Method and device for recovering valuable elements from lead-silver-bismuth slag in copper smelting

A technology for copper smelting and bismuth slag, which is applied in the fields of bismuth, gold, silver and sulfur, and the recovery of lead, copper and arsenic. and other problems, to achieve the effect of good production environment, high metal recovery rate and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

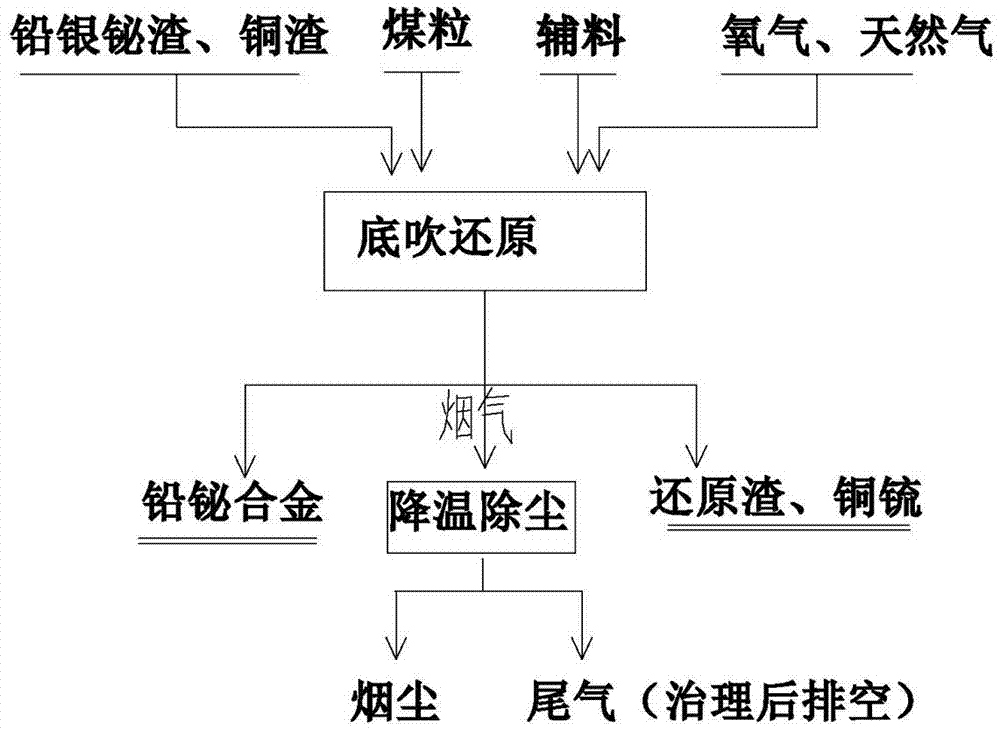

[0030] Embodiment 1: as figure 1 Shown, a kind of method that collects valuable element from the lead-silver-bismuth slag of copper smelting, this method comprises the following steps:

[0031] 1) The lead-silver-bismuth slag, the copper slag with a copper content of 5-20%, the reducing agent and the slagging flux are mixed according to the weight ratio: lead-silver-bismuth slag: copper slag: reducing agent: slagging flux=1 : 2:1:5 metering, batching and mixing granulation to form pellets;

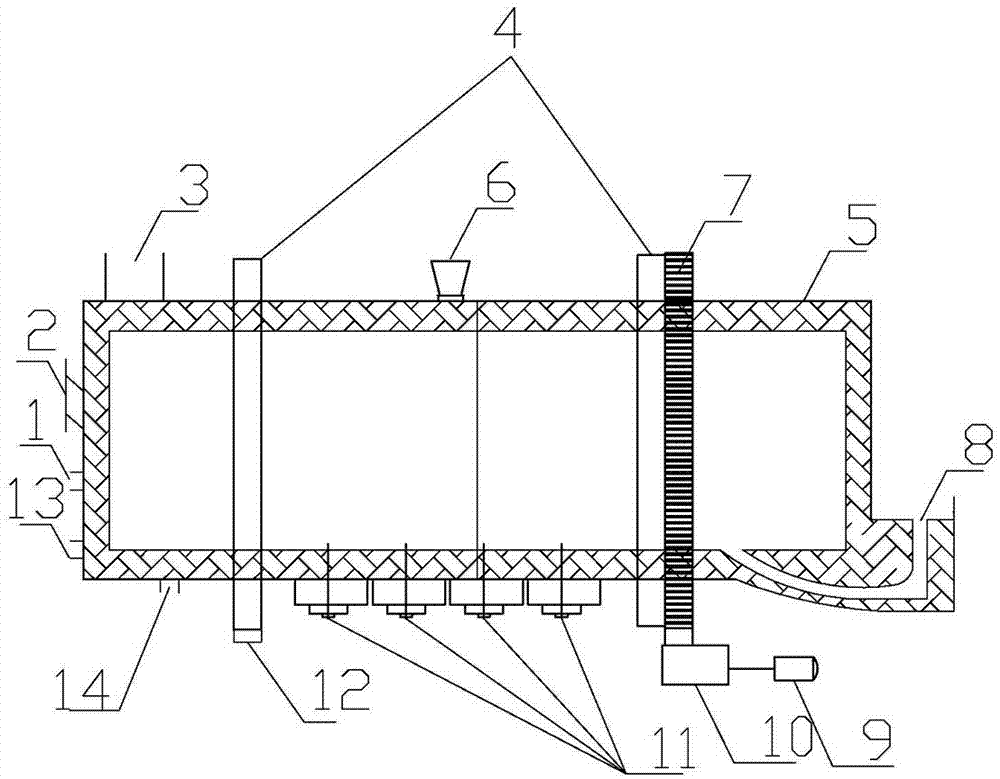

[0032] 2) Turn on the gas immersion combustion device, and the oxygen consumption per ton of material is 20~200Nm3 Add oxygen and fuel with a purity of 50~99.99% and spray it into the furnace, then put the pellets made in step 1) into the bottom-blown alloy furnace, the fuel will burn to release heat, and keep the temperature in the furnace at 800°C~1200°C , so that the materials added to the bottom-blown alloy furnace are continuously melted to form a molten pool, and under the stirring ...

Embodiment 2

[0037] Embodiment 2: as figure 1 Shown, a kind of method that collects valuable element from the lead-silver-bismuth slag of copper smelting, this method comprises the following steps:

[0038] 1) The lead-silver-bismuth slag, the copper slag with a copper content of 5-20%, the reducing agent and the slagging flux are mixed according to the weight ratio: lead-silver-bismuth slag: copper slag: reducing agent: slagging flux=1 : 2:1:5 metering, batching and mixing granulation to form pellets;

[0039] 2) Turn on the gas immersion combustion device, and the oxygen consumption per ton of material is 20~200Nm 3 Add oxygen and fuel with a purity of 50~99.99% and spray it into the furnace, then put the pellets made in step 1) into the bottom-blown alloy furnace, the fuel will burn to release heat, and keep the temperature in the furnace at 800°C~1200°C , so that the materials added to the bottom-blown alloy furnace are continuously melted to form a molten pool, and under the stirrin...

Embodiment 3

[0044] Embodiment 3: as figure 1 Shown, a kind of method that collects valuable element from the lead-silver-bismuth slag of copper smelting, this method comprises the following steps:

[0045] 1) The lead-silver-bismuth slag, the copper slag with a copper content of 5-20%, the reducing agent and the slagging flux are mixed according to the weight ratio: lead-silver-bismuth slag: copper slag: reducing agent: slagging flux=1 : 2:1:5 metering, batching and mixing granulation to form pellets;

[0046] 2) Turn on the gas immersion combustion device, and the oxygen consumption per ton of material is 20~200Nm 3 Add oxygen and fuel with a purity of 50~99.99% and spray it into the furnace, then put the pellets made in step 1) into the bottom-blown alloy furnace, the fuel will burn to release heat, and keep the temperature in the furnace at 800°C~1200°C , so that the materials added to the bottom-blown alloy furnace are continuously melted to form a molten pool, and under the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com