High-strength anti-corrosion aluminum alloy and preparation method thereof

A corrosion-resistant aluminum alloy, high-strength technology, applied in the field of high-strength corrosion-resistant aluminum alloy and its preparation, to achieve the effects of reducing potential difference, simple and easy preparation method, and improving strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

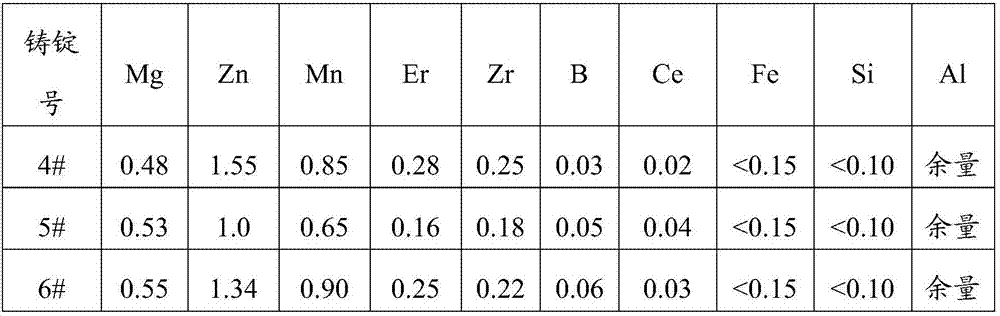

[0017] Table 1 shows the composition and weight percentage of the aluminum alloy.

[0018] Table 1

[0019] Ingot No.

[0020] The preparation method of this alloy is:

[0021] (1) Proportioning raw materials: according to the components and weight percent proportioning raw materials shown in Table 1;

[0022] (2) Raw material smelting: under the temperature condition of 760°C, first melt the high-purity aluminum ingot, and then add Al-Er master alloy, Al-B master alloy, Al-Mn master alloy, Ce-rich rare earth element, Al - Zr master alloy, add pure zinc, pure magnesium and covering agent after the master alloy is melted;

[0023] (3) Refining: add hexachloroethane to the completely melted molten metal for degassing treatment, and fully stir. During refining, the metal temperature should be maintained within the range of 730°C. Not less than 25 minutes;

[0024] (4) Casting: When the temperature of the molten metal drops to 700°C, after it has been allowed to stan...

Embodiment 2

[0034] Table 3 is the composition and weight percentage of the aluminum alloy.

[0035] table 3

[0036]

[0037] The preparation method of this alloy is:

[0038] (1) Proportioning raw materials: according to the components and weight percent proportioning raw materials shown in Table 1;

[0039] (2) Raw material smelting: under the temperature condition of 750°C, first melt the high-purity aluminum ingot, and then add Al-Er master alloy, Al-B master alloy, Al-Mn master alloy, Ce-rich rare earth elements, Al - Zr master alloy, add pure zinc, pure magnesium and covering agent after the master alloy is melted;

[0040] (3) Refining: add hexachloroethane to the completely melted molten metal for degassing treatment, and fully stir. During refining, the metal temperature is maintained within the range of 720°C. After refining, it should be fully allowed to stand. Not less than 25 minutes;

[0041] (4) Casting: when the temperature of the molten metal drops to 690°C, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com