Sliding bearing based on structure energizing material and preparation method thereof

A sliding bearing and energy-enabling technology, which is applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as poor lubrication performance, and achieve the effects of improving anti-rust ability, suppressing fatigue cracks, and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

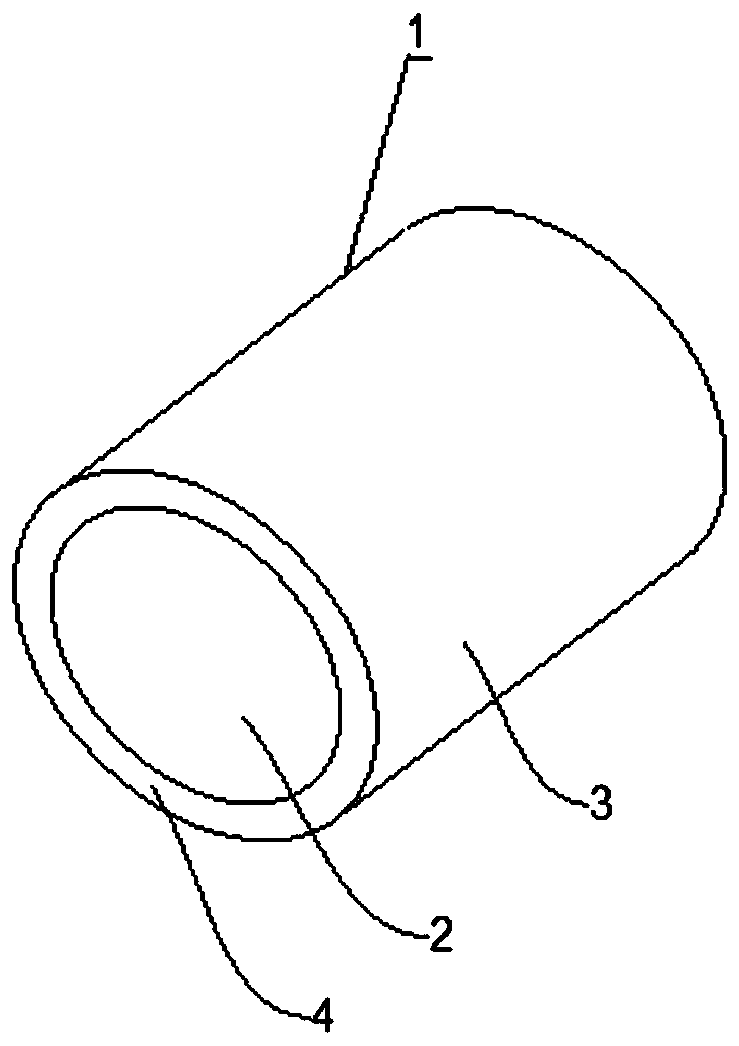

Image

Examples

preparation example Construction

[0047] A method for preparing a sliding bearing based on a structure-enabling material, comprising the following steps:

[0048] Step 1, melting the preset composition material into molten iron in an intermediate frequency induction furnace, the preset composition material is composed of the following components: C: 3.4%-3.6%, Si: 1.6-1.7%, Mn: ≤0.3%, P: ≤0.015%, S: ≤0.015%, Cr: ≤0.3%, other alloying elements: ≤0.5%, the balance is Fe, of which, the carbon content is 99.95%-100% of the theoretical carbon equivalent; add inoculants to molten iron and spheroidizing agent, so that the final silicon content of molten iron after inoculation and spheroidizing treatment is 2.7±0.1%, and the residual magnesium content is 0.04±0.005%;

[0049] The inoculant can promote the spheroidization of graphite, reduce the tendency of whitening, improve the morphology and distribution of graphite, increase the number of eutectic clusters, and refine the matrix structure. Generally, it takes 5-8 m...

Embodiment

[0060] Make a self-lubricating sliding bearing with an outer diameter of 100mm, a wall thickness of 6mm, and a length of 120mm.

[0061] Select QT500-10 grade ductile iron material to draw hollow pipes with an outer diameter of 103mm and an inner diameter of 83mm. The inner diameter of the mold graphite bushing is 103.5mm.

[0062] The casting materials (60% Q14# bread iron, 20% low-carbon steel leftovers, 20% nodular iron return material) are melted into molten iron in an electric furnace, and adjusted to the mass percentage of the following components: C: 3.4%-3.6% , Si: 1.6-1.7%, Mn: ≤0.3%, P: ≤0.015%, S: ≤0.015%, Cr: ≤0.3%, other alloying elements: ≤0.5% and the balance is Fe, the mass of each component The percentages add up to 100%. Wherein, the carbon content is 99.95%-100% of the theoretical carbon equivalent. Add inoculants and nodulizers to the molten iron before pouring, so that the final silicon content of the molten iron after inoculation and nodularization tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com