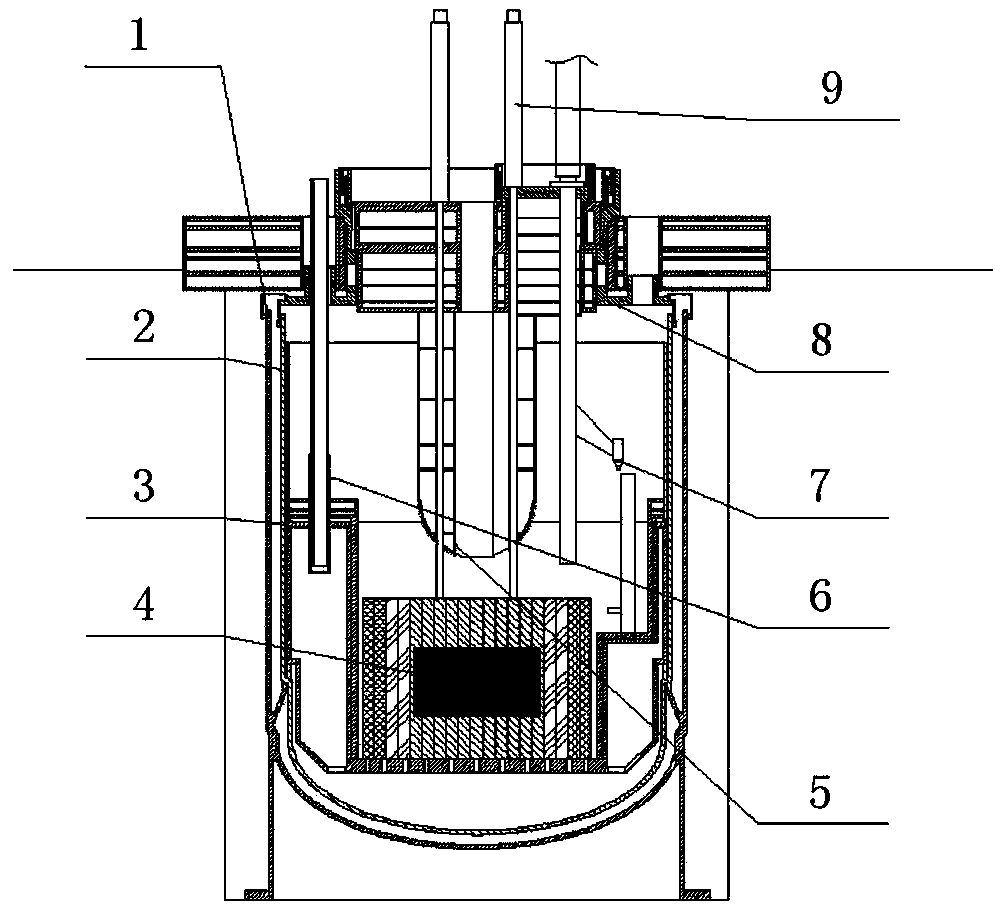

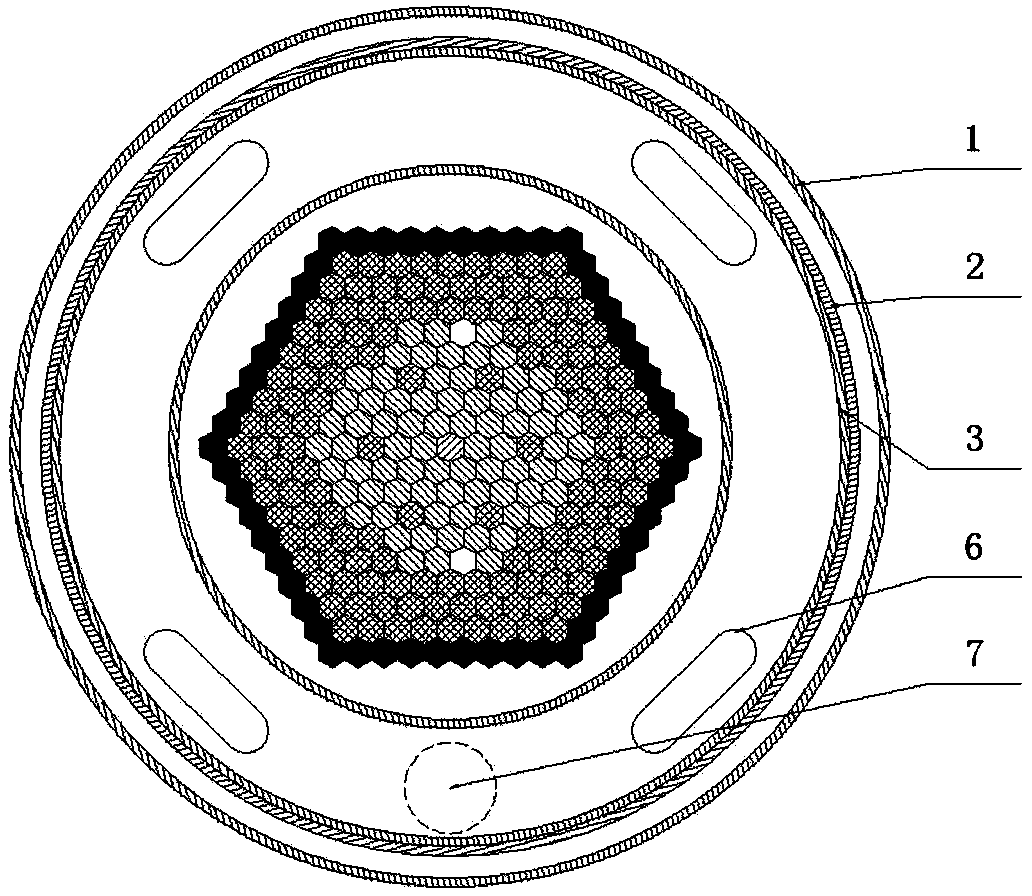

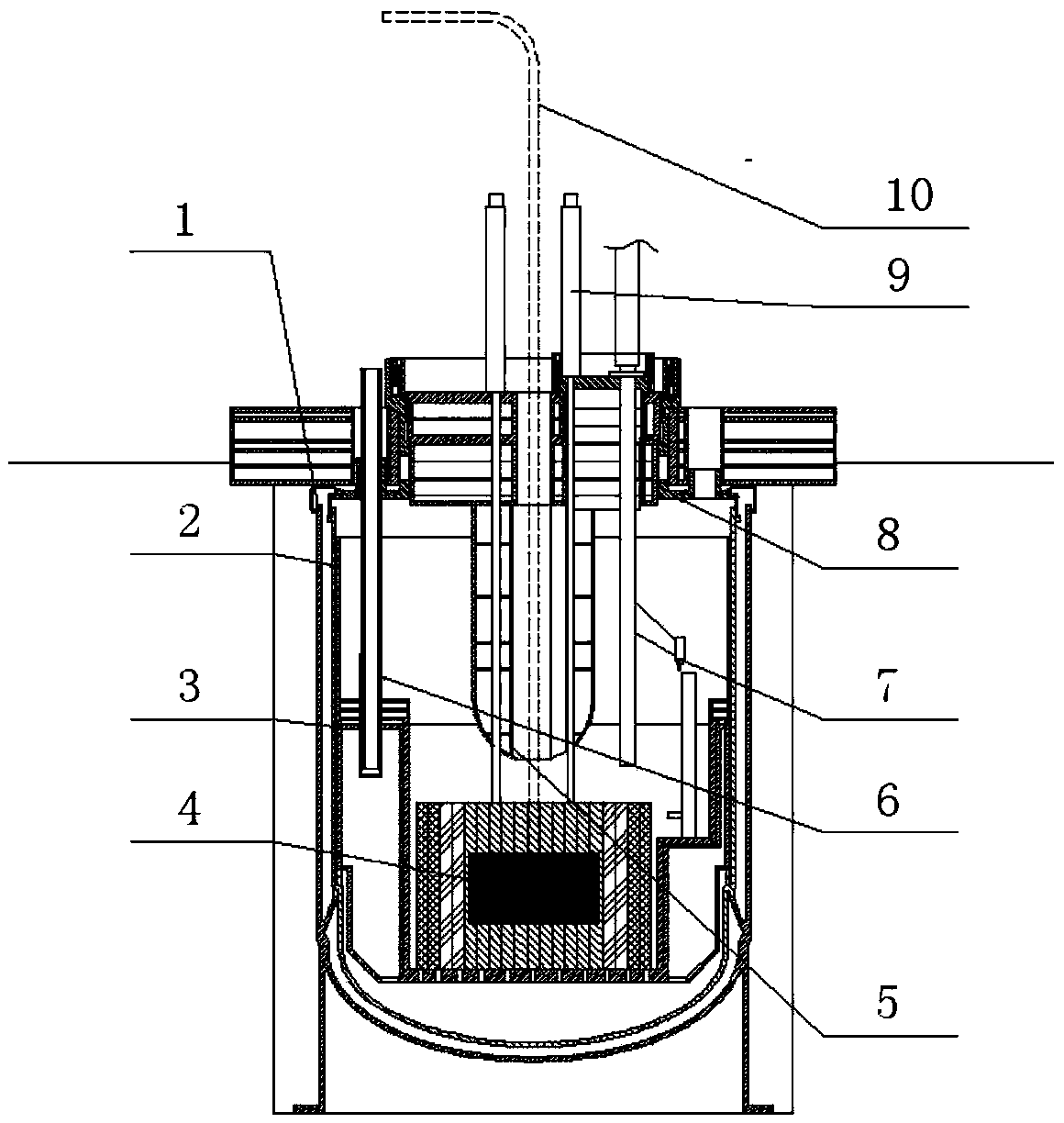

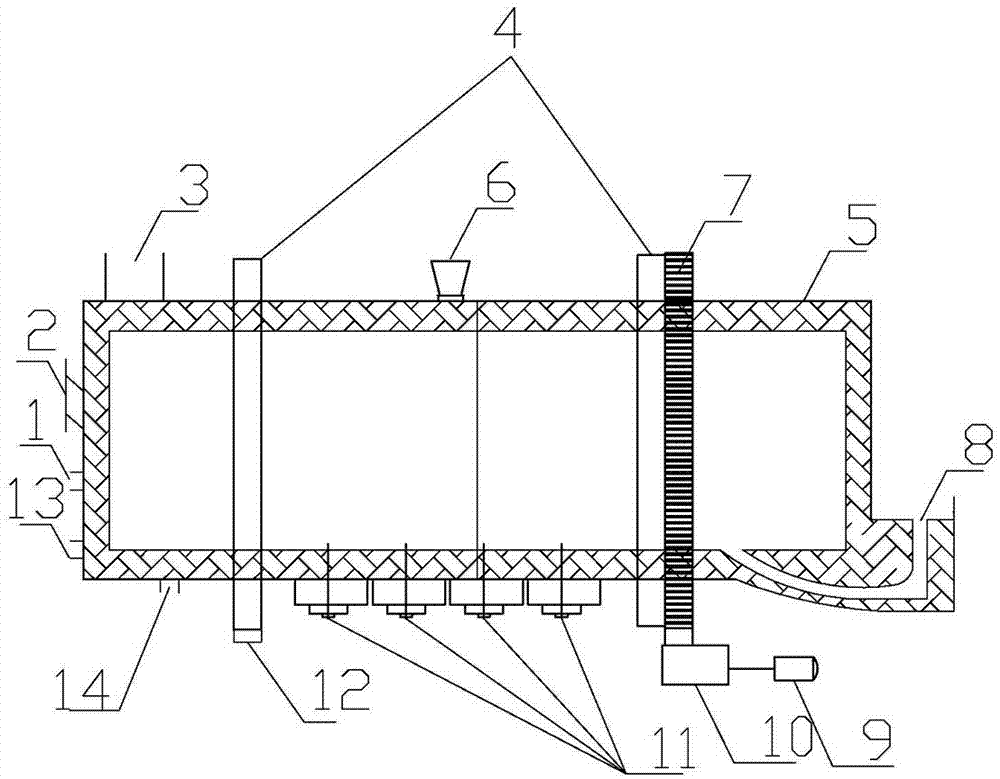

The invention discloses a liquid metal cooling reactor experimental system capable of realizing critical and subcritical running test. The liquid metal cooling reactor experimental system consists of a safety vessel (1), a main vessel (2), a reactor inner supporting structure (3), a reactor core (4), a central measuring column (5), a main heat exchanger (6), a reloading mechanism (7), a reactor top cover (8), a control bar drive mechanism (9) and a neutron source (10); when the critical running test is performed, the neutron source (10) adopts a californium-252 neutron source or a Be-Am neutron source; when the subcritical running test is performed, the neutron source (10) adopts a spallation neutron source or a deuterium tritium neutron source, an isotopic neutron source and a fuel component in the middle part of the reactor core are replaced by an accelerator neutron source according to the real requirement of the spallation neutron source, and the reactor can have the subcritical running test. The reactor experimental system is naturally and circularly cooled by adopting liquid lead-bismuth or lead, so that the usability of the reactor can be improved, the experimental cost can be reduced, and the multifunctional reactor experimental system characteristics can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

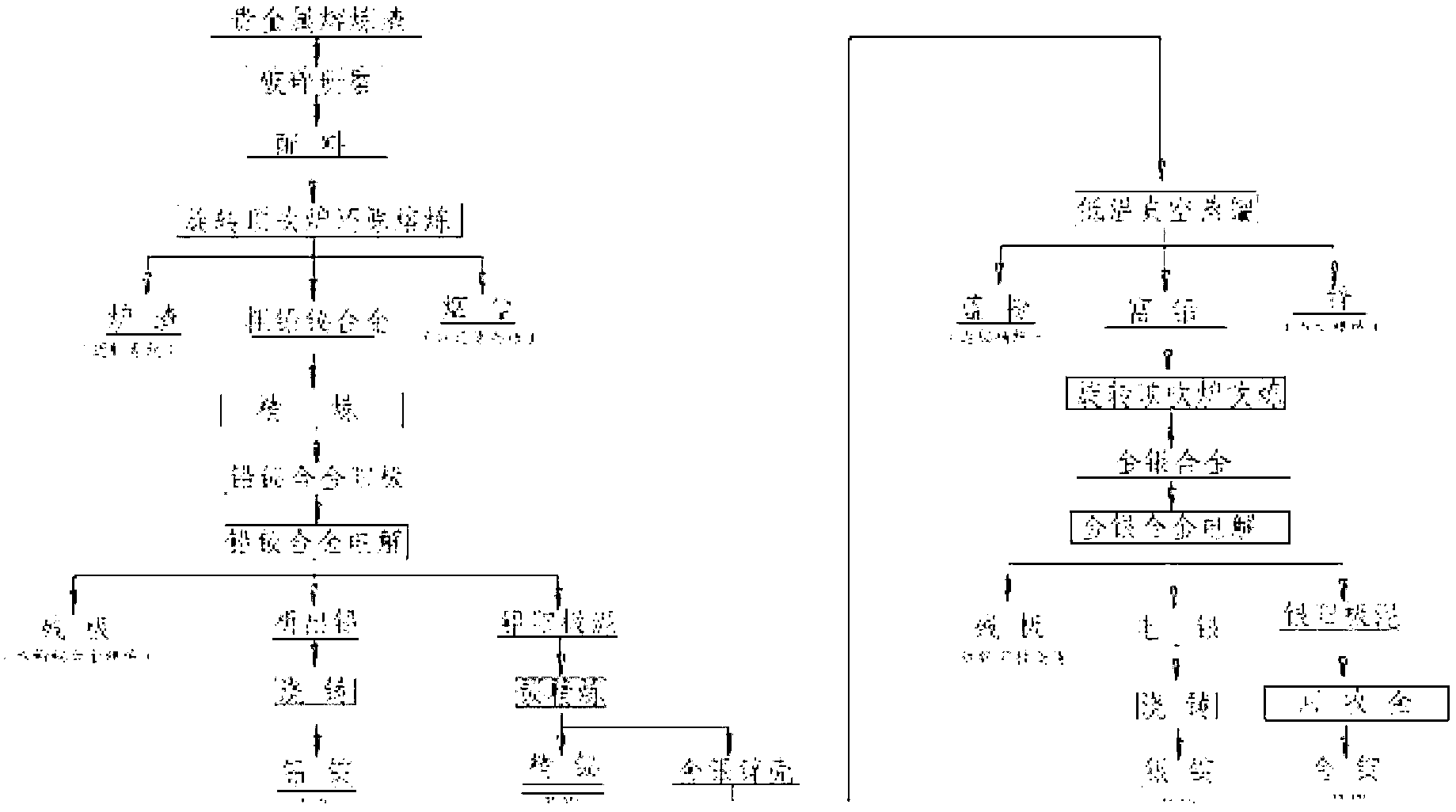

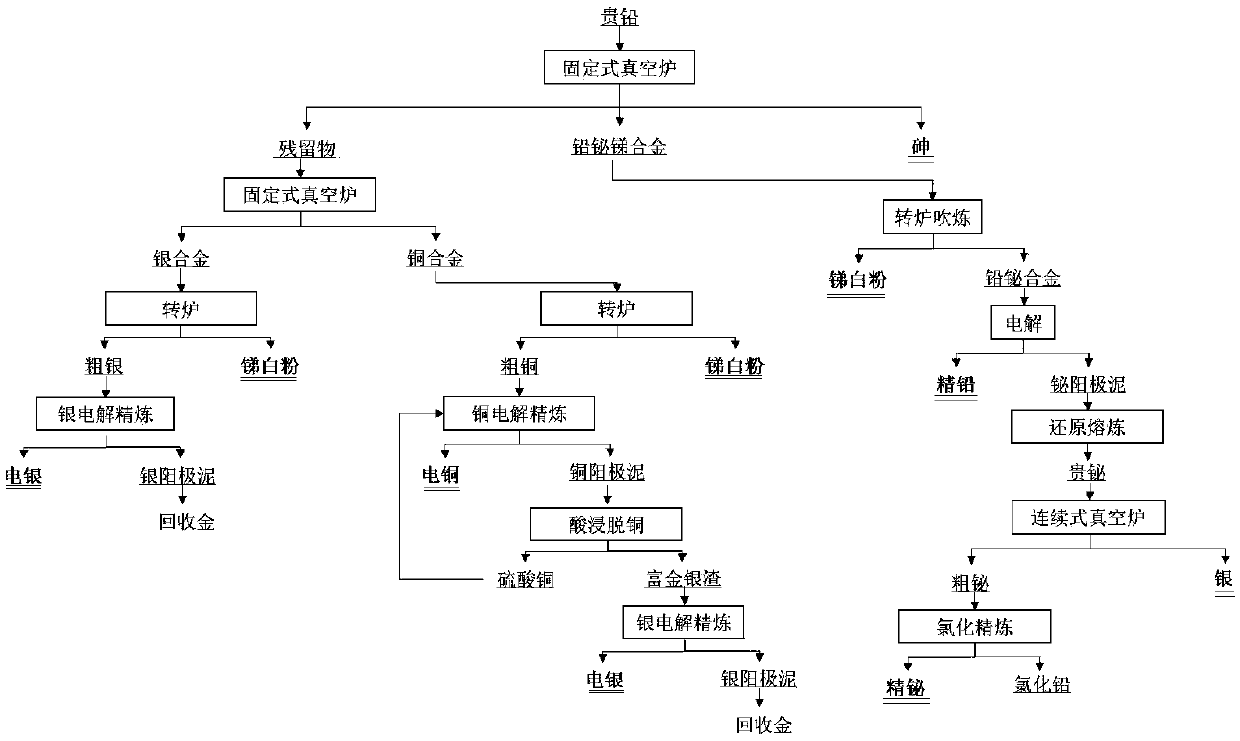

Technology for recovering valuable metals from noble metal slag

The invention discloses a technology for recovering valuable metals from noble metal slag. The technology comprises the following steps of: smelting the noble metal slag and a solvent in a rotary top blowing furnace to obtain lead bismuth alloy, wherein the noble metal slag comprises Au, Ag, Bi and Pb; electrolyzing the lead bismuth alloy under the current density of 60 to 110 A / m<2> to respectively obtain cathode lead and lead anode mud; refining the lead anode mud to respectively obtain bismuth and silver zinc shells; and respectively extracting gold and silver from the silver zinc shells. According to the technology, the rotary top blowing furnace is used as a smelting device, and the solvent proportion is regulated, so that the valuable metals such as gold, silver, bismuth and lead are enriched in the lead bismuth alloy, low gold, silver, bismuth and lead content of the reducing slag is ensured, and the comprehensive recovery rate of the gold, the silver, the bismuth and the lead in the noble metal slag is improved.

Owner:YANGGU XIANGGUANG COPPER

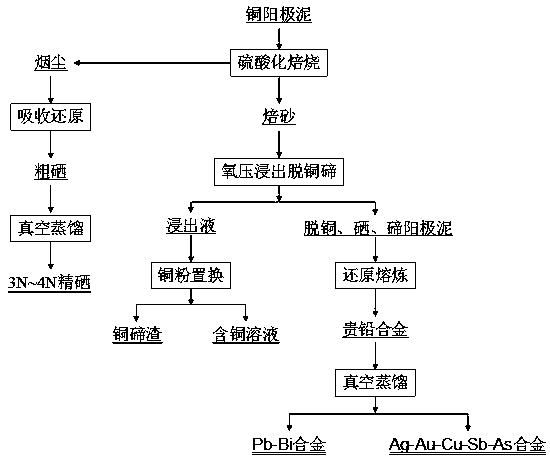

Method for recovering selenium, tellurium, copper and precious metal from copper anode slime

InactiveCN109371228AHigh purityEasy to separateProcess efficiency improvementElemental selenium/telluriumBismuthSelenium

The invention discloses a method for recovering selenium, tellurium, copper and precious metal from copper anode slime. The copper anode slime is subjected to segment treatment, the copper anode slimeis subjected to sulfation roasting at first, mixed gas of SeO2, SO2, SO3 and other gases and a roasted product are obtained, the obtained mixed gas is subjected to absorption reduction and dried, crude selenium is obtained, then the crude selenium is put in a vacuum distillation furnace, and refined selenium is obtained through purification; the roasted product obtained through sulfation roastingis subjected to oxygen pressure acid leaching, and leachate containing copper and tellurium and lead anode slime without selenium, copper and tellurium are obtained; the leachate containing copper and tellurium is subjected to copper powder reduction treatment, and copper-tellurium slag and a copper sulfate solution are obtained after reaction, so that copper and tellurium are convenient to recover; and the lead anode slime without selenium and copper is subjected to reduction smelting, noble lead alloy is obtained and put in a continuous vacuum distillation furnace, volatile lead and volatile bismuth are changed into volatile phases, thus, high-grade lead is recovered, non-volatile metal such as gold, silver, copper, antimony and arsenic remains in residues, and alloy is formed, so thatrecovery of subsequent precious metal is facilitated. Through the method provided by the invention, the refined selenium with the purity being 99.9%-99.99%, the copper sulfate solution, the copper-tellurium slag, the lead bismuth alloy and silver antimony gold copper arsenic alloy can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

Deleading method through vacuum distillation of noble lead materials

The invention relates to a deleading method through vacuum distillation of noble lead materials, wherein the noble lead materials are placed into a vacuum metallurgical furnace, heated to the temperature of more than 100 DEG C, maintained at the temperature for a period of time, and subjected to distillation separation by the difference of vapor pressure of various alloy elements; and gold and silver are enriched in residue and lead, stibium, bismuth and the like are enriched in volatile, and all the elements are metallic products, thereby facilitating further refining treatment. The technical indexes reached by the method are as follows: the content of noble metal such as the silver and the like in lead bismuth alloy is less than 0.05 percent; both the content of the lead and the content of the bismuth in noble-metal alloy are less than 1 percent; the vacuum refining yield of noble metal is more than 98 percent; as for noble lead materials with high arsenic content (approximately 5 percent), more than 85 percent of arsenic can be removed through vacuum distillation; and each ton of the materials need approximately 300 to 450 degrees of power, and the value is reduced by approximately 7 percent compared with the prior art.

Owner:KUNMING DIBOO TECH

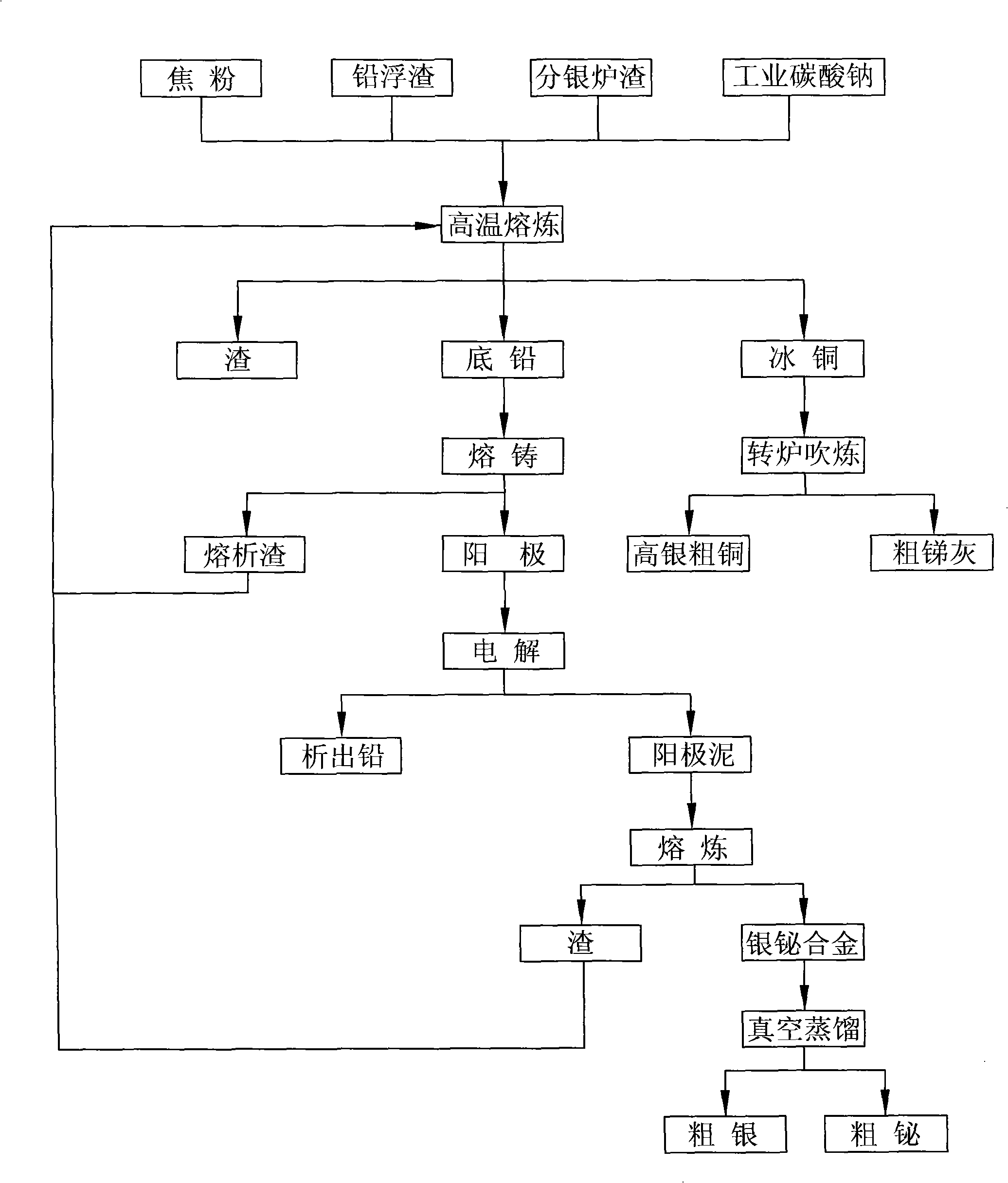

Separation process for material containing lead, antimony, copper, bismuth and silver

ActiveCN101525694AEasy to separateImprove direct yieldPhotography auxillary processesProcess efficiency improvementCompound aLead bismuth

The invention relates to a separation process for a material containing lead, antimony, copper, bismuth and silver. The separation process comprises the following steps: compounding a lead-contained oxide material one to twice the weight of a raw material into the raw material containing the lead, the antimony, the copper, the bismuth and the silver, adding calcined soda and a reducer which occupies 5 percent to 10 percent of the weight of the raw material, and melting the mixture at a temperature of 1100 DEG C to 1200 DEG C so as to form an upper copper-antimony-silver ally layer and a lower lead-bismuth-silver alloy layer in a melting furnace and separate copper-antimony from bismuth-silver, thereby realizing the favorable separation of lead-silver-bismuth from copper-antimony. The obtained bismuth-silver alloy is an optimal raw material for extracting the bismuth and the silver, and a vacuum distillation process treatment is adopted to obtain rough bismuth and rough silver; and the obtained separated lead contains larger than 99 percent of lead and can be made as supplementary lead for a blast furnace condenser to relieve the external stress of the supplementary lead. The direct yield rate of valuable metals in the full process is high, the yield rate of the silver extracted from a lead-bismuth alloy is larger than 74 percent or larger than 98 percent if adding the silver extracted from rough copper, the yield rate of the bismuth is 83 percent, and the yield rate of the copper is 90 percent.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

Method for reducing contact resistance based on low-melting-point metal and oxide thereof

ActiveCN103066475AReduce contact resistanceImprove efficiencyLine/current collector detailsMetal/alloy conductorsIndiumRubidium

The invention relates to a method for reducing contact resistance based on low-melting-point metal and an oxide thereof. By coating the low-melting-point metal and the oxide thereof between electric terminals connected with machinery, the contact resistance between the mechanical electric terminals is reduced effectively. The invention further relates to a conductive paste composing of the low-melting-point metal and the oxide thereof. The oxide takes 0.05% to 50% of the total weight of the conductive paste. The low-melting-point metal is one type or a combination of any two types selected from sodium, potassium, lithium, rubidium, cesium, gallium, indium, mercury, lead bismuth alloy, gallium-base binary alloy, gallium-base complex alloy, indium-base alloy, bismuth-base alloy, mercury-base alloy and sodium-potassium alloy which are lower than 200 DEG C in melting point. With the compound of the low-melting-point metal and the oxide thereof as the conducting medium, the method for reducing contact resistance can effectively reduce the contact resistance between the electric terminals connected with the machinery, significantly reduce the contact resistance heat effect, improve transmission efficiency of electric energy and prolong the service life of the machinery. The method for reducing contact resistance based on the low-melting-point metal and the oxide thereof can be widely applied to the technical fields of electric power and energy.

Owner:郭瑞

Efficient nuclear waste evolution sub-critical reactor core based on mixed energy spectrum

InactiveCN102623078AIncrease profitSimple structureRadioactive decontaminationLead bismuthLiquid state

The invention relates to an efficient nuclear waste evolution sub-critical reactor core based on a mixed energy spectrum, comprising an external neutron source area, an evolution area, a slowing-down layer area, a reflecting layer area and a shielding layer area from the center to the outside in sequence; and as the slowing-down layer area and the reflecting layer area are arranged on the periphery of the evolution area, a neutron is sufficiently slowed down and then is reflected back to the evolution area to form a mixed energy spectrum, and the mixed energy spectrum is utilized to carry out evolution to sub-actinium-series nuclide (MA) and long-life fission products (LLFP) simultaneously. According to the invention, the mixed energy spectrum is formed by reasonable reactor core structure arrangement, a transuranium nuclide (TRU) fuel area and an LLFP fuel area are respectively arranged according to the distribution conditions of fast neutrons and thermal neutrons, and the two fuel areas adopt a same fuel assembly form, so as to realize evolution of the MA and the LLFP simultaneously in a same evolution area and in a same reaction core; the reactor core structure is simple, the neutron utilization rate is high, the function of efficient nuclear waste evolution is realized, and a liquid state lead-bismuth alloy is adopted as a cooling agent to take fission energy generated in the evolution area out of the reactor core to realize the capacity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Device and method for controlling oxygen content in liquid lead bismuth alloy

ActiveCN103914088APrevent oxidationIncrease vacuumControlling ratio of multiple fluid flowsChemical reactionLiquid storage tank

The invention belongs to the technical field of nuclear science and engineering, and relates to a device and method for controlling the oxygen content in liquid lead bismuth alloy. The device for controlling the oxygen content in the liquid lead bismuth alloy is mainly characterized in that a heating cavity is formed in front of the liquid inlet end of an oxygen content control chamber, the heating cavity is connected with a liquid metal mechanical pump through the oxygen content control chamber, a liquid inlet end oxygen probe is arranged at the liquid inlet end of the oxygen content control chamber, and a liquid outlet end oxygen probe is arranged at the liquid outlet end of the oxygen content control chamber; a liquid metal flow meter is arranged at the outlet end of the liquid metal mechanical pump, an outlet of the liquid metal flow meter is connected with a liquid lead bismuth alloy valve, and a reflux inlet of the liquid lead bismuth alloy valve is communicated with a liquid storage tank through a reflux pipeline and is communicated with the heating cavity; vacuum pumping and measuring systems are arranged in the liquid storage tank and the oxygen content control chamber. The device and method have the advantages that Ar-H2 mixed gas and reactive oxygen in the liquid lead bismuth alloy conduct chemical reaction in the oxygen content control chamber, and then the oxygen content can be controlled.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Thermally-operated conversion system

ActiveCN103928064ABring out efficientlyImprove thermal conductivityNuclear energy generationCooling arrangementLead bismuthNuclear reactor

The invention belongs to the technical field of nuclear reactor engineering, and in particular relates to a thermally-operated conversion system which adopts lead or lead-bismuth alloy intermediate loops. The system comprises three loops; a first loop comprises a cold pool, a main pump, a reactor core, a thermal pool and an intermediate heat exchanger arranged in a main container and connected in sequence; a second loop comprises a second loop circulating pump, the intermediate heat exchanger and a steam generator connected in sequence; a third loop comprises a water supplying pump, the steam generator and a steam turbine connected in sequence; a working medium of the first loop is liquid metallic sodium, a working medium of the second loop is liquid metallic lead or a liquid lead-bismuth alloy, and the third loop is a conventional water-steam loop. By adopting the system disclosed by the invention, heat generated by the reactor core can be safely and efficiently brought out of a reactor, so that high-temperature steam is generated in the steam generator and used for pushing the steam turbine to apply work, and heat energy generated by the reactor is converted into mechanical energy.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

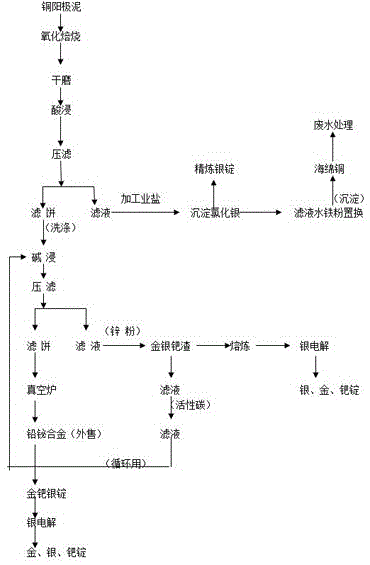

Method for separating and recovering valuable metals from copper anode slime

ActiveCN105543485ALess investmentShorten the timeProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionLead bismuth

The invention discloses a method for separating and recovering valuable metals from copper anode slime. The method comprises the following steps: (1) the copper anode slime is subjected to oxidizing roasting, and primary dust and a roasting product are obtained; selenium is recovered from the primary dust, and secondary dust and crude selenium powder are obtained; (2) the roasting product is broken and added to a reactor, acid is added for acid leaching, an oxidizing agent is added continuously in an acid leaching process, acid leached residues and an acid leached liquid are obtained, and silver and copper are recovered from the acid leached liquid; (3) alkali is added to the acid leached residues for alkaline leaching, sodium cyanide and an ore selecting agent are added simultaneously, alkaline leached residues and an alkaline leached liquid are obtained, the valuable metals are recovered from the alkaline leached liquid, and a lead bismuth alloy and heavy metals are recovered from the alkaline leached residues. The method has the advantages of short process flow, low investment, short time, fast effect taking, high comprehensive recovery rate, high technical-economic indicators and high metal recovery rate.

Owner:郴州百一环保高新材料有限公司

High-strength painted bundling belt and manufacturing method thereof

InactiveCN102978512ANot perishableSpeed up evaporationFlexible elementsLead bismuthChemical composition

The invention discloses a high-strength painted bundling belt. The high-strength painted bundling belt comprises the following chemical components by weight percent: 0.12-0.20% of C, 0.2-0.6% of Si, 1.2-2.0% of Mn, less than or equal to 0.025% of P, less than or equal to 0.02% of S and 0.01-0.05% of Nb. The high-strength painted bundling belt is prepared by the steps of smelting, casting a blank, and then carrying out hot-rolling to form coils; carrying out acid cleaning; carrying out cold rolling; uncoiling, splitting and conducting deburring; carrying out tempering treatment in a lead-bismuth furnace; carrying out water cooling; painting by adopting a dip-coating wiping mode and carrying out sectional baking; and waxing and drying by adopting hot air. The high-strength painted bundling belt disclosed by the invention has the advantages that since a proper amount of Nb is added, the influence on crystal lattice distortion caused by overlarge volume mismatching of enhanced element atoms and Fe atoms is overcome, namely a value sigma b is increased, the overhigh yielding-to-tensile ratio can be restrained, and a steel belt with high strength, good elasticity, excellent mechanical property is produced; and the energy consumption is low, the process is simple, the painted surface is uniform, the anti-rusting performance is good and the process is simple.

Owner:武钢集团有限公司

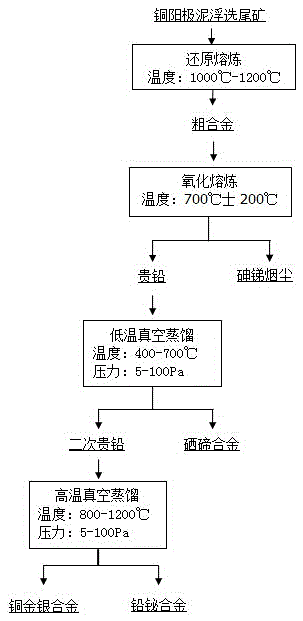

Method for recovering valuable metals from copper anode mud flotation tailings

InactiveCN105483384ASettle the lossHigh removal rateSelenium/tellurium compundsProcess efficiency improvementSootAntimony

The invention relates to a method for recovering valuable metals from copper anode mud flotation tailings and belongs to the technical field of thermometallurgy. The method comprises: firstly, performing retailoring on the copper anode mud flotation tailings to obtain a reduction product, and then performing oxidative blowing on the reduction product to obtain rich lead and arsenic and antimony containing soot; first-stage low-temperature vacuum distillation: performing primary low-temperature vacuum distillation on the obtained rich lead under the conditions of a temperature of 400-700 DEG C and a pressure of 1-100Pa for 1-3h, thereby obtaining secondary rich lead and a selenium-tellurium alloy; and second-stage high-temperature vacuum distillation: performing primary high-temperature vacuum distillation on the obtained secondary rich lead under the conditions of a temperature of 800-1200 DEG C and a pressure of 1-100Pa for 1-3h, thereby obtaining a lead-bismuth and a copper-gold-silver alloy. The method for recovering valuable metals from copper anode mud flotation tailings is safe and controllable in whole process flow, simple and convenient to operate, simple in equipment needed, free from three-waste emissions, and environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

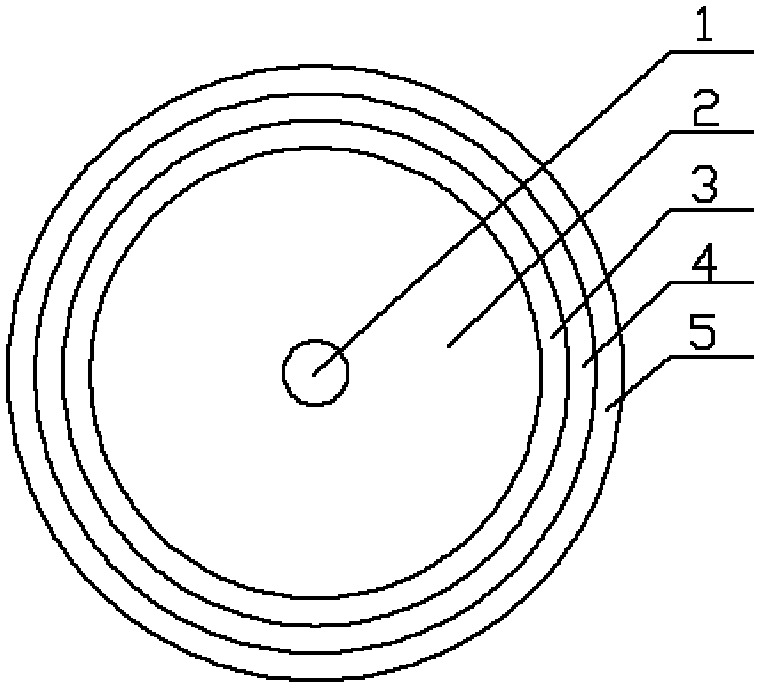

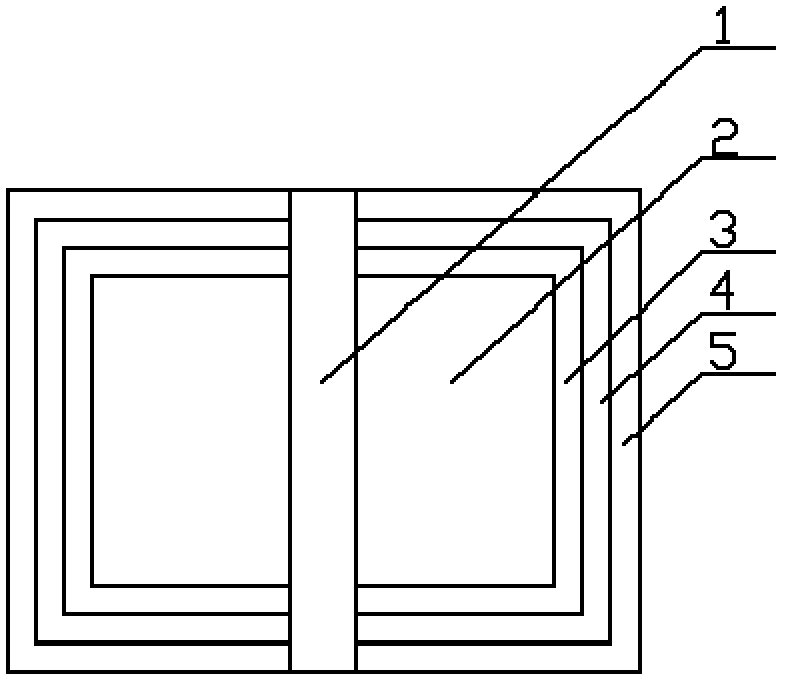

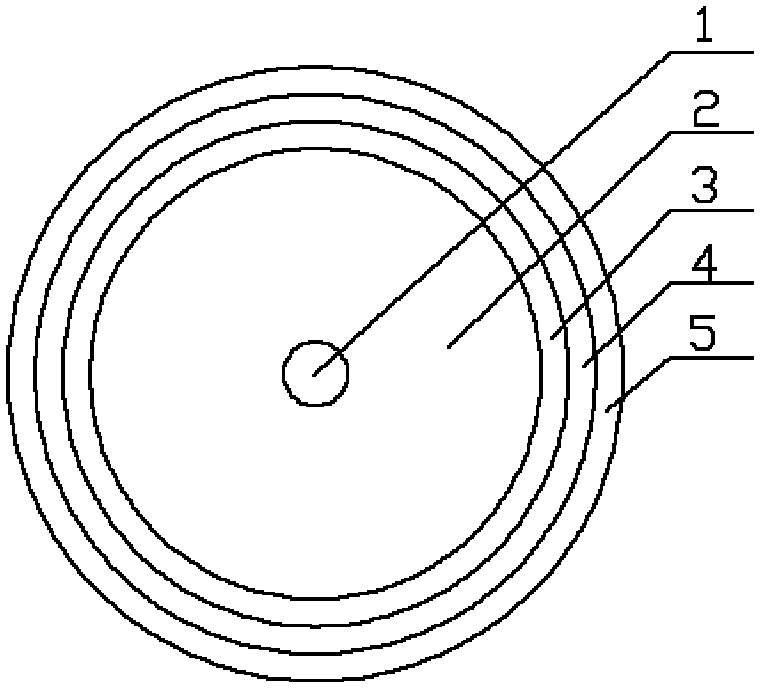

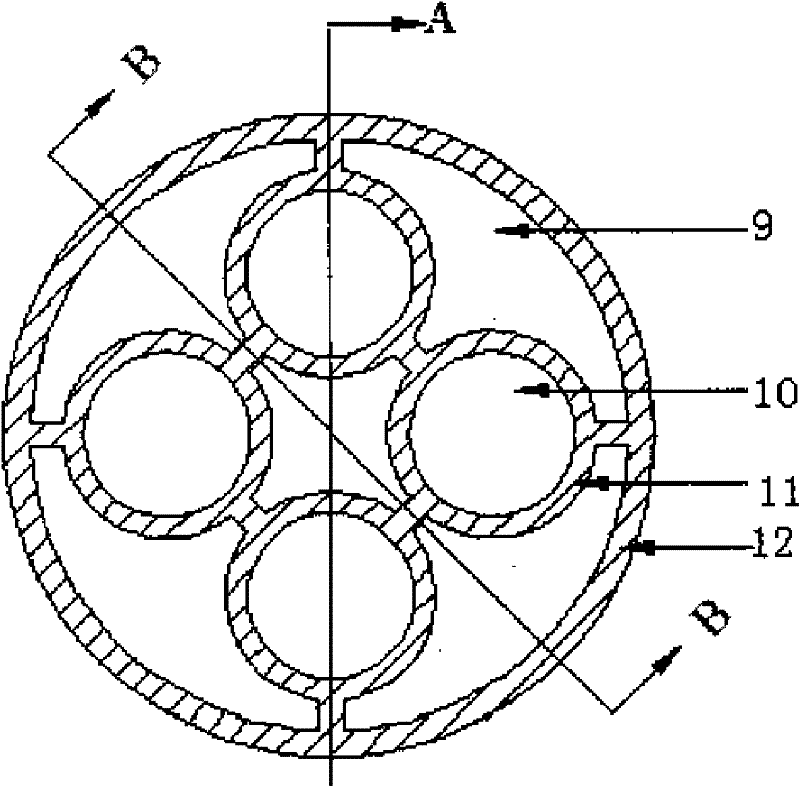

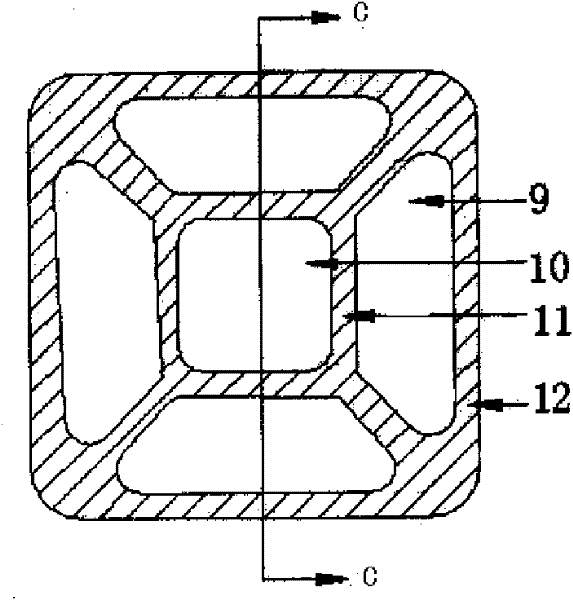

Passive natural-circulation lead bismuth heat exchange device and method for discharging heat out of reactor core

InactiveCN102446564AImprove securityImprove reliabilityNuclear energy generationStationary tubular conduit assembliesLead bismuthNuclear engineering

The invention discloses a passive natural-circulation lead bismuth heat exchange device for heat transfer by a lead bismuth fluid and a method for discharging heat out of reactor core, belonging to the field of nuclear energy heat exchange equipment. The heat exchange device particularly comprises two natural-circulation heat transfer loop structures, namely a round loop and a square loop, and is a device which realizes natural-circulation heat transfer at two sides. The inner ring of an inner ring pipe is a primary side lead bismuth alloy fluid passage, and a secondary side fluid passage is arranged between the outer ring of the inner ring pipe and the inner wall of an outer ring pipe. Heat generated by a subcritical reactor of an ADS (accelerator driven system) is transferred to coolants of the two loops by the liquid lead bismuth alloy through the inner ring pipe of the device, the lead bismuth alloy flows through the device to exchange heat with a secondary side fluid. The primary side heat exchange fluid and the secondary side heat exchange fluid form natural circulation under the driving of a density difference, and the high-efficiency, energy-saving, safe and reliable passive characteristic is achieved. The device is simple and easy to operate, is free of a complicated lead bismuth pump, is in no need of a power source and has the characteristics of energy conservation, high safety and high reliability. The passive natural-circulation lead bismuth heat exchange device and the method for discharging heat out of the reactor core comply with the current policy of energy conservation and emission reduction and are easy in market promotion.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

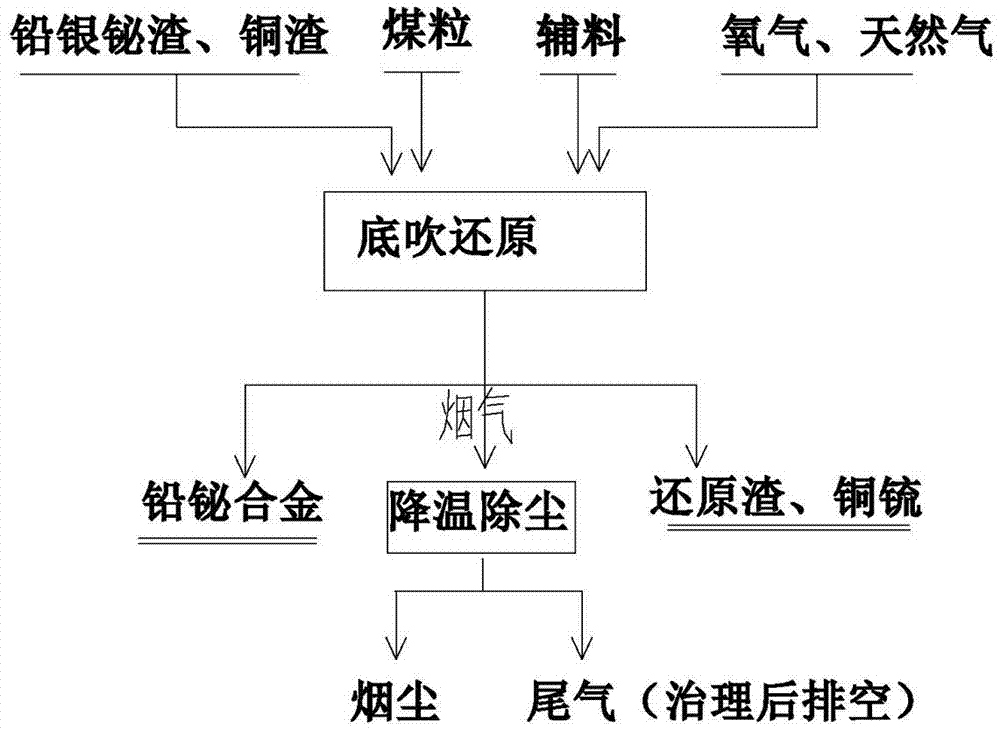

Method and device for recovering valuable elements from lead-silver-bismuth slag in copper smelting

ActiveCN103114206AImprove melt strengthImprove work efficiencyProcess efficiency improvementHigh pressureLead bismuth

The invention belongs to nonferrous metal metallurgy industry, and particularly relates to a method and device for recovering valuable elements (lead, gold, silver, bismuth, copper, arsenium and sulfur) from lead-silver-bismuth slag in copper smelting. The method comprises the following steps: adding lead-silver-bismuth slag, copper slag, reducer and slagging flux through a feed port at the upper part of a bottom-blowing alloying furnace, performing reduction reaction under high-temperature conditions to generate metal lead, metal bismuth and copper matte; under the stirring action of high-pressure gas supplied by a submerged combustion device at the bottom, continuously blowing and dispersing the molten lead deposited at the bottom to the molten mass at the upper part, and using the molten lead to continuously trap gold, silver and bismuth to obtain a lead-bismuth alloy which is rich in gold and silver; and under the action of iron chips and the reducer at high temperature, forming copper in the lead-silver-bismuth slag into copper matte, wherein the copper matte is enriched with arsenium. The method provided by the invention is high in smelting strength, high in operating efficiency, high in metal recovery rate, favorable in device sealing property, low in heat loss, low in energy consumption, high in automation level, low in labor intensity, favorable in stability and convenient to operate, and can realize converter tipping quickly.

Owner:HENAN YUGUANG GOLD & LEAD

Method for recovering bismuth from bismuth slag

ActiveCN102586627AAvoid safety hazardsReduce labor intensityProcess efficiency improvementElectrolysisSlag

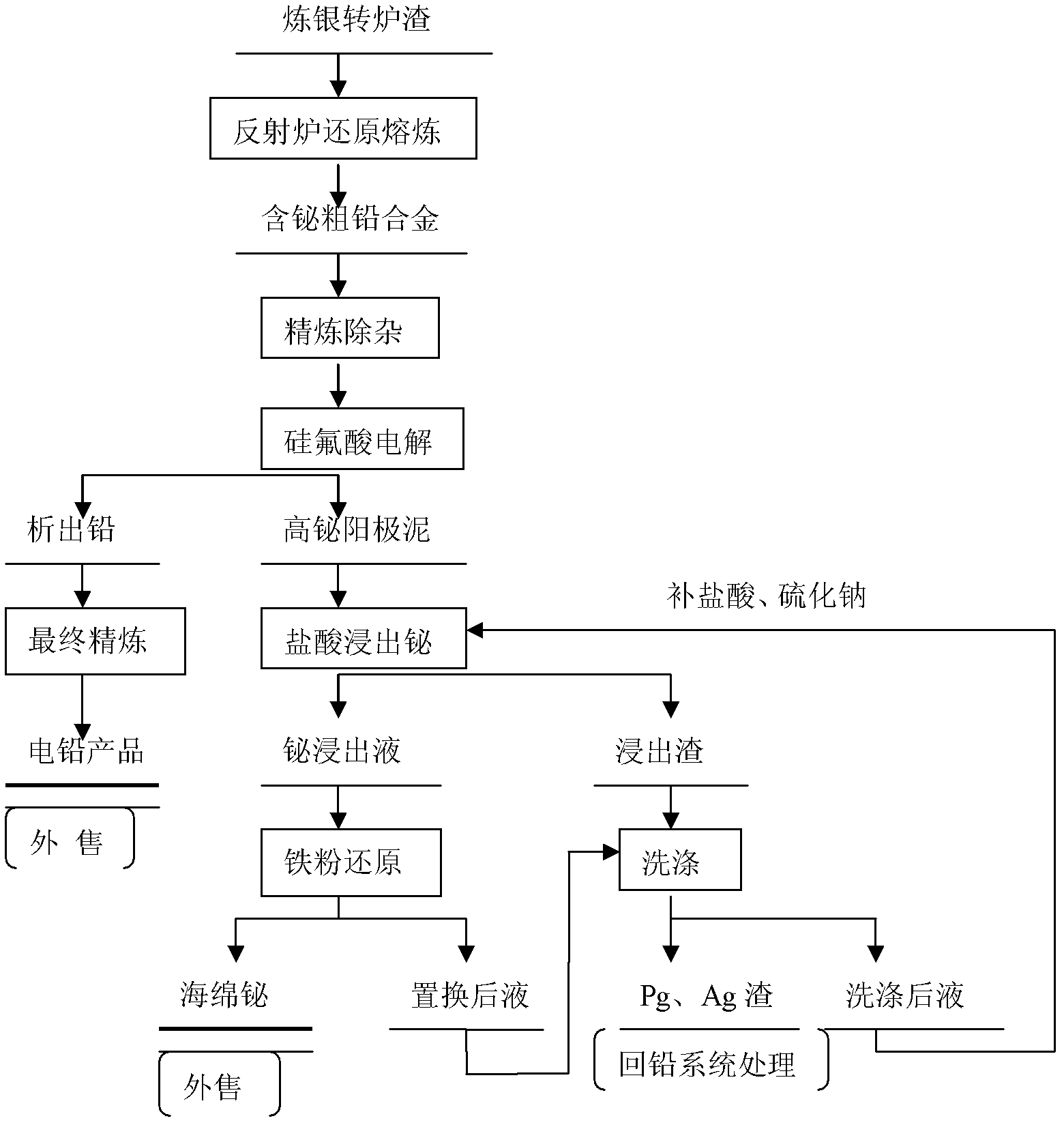

The invention relates to a method for recovering bismuth from bismuth slag, which includes steps of: firstly, smelting silver-refining converter oxidizing slag in high-temperature restoring mode to obtain lead-bismuth alloy, performing silico-fluoric acid system lead-bismuth alloy electrolysis to obtain electric lead products and high-bismuth anode mud; secondly performing hydrochloric acid leaching on the high-bismuth anode mud, filtering to obtain bismuth-contained leaching liquid, wherein the leaching condition is that: liquid-solid ratio (weight ratio) is 3-6:1, process temperature is 40-70 DEG C, hydrochloric acid concentration is 150-200g / L, and reaction time is1.5-2.5h; and thirdly, replacing bismuth in the leaching liquid through reduced iron powder to obtain sponge bismuth and obtain refined bismuth with high purity in pyro-refining electrolysis. Sodium sulfide for sedimenting silver is added in the leaching process to obtain bismuth leaching liquid, silver can be prevented from immersing into the liquid as much as possible, when return washing liquid is used for leaching high-bismuth anode mud, a part of hydrochloric acid is refilled to maintain necessary potential of hydrogen (pH) value, concentration of Cl- is controlled to be 150-200g / L, and simultaneously bismuth ion hydrolysis can be avoided. Compared with the prior art, the method has no operations of water quenching, ball milling, hydrolysis, neutralization and the like of coarse bismuth alloy, has less procedures, is low in cost and free of pollution, simultaneously achieves double-metal electrolysis of the lead-bismuth alloy and does not influence the electric-lead main system.

Owner:蒙自矿冶有限责任公司

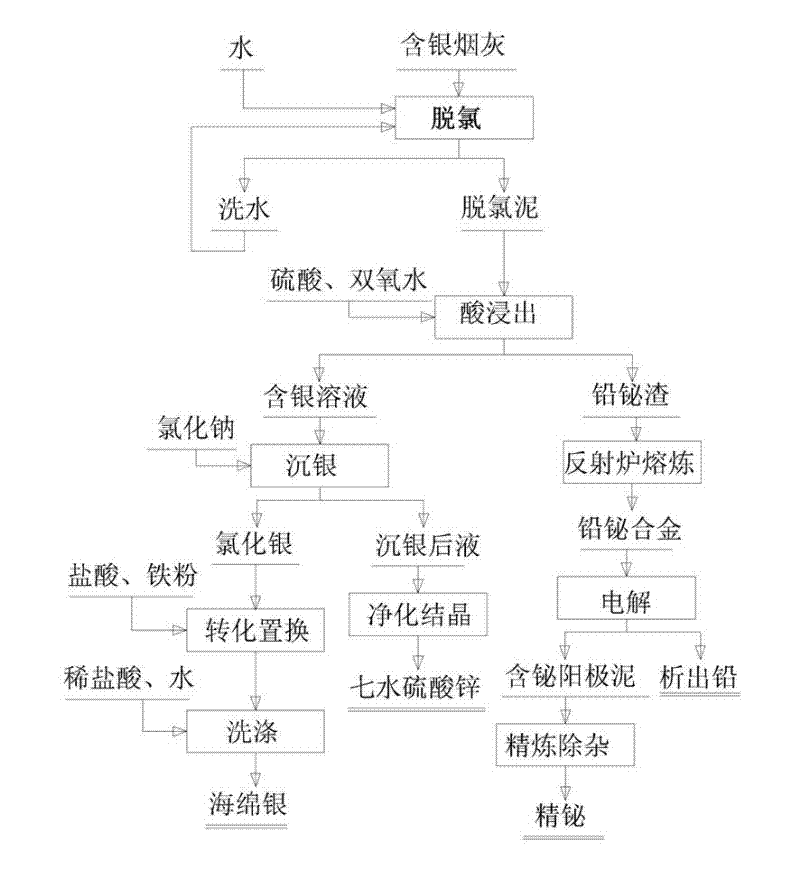

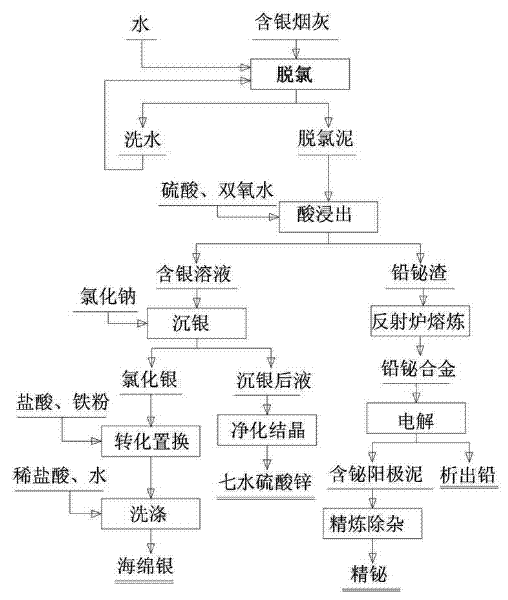

Process for recovering silver, lead and bismuth from silver-bearing soot comprehensively

InactiveCN102363839AFaster turnaroundProcess environmental protectionProcess efficiency improvementReverberatory furnaceSoot

The invention relates to a process for recovering silver, lead and bismuth from silver-bearing soot comprehensively, and belongs to the technical field of comprehensive recovery of noble metals. The process comprises the following steps of: removing chlorine from silver soot by using clear water, and performing acid leaching on the silver in the silver soot by using sulfuric acid and an oxidizing agent; adding sodium chloride into silver-bearing solution to obtain pure silver chloride, and performing the conversion of hydrochloric acid, iron powder metathesis and the washing of acidized purified water on the silver chloride to obtain high-purity sponge silver; after the silver is precipitated, purifying solution, removing impurities and crystallizing to obtain zinc sulfate heptahydrate; and smelting the lead and bismuth which are left in lead bismuth dregs to form a lead bismuth alloy by reverberatory furnace, electrolyzing to obtain precipitated lead and bismuth-bearing anode mud, and refining the bismuth-bearing anode mud and removing impurities to obtain refined bismuth. The process is suitable for processing the silver-bearing soot of which the silver content is over 0.8 percent; and compared with the prior art, the process has the advantages of environment friendliness, silver direct yield of more than or equal to 99.2 percent, high recovery rate, low machining cost and quick capital turnover.

Owner:郴州雄风环保科技有限公司

Natural circulation loop system of lead-bismuth alloy

ActiveCN103413579ASimple structureSimple and fast operationNuclear energy generationNuclear monitoringElectricityLead bismuth

The invention discloses a natural circulation loop system of a lead-bismuth alloy. The system comprises a storage tank, a first subchannel, a visual pipeline, a rising pipeline, a condenser, a water pump, a top pipeline, a descending pipeline, a second subchannel and an electric-heating section. The system has the characteristics of being simple in structure and simple and convenient to operate. Based on the secondary heat exchange of the condenser and the electric-heating section, the heat exchange effect of the system is good; pressure gauges and temperature instruments are arranged on all the pipelines of the system while the pipelines are controlled by a valve, so that the safety coefficient of the system is high; the cooling in nuclear industry is carried out by a natural circulation loop, so that the heat energy generated by the nuclear industry is utilized effectively, i.e., the waste of energy sources is avoided. The system not only can be applied to the nuclear industry but also can be applied to scientific research. As a result, the system disclosed by the invention can serve as a practical tool and a scientific-research tool simultaneously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

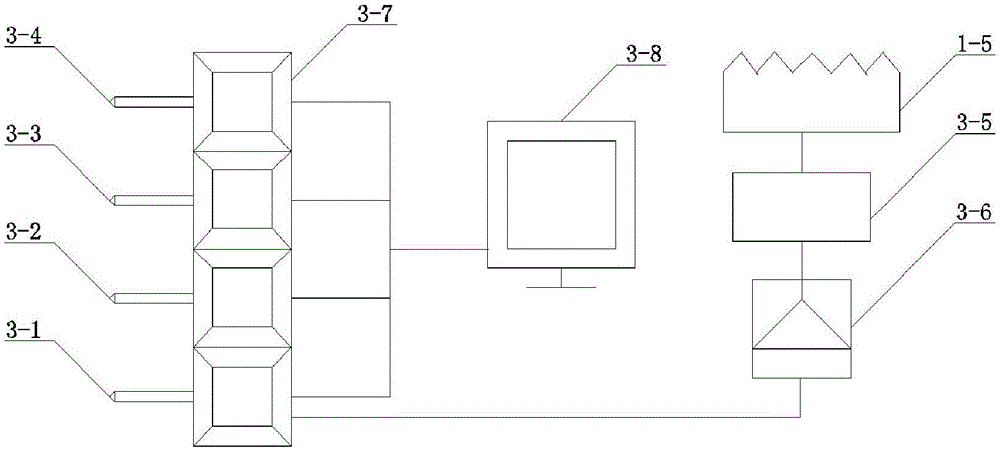

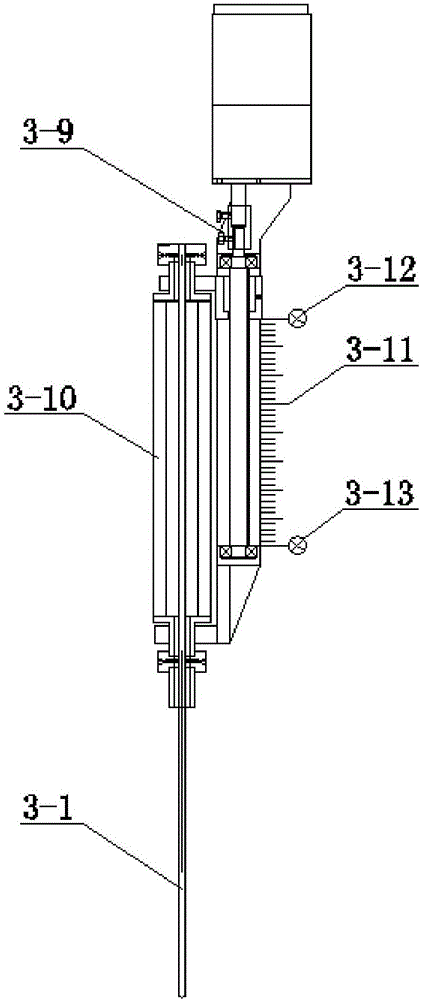

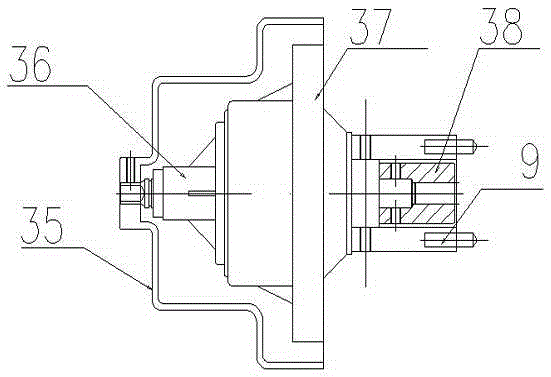

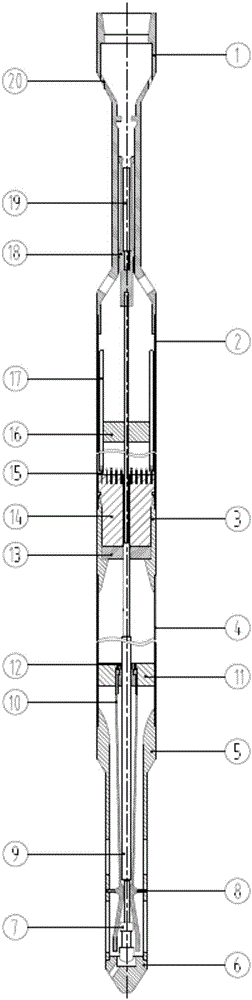

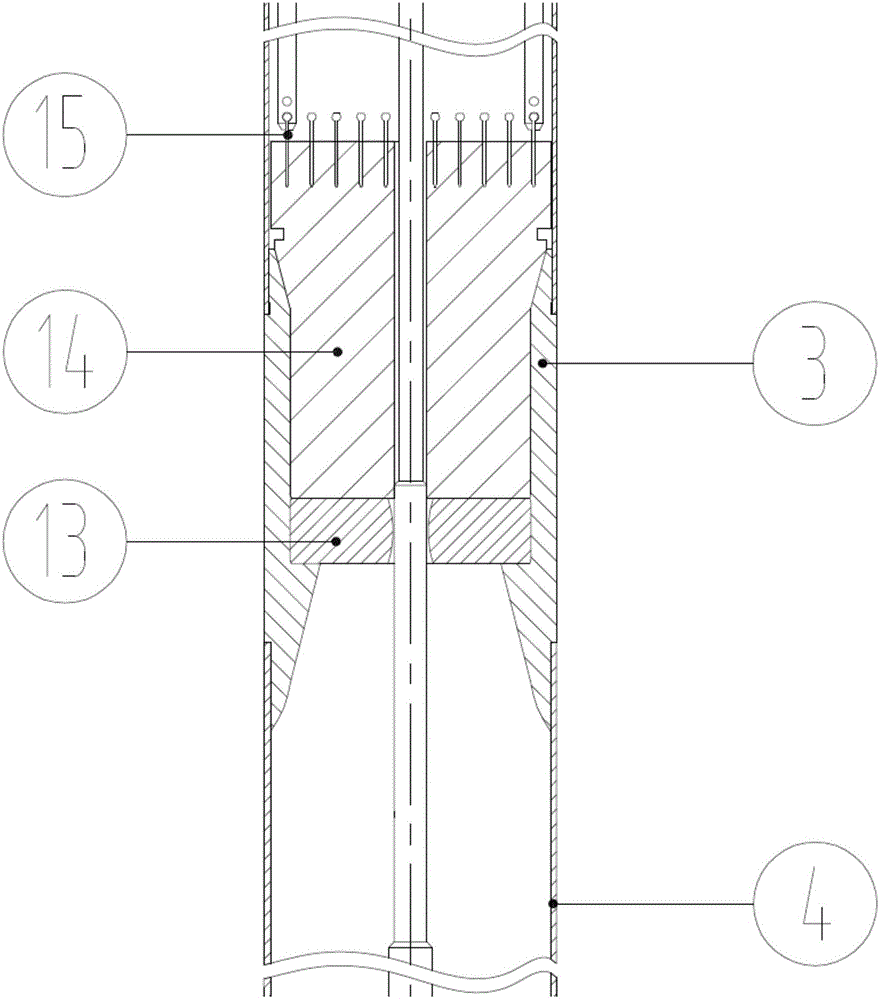

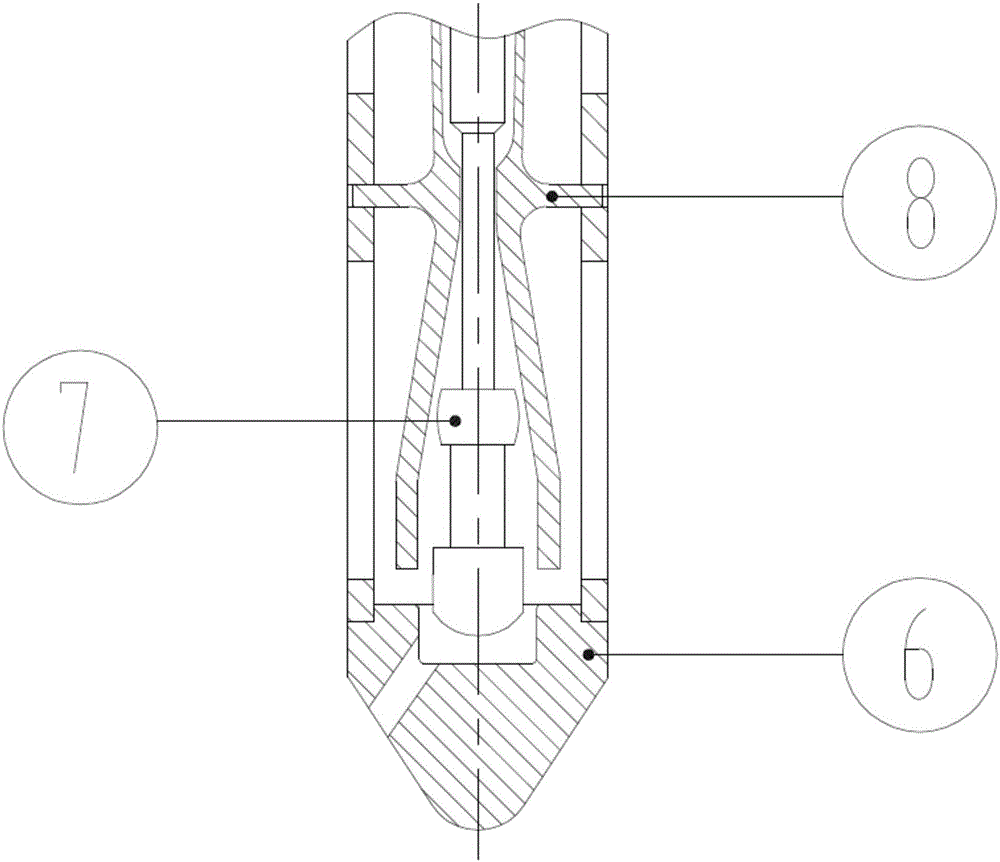

Accelerator driven sub-critical system split type central measuring cylinder system

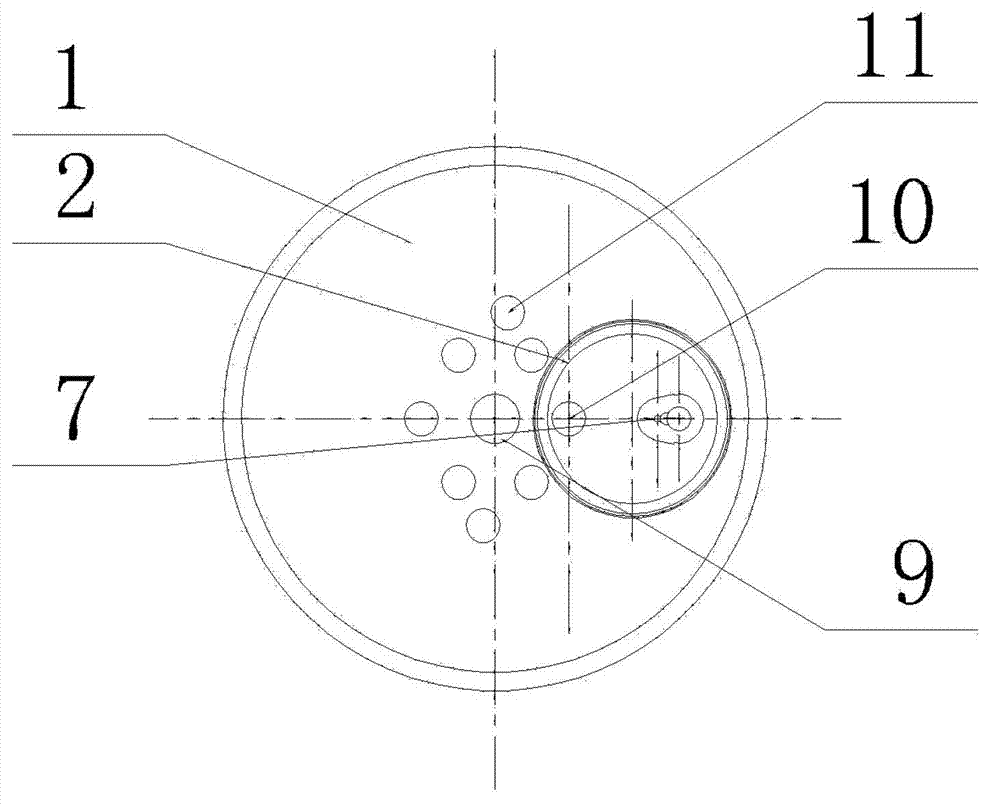

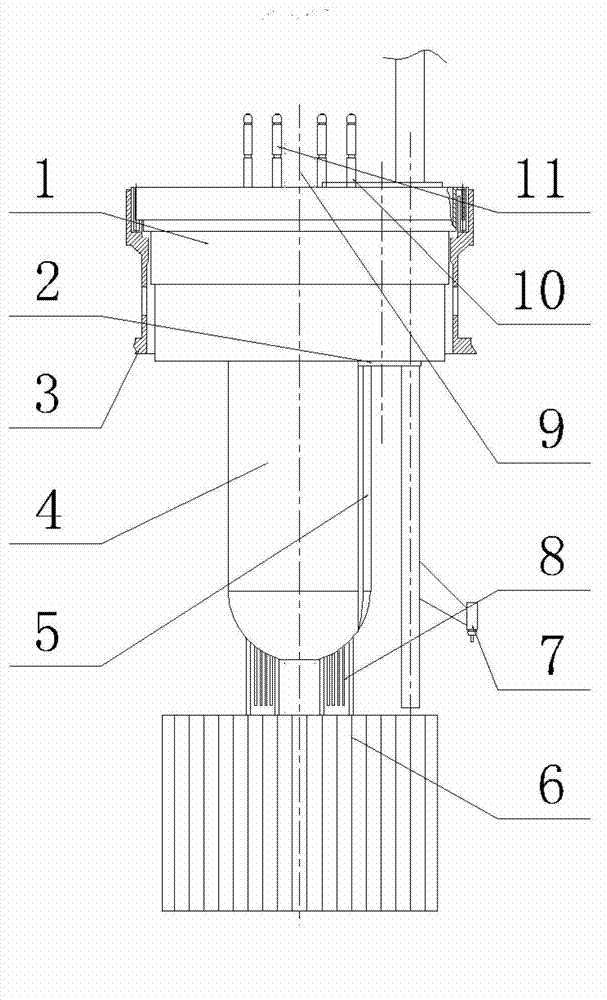

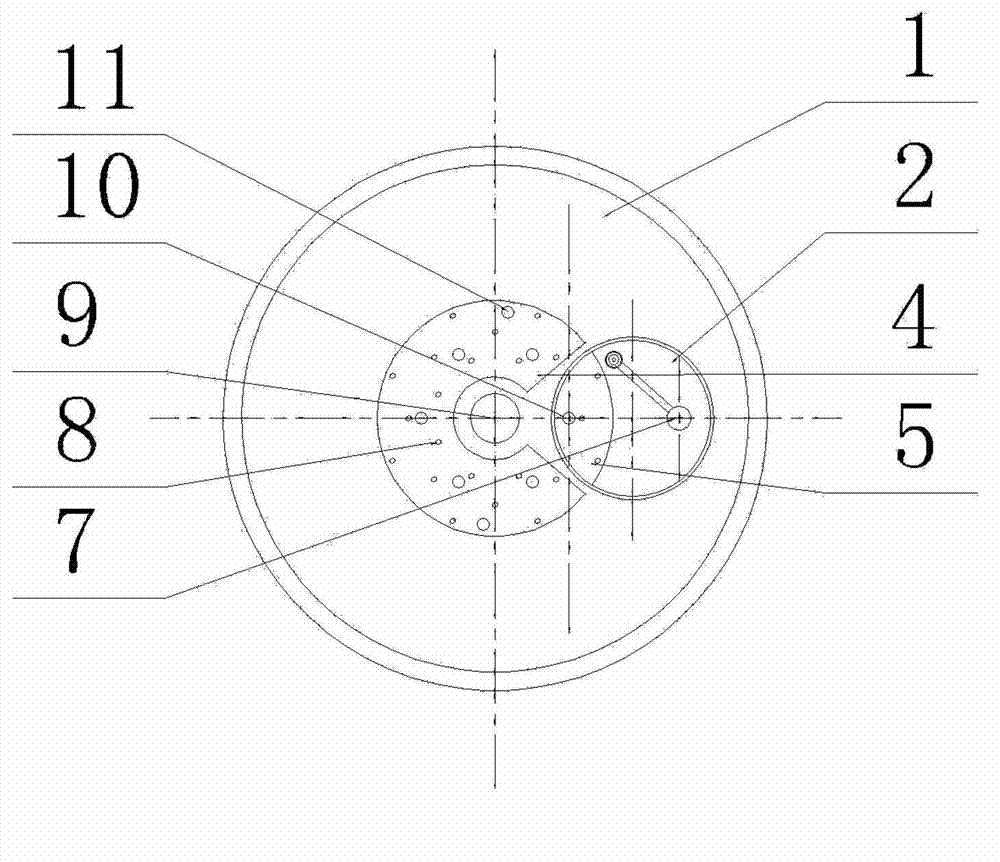

ActiveCN103093841AFunctionality is not affectedReduce capacityNuclear energy generationNuclear monitoringLead bismuthBeam tube

The invention provides an accelerator driven sub-critical system split type central measuring cylinder system which mainly comprises large and small plugs, a central measuring cylinder main fan-shaped section welded below the large plug, a central measuring cylinder branched fan-shaped section welded below the small plug, a control rod driving mechanism, a proton beam tube, a measuring guide tube, a refueling machine and the like, wherein the large plug is positioned in the center of a system top cover; the small plug is screwed to the large plug and is eccentric to the large plug; the refueling machine is arranged on the small plug and is eccentric to the small plug; and the proton beam tube penetrates through the center of the large plug. During system operation, the lower fan-shaped sections of the large and small plugs are closed to form the central measuring cylinder, the lower fan-shaped section of the small plug rotates during refueling, so that the refueling mechanism enters the system to replace a fuel component. The system mainly aims at an accelerator driven lead bismuth cooling rapid neutron transmutation system, and the problem that the system core refueling is obstructed by the integrated central measuring cylinder is solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

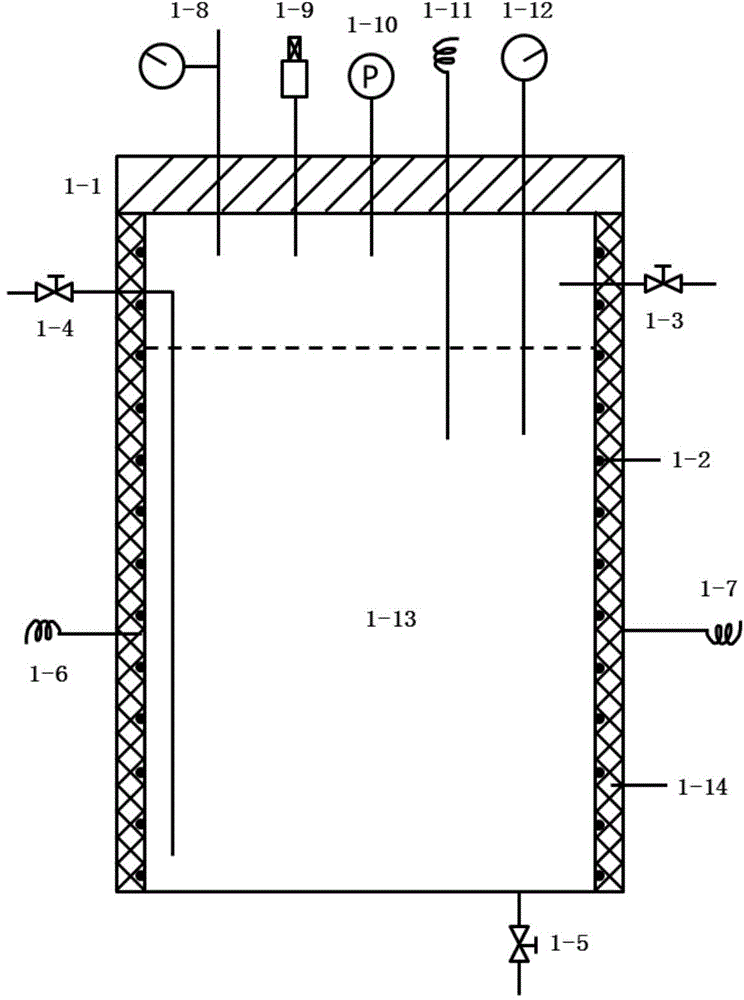

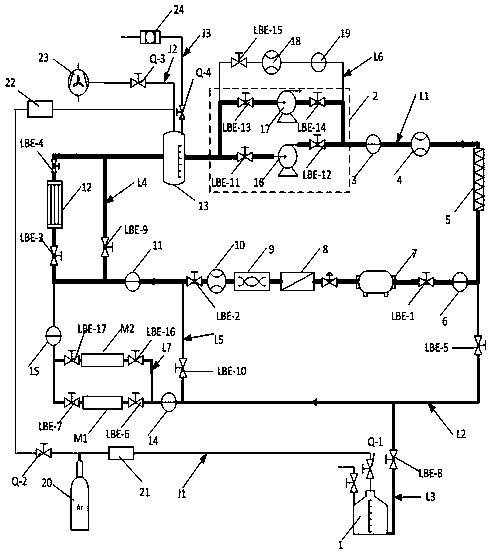

Device and method for automatically controlling oxygen/corrosion for high-temperature lead-bismuth melt

ActiveCN106323855AReduce oxidationReduce heat transferControlling ratio of multiple fluid flowsWeather/light/corrosion resistanceAutomatic controlEngineering

The invention belongs to the field of devices for controlling oxygen / corrosion for high-temperature lead-bismuth melt in nuclear science, and relates to a device and a method for automatically controlling oxygen corrosion for high-temperature lead-bismuth melt. The device for automatically controlling the oxygen / corrosion for the high-temperature lead-bismuth melt is characterized by comprising a storage tank; a vacuum system, a temperature control system, a cooling system, an oxygen concentration control system, a sample corrosion experiment system and an automatic control and data processing system are arranged on the storage tank. The device and the method have the advantages that the vacuum of 1*100<-2> Pa can be generated by the vacuum system and is matched with a gas inlet pipeline of an upper cover, a tank can be repeatedly washed by the aid of high-purity Ar gas, and accordingly oxidation of lead and bismuth in early running stages and shutdown phases of the device can be effectively relieved; a water jacket is arranged on an upper cover structure, a plurality of layers of heat-insulation plates are arranged below the upper cover structure, the water jacket, the heat-insulation plates and the cooling system are combined with one another, accordingly, influence of heat conduction and heat radiation of the high-temperature lead and bismuth on the upper cover can be effectively relieved, and components of the upper cover can assuredly normally work in safety ranges when the lead-bismuth melt is operated at the high temperatures of 650 DEG C.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

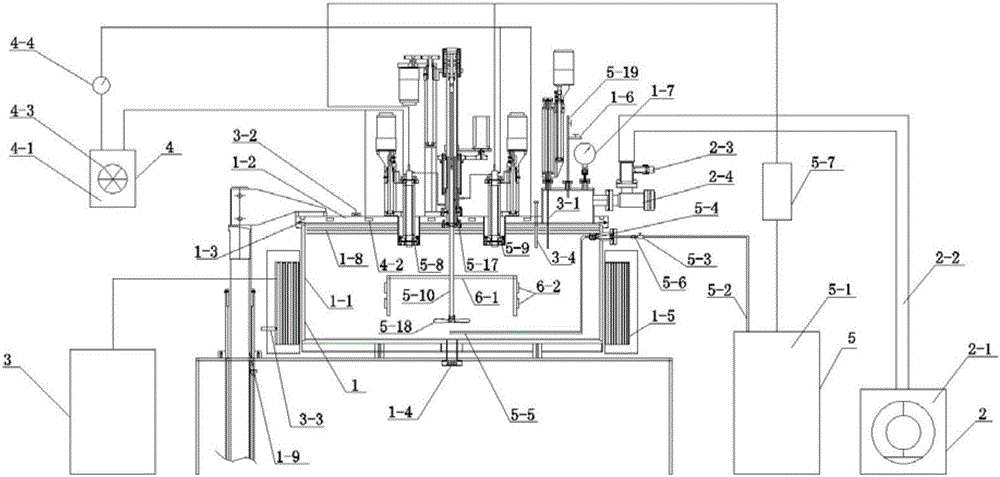

Experimental system for thermal-hydraulic characteristics and corrosive properties of liquid lead-bismuth alloy

PendingCN108761022AAvoid problems caused by solidificationEfficient heatingWeather/light/corrosion resistanceMaterial heat developmentLead bismuthLiquid state

The invention provides an experimental system for thermal-hydraulic characteristics and corrosive properties of a liquid lead-bismuth alloy. The experimental system comprises a liquid lead-bismuth cycling experiment device, wherein the liquid lead-bismuth cycling experiment device specifically comprises a power pump group, a preheater, a first experimental section, a second experimental section, aheat exchanger, an oxygen control system, a purification system, an expansion box, a storage box, a plurality of flow meters, a plurality of pressure transmitters and a plurality of lead-bismuth valves. By controlling opening or closing of different lead-bismuth valves, different loops are selected for completing experiments on the thermal-hydraulic characteristics and corrosive properties of equipment associated with the liquid lead-bismuth alloy in different experimental sections of the system, as well as experiments on compatibility characteristics of equipment materials and lead-bismuth.With implementation of the system, defects in the prior art can be overcome, and analytical study on the thermal-hydraulic characteristics and corrosive properties of the liquid lead-bismuth alloy isrealized.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Lead-bismuth-lithium-titanium-scandium-niobium series piezoelectric ceramic with high Curie temperature and high piezoelectricity property

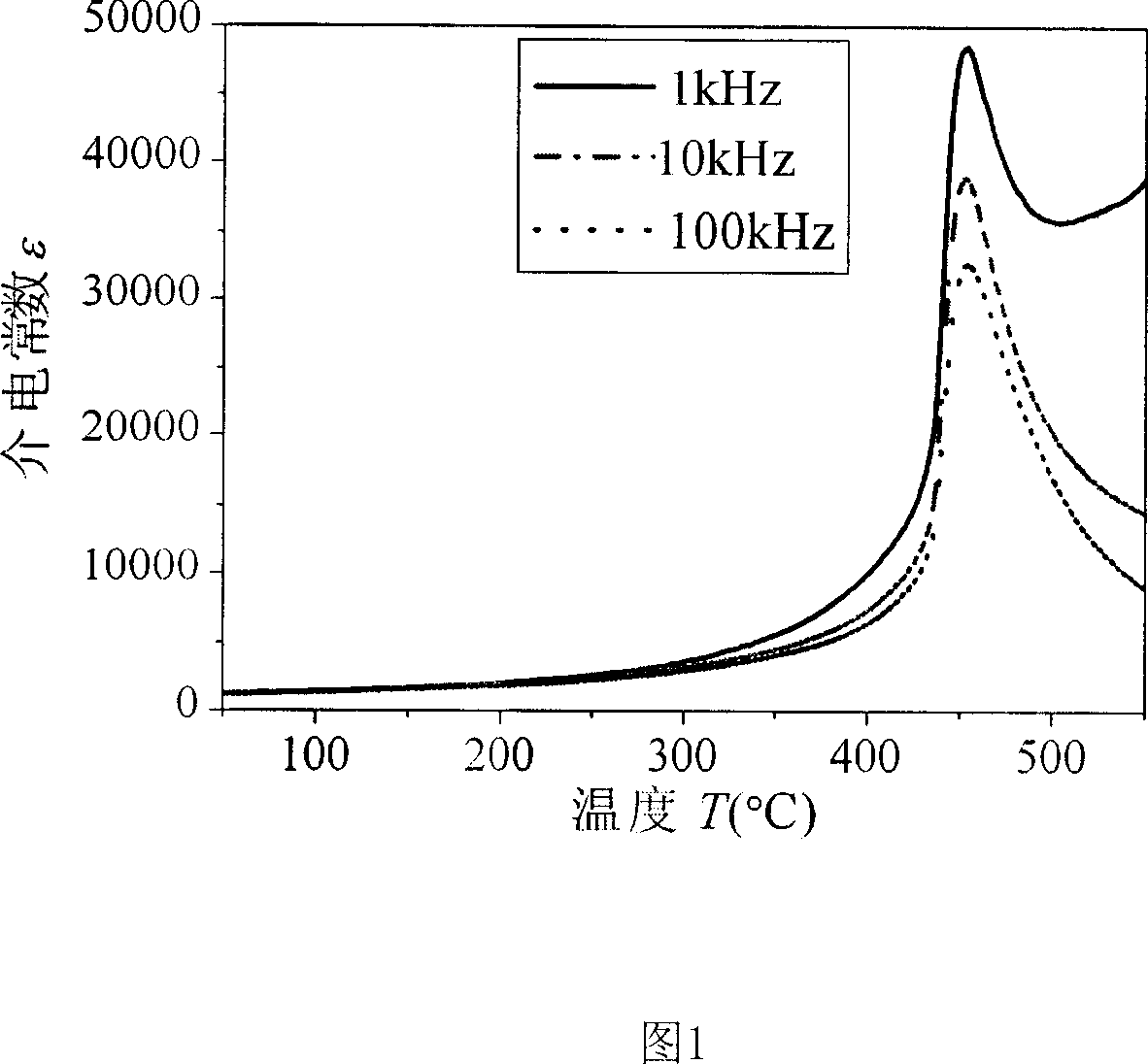

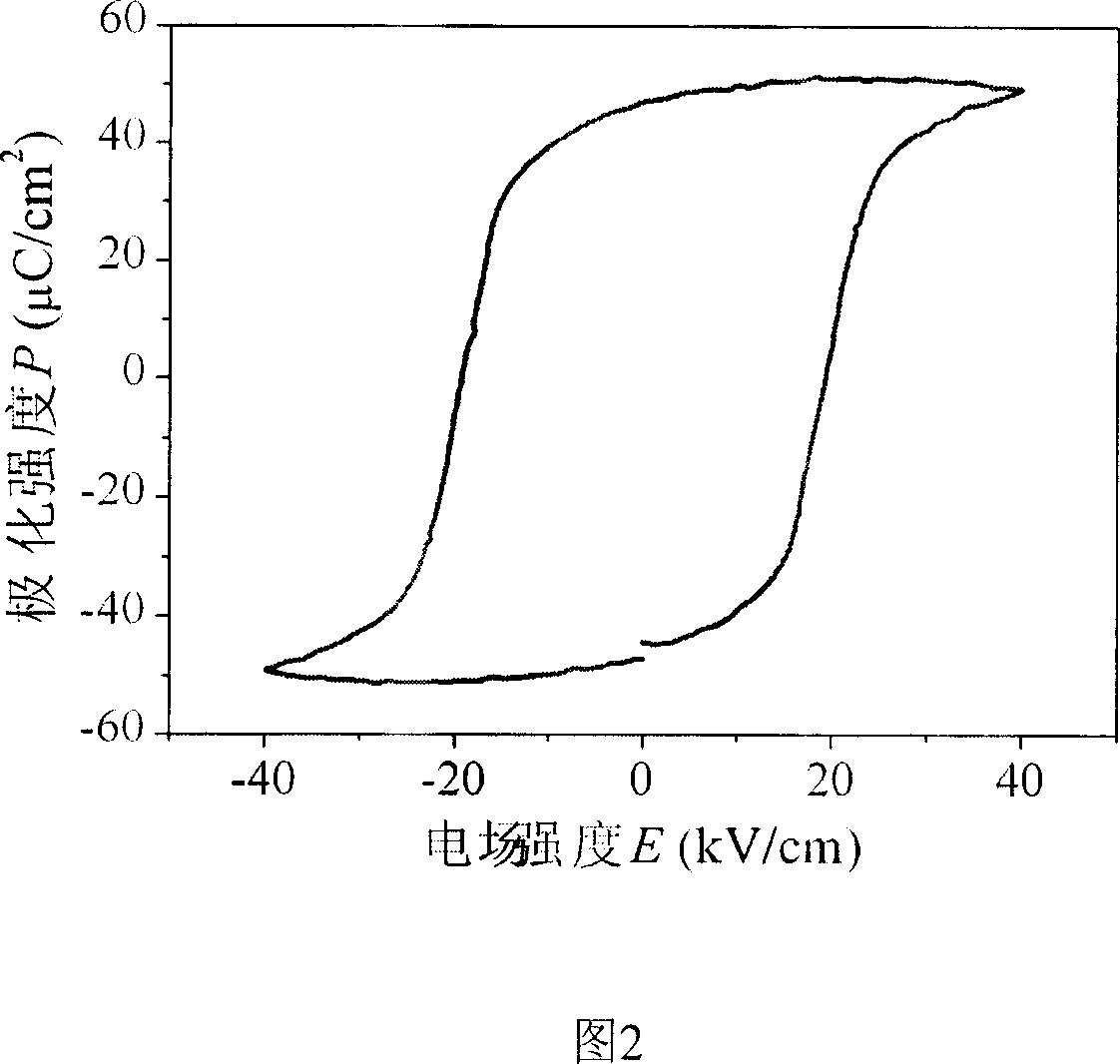

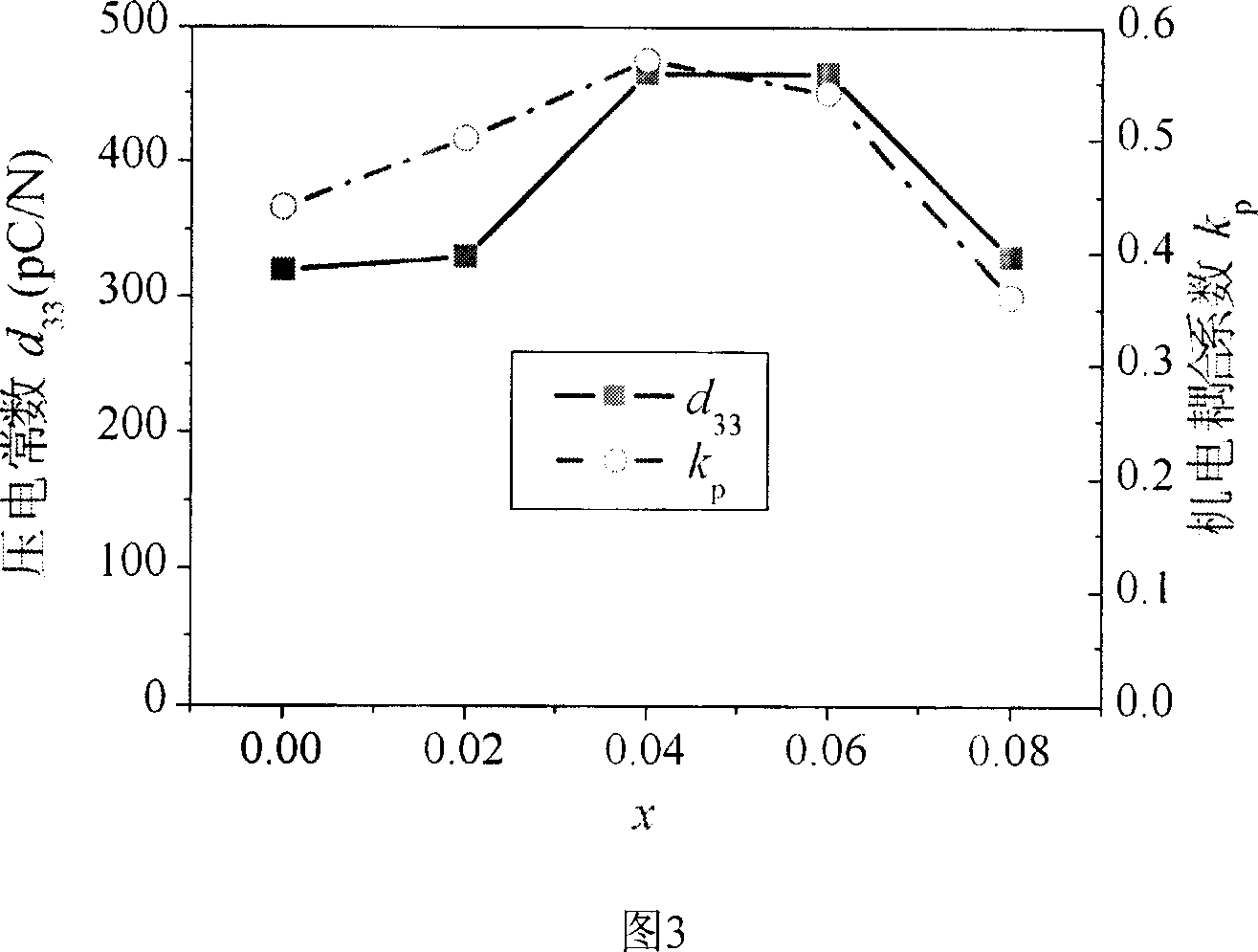

InactiveCN101033133AExcellent piezoelectric propertiesHigh curie temperatureCeramicsPiezoelectric/electrostrictive devicesNiobiumCurie temperature

This invention discloses a Ti Sc Pb Bi Li niobate series of piezoelectric ceramic with high Tc and high piezoelectric performance and puts forward a general formula to express the material: (1-x)BiScO3-xPb(1-y)LiyTi(1-y)NbyO3, in which, x and y show the atomic number of related element materials in compound ions in each set, namely, the atom percentage, x is greater than or equal to 0.50 but less than or equal to 0.90, y is greater than or equal to 0 but less than or equal to 0.10, and traditional preparation technology and industrial raw materials can be applied for said piezoelectric ceramics and sintered at 1150deg.C or even lower, which has fine piezoelectric performance and practical plane electromechanical coupled coefficient, its kp is greater than 40%, d33 is over 300pC / N and Tc is greater than 400deg.C.

Owner:SICHUAN UNIV

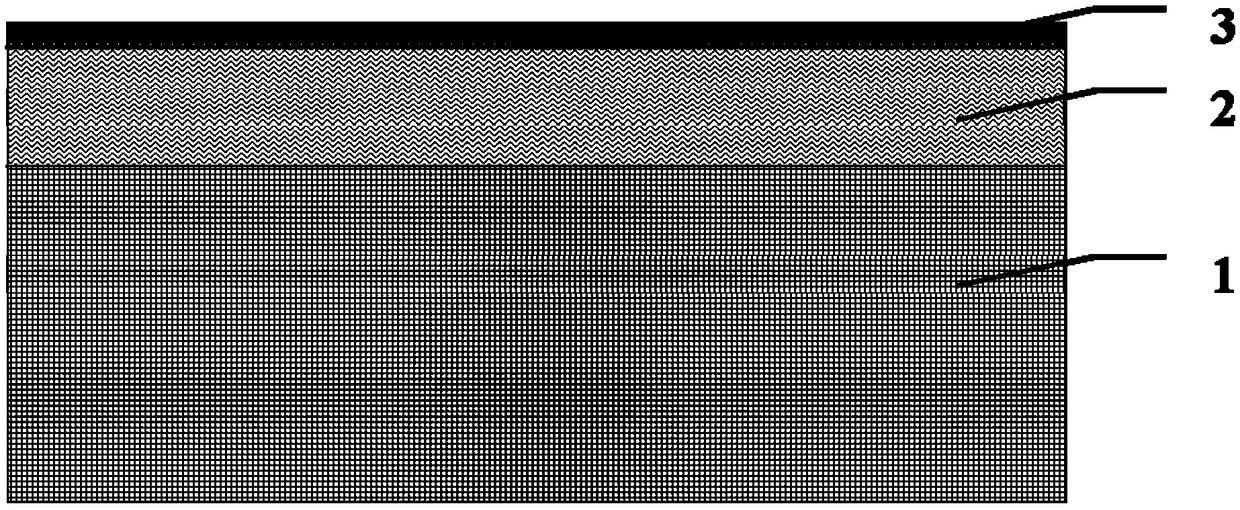

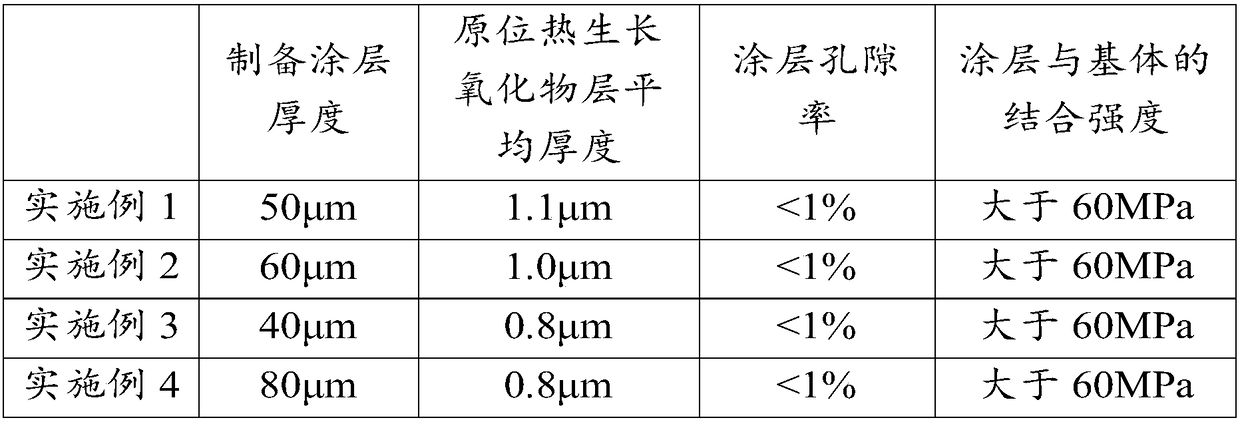

Liquid-state lead bismuth alloy corrosion resisting coating layer and preparation method thereof

ActiveCN108866471ACompact structureUniform and controllable thicknessMolten spray coatingLead bismuthCoated surface

The invention provides a liquid-state lead bismuth alloy corrosion resisting coating layer and a preparation method thereof and relates to the technical field of material surface treatment. The liquid-state lead bismuth alloy corrosion resisting coating layer comprises a matrix, a coating layer body and a thermally-growing oxide layer, wherein the coating layer body is attached to the surface of the matrix, the thermally-growing oxide layer is attached to the surface of the coating layer body, and the coating layer body is prepared from a material of FeCrAlY. The preparation method of the liquid-state lead bismuth alloy corrosion resisting coating layer comprises the steps: preparing the coating layer body on the surface of the pretreated matrix and then directly performing pre-oxidation treatment on the coating layer body. The FeCrAlY coating layer body of the liquid-state lead bismuth alloy corrosion resisting coating layer disclosed by the invention has good combination with the matrix; the liquid-state lead bismuth alloy corrosion resisting coating layer has the advantages of compact structure, even and controllable thickness, low oxygen content and low surface roughness; pre-oxidation is directly performed on the surface of the coating layer body to in situ generate an even, continuous and compact thermally-growing oxide layer, the thermally-growing oxide layer can directly contact a lead bismuth cooling agent for a long time, and liquid-state lead bismuth alloy corrosion resistance of the coating layer body is improved; a preparation process has the advantages of lowcost, high, efficiency, greenness, environmental friendliness and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for preparing lead bismuth alloy for nuclear reactor

ActiveCN102304632AWell mixedSolve problems such as composition segregationOptical rangefindersNuclear energy generationNuclear reactor coreNuclear reaction

The invention relates to a method for preparing a lead bismuth alloy for a nuclear reactor. In the method, the lead bismuth alloy is smelted by vacuum induction. The method comprises the following steps of: 1) putting lead serving as a raw material into a crucible in a glove box, heating to the temperature of between 450 and 800 DEG C, and introducing high-purity hydrogen for pretreatment; 2) passivating the crucible; 3) charging according to design ingredients, cooling the lead, putting into the crucible, and putting bismuth into a hopper; 4) introducing mixed gas of argon and the hydrogen under vacuum of between 0.1 and 10Pa until the mixed gas has the pressure of between 0.01 and 0.5Mpa, and melting at the temperature of between 400 and 600 DEG C, wherein the content of the hydrogen is between 2 and 7 volume percent; 5) adding the bismuth serving as a raw material in batch, and stirring in an electromagnetic and mechanical stirring combination mode; 6) detecting alloy ingredients by using a direct-reading spectrometer, and supplementing alloy elements according to a test result; and 7) pouring at the temperature of between 200 and 400 DEG C under the vacuum after the ingredients are qualified. By the method, the ingredients and purity of the produced lead bismuth alloy meet design requirements, and ingredient segregation and tissue segregation are prevented; the method is suitable for the nuclear reactor; and a process has the characteristics of short production time, high repeatability and low production cost and is easy to operate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

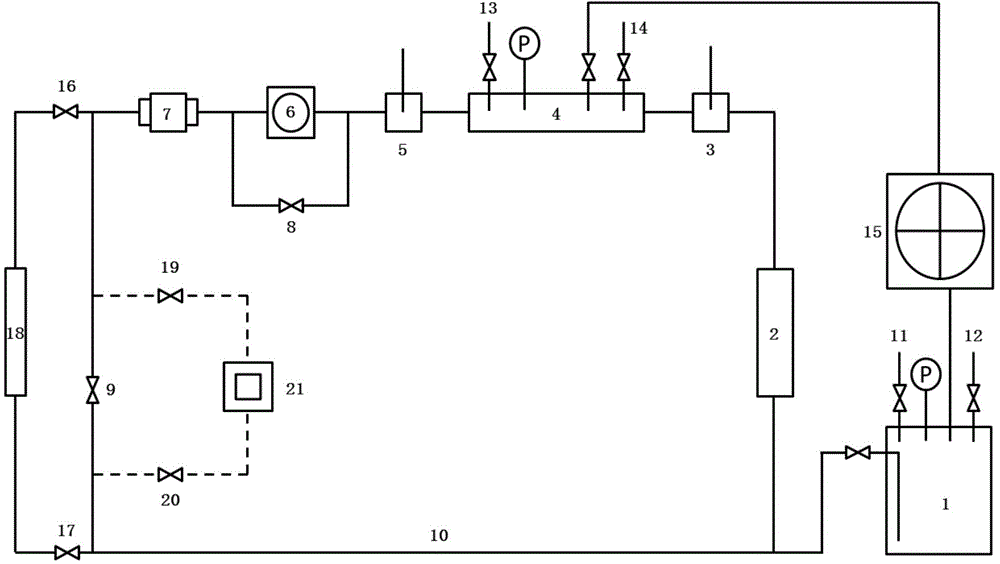

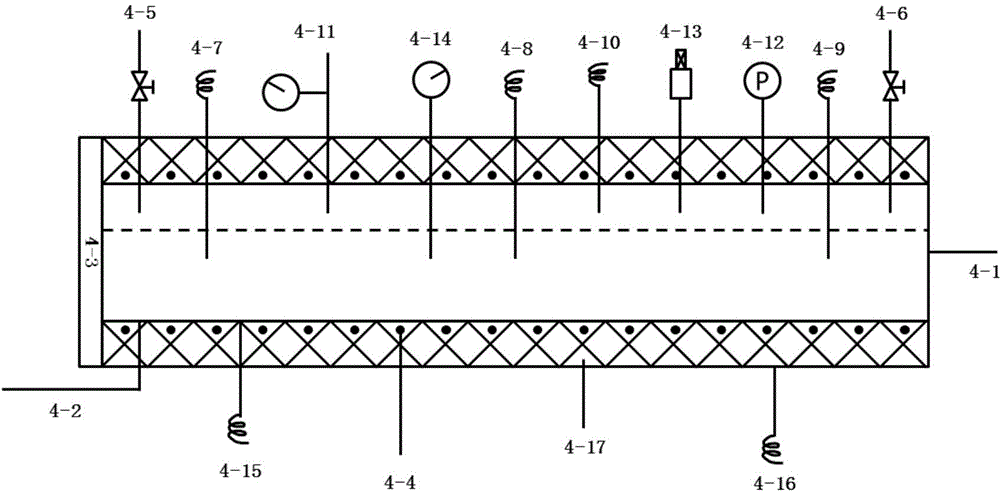

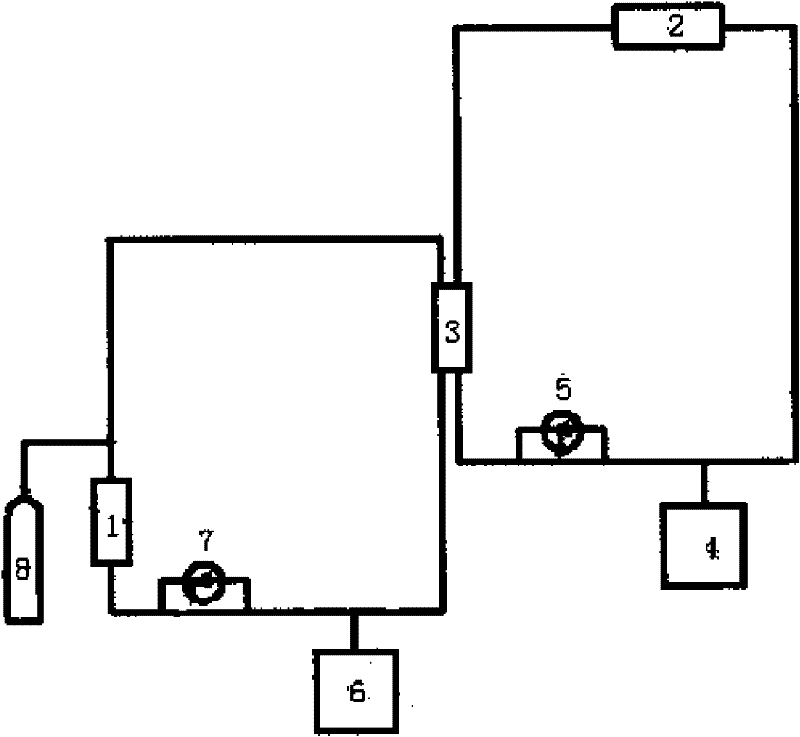

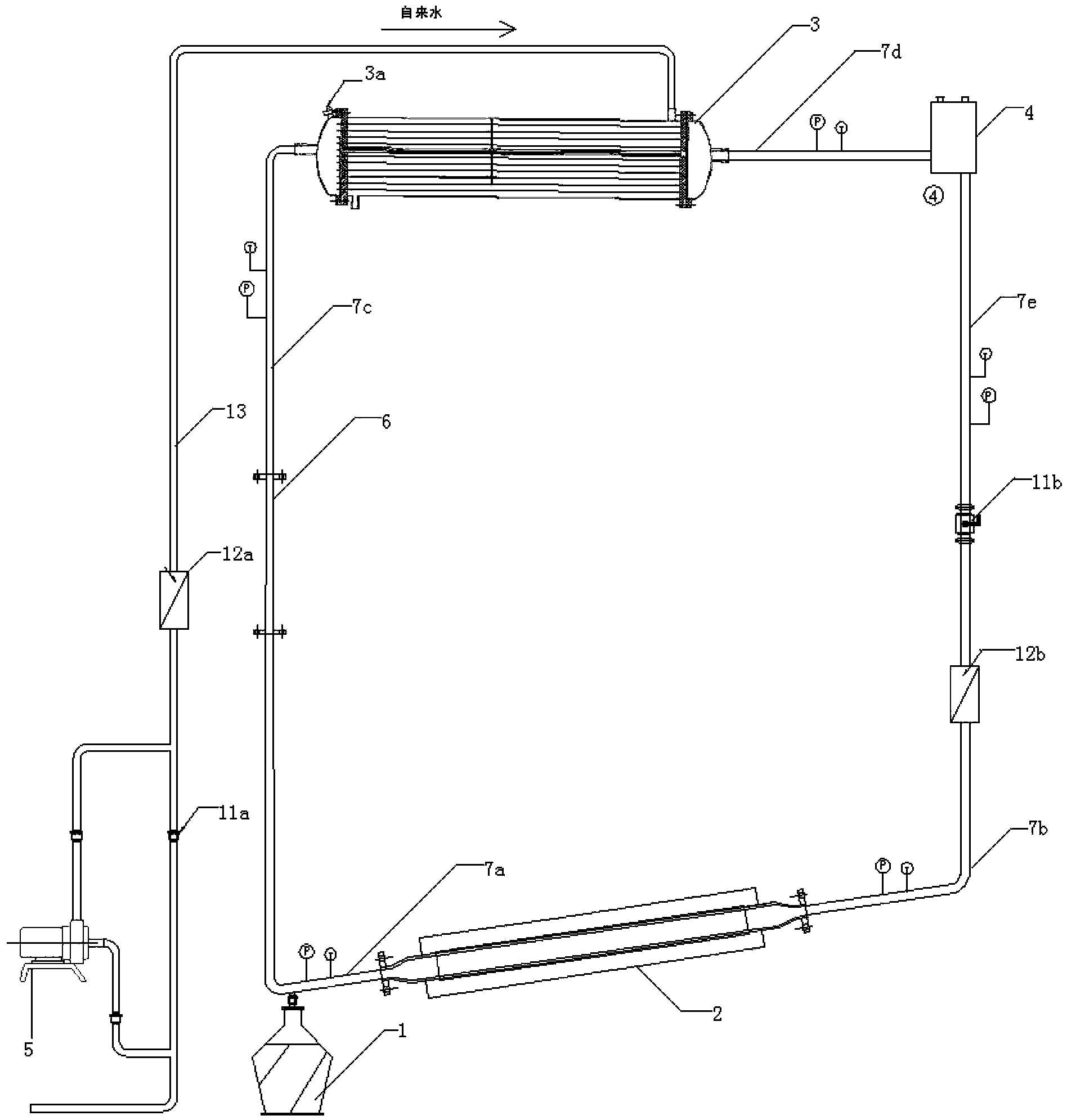

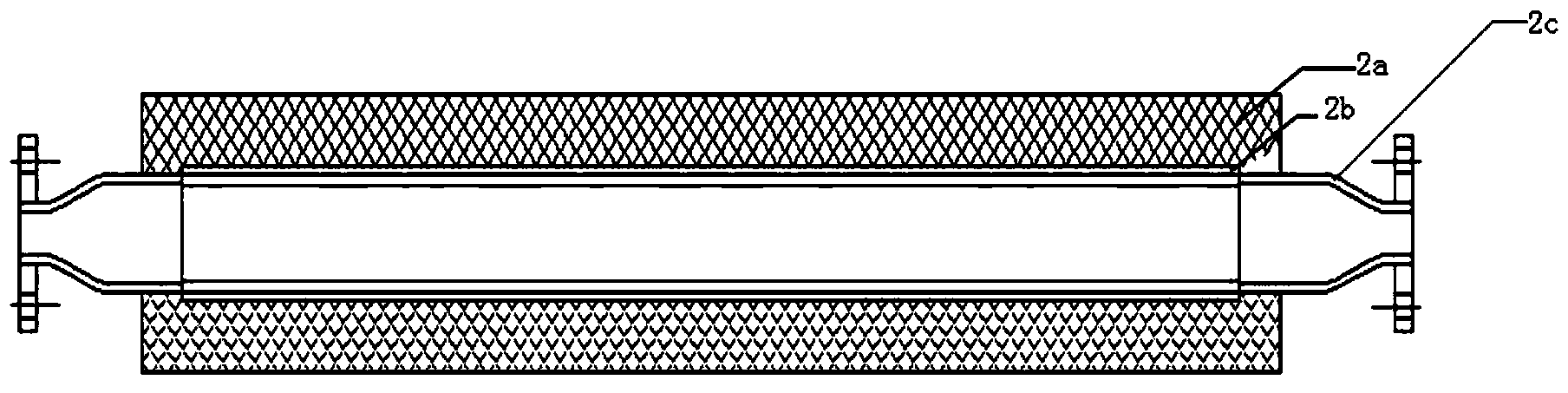

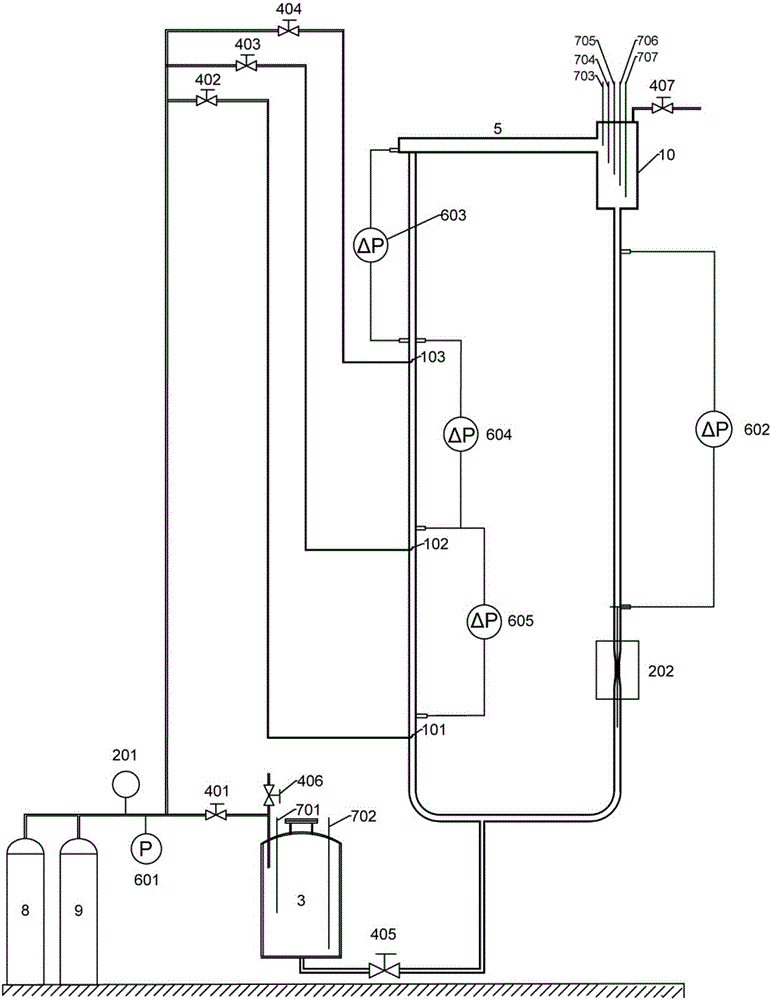

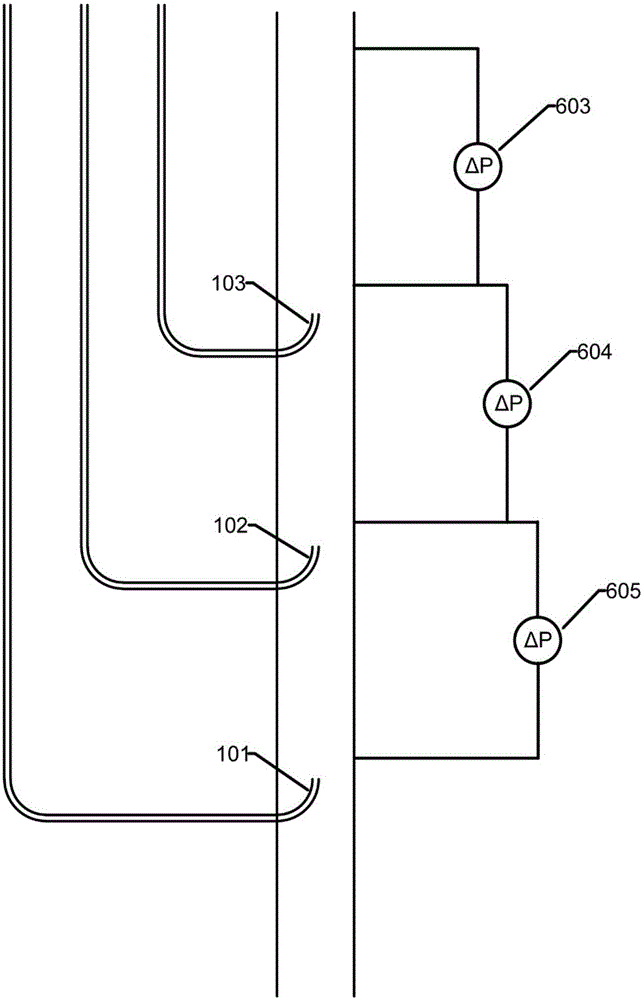

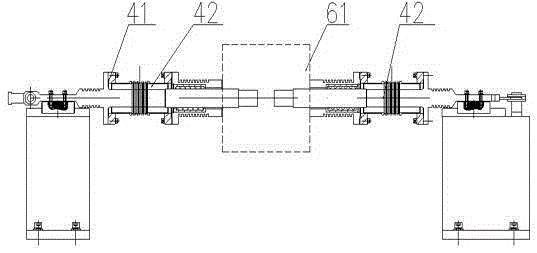

Lead bismuth alloy bubble pump circulation capability experiment system and experiment method thereof

ActiveCN106837769AInjection flow adjustableAvoid cloggingPump testingAerodynamic testingStable stateLead bismuth

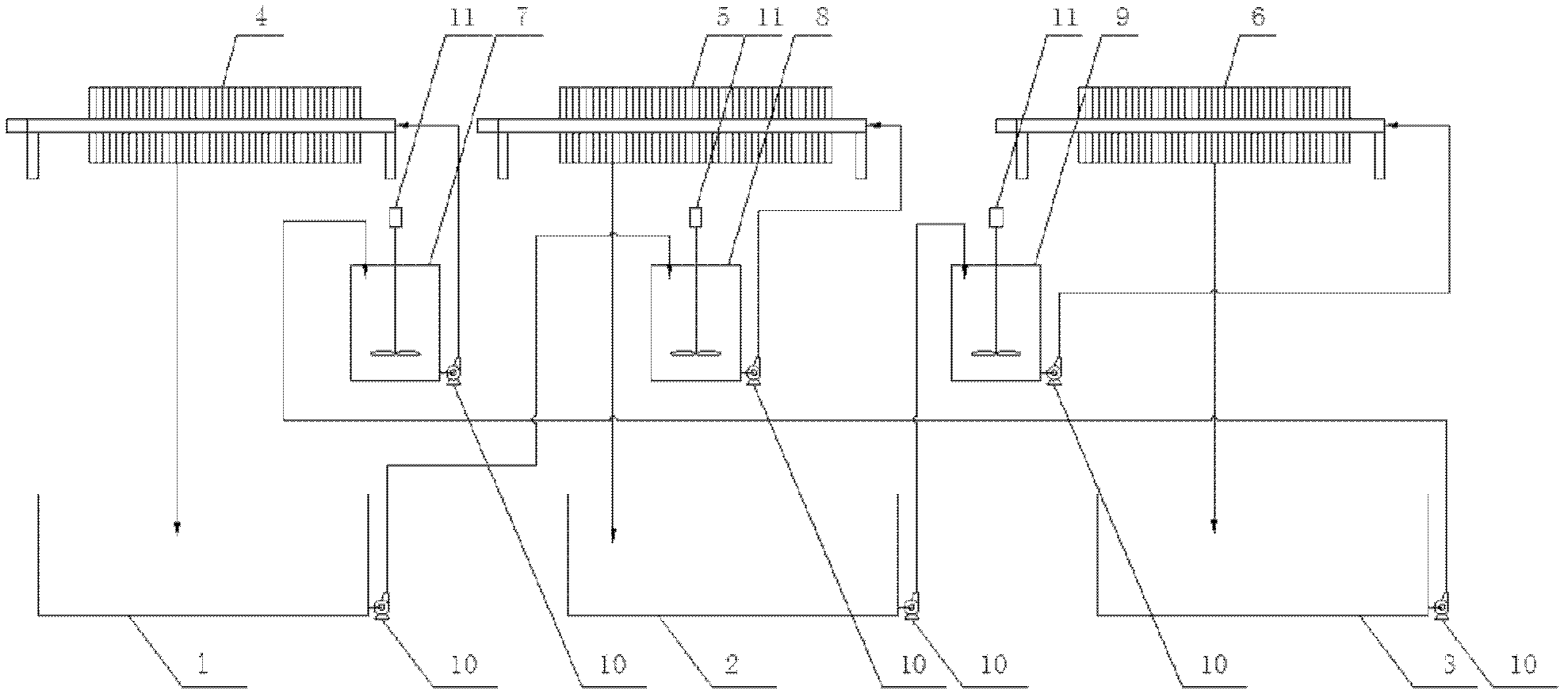

The invention discloses a lead bismuth alloy bubble pump circulation capability experiment system and an experiment method. The system comprises a lead bismuth alloy storing and melting module composed of a lead bismuth alloy storing tank, a liquid level probe, a valve and a pipeline connected to a lead bismuth experiment loop, a gas module composed of an argon bottle, a flow meter, a pressure gauge, a valve and a pipeline connected to the lead bismuth alloy storing tank and an experiment section, an electromagnetic flow meter calibration module composed of an electromagnetic flow meter, a checking cylinder, a liquid level probe and a valve, and an experiment module composed of a gas injection pipe, the experiment section and a measuring instrument. After a lead bismuth alloy is melted in the storing tank, argon is used for pressing the lead bismuth alloy into the experiment loop, and the lead bismuth alloy in the loop subsequently passes through the checking cylinder, a descending section, the electromagnetic flow meter, a horizontal section, the experiment section and a gas-liquid separation section to form closed circulation. The invention further provides the experiment method of the system. The system can bear working conditions with a high temperature and ensure that the lead bismuth alloy cyclically run with a stable state in a large-flow state, and meanwhile system parameters can be simply, conveniently and rapidly adjusted.

Owner:XI AN JIAOTONG UNIV

Alloy welding flux, preparation method thereof and application thereof

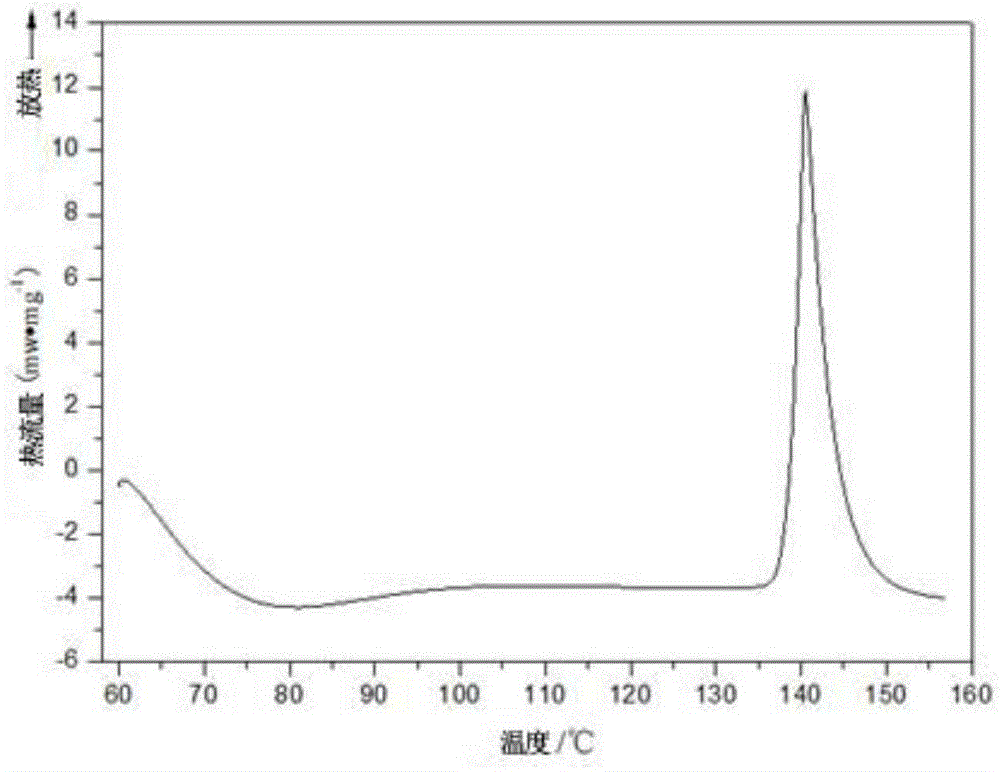

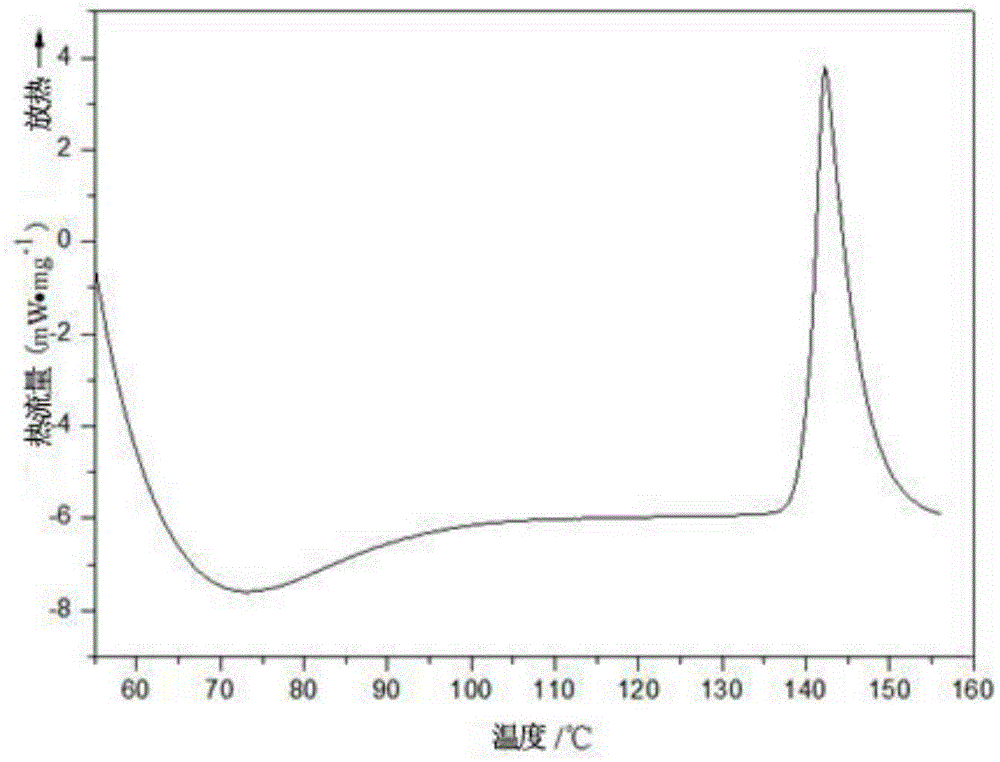

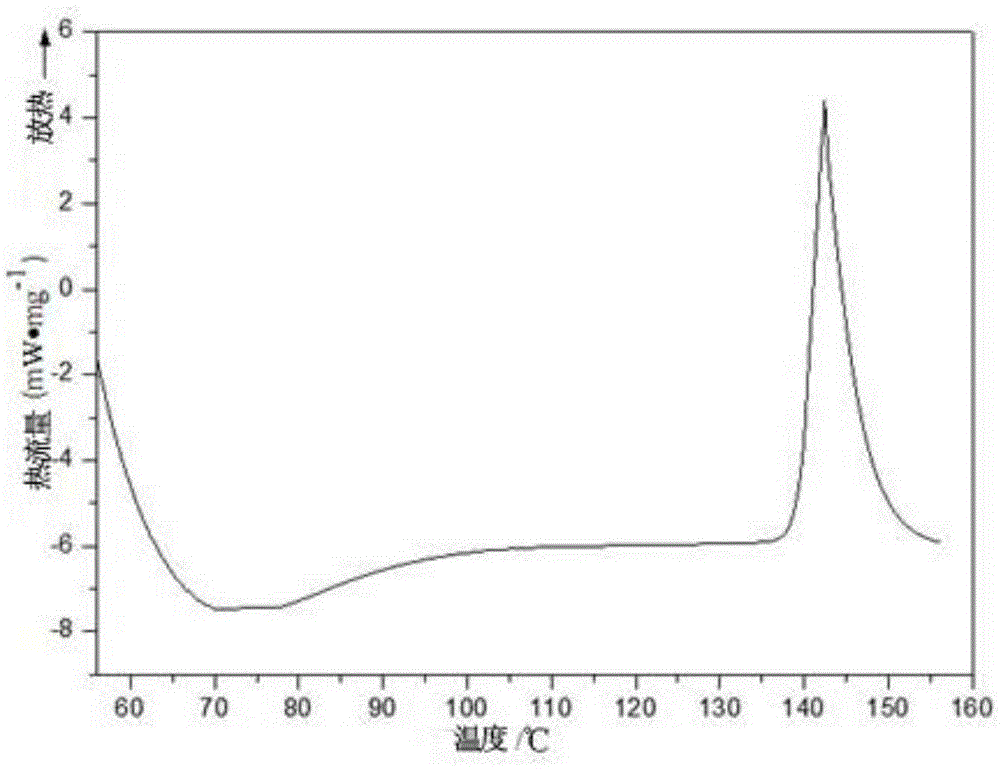

ActiveCN105382443ALow melting pointAchieve integrationWelding/cutting media/materialsSoldering mediaRare-earth elementLead bismuth

The invention relates to low-temperature alloy welding flux, a preparation method thereof and an application thereof. The alloy welding flux comprises the following components in parts by weight: 17-35 parts of tin, 20-45 parts of lead, 20-40 parts of bismuth, 0.1-2 parts of indium, 0.1-0.5 part of antimony, 0.01-0.2 part of phosphor and 0.01-0.8 part of a rare earth element. The alloy welding flux is the alloy welding flux which takes a tin-lead-bismuth three-phase alloy as a principle component, has a melting point lower than 145 DEG C which is lower than a laminating temperature during welding of a tinned copper wire, is suitable for a laminating process of a photovoltaic module, and realizes integration of a welding process and the laminating process of a main-grid-free battery.

Owner:QINGHAI HUANGHE HYDROPOWER DEV +2

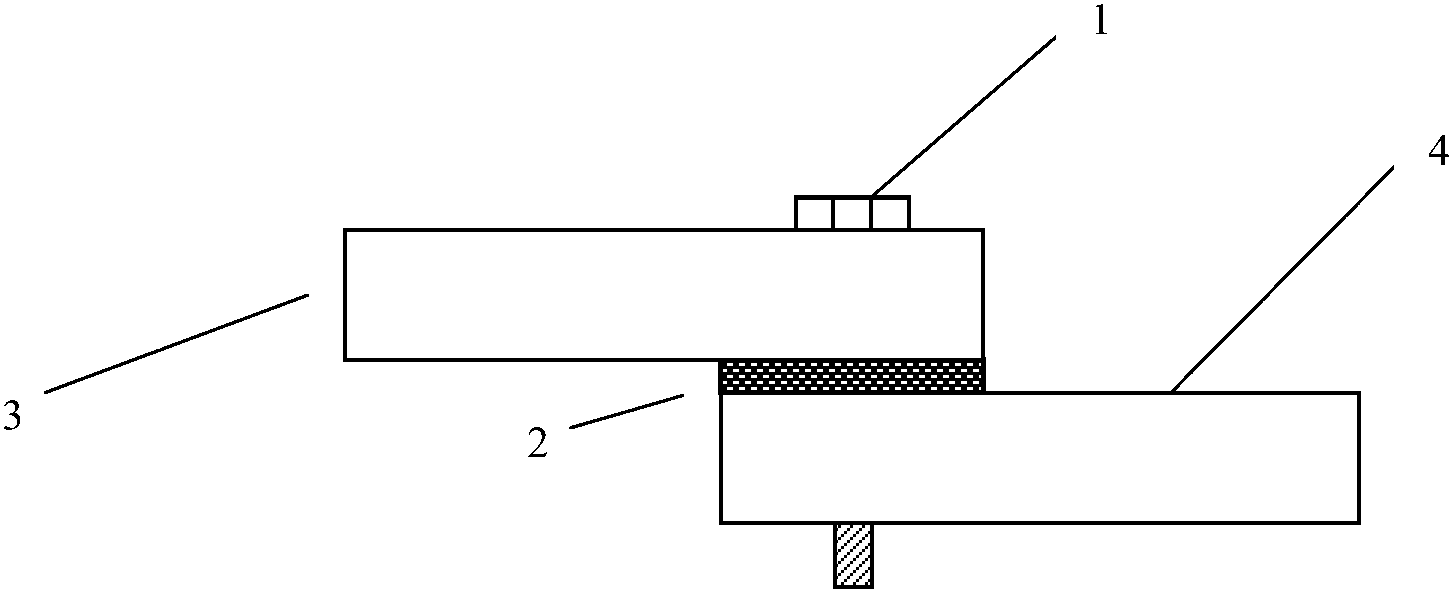

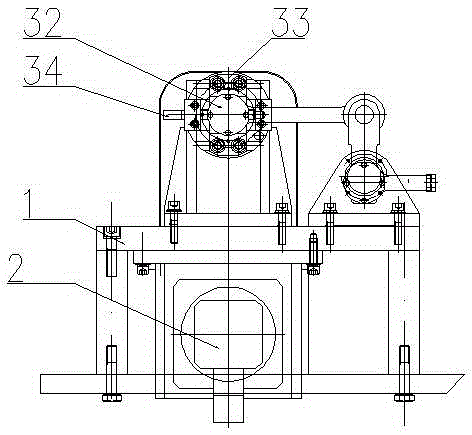

High-temperature vacuum fretting corrosion-wear test bed

The invention discloses a high-temperature vacuum fretting corrosion-wear test bed. The high-temperature vacuum fretting corrosion-wear test bed comprises a rack, a servo motor, a displacement adjustment device, a displacement executing mechanism, a friction force measuring mechanism, a friction pair system, a test force loading mechanism, a lead bismuth alloy cavity, a circulating water way and a vacuum system, the vacuum system is arranged in the interiors of the displacement executing mechanism, the friction force measuring mechanism and the test force loading mechanism, the vacuum system comprises a fusing cavity and a vacuum test cavity, the circulating water way is welded to the outer wall of the vacuum test cavity, a cavity body of the vacuum test cavity is further provided with an inflation valve which can introduce protective gas into the cavity body of the vacuum test cavity, and the fusing cavity and the vacuum test cavity together use a vacuum pumping device and are connected with a pipeline system attached with a heating device; the lead bismuth alloy cavity is filled with lead bismuth alloy, the lead bismuth alloy is melted through the fusing cavity and enters the test cavity, and a lead bismuth alloy testing environment is formed.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI +1

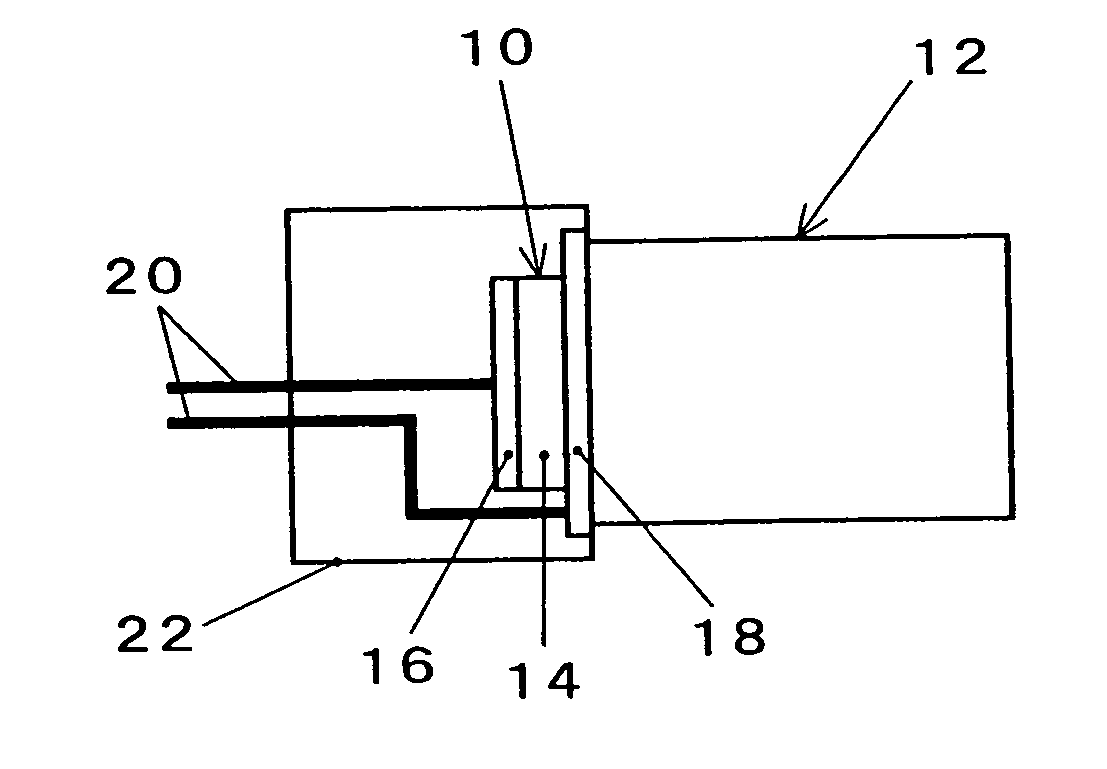

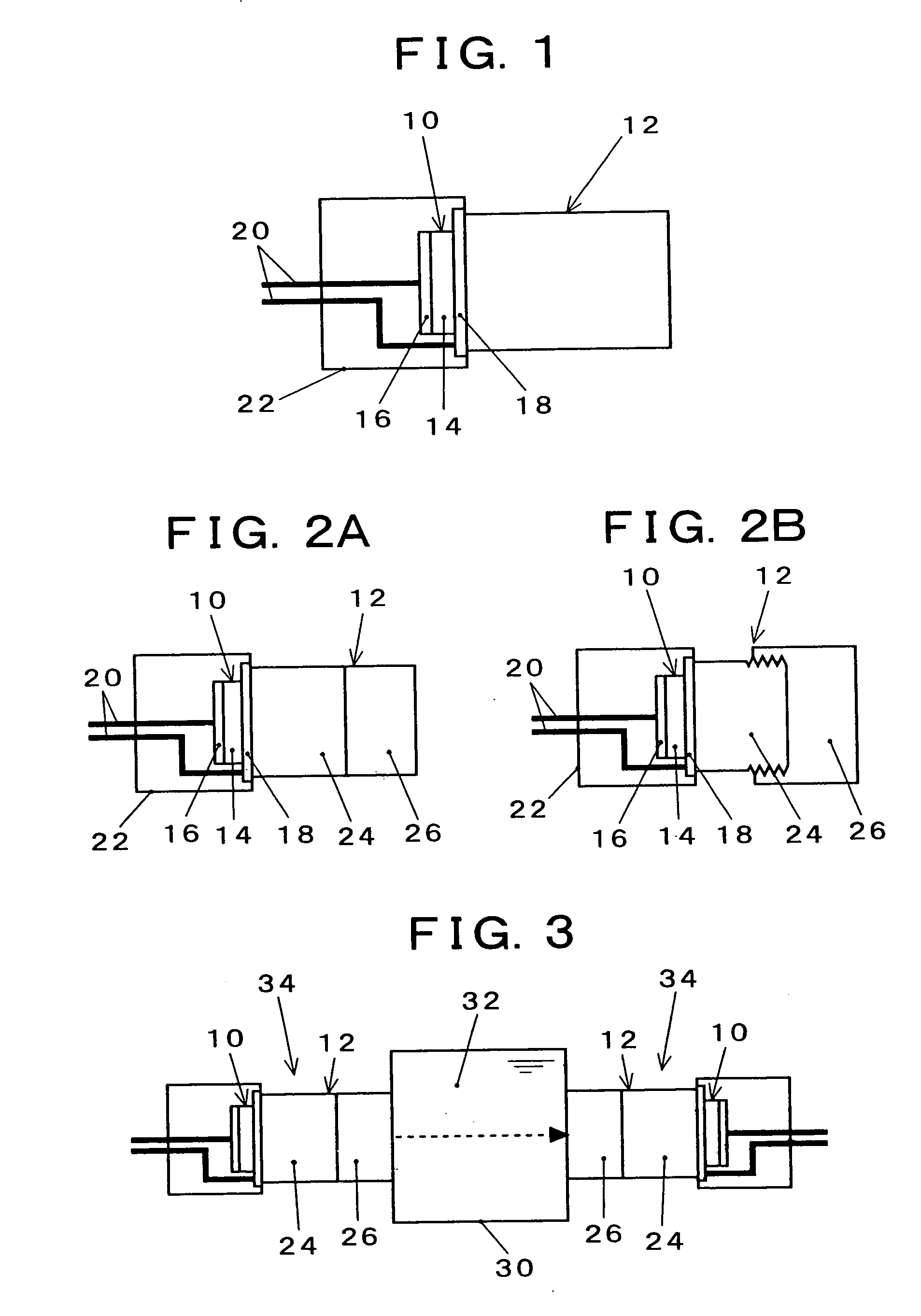

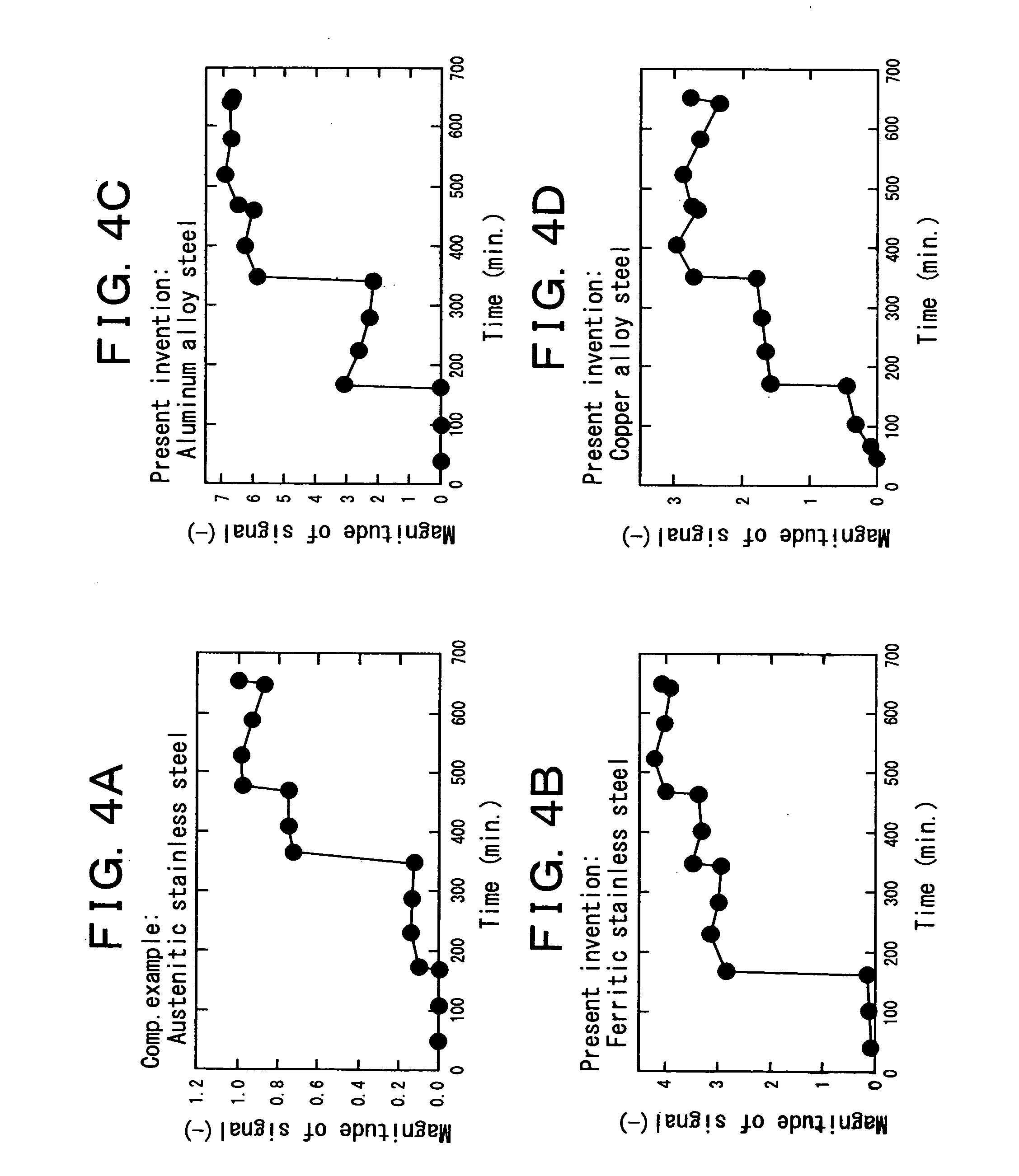

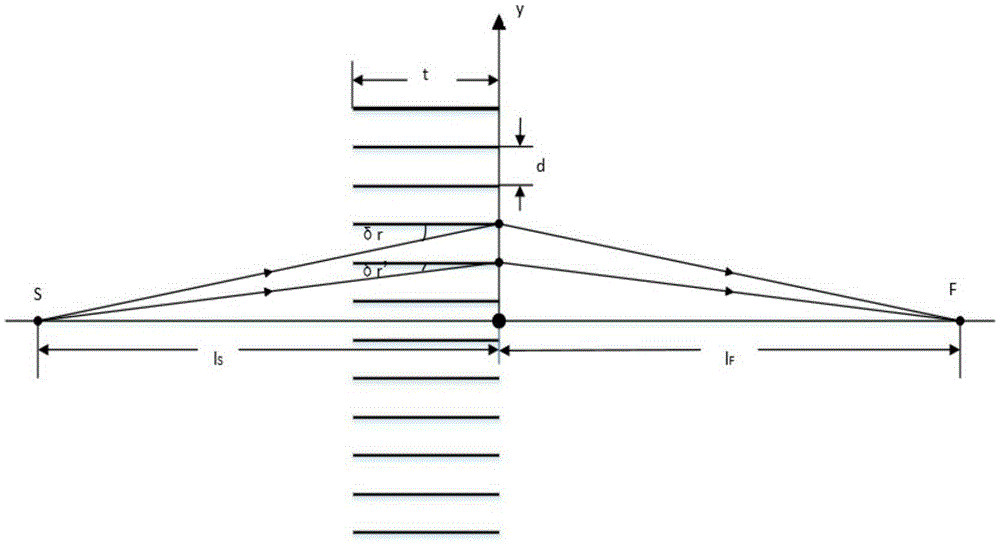

Ultrasonic transducer for liquid metal

InactiveUS20060260929A1Increase sound pressureDiscriminationVolume/mass flow measurementVolume meteringLead bismuthUltrasonic sensor

In an ultrasonic transducer comprising a combination of an ultrasonic oscillator 10 and an oscillation transmission section 12 and is capable of sending ultrasonic waves into liquid heavy metal through the oscillation transmission section and receiving ultrasonic waves transmitted in the liquid heavy metal, at least a front end wetted portion coming into contact with the liquid heavy metal (e.g. lead-bismuth) of the oscillation transmission section is made of any of ferritic stainless steel, aluminum alloy steel having an aluminum content of 70% or more and copper alloy steel having a copper content of 50% or more. The ultrasonic transducer improves sound pressure transmission efficiency by optimizing acoustic coupling in a wetted interface, thereby facilitating entering of ultrasonic saves into liquid heavy metal and enabling measurement of flow rate, flow velocity, temperature, liquid level, etc. with ease and high precision.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

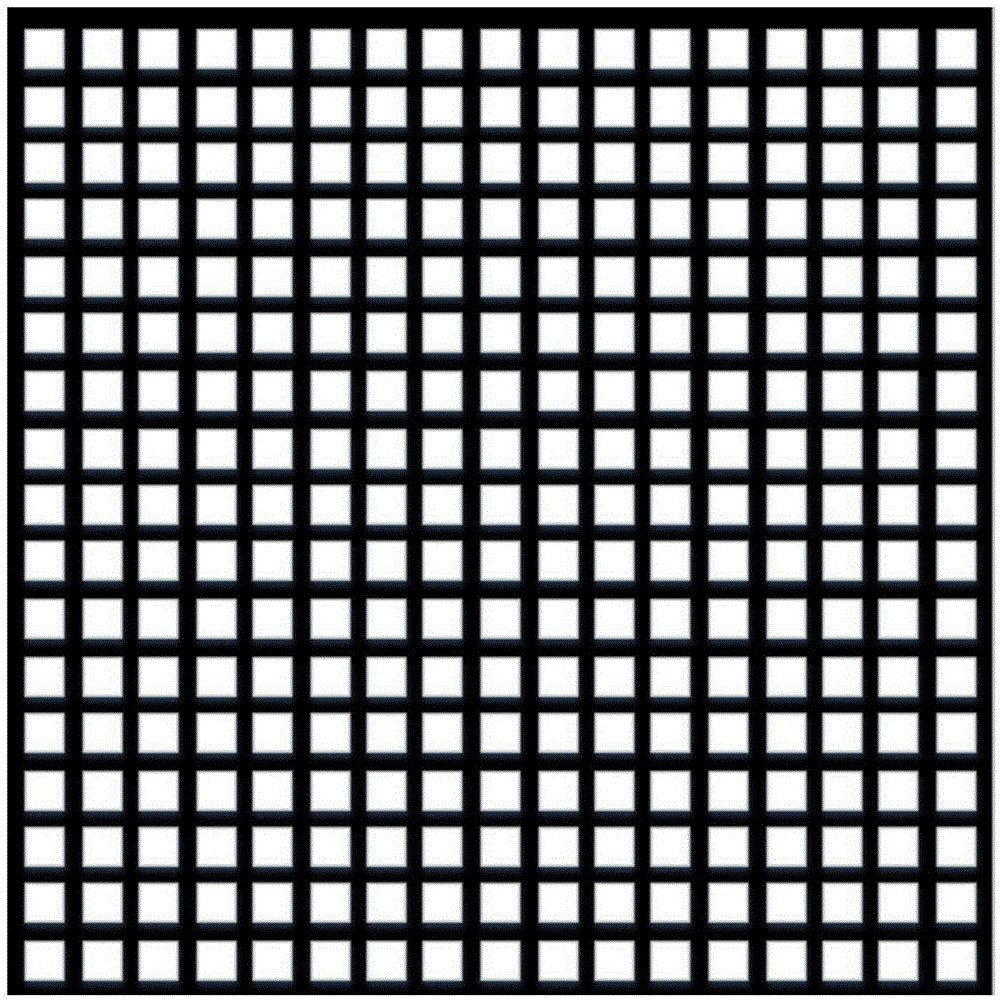

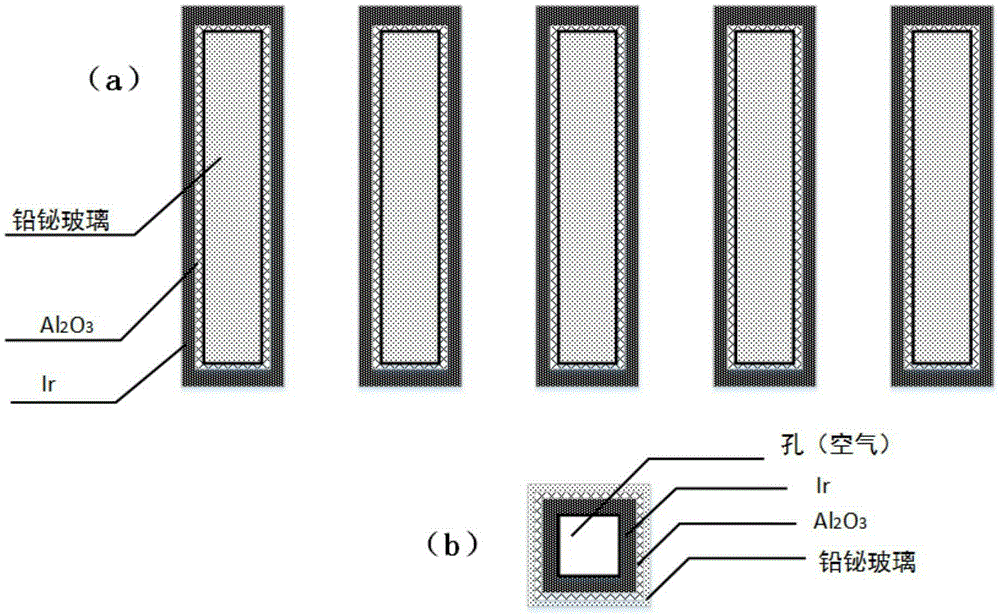

Method and product for improving microchannel plate soft X-ray-extreme ultraviolet ray imaging performance

InactiveCN105349962AHigh feasibilityIncrease reflectionElectron multiplier detailsChemical vapor deposition coatingUltravioletOxygen

The invention discloses a method and product for improving microchannel plate soft X-ray-extreme ultraviolet ray imaging performance. The method includes the steps that gaseous aluminium trimethide serves as an aluminum source, gaseous deionized water servers as an oxygen source, high-purity nitrogen serves as carrier gas and cleaning gas, an atom layer deposition system is utilized, and an aluminum oxide film is deposited on a square-hole microchannel plate made of lead-bismuth glass; and solid iridium acetylacetonate serves as an iridium source, metal iridium reduction is conducted with high-purity oxygen as an oxygen source, the high-purity nitrogen serves as the carrier gas and the cleaning gas, the atom layer deposition system is utilized, and the iridium film is deposited. Compared with an untreated microchannel plate, according to an aperture inner wall reflection increasing film of the square-hole microchannel plate manufactured through the method, the iridium serves as the metal reflection increasing film, and reflection efficiency is improved remarkably, so that the light intensity efficiency of the microchannel plate in the soft X-ray-extreme ultraviolet waveband imaging process can be improved effectively. By means of the method, the performance of the square-hole microchanel plate is improved, and application of the microchannel plate in a grazing incidence imaging system such as an X-ray telescope is further promoted.

Owner:ZHEJIANG UNIV

Bullion lead comprehensive treatment method

ActiveCN110172578AAchieve enrichmentImprove direct yieldAntimony oxides/hydroxides/oxyacidsLead halidesElectrolysisAntimony trioxide

The invention belongs to the technical field of solid waste recycling and reusing and particularly relates to a bullion lead comprehensive treatment method. Through the bullion lead comprehensive treatment method provided by the invention, open-circuit of arsenic, lead, bismuth and antimony and high-efficiency enrichment of precious metals gold and silver are realized through twice vacuum distillation, and elementary arsenic, a lead-bismuth-antimony alloy, a silver alloy and a copper alloy can be obtained respectively; the lead-bismuth-antimony alloy, the silver alloy and the copper alloy aretreated through oxidizing refining, electrolytic refining and chlorination refining to obtain refined lead, refined bismuth, antimony trioxide and electrolytic silver and electrolytic silver, and goldenrichment is realized; the bullion lead comprehensive treatment method has the advantages of being high in metal direct yield, low in energy consumption, short in flow, simple in equipment and the like in the whole treatment process; and moreover, vacuum distillation belongs to the physical process; the alloys can be separated through the saturated vapor pressure difference of the metals withoutgeneration of waste water, waste gas and waste residues, and industrialization, automation and continuity of bullion lead treatment can be achieved easily.

Owner:KUNMING UNIV OF SCI & TECH +1

Fuel assembly for lead bismuth stack

InactiveCN106782682AImprove heat transfer efficiencyAvoid overall overheatingFuel elementsNuclear energy generationLead bismuthFixed frame

The present invention provides a fuel assembly for a lead bismuth stack, the fuel assembly includes an inner shaft, a bearing part, a casing and a fuel element; the inner shaft is arranged in the casing by the positioning and supporting effect of the bearing part, the inner shaft and the casing are locked and released by up-and-down moving of the inner shaft, beneficial effects are that on the basis of the compact space layout of the lead bismuth stack and heat transfer characteristics of a primary circuit lead bismuth coolant, the heat transfer efficiency of a primary circuit can be improved by optimization of a cooling channel of the fuel element and positioning design of a locking device, overheating of the fuel assembly is prevented, reliable locking and releasing operation of the fuel assembly and an outer fixed frame can be realized, and large size tube type fuel assembly device used at present in the prior art can be replaced.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com