Method for recovering valuable metals from copper anode mud flotation tailings

A technology for flotation tailings and copper anode slime, which is applied in the direction of non-metallic elements, chemical instruments and methods, and process efficiency improvement, can solve the problems of increasing production costs in the copper smelting process, and achieve high direct recovery rate and efficient recovery , the effect of high metal removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

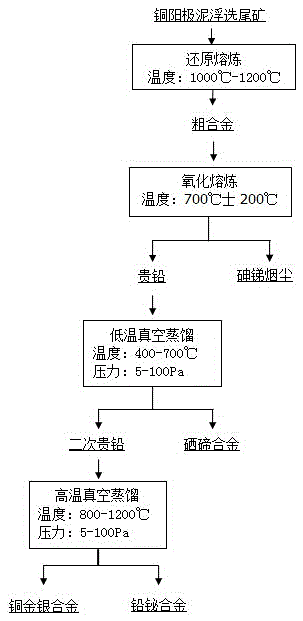

[0022] Such as figure 1 As shown, the method for recovering valuable metals from copper anode slime flotation tailings, its specific steps are as follows:

[0023] (1) First, the copper anode slime flotation tailings are reduced and smelted to obtain the reduced product, and then the reduced product is oxidized and blown to obtain noble lead and arsenic-containing antimony soot; the original smelting conditions are: add charcoal, and the carbon ratio is 1 : 1.2, the temperature is 1000°C, the smelting time is 2.5 hours; the oxidation blowing conditions are: feed oxygen enrichment, the flow rate is 0.2L / min, the temperature is 800°C, and the holding time is 0.5 hours;

[0024] (2) One-stage low-temperature vacuum distillation: The precious lead obtained in step (1) is subjected to a low-temperature vacuum distillation for 1.5 hours at a temperature of 500°C and a pressure of 35Pa. After the vacuum distillation stage is over, keep the vacuum pump and cooling water continuously w...

Embodiment 2

[0030] Such as figure 1 As shown, the method for recovering valuable metals from copper anode slime flotation tailings, its specific steps are as follows:

[0031] (1) First, the copper anode slime flotation tailings are reduced and smelted to obtain the reduced product, and then the reduced product is oxidized and blown to obtain noble lead and arsenic-containing antimony soot; the original smelting conditions are: add charcoal, and the carbon ratio is 1 : 0.5, the temperature is 1200°C, the melting time is 0.5 hours; the oxidation blowing conditions are: feed oxygen enrichment, the flow rate is 0.5L / min, the temperature is 900°C, and the holding time is 2.5 hours;

[0032] (2) One-stage low-temperature vacuum distillation: The precious lead obtained in step (1) is subjected to a low-temperature vacuum distillation for 2 hours at a temperature of 600°C and a pressure of 35 Pa. After the vacuum distillation stage is over, keep the vacuum pump and cooling water working continuo...

Embodiment 3

[0038] Such as figure 1 As shown, the method for recovering valuable metals from copper anode slime flotation tailings, its specific steps are as follows:

[0039] (1) First, 2000g of copper anode slime flotation tailings (copper anode slime flotation tailings include the following mass percentage components: Au0.01%, Ag0.02%, Cu<5%, Se10%, Te30%, Pb30%, As<5%, Sb5%, Bi20%) obtain reduction products by reduction smelting, and then oxidize the reduction products to obtain noble lead and arsenic-containing antimony soot; the original smelting conditions are: adding charcoal, carbon ratio The temperature is 1:2, the temperature is 1100°C, and the melting time is 3 hours; the oxidation blowing conditions are: feed oxygen enrichment, the flow rate is 0.1L / min, the temperature is 500°C, and the holding time is 3 hours;

[0040] (2) One-stage low-temperature vacuum distillation: The precious lead obtained in step (1) is subjected to a low-temperature vacuum distillation for 1 hour a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com