Method for reducing contact resistance based on low-melting-point metal and oxide thereof

A low-melting-point metal and contact resistance technology, applied in the direction of metal/alloy conductors, circuits, connections, etc., can solve the problems of limited effect of filling conductive paste on the contact interface, increased maintenance costs, limited conductivity, etc., to improve power transmission efficiency, The effect of prolonging the service life of equipment and improving the efficiency of electric energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

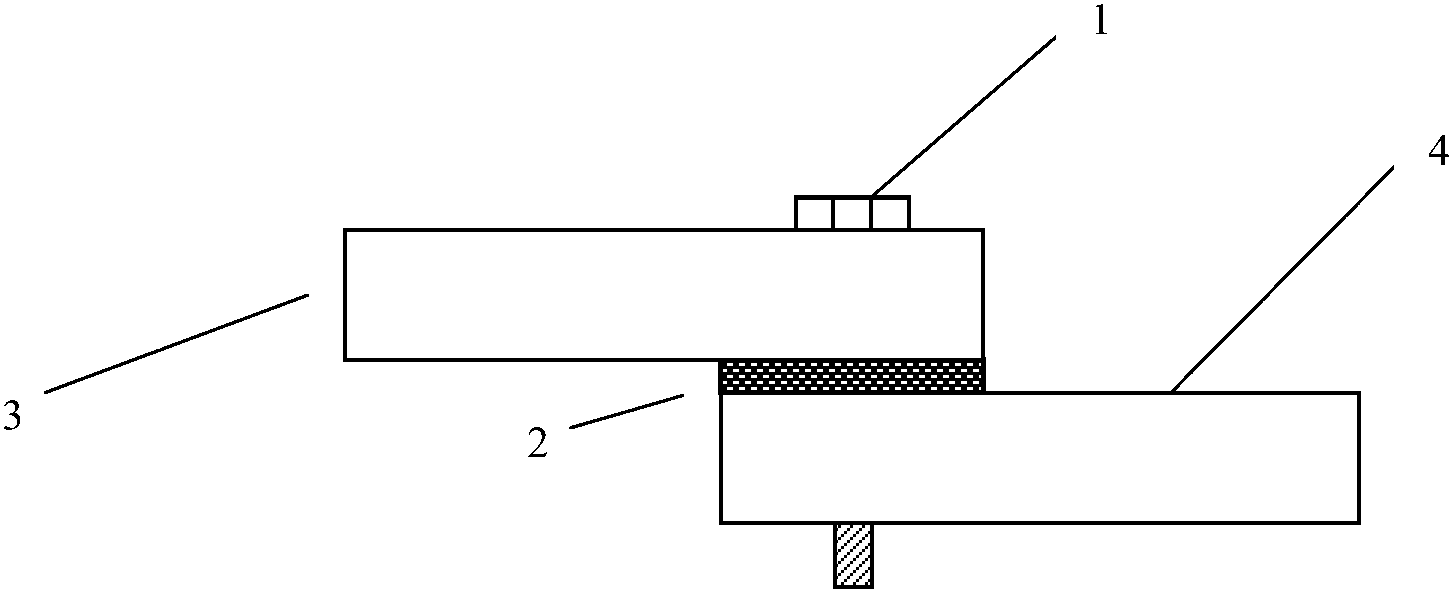

[0021] The invention provides a method for reducing contact resistance by using low melting point metal and its oxide. Such as figure 1 As shown, the component consists of fastening screws 1, a mixture of low melting point metals and their oxides 2, two smooth rectangular electrical connectors (that is, metal sheets with screw holes) 3, 4. The size of the electrical connector 3 is 6cm×3cm×1cm; the size of the electrical connector 4 is 6cm×3cm×1cm. The electric connector 3 and the electric connector 4 are made of red copper (in addition, they can also be aluminum or stainless steel); the fastening screw 1 is made of brass.

[0022] The conductive paste (mixture 2 of low melting point metal and its oxide) of the present invention is composed of gallium indium tin alloy and gallium oxide, wherein the mass fraction of gallium oxide is 1%. When in use, evenly coat the mixture 2 of the low melting point metal and its oxide on the contact surface of the metal sheet 3 and make it fu...

Embodiment 2

[0025] The invention provides a method for reducing contact resistance by using low melting point metal and its oxide. Such as figure 1 As shown, the component consists of fastening screws 1, a mixture of low melting point metals and their oxides 2, two smooth rectangular electrical connectors (that is, metal sheets with screw holes) 3, 4. The size of the electrical connector 3 is 10 cm×5 cm×1 cm; the size of the electrical connector 4 is 10 cm×5 cm×1 cm. The electric connector 3 and the electric connector 4 are made of stainless steel (in addition, they can also be aluminum or copper); the fastening screw 1 is made of brass.

[0026] The conductive paste (mixture 2 of low melting point metal and its oxide) of the present invention is composed of gallium indium copper bismuth alloy, gallium oxide and indium oxide, wherein the mass fraction of gallium oxide is 2%, and the mass fraction of indium oxide is 1%. When in use, evenly coat the mixture 2 of the low melting point meta...

Embodiment 3

[0029] The invention provides a method for reducing contact resistance by using low melting point metal and its oxide. Such as figure 1 As shown, the component consists of fastening screws 1, a mixture of low melting point metals and their oxides 2, two smooth rectangular electrical connectors (that is, metal sheets with screw holes) 3, 4. The size of the electrical connector 3 is 8cm×8cm×4cm; the size of the electrical connector 4 is 8cm×8cm×4cm. The electric connector 3 is made of stainless steel, the electric connector 4 is made of red copper; the fastening screw 1 is made of brass.

[0030] The conductive paste (mixture 2 of low melting point metal and its oxide) of the present invention is composed of gallium-tin-silver-copper alloy, gallium oxide and copper oxide, wherein the mass fraction of gallium oxide is 3%, and the mass fraction of copper oxide is 1%. When in use, evenly coat the mixture 2 of the low melting point metal and its oxide on the contact surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com