Hypereutectic high-chromium alloy white cast iron chute lining plate and preparation method thereof

A high-chromium alloy and white cast iron technology, applied in the field of metal wear-resistant materials, can solve problems such as insufficient wear resistance, achieve improved wear resistance, high temperature resistance, wear resistance and corrosion resistance, hardness and carbide The effect of increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The chute lining plate of this embodiment is made of hypereutectic high-chromium alloy white cast iron material, which is composed of the following chemical components in mass fractions: C3.5%, Si0.4%, Mn0.9%, Cr25.0%, Mo1. 2%, W1.8%, Cu0.6%, V0.48%, Ti0.28%, Nb0.11%, Zr0.08%, RE0.08%, Y0.02%, B0.0028%, S0. 037%, P0.028%, and the rest is Fe.

[0046] The preparation method of the hypereutectic high chromium alloy white cast iron material for the chute liner of the present embodiment comprises the following steps:

[0047] ⑴ Add scrap steel, high-carbon ferrochrome, ferromolybdenum, ferrotungsten, scrap brass and other metal materials to the furnace for melting, and the melting temperature is 1540°C;

[0048] (2) Composition analysis in front of the furnace to adjust the balance of C and Cr;

[0049] (3) Add ferromanganese for deoxidation, add silicon aluminum calcium barium compound refining deoxidizer, refining deoxidation;

[0050] (4) Add ferro-vanadium, ferroniob...

Embodiment 2

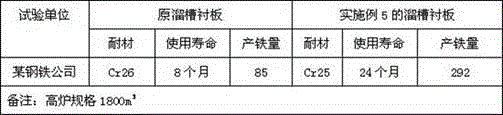

[0057] The chute liner of this embodiment is made of hypereutectic high-chromium alloy white cast iron material, which is composed of the following chemical components in mass fractions: C3.66%, Si0.41%, Mn1.0%, Cr26.0%, Mo1. 1%, W1.75%, Cu0.5%, V0.5%, Ti0.25%, Nb0.12%, Zr0.07%, B0.025%, RE0.07%, Y0.03%, S0. 043%, P0.022%, and the rest is Fe.

[0058] The preparation method of the hypereutectic high chromium alloy white cast iron material for the chute liner of the present embodiment comprises the following steps:

[0059] ⑴ Add scrap steel, high-carbon ferrochrome, ferromolybdenum, ferrotungsten, scrap brass and other metal materials to the melting furnace for melting, and the melting temperature is 1550°C;

[0060] (2) Composition analysis in front of the furnace to adjust the balance of C and Cr;

[0061] (3) Add ferromanganese for deoxidation, add silicon aluminum calcium barium compound refining deoxidizer, refining deoxidation;

[0062] (4) Add ferro-vanadium, ferroni...

Embodiment 3

[0069] The chute lining plate of this embodiment is made of hypereutectic high-chromium alloy white cast iron material, which is composed of the following chemical components in mass fractions: C4.01%, Si0.48%, Mn0.82%, Cr28.0%, Mo0.95 %, W1.62%, Cu0.4%, V0.45%, Ti0.24%, Nb0.15%, Zr0.06%, RE0.06%, Y0.04%, B0.024%, S0.041 %, P0.028%, and the rest is Fe.

[0070] The preparation method of the hypereutectic high chromium alloy white cast iron material for the chute liner of the present embodiment comprises the following steps:

[0071] ⑴ Add scrap steel, high-carbon ferrochromium, ferromolybdenum, ferrotungsten, scrap brass and other metal furnace materials to the melting furnace for melting, and the melting temperature is 1560°C;

[0072] (2) Composition analysis in front of the furnace to adjust the balance of C and Cr;

[0073] (3) Add ferromanganese for deoxidation, add silicon aluminum calcium barium compound refining deoxidizer, refining deoxidation;

[0074](4) Add ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com